Two-step crosslinking preparation method for keratin/PEO biological nanofiber membrane

A technology of biological nanofibers and keratin fibers, applied in the direction of animal fibers, fiber types, fiber treatment, etc., can solve the problems of difficulty in increasing keratin content, environmental pollution, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

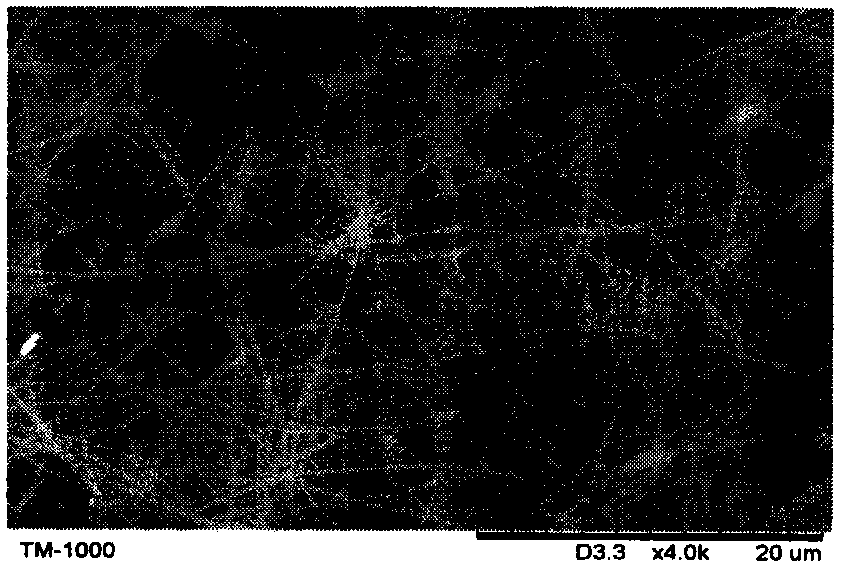

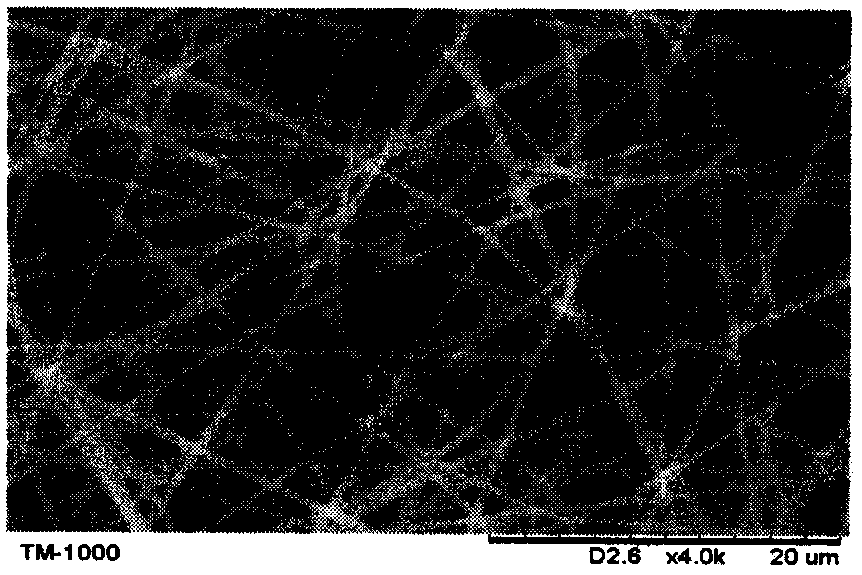

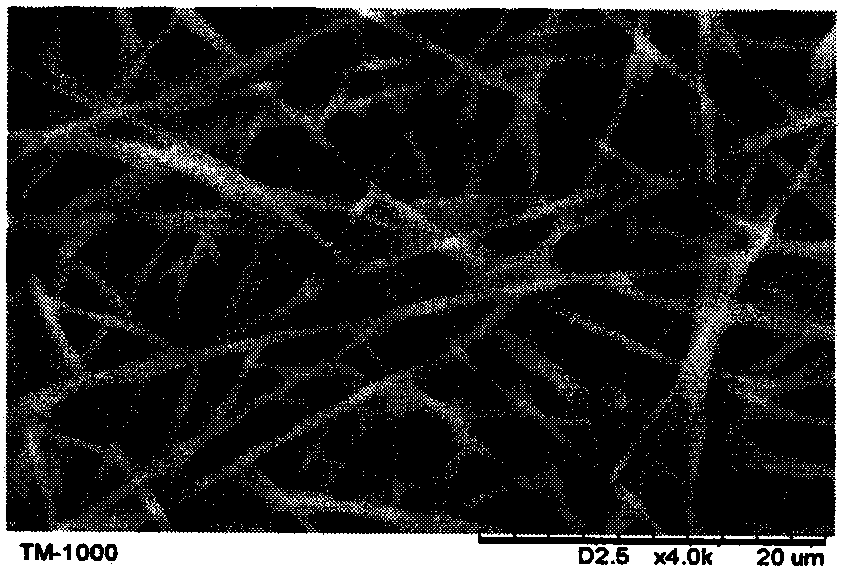

Image

Examples

Embodiment 1

[0028] After the human hair fiber is opened, removed, cleaned and dried in sequence, it is cut into 3-6mm fiber segments, and immersed in a solution containing a reducing agent and a protein denaturant at a solid-to-liquid ratio of 2.5g / 250ml at 90 Stir at ℃ for 2h, the stirrer speed is 400r / min. The mixture obtained after stirring was filtered with an 80-mesh screen to remove unreacted fibers, and fine impurities in the filtrate were removed by centrifugation at a centrifugation speed of 3000 rpm for 1 h, and then the supernatant was taken. At room temperature, the supernatant is dialyzed with deionized water to remove small molecular substances in the solution, and then concentrated to obtain a pure keratin solution with a concentration of 5% by mass. The concentrated keratin solution is frozen for 24 hours with a freeze dryer at -40--60° C. and then dried for 24 hours to obtain keratin powder.

[0029] Prepare a keratin / PEO aqueous solution with a mass percentage concentra...

Embodiment 2

