Low-temperature-curable epoxy resin used for matting powder B68, and preparation method and application thereof

An epoxy resin, curing technology, applied in the field of powder coatings, can solve the problems of affecting product gloss, high curing energy consumption, high curing temperature, and achieve the effect of excellent matting effect, meeting effect requirements and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

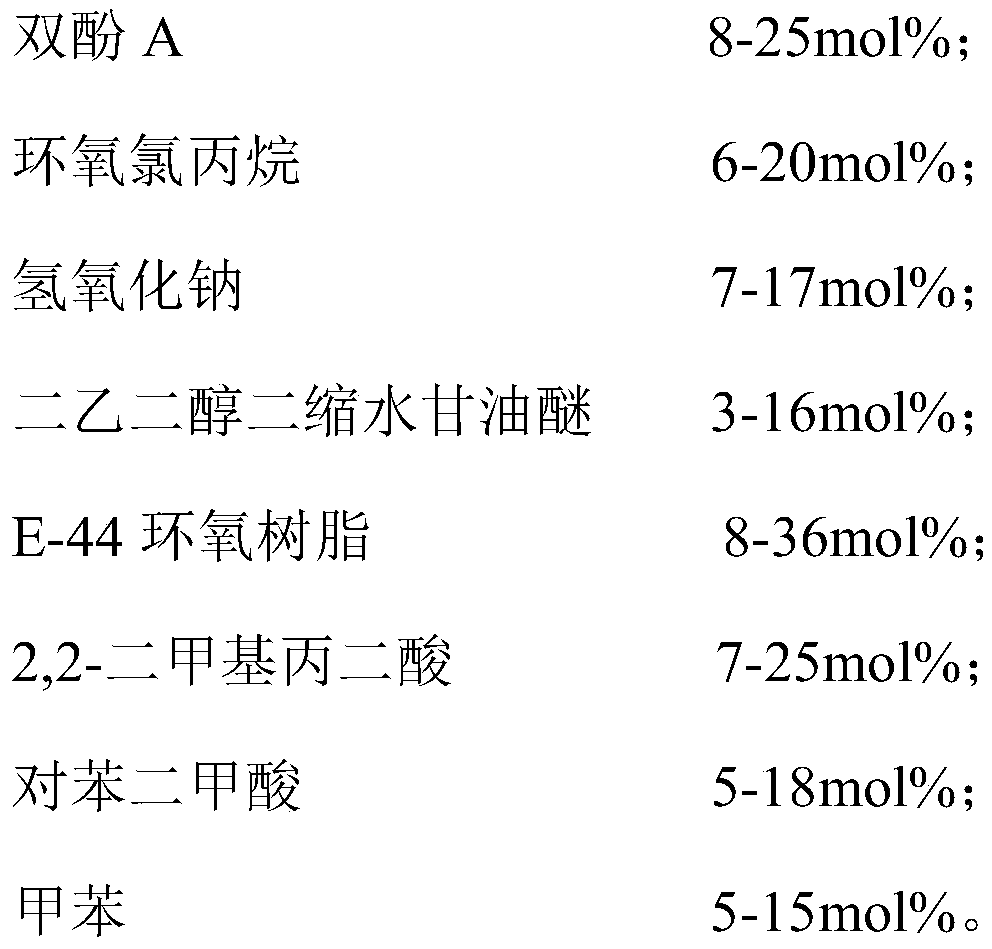

[0027] The epoxy resin for low-temperature curing type B68 matting powder described in this embodiment, its preparation raw material includes the raw material component of following mole percentage:

[0028]

[0029]

[0030] The preparation method of epoxy resin for low-temperature curing type B68 matting powder described in this embodiment comprises the following steps:

[0031] (1) Prepare the sodium hydroxide solution of the formula quantity with water to obtain a 30% solid content sodium hydroxide solution, and pump it into the reactor I, heat up to 30°C, add the bisphenol A of the formula quantity, and carry out the heat preservation reaction for 1-2h Then add the formula amount of epichlorohydrin, carry out heat preservation reaction at 80°C for 2-4h, after testing the pH of the solution, when the pH reaches below 9.5, stop the reaction to obtain a bisphenol A-terminated epoxy resin;

[0032] (2) Add a formulated amount of diethylene glycol diglycidyl ether to the...

