Method for preparing super-hole fibrin microsphere protein absorbing medium

A technology of cellulose microspheres and adsorption media, applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of application limitations, low adsorption capacity, and poor pressure resistance, and achieve good environment and adsorption Large capacity and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

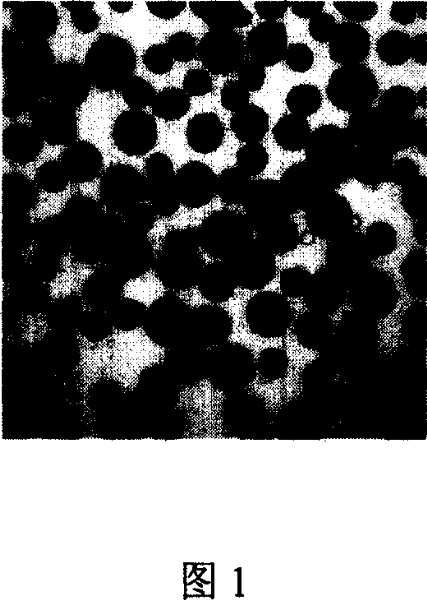

[0018] After 5 g of absorbent cotton was basified in 19% NaOH solution for 2 hours, the lye was squeezed out and placed in a water-bath shaker at 25°C for aging for 48 hours; the aged absorbent cotton was soaked in 2.5 mL of carbon disulfide (CS 2 ) after sulfonation for 10 hours, add 6% NaOH solution to dilute to 8% viscose solution, add 6g CaCO 3 , add this viscose solution to 600mL transformer oil containing compound emulsifier, and keep stirring at a stirring speed of 500rpm until it is dispersed into uniform droplets. The content of compound emulsifier in the oil phase is 0.4%, of which potassium oleate The mass ratio of Span60 and Span60 is 1:2.5, the dispersed system is placed in a super constant temperature water bath, the temperature is raised to 90°C, and the heat preservation is continued for 2.5 hours; after the material liquid is cooled, all the reaction mixture is poured out, let it stand for a while, and the upper layer of oil is centrifuged Pour off the phase l...

Embodiment 2

[0021] After 5 g of absorbent cotton was basified in 19% NaOH solution for 2 hours, the lye was squeezed out and placed in a water-bath shaker at 25°C for aging for 48 hours; the aged absorbent cotton was soaked in 2.5 mL of carbon disulfide (CS 2 ) after sulfonation for 8 hours, add 6% NaOH solution to dilute to 6% viscose solution, add 4gCaCO 3 , add this viscose solution to 600mL transformer oil containing compound emulsifier, and continue to stir and disperse at a stirring speed of 500rpm until the viscose is dispersed into uniform droplets. The mass ratio of potassium oleate and Span60 in the oil phase compound emulsifier The ratio is 1:2; the dispersed system is placed in a super constant temperature water bath, the temperature is raised to 90 ° C, and the temperature is continued for 2.5 hours; after the material liquid is cooled, the reaction mixture is poured out, and it is left to stand for a while, and the upper oil phase liquid is poured out by centrifugation. Wash...

Embodiment 3

[0024] Get 5g of the super-macroporous cellulose microsphere medium (calcium carbonate has been removed) prepared in Example 1, move it into a 250mL Erlenmeyer flask I, add 20mL 0.6mol / L DEAE-Cl to mix, and take another 250mL Erlenmeyer flask II Add 20mL of 3.5mol / L NaOH, seal it and place it in a constant temperature shaker at 60°C to preheat. After 10 minutes, add the NaOH in the Erlenmeyer flask II to the Erlenmeyer flask I and seal it. After reacting for 1 hour, the Erlenmeyer flask I was taken out and cooled with water. The modified macroporous medium was washed with deionized water in a sand core funnel until neutral.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com