Patents

Literature

96results about How to "Reduce insulation thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

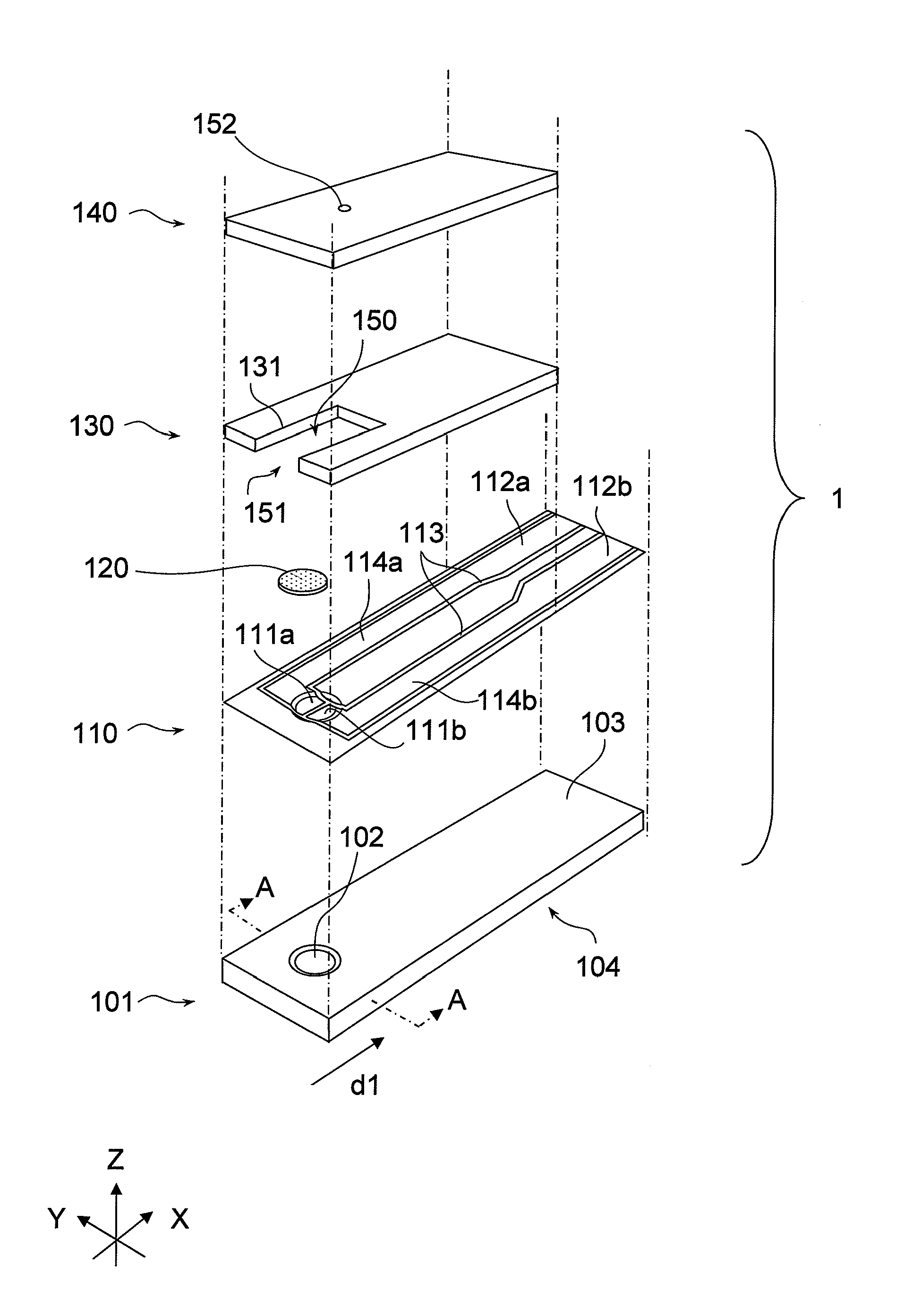

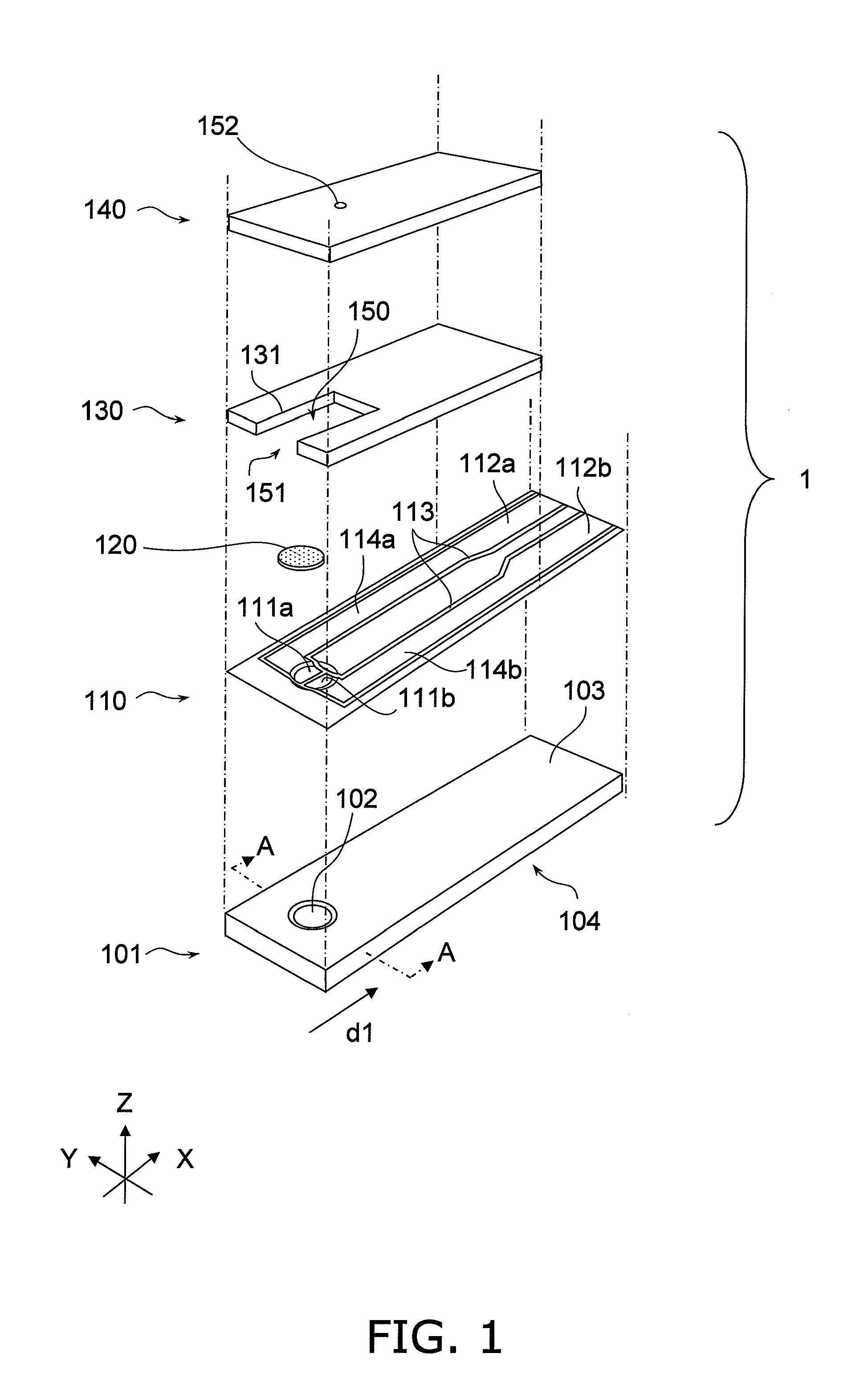

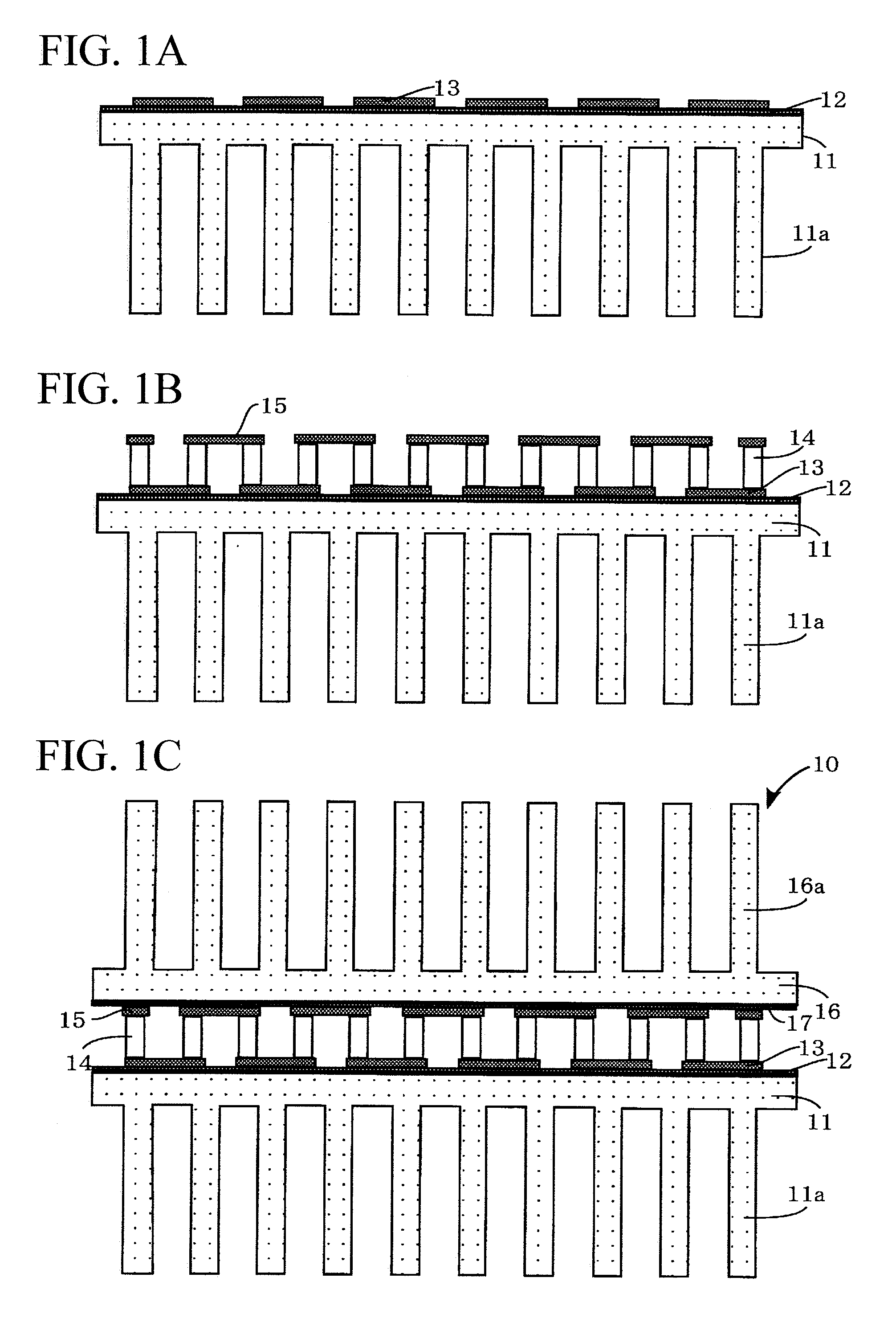

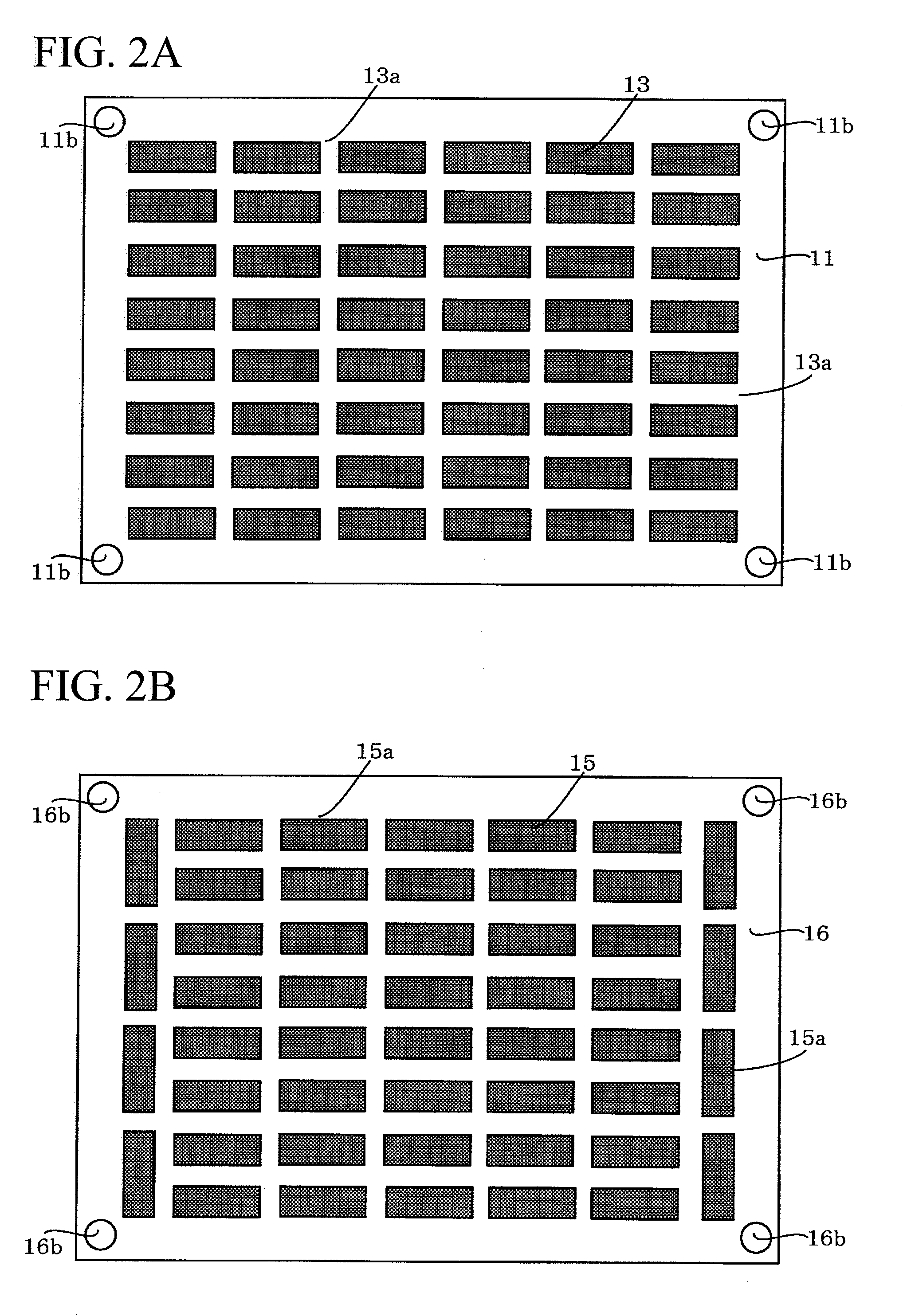

Biosensor, method of producing the same and detection system comprising the same

ActiveUS20090321257A1Reduce insulation thicknessImmobilised enzymesBioreactor/fermenter combinationsBiosensorAmount of substance

A biosensor that detects a target substance contained in a liquid sample has an insulating base plate including a recess formed in a portion that is thinner than the surrounding part, a working electrode and a counter electrode, at least one of which is disposed in the recess, and a reaction reagent that is disposed in the recess and reacts with a specific substance in the liquid sample.

