Super heat insulation aerogel sandwich composite wall plate with decorative face and preparation method of super heat insulation aerogel sandwich composite wall plate

A composite wallboard and airgel technology, which is applied in the direction of walls, insulation improvement, climate change adaptation, etc., can solve the problems that cannot be fully applied to high-rise buildings, and achieve the effect of excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

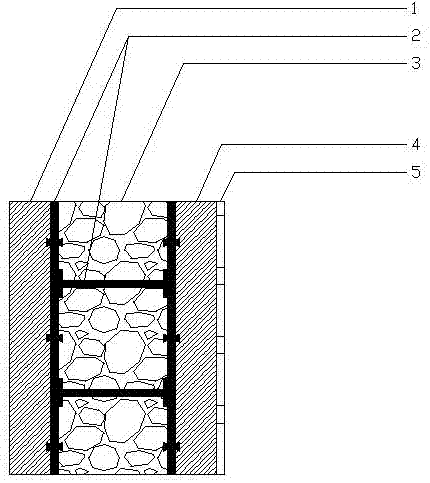

[0036] A preparation method of a super heat-insulating airgel sandwich composite wallboard with a decorative surface, comprising the following steps:

[0037] (1) Cavity preparation, place the mold on both sides, place the high-wall partition board components and embedded parts in the mold to form a cavity;

[0038] (2) cloth, adding the wet material of the inner high-strength inorganic board, the airgel heat insulation core material, and the wet material of the outer high-strength inorganic board into the cavity of step (1);

[0039] (3) Molding process;

[0040] (4) Demoulding, after the high-strength inorganic board has strength, demoulding;

[0041] (5) Fabricate the decorative layer on the surface of the outer high-strength inorganic board.

[0042] Thus, the preparation process of the present invention is simple, practical and very suitable for industrial production.

[0043] In this embodiment, the cloth is clothed three kinds of materials at one time or three times ...

Embodiment 1

[0055] The following steps were used to prepare SiO with marbled surface 2 Airgel Super Insulation Sandwich Composite Wall Panel:

[0056] (1) Detection of SiO to be treated using a contact angle meter 2 The contact angle between the surface of the airgel powder and water, the test result is 55°, and then SiO with a particle size of 56 μm 2 The airgel powder is placed in a vacuum heating furnace, and the weighed hexamethyldisilazane is placed in a vacuum heating furnace with a container, heated and vaporized, and hydrophobically modified for 1.5 hours to obtain hydrophobic SiO 2 Airgel powder, detection of hydrophobic SiO by contact angle meter 2 The contact angle between the surface of the airgel powder and water is 147°;

[0057] (2) At room temperature, weigh sodium alkylbenzenesulfonate, n-hexane and deionized water at a mass ratio of 1:0.5:99, mix them evenly, and prepare a surface hydrophilic modification solution;

[0058] (3) According to hydrophobic SiO 2 The vol...

Embodiment 2

[0068] The following steps were used to prepare SiO with water-in-water coating decorative surface 2 Airgel Super Insulation Sandwich Composite Wall Panel:

[0069] (1) Detection of SiO to be treated using a contact angle meter 2 The contact angle between the surface of the airgel powder and water, the test result is 45°, and then SiO with a particle size of 67 μm 2 The airgel powder is placed in a vacuum heating furnace, and the weighed trimethylchlorosilane is placed in a vacuum heating furnace with a container, heated and vaporized, and hydrophobically modified for 1.5 hours to obtain hydrophobic SiO 2 Airgel powder, detection of hydrophobic SiO by contact angle meter 2 The contact angle between the surface of the airgel powder and water is 146°;

[0070] (2) At room temperature, weigh fatty alcohol polyoxyethylene ether sodium sulfate, sodium alkylbenzene sulfonate, n-hexane and deionized water according to the mass ratio of 1:1:1000, mix them evenly, and prepare the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com