Production method of no-powder-falling interlayer structure super heat insulation gas gel composite material

A composite material and production method technology, applied in the direction of layered products, chemical instruments and methods, lamination, etc., can solve the performance degradation of airgel-based materials, affect the use effect and life, powder drop of airgel-based materials, etc. problems, to achieve the effect of long service life, low cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

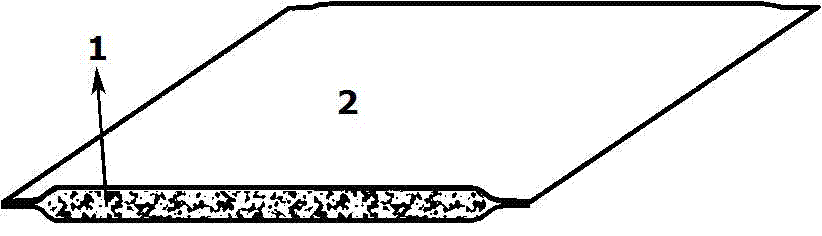

[0020] Example 1 : Manufacture of glass fiber fireproof cloth veneered airgel sandwich panel

[0021] The airgel-based substrate is rolled to remove powder or particles that are easy to fall off on the surface. Next, the surface of the pretreated airgel-based material 1 is evenly coated with a silicate or phosphate inorganic binder, and the glass fiber-based fireproof cloth 2 is uniformly and evenly bonded to the outer surface of the airgel-based material. After curing, the glass fiber fireproof cloth veneered airgel sandwich panel is obtained. The product schematic diagram is as follows figure 2 shown. The density of the sandwich panel is about 170 kg / m 3 , the thermal conductivity is only 0.015 W / m.K, which is the same performance parameter as the airgel substrate.

Embodiment 2

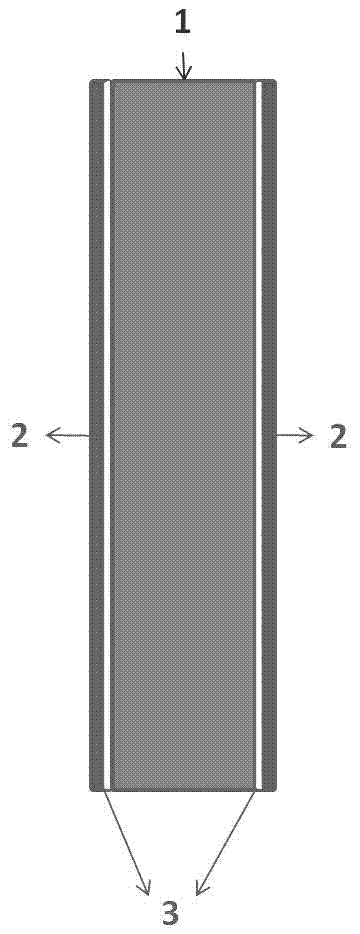

[0022] Example 2 : Manufacture of Teflon fireproof cloth veneer airgel interlayer sleeve block

[0023] The airgel-based substrate is rolled to remove powder or particles that are easy to fall off on the surface. Cut the board into the designed size, and then coat the oxide inorganic binder on the Teflon fireproof cloth 2 with the designed shape and size, and compound it with the cut airgel board 1 according to the design. After curing, the Obtain Teflon fireproof cloth veneer airgel interlayer sets, the product structure diagram is as follows image 3 shown. The block can be directly wrapped on the T-shaped structure for efficient heat insulation. The basic material density of the block is about 170 kg / m 3 , the thermal conductivity is only 0.015 W / m.K, which is the same performance parameter as the airgel substrate.

Embodiment 3

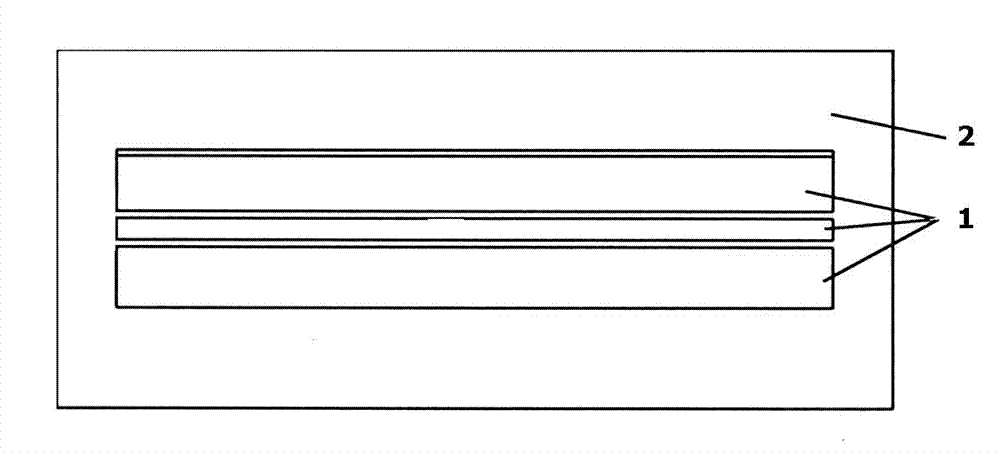

[0024] Example 3: Manufacture of asbestos fireproof cloth veneer airgel interlayer felt

[0025] The airgel-based felt is rolled to remove powder or particles that are easy to fall off on the surface. Then, the borate inorganic binder is coated on the asbestos fireproof cloth, and it is uniformly and evenly bonded to the outer surface of the airgel-based material. After curing, the airgel interlayer felt covered with asbestos fireproof cloth can be obtained. The interlayer felt has a smooth appearance, no powder shedding, and increased toughness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com