50:50 polyester resin for indoor high-hardness and high-gloss powders, and preparation method thereof

A polyester resin, high hardness technology, used in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of low coating film hardness, pencil hardness can only reach 2B, and the hardness requirements cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

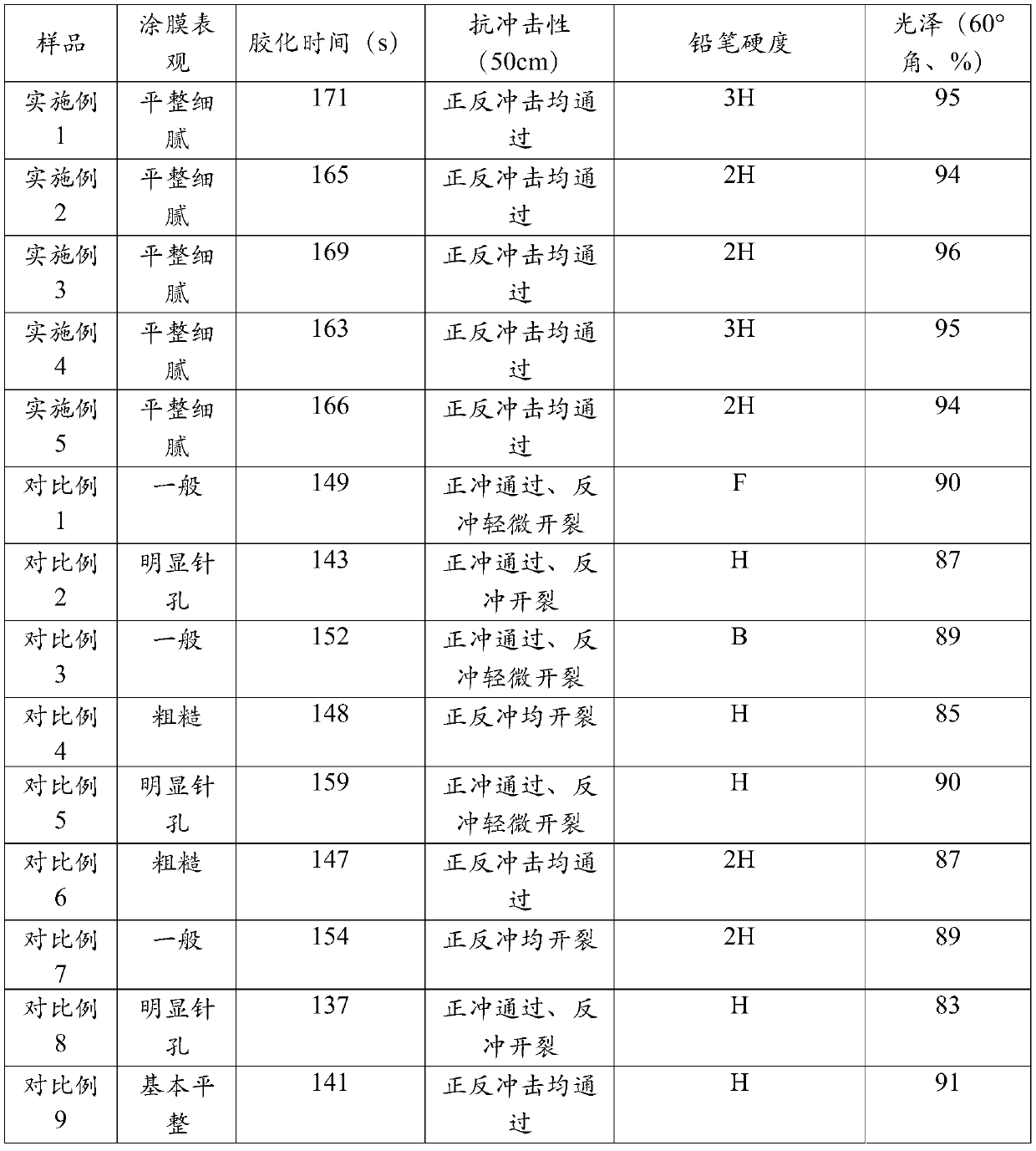

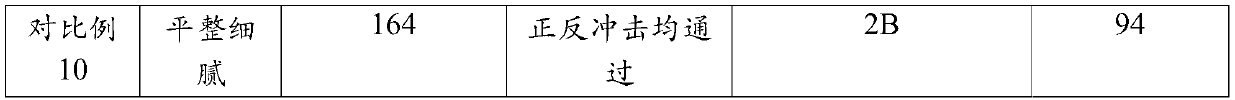

Embodiment 1

[0042] The main raw materials used are as follows:

[0043] Dimethyl 1,2-cyclohexyldicarboxylate, terephthalic acid, dipentaerythritol, neopentyl glycol, 5-hydroxylauric acid glyceride, tris(trimethylsilyl) phosphate, ethylene glycol diglycidyl ether , (2,7-octanediol-1-yl) succinic anhydride;

[0044] Can be used for the preparation method of 50:50 polyester resin for indoor high hardness, high gloss powder coating, comprises the following steps:

[0045] (1) Add 10mol% dipentaerythritol and 20mol% neopentyl glycol into the reaction kettle, and heat and melt at 130°C to obtain a mixed material;

[0046] (2) Add 16 mol% dimethyl 1,2-cyclohexyldicarboxylate to the mixed material of (1), and add a catalyst at the same time, slowly raise the temperature to 185°C at a heating rate of 5°C / h and keep it warm for the initial esterification reaction. After 3 hours of heat preservation reaction at 190°C, add 12mol% 5-hydroxyl dodecanoin, 8mol% ethylene glycol diglycidyl ether and 15m...

Embodiment 2

[0052] Can be used for the preparation method of 50:50 polyester resin for indoor high hardness, high gloss powder coating, comprises the following steps:

[0053] (1) Add 6mol% dipentaerythritol and 24mol% neopentyl glycol into the reaction kettle, and heat and melt at 130°C to obtain a mixed material;