Owner:PHC HLDG CORP

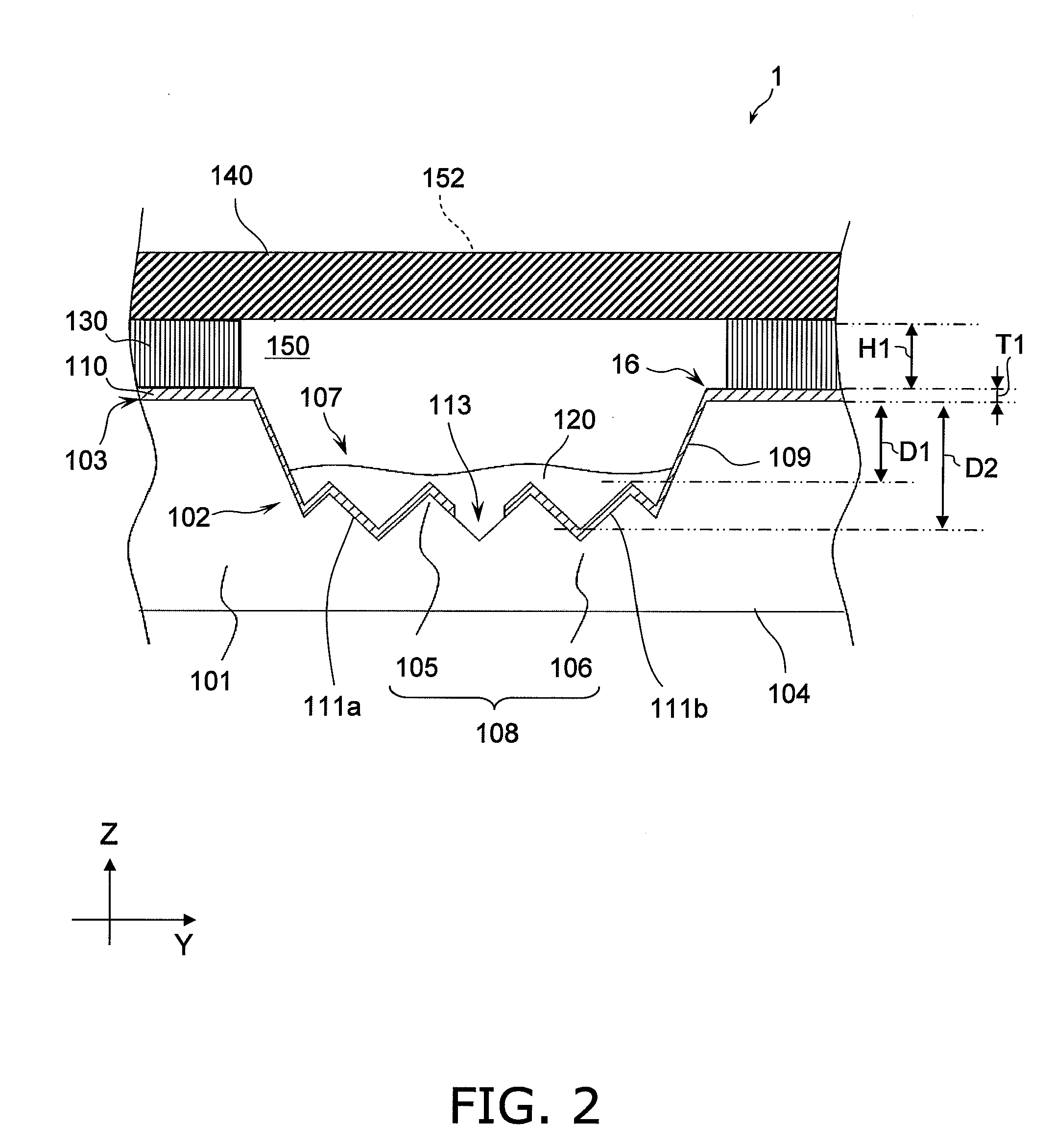

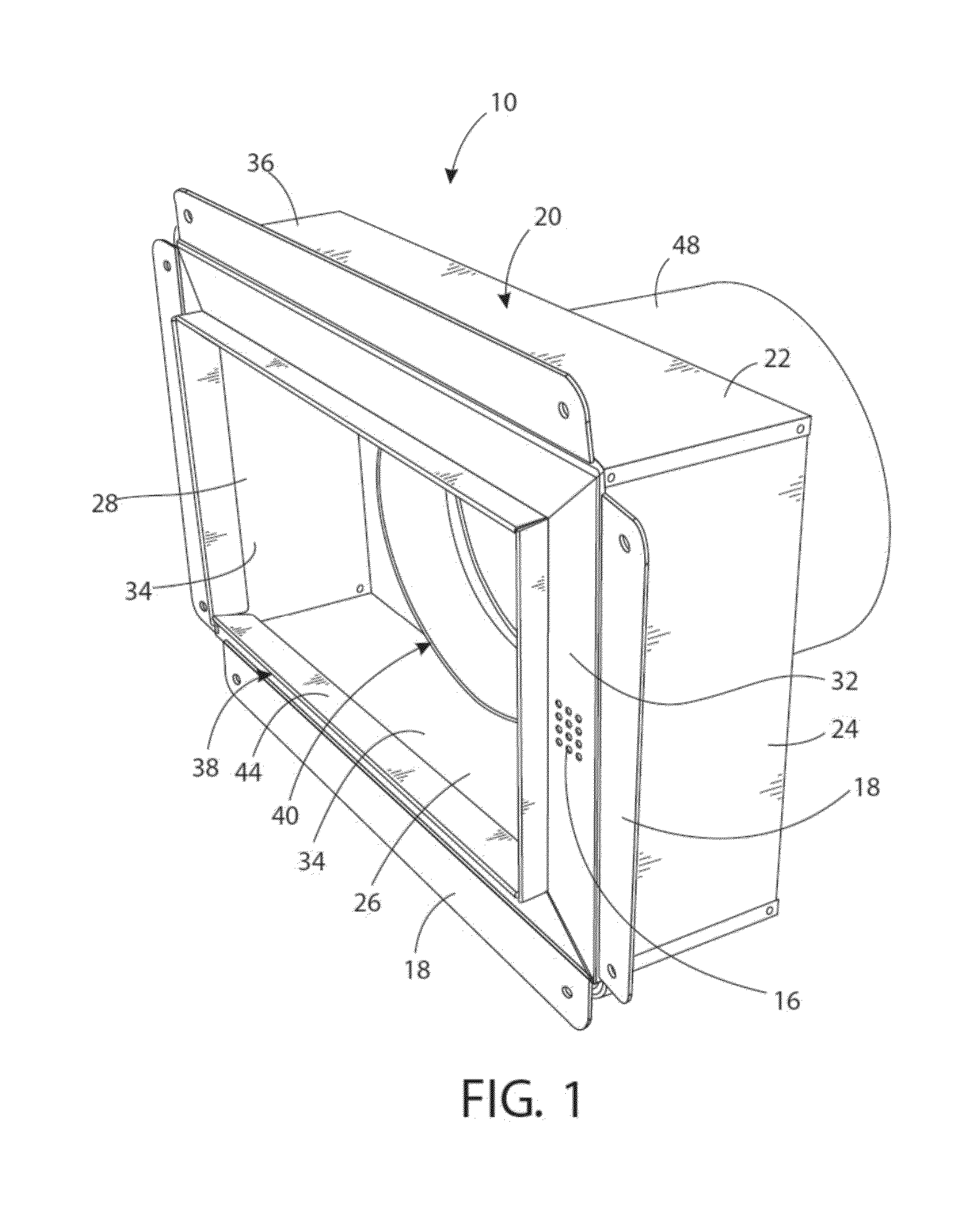

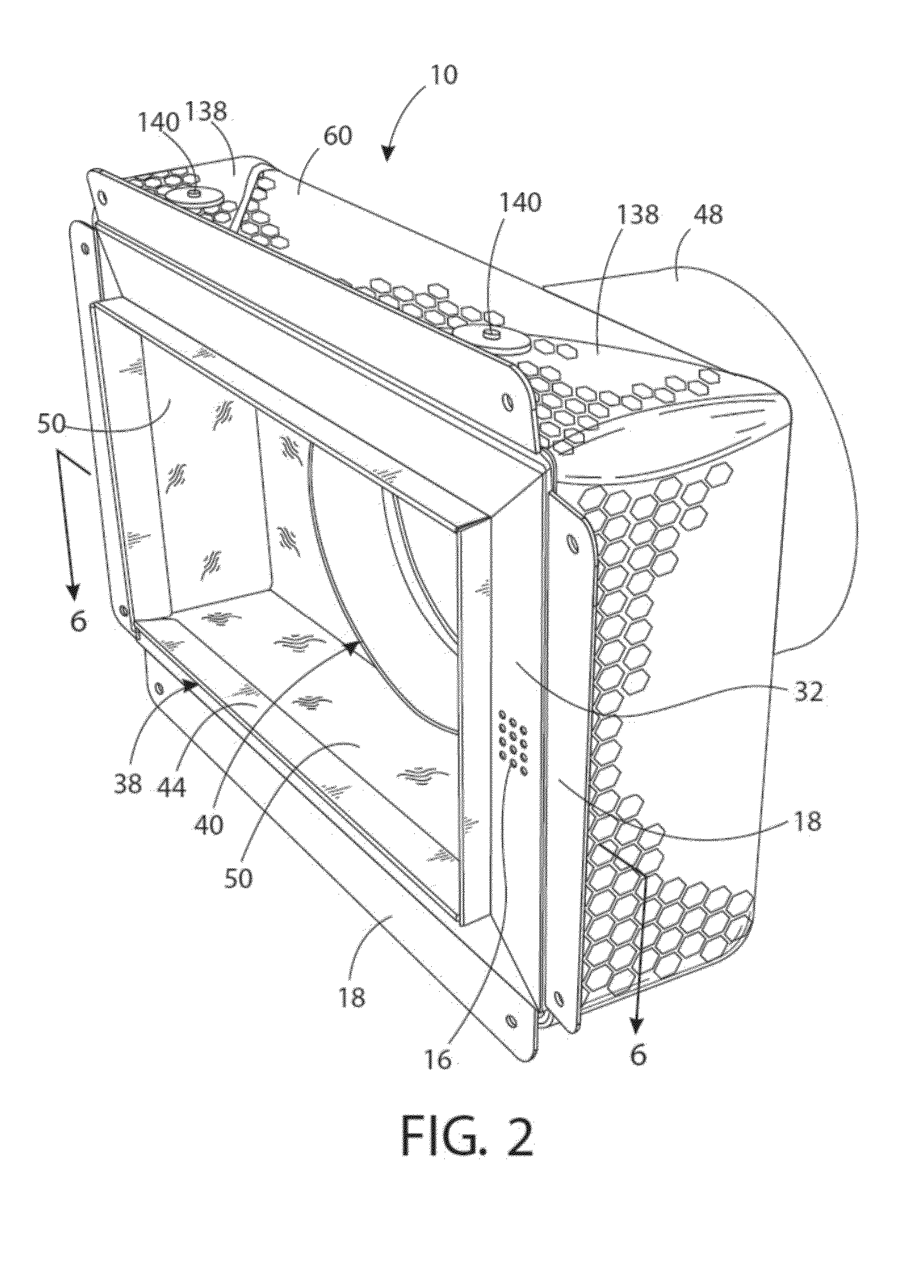

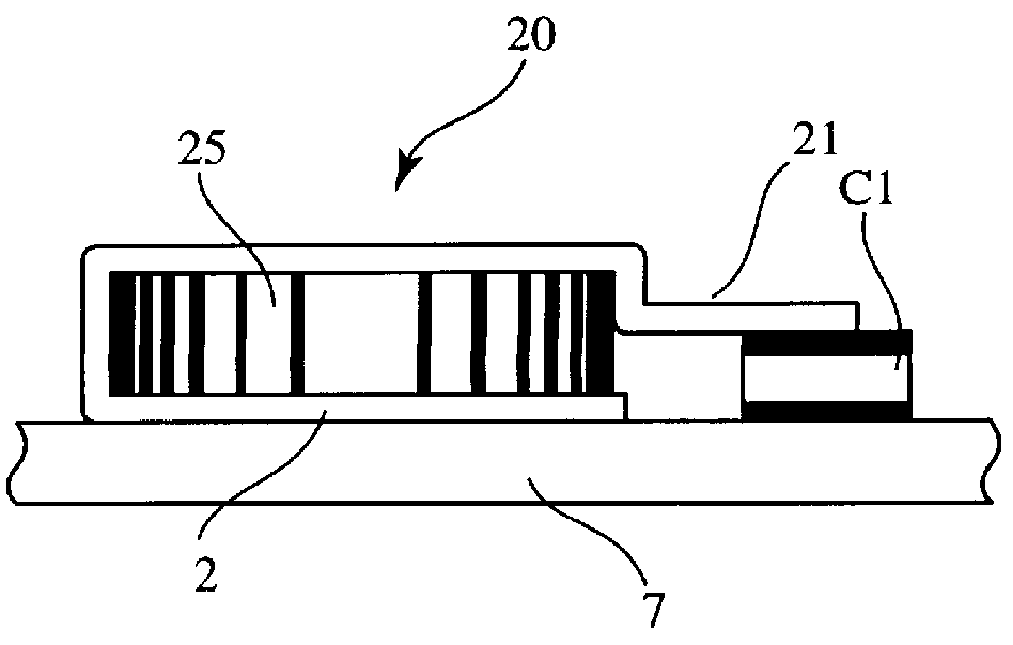

Reflective Laminate Insulating Assembly

ActiveUS20150204573A1Improve the immunityReduce insulation thicknessStampsDucting arrangementsInsulation layerEngineering

An insulated HVAC duct component such as a transition box includes a first insulation layer and a second, different insulation layer. The transition box includes at least four sidewalls and one of a top and a back wall, the transition box further including a first access port and a second access port, the first access port having a different cross section than the second access port, one of the access ports being spaced from a nearest sidewall by less than 2 inches. The first insulation layer is located along an inside surface of the box. The second different insulation layer overlies the first insulation layer, the second different insulation layer having an air impervious surface, wherein the combined thickness of the first insulation layer and the second different insulation layer is less than 2 inches.