Embodiment 2

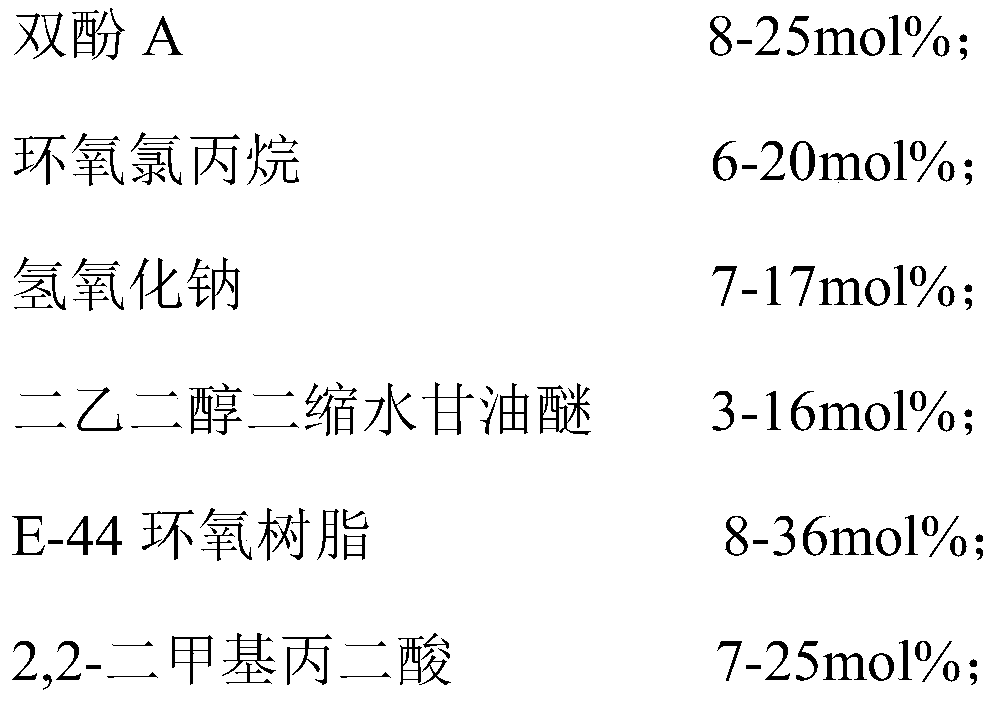

[0037] The epoxy resin for low-temperature curing type B68 matting powder described in this embodiment, its preparation raw material includes the raw material component of following mole percentage:

[0038]

[0039] The preparation method of epoxy resin for low-temperature curing type B68 matting powder described in this embodiment comprises the following steps:

[0040] (1) Add water to prepare the sodium hydroxide solution of the formula quantity to obtain a sodium hydroxide solution with a solid content of 40%, and pump it into the reactor I, heat up to 35°C, add the bisphenol A of the formula quantity, and carry out the heat preservation reaction for 1-2h Then add the formula amount of epichlorohydrin, and carry out the heat preservation reaction at 90° C. for 2-4 hours. After testing the pH of the solution, when the pH reaches below 9.5, stop the reaction to obtain a bisphenol A-terminated epoxy resin;

[0041](2) Add a formulated amount of diethylene glycol diglycidy...

Embodiment 3

[0046] The epoxy resin for low-temperature curing type B68 matting powder described in this embodiment, its preparation raw material includes the raw material component of following mole percentage:

[0047]

[0048] The preparation method of epoxy resin for low-temperature curing type B68 matting powder described in this embodiment comprises the following steps:

[0049] (1) Prepare the sodium hydroxide solution of the formula quantity with water to obtain a 50% solid content sodium hydroxide solution, and pump it into the reactor I, heat up to 40°C, add the bisphenol A of the formula quantity, and carry out the heat preservation reaction for 1-2h Then add the formula amount of epichlorohydrin, and carry out the heat preservation reaction at 100 ° C for 2-4 hours. After testing the pH of the solution, when the pH reaches below 9.5, stop the reaction to obtain a bisphenol A-terminated epoxy resin;

[0050] (2) Add a formulated amount of diethylene glycol diglycidyl ether to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com