Highly-impact-resistant highly-light-transmitting highly-heat-insulating polymethylmethacrylate composite material and preparation method thereof

A technology of polymethyl methacrylate and composite materials, which is applied in the field of building thermal insulation materials to achieve the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

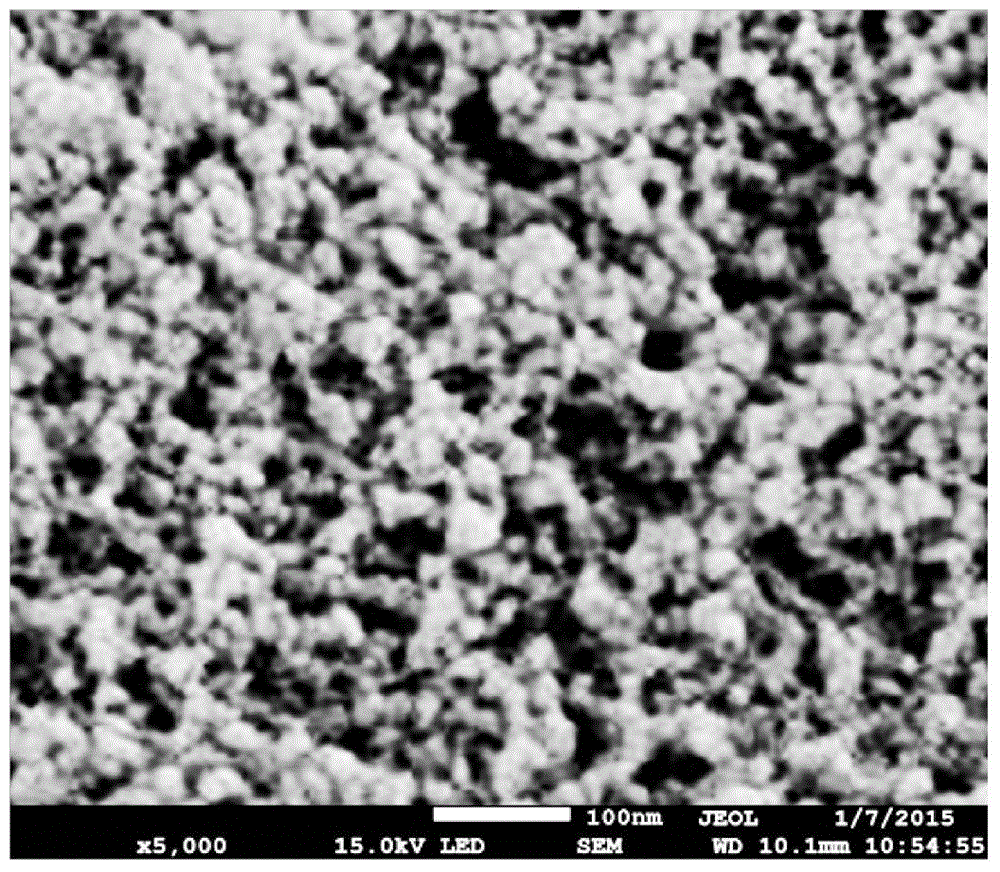

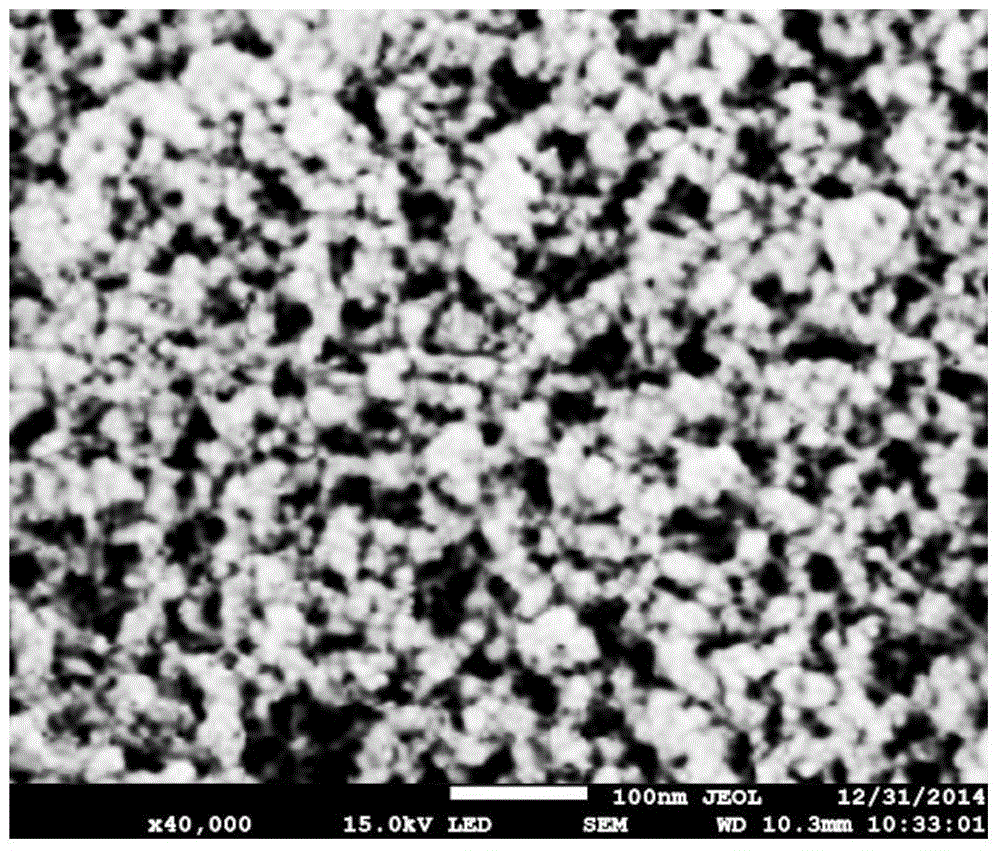

Image

Examples

Embodiment 1

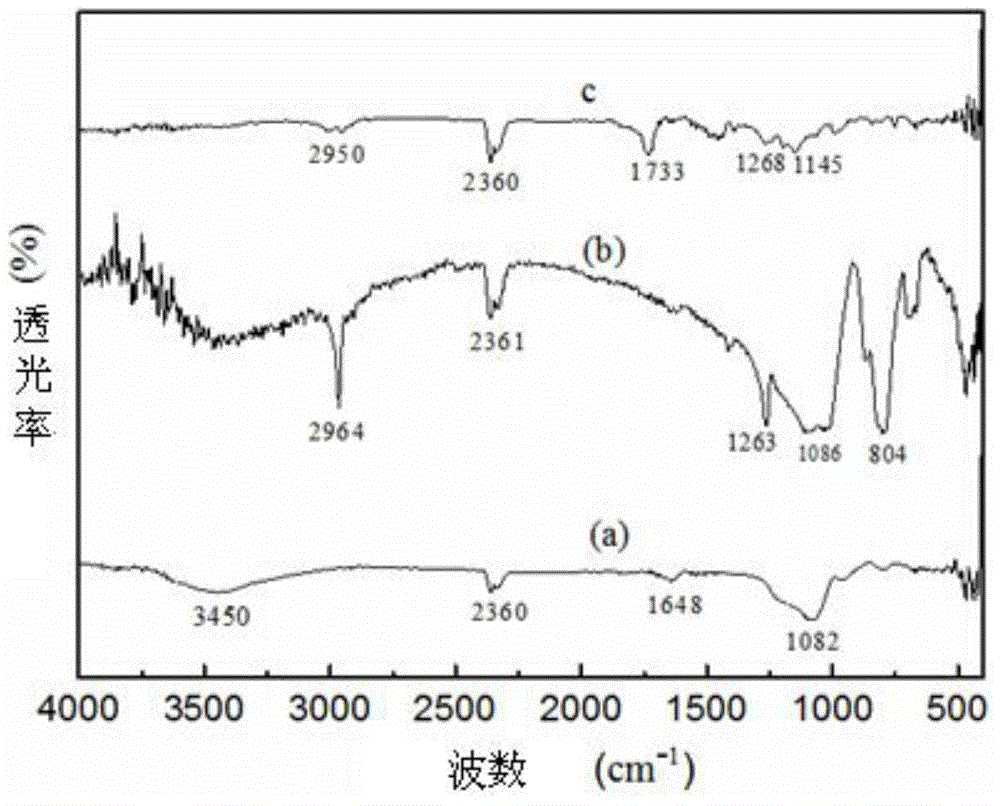

[0031] (1) Mix and stir 150g tetraethyl orthosilicate and 170g absolute ethanol at 70°C for 30min, add 0.1g hydrochloric acid, stir at room temperature for 30min and then let stand for 180min, then add 0.01g sodium hydroxide, stir until it is completely dissolved, After the above solution was left to stand for 6 hours to obtain a wet gel, add 1g of N,N'-carbonyldiimidazole to the wet gel, let it stand at 60°C for 1 hour, and then add 1g of N,N'-carbonyldiimidazole with a number average molecular weight of 5000 and a vinyl content of 5% by mole Amino single-terminated polydimethyldivinylsiloxane, let stand at 60°C for 24h, put the product in CO 2 In a supercritical