High performance filter media with internal nanofiber structure and manufacturing methodology

a technology of nanofibers and filter media, applied in the field of filter media, can solve the problems of needing a supporting substrate, risk of nanofiber layer delamination from the substrate, and more rapid plugging of the filter, and achieve the effect of high performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

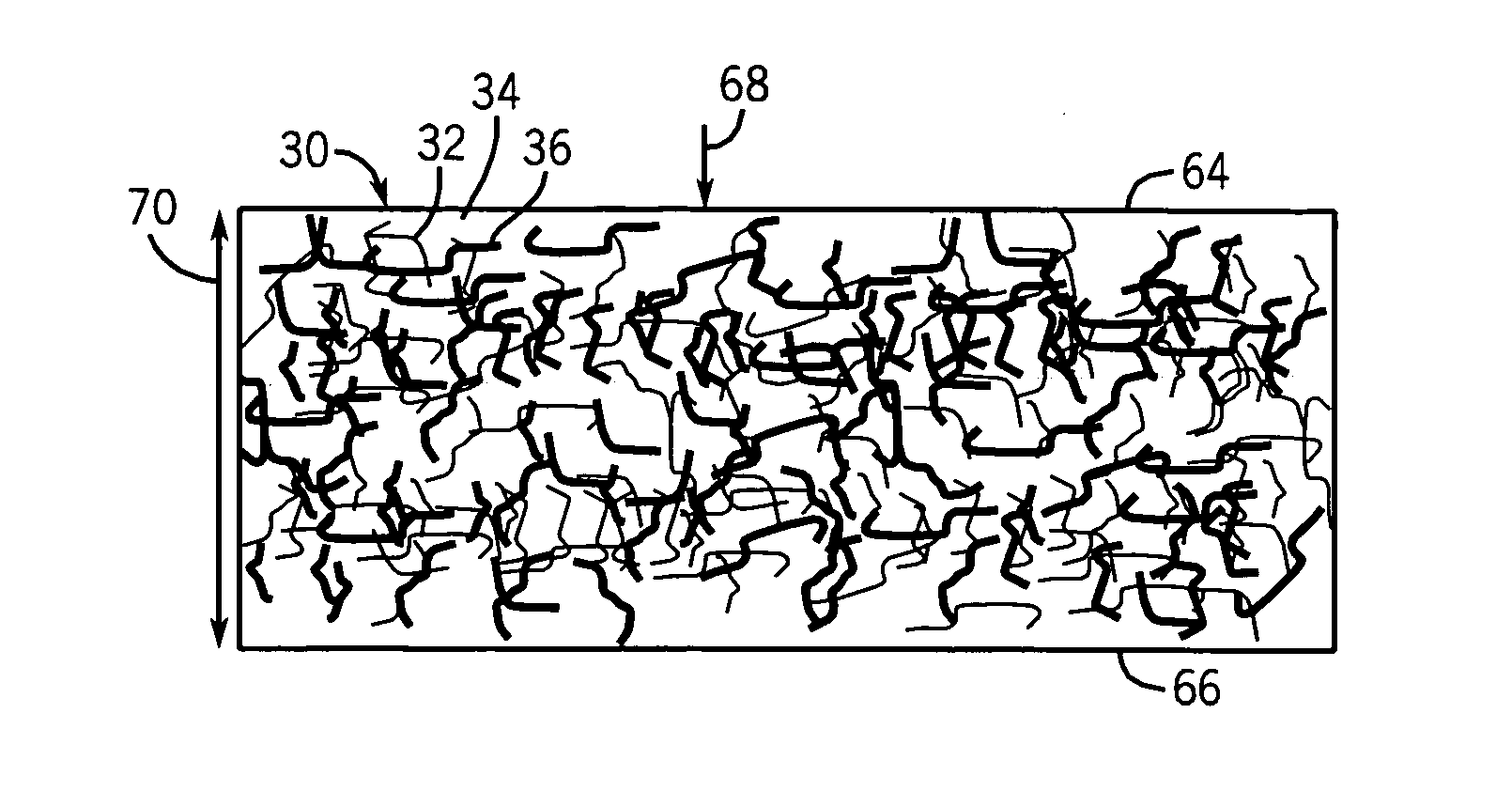

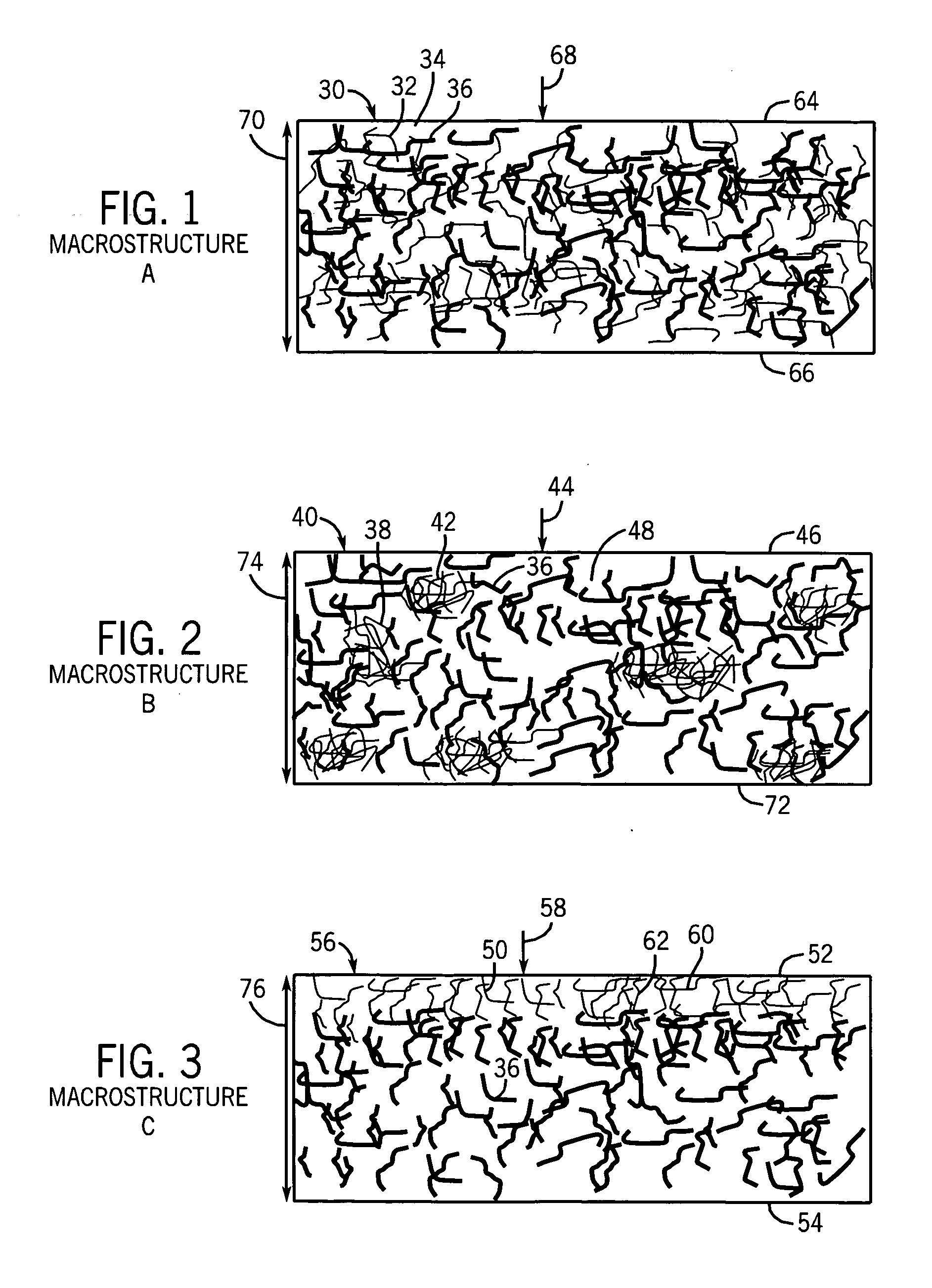

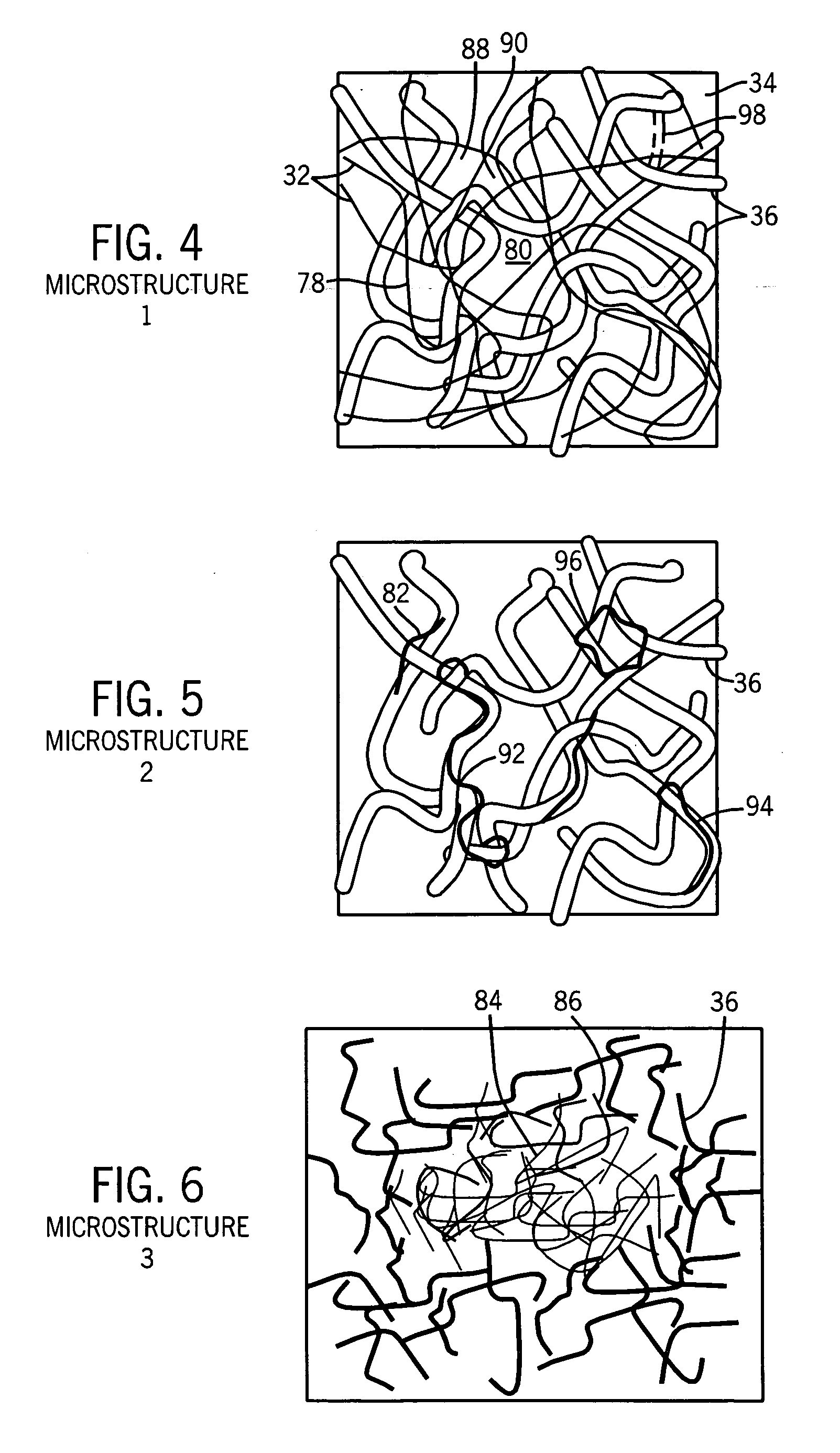

[0025]FIG. 1 shows high performance filter media 30 having nanofibers 32 of diameter less than 1 μm incorporated and processed into internal structure of a filter medium 34 dominantly composed of coarse fibers 36 of diameter greater than 1 μm. In some embodiments, to be described, nanofibers 32 and coarse fibers 36 are of different materials. Nanofibers 32 are preferably selected from the group consisting of: polymeric materials; ceramic materials; acrylic; nylon; polyvinyl alcohol; polymeric halocarbon; polyester; polyaramid; polyphenylsulfide; cellulose; titania; glass; alumina; and silica. Coarse fibers 36 are preferably selected from the group consisting of: polymeric materials; ceramic materials; polyvinyl alcohol; cellulose; acrylic; polyester; polyaramid; titania; glass; silica; nylon; polyphenylsulfide; polymeric halocarbon; and alumina. The ratio of coarse fiber diameter to nanofiber diameter is between 10 and 1,000. In some embodiments, particularly for liquids, the nanofi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com