Normal temperature dipping-type epoxy anhydride heat-resistant resin as well as preparation method and application thereof

A technology of epoxy anhydride and heat-resistant resin, which is applied in the direction of epoxy resin coating, plastic/resin/wax insulator, coil manufacturing, etc. It can solve the problems of poor insulation performance of products, achieve low VOC content, save energy, and reduce thickness Effect of Coil Insulation Thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of normal temperature impregnated epoxy anhydride heat-resistant resin

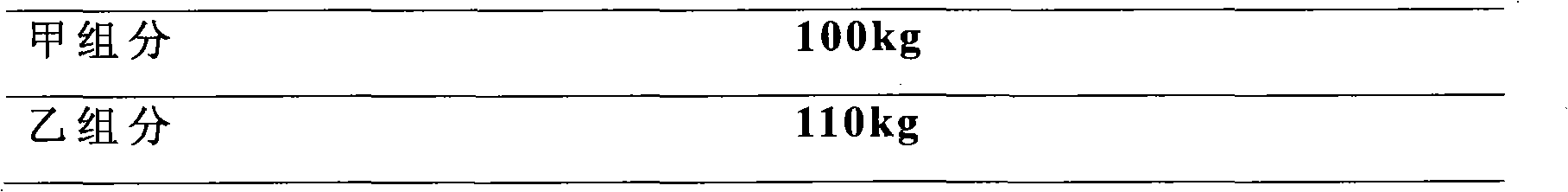

[0036] The composition of normal temperature impregnated epoxy anhydride heat-resistant resin is as follows:

[0037]

[0038] Among them, component A is prepared by the following method: add 90 kg of JF9955A molecularly distilled bisphenol A epoxy resin and 10 kg of neopentyl glycol diglycidyl ether into a 40°C reactor for stirring, vacuum dehumidify for 0.5h, and stir the materials Uniform, filtered, airtight packaging is the first component.

[0039] Component B is prepared from methyl hexahydrophthalic anhydride by the following method: Add 110 kg of methyl hexahydrophthalic anhydride into the reaction kettle and stir evenly, vacuum dehumidify for 0.5h, filter, and seal The packaging is the B component.

[0040] The transportation and storage method of components A and B, this method is suitable for vacuum pressure impregnation heat-resistant impregnation resin at roo...

Embodiment 2

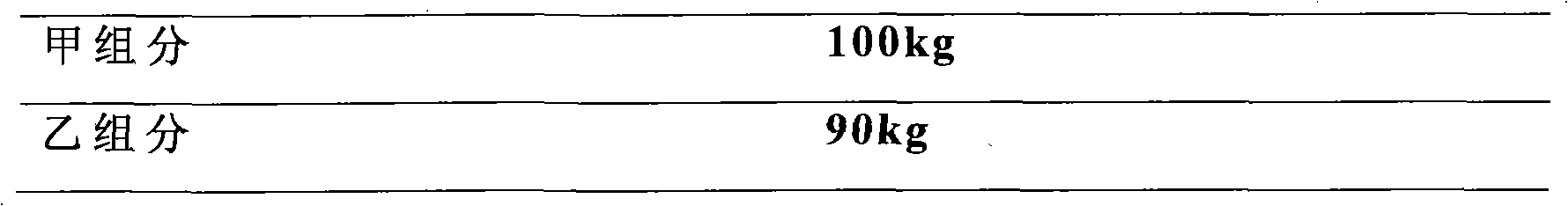

[0042] Example 2 Preparation of normal temperature impregnated epoxy anhydride heat-resistant resin

[0043]

[0044] Among them, component A is prepared by the following method: 80 kg of JF9955A molecularly distilled bisphenol A epoxy resin and 20 kg of neopentyl glycol diglycidyl ether are added to a 50°C reactor for stirring, vacuum dehumidification for 0.5h, and the materials are stirred Uniform, filtered, airtight packaging is the first component.

[0045] Component B is prepared from methyl hexahydrophthalic anhydride by the following method: Add 90 kg of methyl hexahydrophthalic anhydride into the reaction kettle and stir evenly, vacuum dehumidify for 0.5h, filter, and seal The packaging is the B component.

[0046] Other preparation methods are similar to Example 1.

Embodiment 3

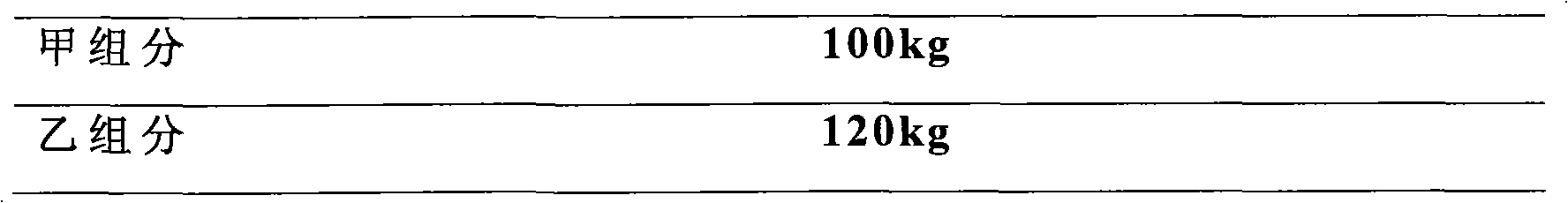

[0047] Example 3 Preparation of normal temperature impregnated epoxy anhydride heat-resistant resin

[0048]

[0049] Among them, component A is prepared by the following method: 85 kg of JF9955A molecularly distilled bisphenol A epoxy resin and 15 kg of cyclohexanediol diglycidyl ether are added to a 50°C reactor for stirring, vacuum dehumidification for 0.5h, and the materials are stirred Uniform, filtered, airtight packaging is the first component.

[0050] Component B is prepared from methyl hexahydrophthalic anhydride by the following method: add 120 kg of methyl nadic anhydride into the reaction kettle and stir evenly, vacuum dehumidify for 0.5h, filter, and seal the package to obtain B component. components.

[0051] Other preparation methods are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com