[0054] (2) Add 15 mol% dimethyl 1,2-cyclohexyldicarboxylate to the mixed material of (1), and add a catalyst at the same time, slowly raise the temperature to 185°C at a heating rate of 5°C / h and keep it warm for the initial esterification reaction. After 190°C heat preservation reaction for 3 hours, add 15mol% 5-hydroxydodecanoin, 10mol% ethylene glycol diglycidyl ether and 10mol% terephthalic acid at this time, pass through nitrogen protection, and then use 10°C / h The heating rate is to gradually raise the temperature to 235°C, and then keep the temperature until no obvious distillate is distilled out, and the acid value of the reactant is 24mgKOH / g;

[0055] (3) Add an an...

Embodiment 3

[0060] Can be used for the preparation method of 50:50 polyester resin for indoor high hardness, high gloss powder coating, comprises the following steps:

[0061] (1) Add 8mol% dipentaerythritol and 20mol% neopentyl glycol into the reaction kettle, and heat and melt at 130°C to obtain a mixed material;

[0062] (2) Add 12 mol% dimethyl 1,2-cyclohexyldicarboxylate to the mixed material of (1), and add a catalyst at the same time, slowly raise the temperature to 185°C at a heating rate of 5°C / h and keep it warm for the initial esterification reaction. After 3 hours of heat preservation reaction at 190°C, add 16mol% 5-hydroxydodecanoin, 8mol% ethylene glycol diglycidyl ether and 15mol% terephthalic acid at this time, pass through nitrogen protection, and then use 10°C / h The heating rate is to gradually raise the temperature to 235°C, and then keep the temperature until no obvious distillate is distilled out, and the acid value of the reactant is 24mgKOH / g;

[0063] (3) Add an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com