Owner:GRAY WILLIAM R

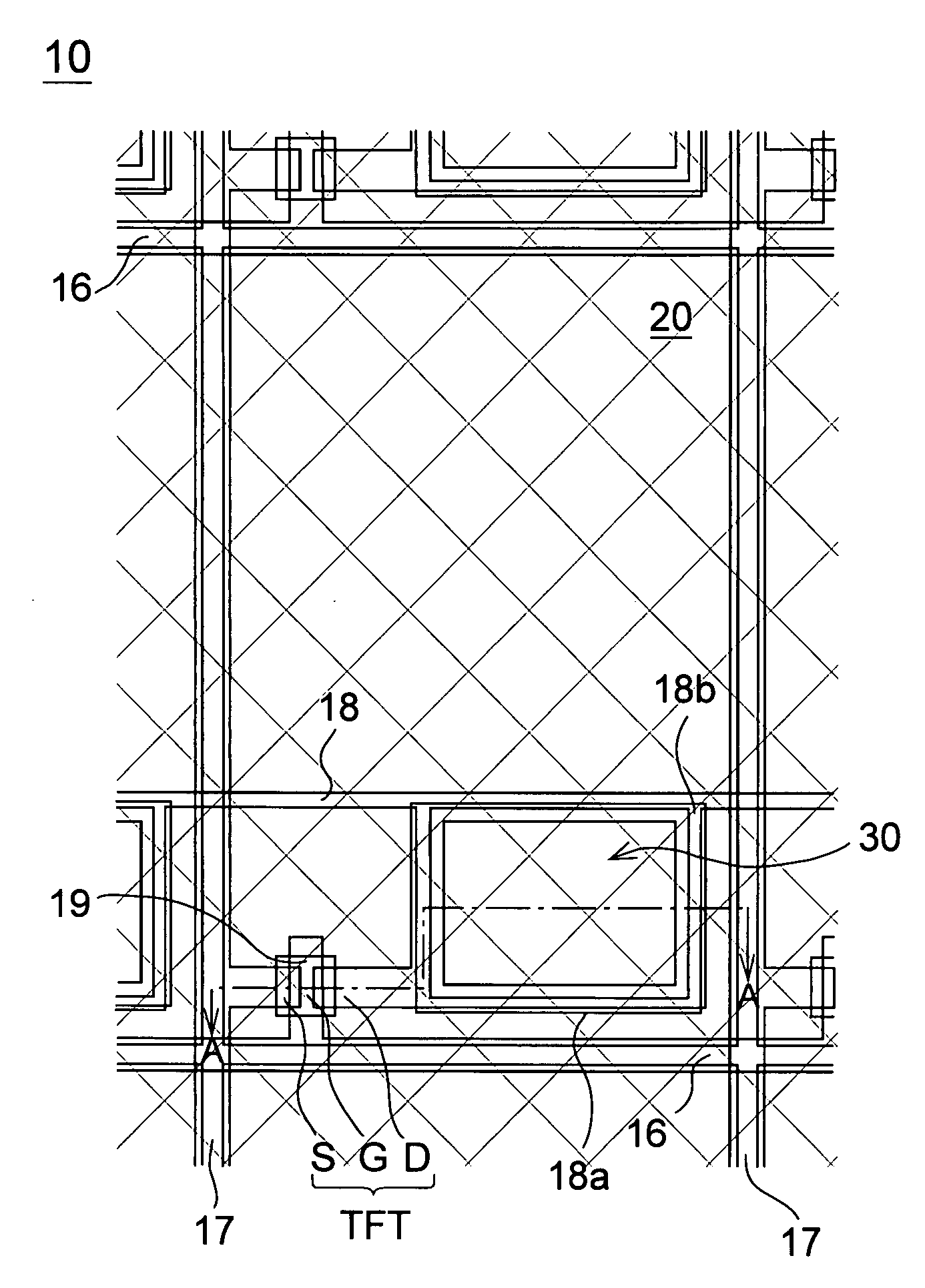

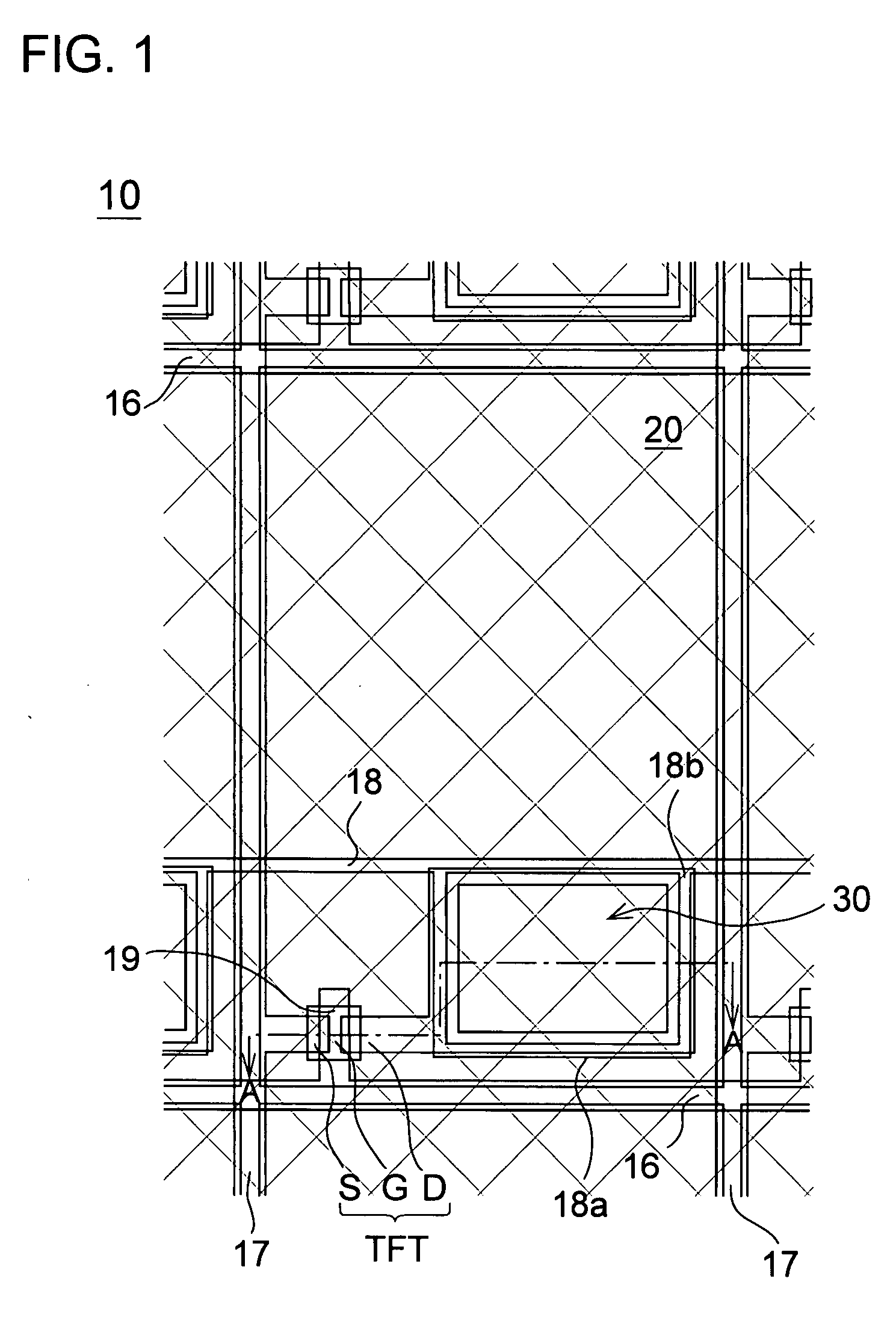