[0031] After the wool fiber is opened, impurity removed, washed and dried in sequence, it is cut into 3-6mm fiber segments, immersed in a solution containing a reducing agent and a protein denaturant at a solid-to-liquid ratio of 4g / 250ml and stirred at 85°C 2.5h, the speed of the stirrer is 350r / min. Filter the mixture obtained after stirring with a 100-mesh sieve to remove unreacted natural keratin fibers, and centrifuge to remove fine impurities in the filtrate at a centrifugal speed of 3500 rpm for 0.8 h, and then take the supernatant. At room temperature, the supernatant is dialyzed with deionized water to remove small molecular substances in the solution, and then concentrated to obtain a pure keratin solution with a concentration of 5.5% by mass. The concentrated keratin solution is frozen for 36 hours with a freeze dryer under the condition of -40° C. to 60° C. and then dried for 36 hours to obtain keratin powder.

[0032] Prepare a keratin / PEO aqueous solution with a...

Embodiment 3

[0034] After the rabbit hair fiber is opened, removed, cleaned and dried in sequence, it is cut into 3-6mm fiber segments, and immersed in a solution containing a reducing agent and a protein denaturant at a solid-to-liquid ratio of 5.5g / 250ml at 80 Stir at ℃ for 3h, the stirrer speed is 300r / min. Filter the mixture obtained after stirring with a 120-mesh sieve to remove unreacted natural keratin fibers, and centrifuge to remove fine impurities in the filtrate at a centrifugal speed of 4000rpm for 0.6h, and then take the supernatant. At room temperature, the supernatant is dialyzed with deionized water to remove small molecular substances in the solution, and then concentrated to obtain a pure keratin solution with a concentration of 6% by mass. The concentrated keratin solution is frozen with a freeze dryer at -40--60°C for 24 hours and then dried for 48 hours to obtain keratin powder.

[0035] Prepare a keratin / PEO aqueous solution with a mass percentage concentration of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com