Transport container for keeping frozen material chilled

A transport container and container technology, applied in the field of refrigerants, can solve the problems of difficult transport transport containers, large volume, etc., and achieve the effect of simple manufacture and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

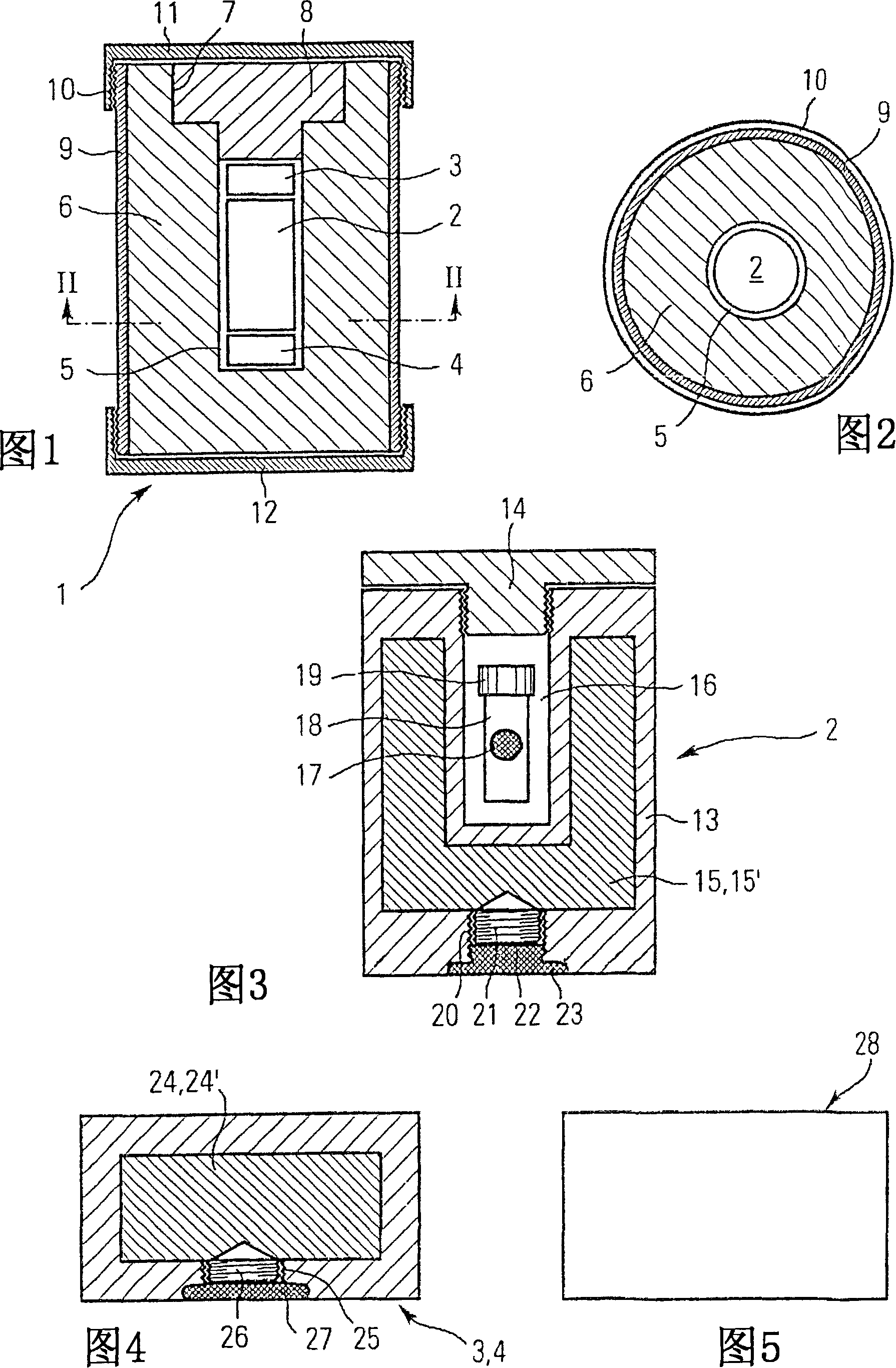

[0030] [0011] The transport container 1 according to FIGS. 1 and 2 has a cylindrical shape. The transport container 1 comprises a coaxially arranged likewise cylindrical inner container 2 and two likewise cylindrical additional containers 3 , 4 which are arranged at the ends of the inner container 2 in a thermally insulating chamber 5 . above and below. The insulating chamber 5 is formed by a thick-walled cup-shaped insulation 6 with an inwardly directed stepped upper edge 7 receiving a correspondingly stepped thick-walled closure 8 in the form of a lid for closing the insulating chamber 5 . The insulator 6 is tightly surrounded by a rigid protective tube 9, at both ends of which are respectively provided external threads, which are tightly screwed with the engaging-over threaded edges 10 of the screw caps 11 and 12, respectively.

[0031] [0012] The insulation 6 and the insulation closure 8 are made of a high-grade insulation material with a very low thermal conductivity λ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com