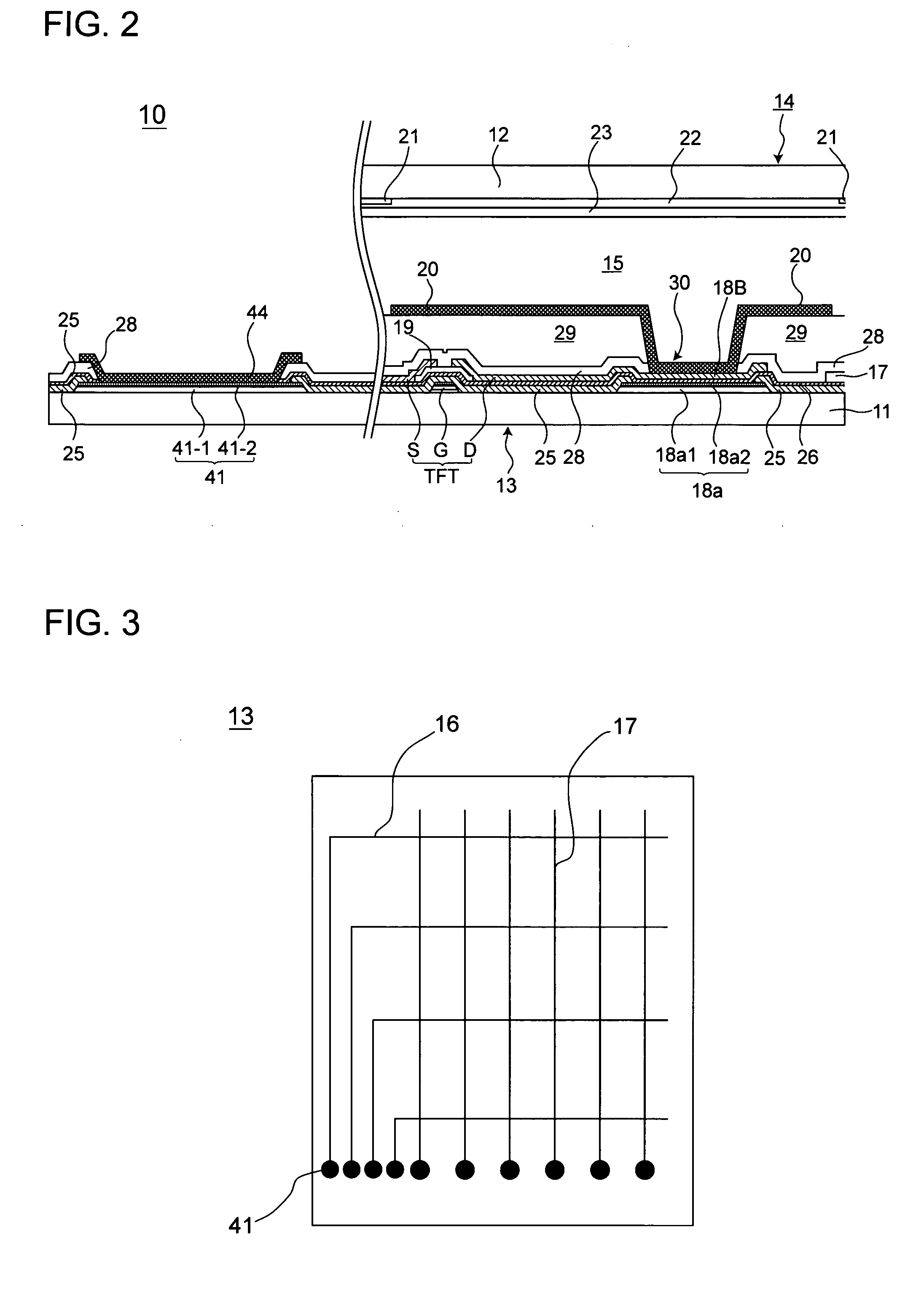

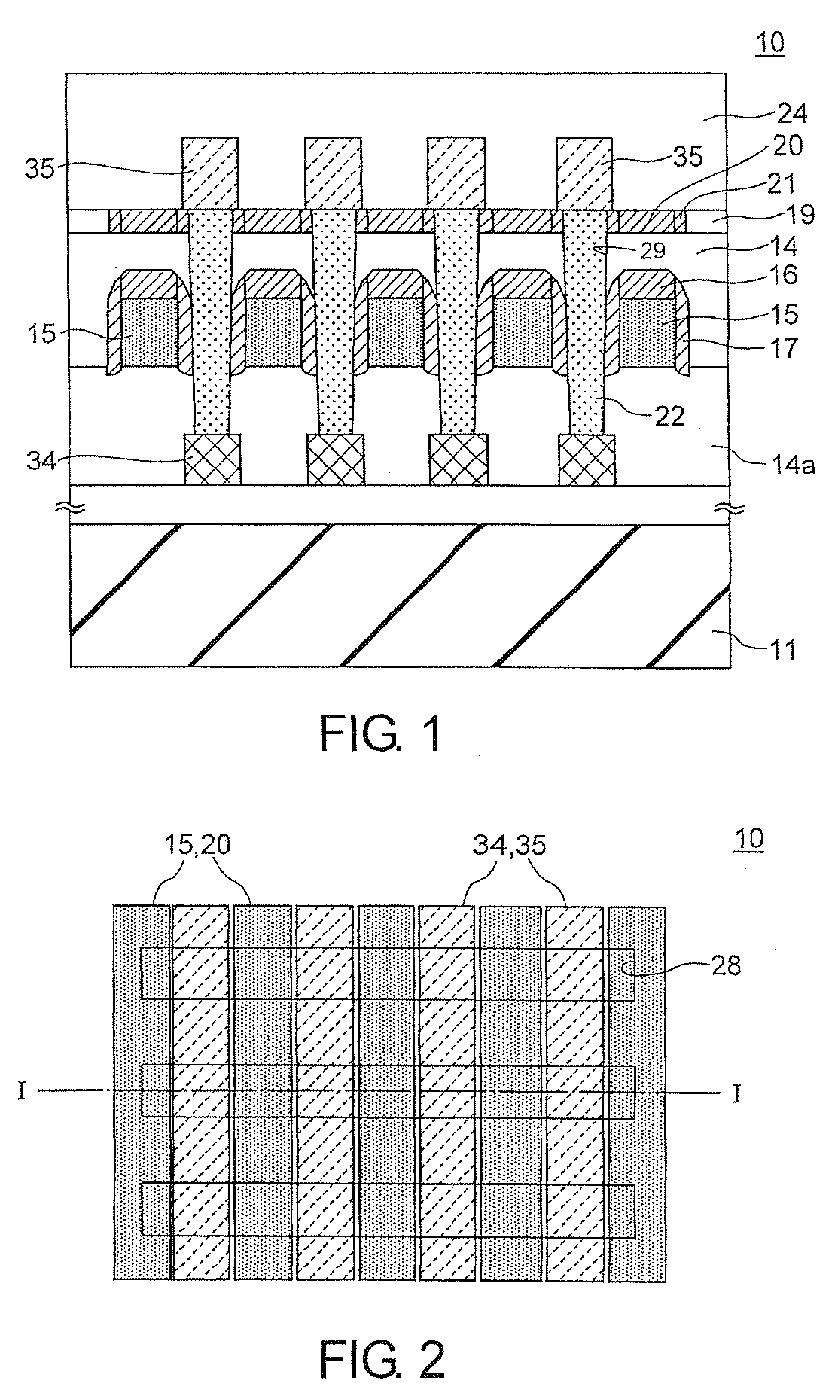

