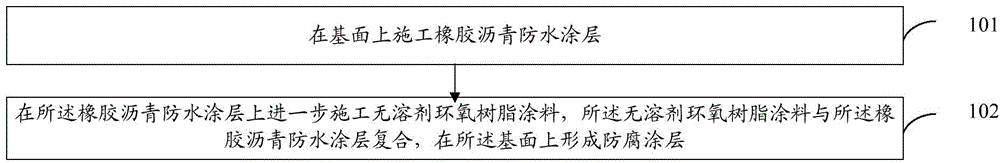

Construction method of novel anticorrosive coating layer

A construction method and anti-corrosion coating technology, which is applied in the field of materials, can solve the problems of FRP strength attenuation, inability to fully fit, and insufficient corrosion resistance, etc., and achieve the effect of reducing viscosity, not easy to peel off, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] 1. Prepare solvent-free epoxy resin coating and rubber asphalt waterproof coating.

[0085] The ratio of each component in the solvent-free epoxy resin coating is: bisphenol A epoxy resin 80kg; polyurethane modified epoxy resin 20kg; epoxy reactive diluent (dodecyl glycidyl ether) is 10kg; leveling agent (polyacrylate) is 0.5kg; rheological additive (meteorological silica) is 2kg; dispersant is 1kg; substrate wetting agent is 0.7kg; defoamer is 0.3kg; UV absorber is 1kg; White powder: 8kg; talc powder: 30kg; wet process sericite powder: 30kg; wollastonite powder: 30kg; ceramic powder: 15kg; component B: aliphatic modified polyamine: 110kg.

[0086]The ratio of each component in the rubber asphalt waterproof coating is: 90kg of vulcanized rubber modified anionic emulsified asphalt (including: 87.3kg (97%) of asphalt and 2.7kg (3%) of styrene-butadiene-benzene Ethylene block copolymer); 10kg of rubber emulsion (chloroprene rubber); 0.1kg of surfactant (rosin soap); 0.1kg...

Embodiment 2

[0090] 1. Prepare solvent-free epoxy resin coating and rubber asphalt waterproof coating.

[0091] The ratio of each component in the solvent-free epoxy resin coating is: bisphenol A epoxy resin 90kg; rubber modified epoxy resin 10kg; epoxy reactive diluent 15kg, wherein, dodecyl glycidyl ether (10) kg , 1,4-butanediol diglycidyl ether (5) kg; leveling agent (polyorganosiloxane) is 1 kg; rheology additive is 4 kg, of which, N-methylpyrrolidone (2) kg, hydrogenated Castor oil (1) kg; dispersant is 2 kg; substrate wetting agent is 2 kg; defoamer is 1.5 kg; ultraviolet absorber is 3 kg; titanium dioxide is 10 kg; ; Wollastonite powder: 20kg; ceramic powder: 5kg; B component: polyamide: 115kg.

[0092] The ratio of each component in the rubber asphalt waterproof coating is: 50kg of vulcanized rubber modified anionic emulsified asphalt (including: 42.5kg (85%) of asphalt and 7.5kg (15%) of binary ethylene propylene rubber Olefinic elastomer and EPDM rubber); 50kg of rubber emulsi...

Embodiment 3

[0096] 1. Prepare solvent-free epoxy resin coating and rubber asphalt waterproof coating.

[0097] The ratio of each component in the solvent-free epoxy resin coating is: bisphenol A epoxy resin 100kg;

[0098] Epoxy active diluent 20kg, wherein, dodecyl glycidyl ether (10) kg, 1,4-butanediol diglycidyl ether (4) kg, ethylene glycol diglycidyl ether (6) kg; Leveling agent is 2kg, wherein, polyacrylate is (1) kg, polyorganosiloxane is (1) kg; rheology additive is 6 kg, wherein, meteorological silica (3) kg, N-methylpyrrolidone (1); kg, hydrogenated castor oil (2) kg; dispersant is 3kg; substrate wetting agent is 3kg; defoamer is 3kg; ultraviolet absorber is 1.5kg; titanium dioxide is 15kg; talcum powder is 60kg; Wet-process sericite powder is 20kg; wollastonite powder is 20kg; component B is 120kg, in which aliphatic modified polyamine:polyamide=4:1.

[0099] The ratio of each component in the rubber asphalt waterproof coating is:

[0100] 30kg of vulcanized rubber-modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com