high-pressure extraction device, CO 2 The medium is subjected to supercritical drying at a temperature of 50°C and an air pressure of 10MPa for 3 hours, that is, functionalized silica airgel;

[0032] (2) Add 10 g of the functionalized silica airgel obtained in step (1) to 100 g of methyl methacrylate, then ultrason...

Embodiment 2

[0034] (1) Mix and stir 80g ethyl orthosilicate and 100g absolute ethanol at 50°C for 5 minutes, add 0.1g hydrochloric acid, stir at room temperature for 5 minutes and then let it stand for 30 minutes, then add 0.01g sodium hydroxide and stir until it is completely dissolved. After the above solution was left to stand for 2 hours to obtain a wet gel, add 1g of N,N'-carbonyldiimidazole to the wet gel, let it stand at 65°C for 1 hour, then add 1g of number average molecular weight, number average molecular weight, 1000 vinyl content mole percent 0.1% amino double-terminated polydimethyldivinylsiloxane, stand at 60°C for 24h, put the product in CO 2 In a supercritical high-pressure extraction device, CO 2 The medium is subjected to supercritical drying for 3 hours at a temperature of 35°C and an air pressure of 7 MPa, that is, functionalized silica airgel;

[0035] (2) Add 5 g of the functionalized silica airgel obtained in step (1) to 100 g of methyl methacrylate, then ultrason...

Embodiment 3

[0037] (1) Mix and stir 96g ethyl orthosilicate and 145g absolute ethanol at 65°C for 24min, add 0.5g hydrochloric acid, stir at room temperature for 12min and then let stand for 87min, then add 0.13g sodium hydroxide, stir until it is completely dissolved, After the above solution was left to stand for 5 hours to obtain a wet gel, add 1g of N,N'-carbonyldiimidazole to the wet gel, let it stand at 68°C for 1 hour, and then add 1g of N,N'-carbonyldiimidazole with a number average molecular weight of 3500 and a vinyl content of 3.4% Amino single-terminated polydimethyldivinylsiloxane, let stand at 60°C for 24h, put the product in CO 2 In a supercritical high-pressure extraction device, CO 2 The medium is subjected to supercritical drying at a temperature of 44°C and an air pressure of 9 MPa for 3 hours, that is, functionalized silica airgel;

[0038] (2) Add 7g of the functionalized silica airgel obtained in step (1) to 100g of methyl methacrylate, then perform ultrasonic dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com