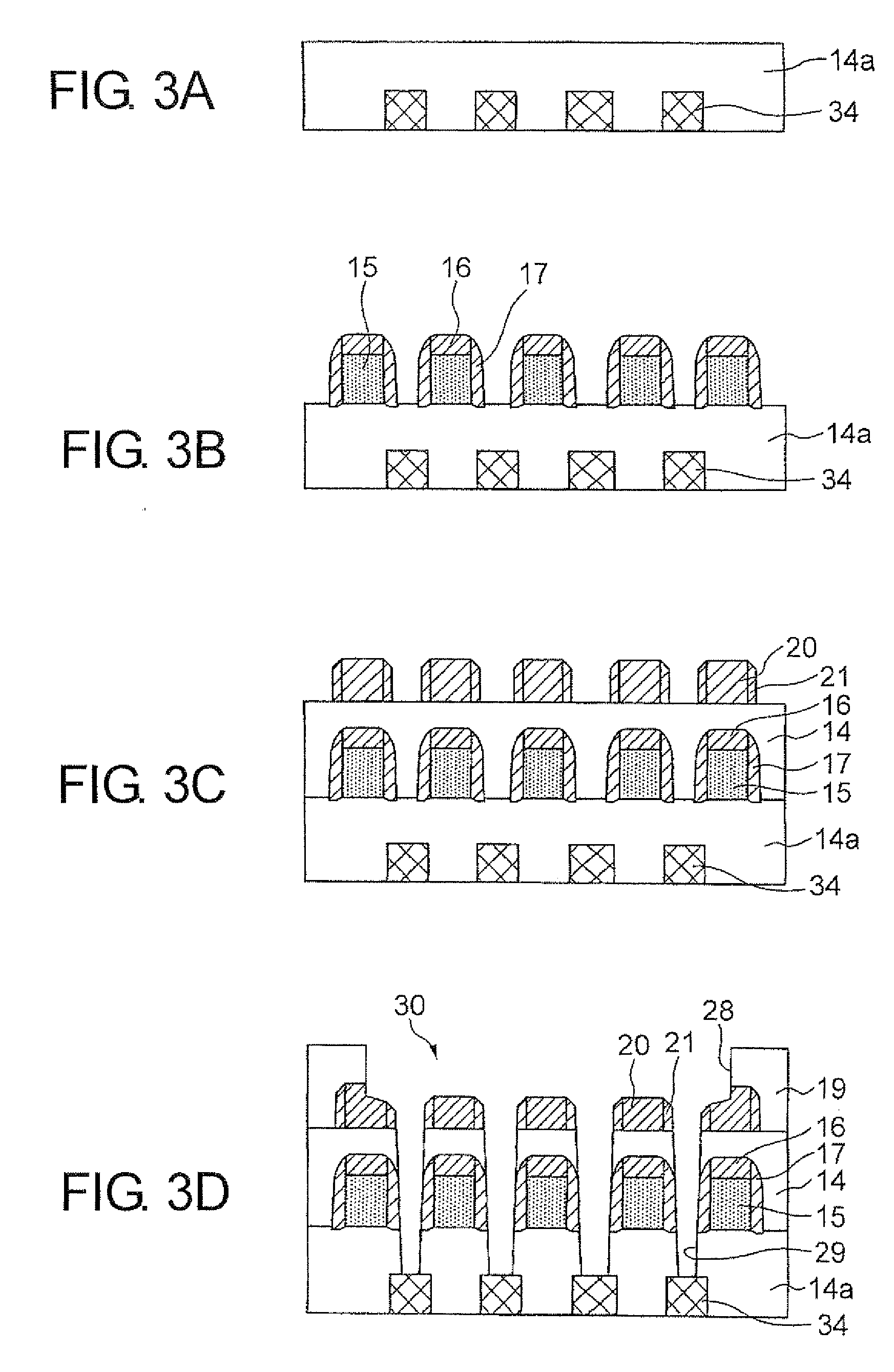

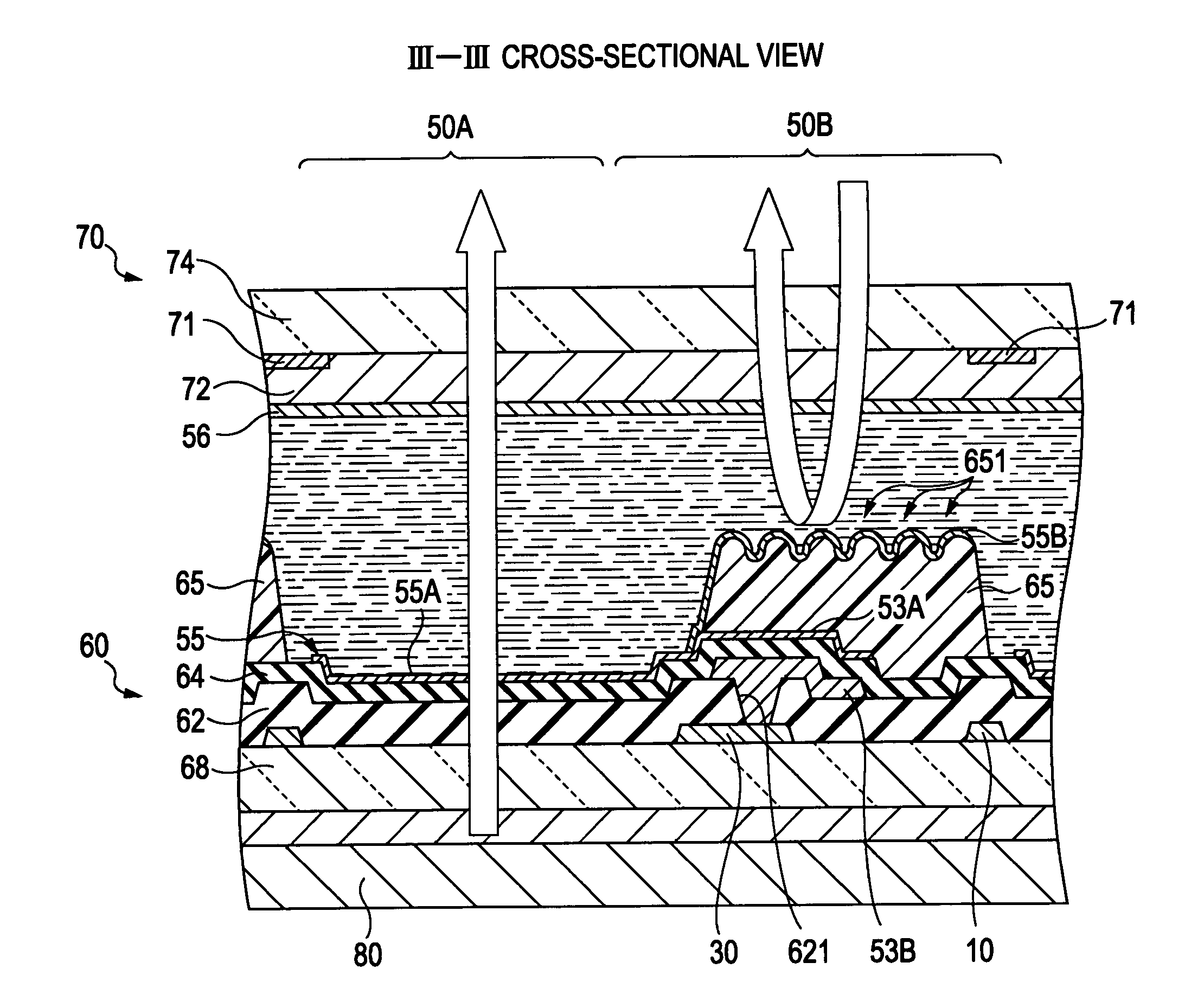

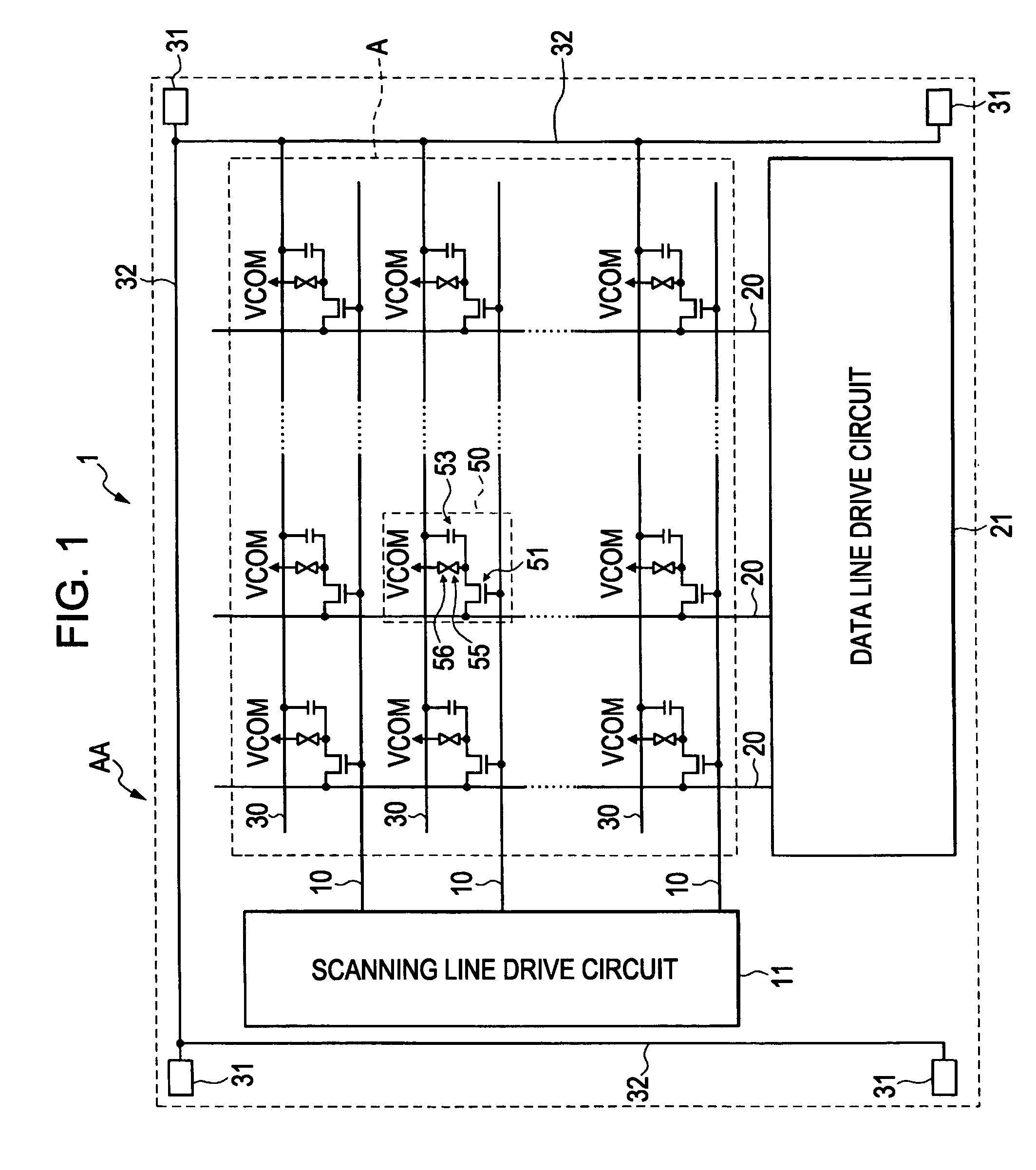

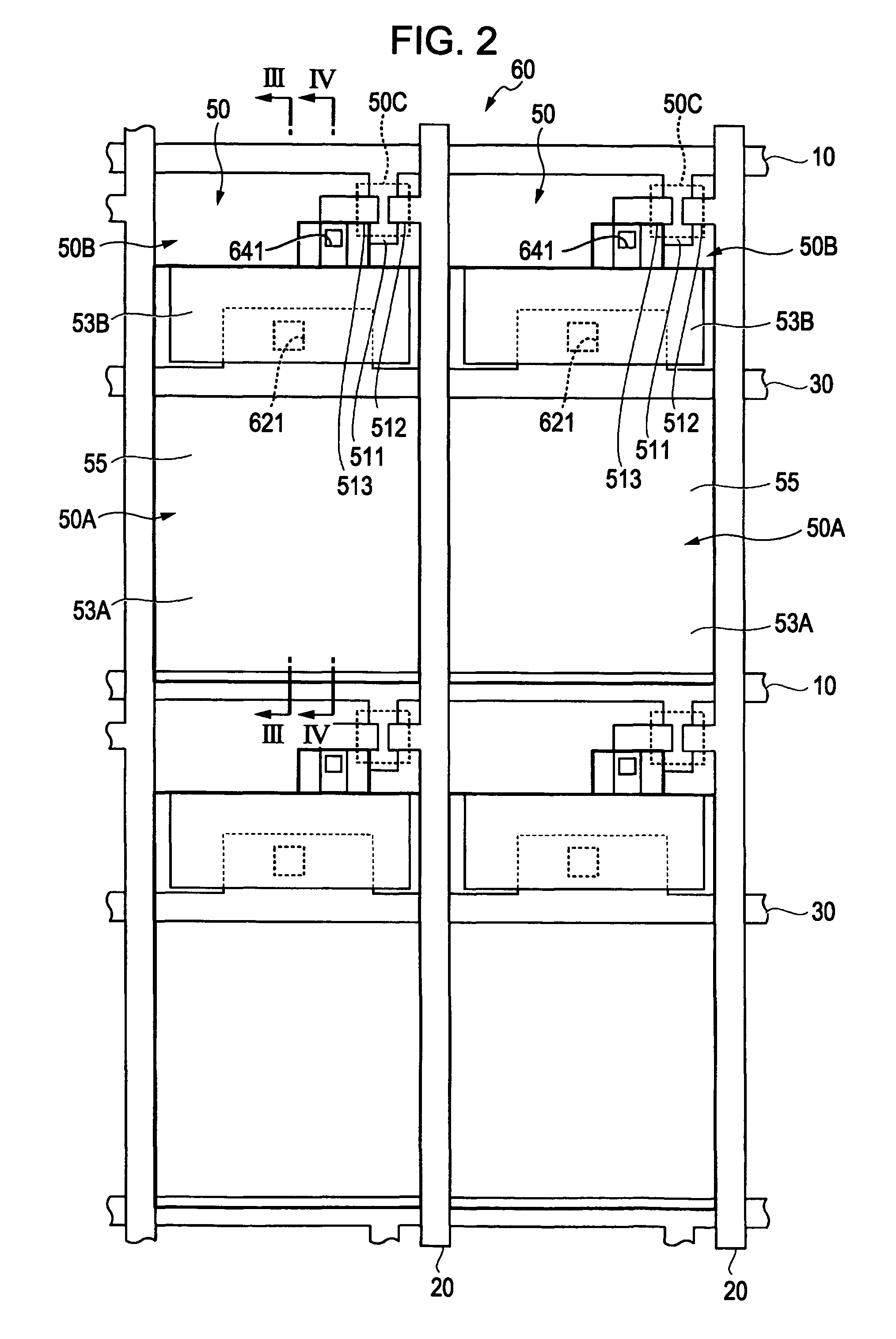

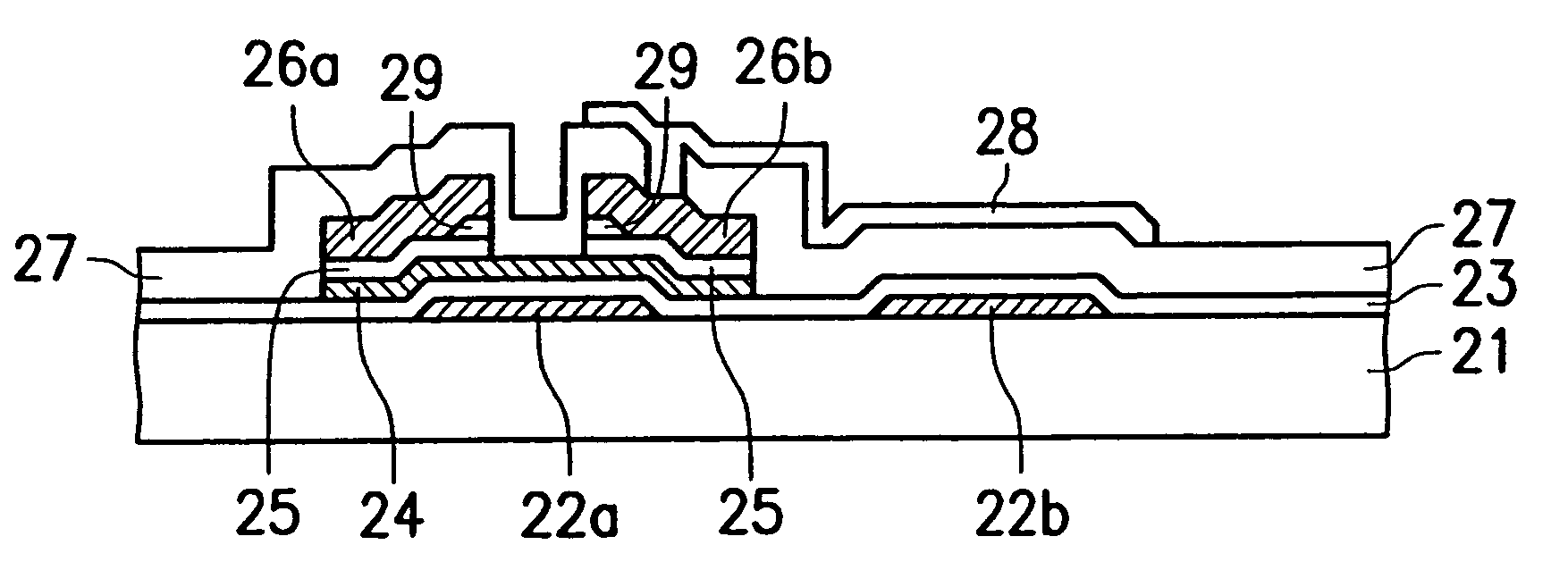

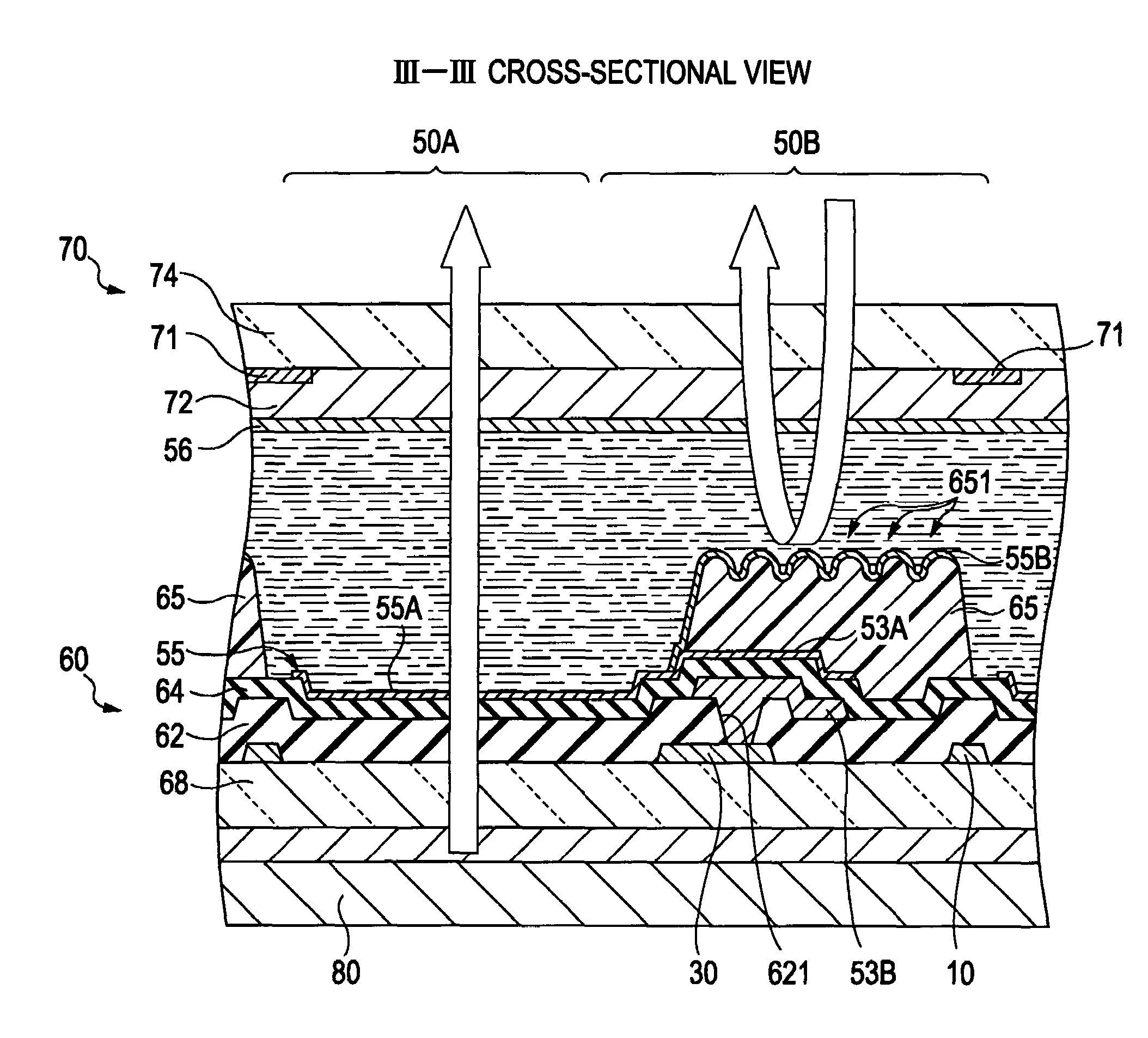

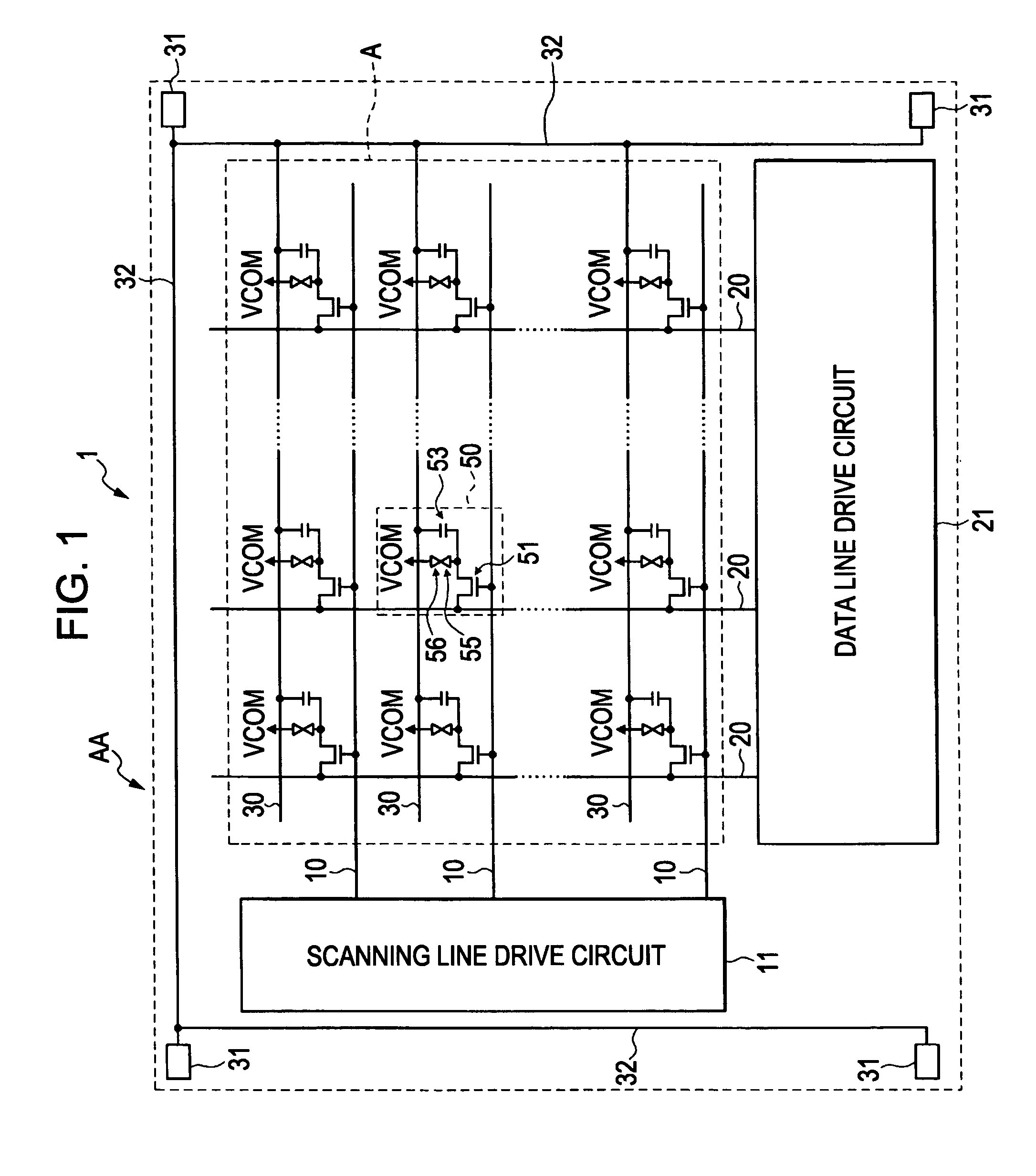

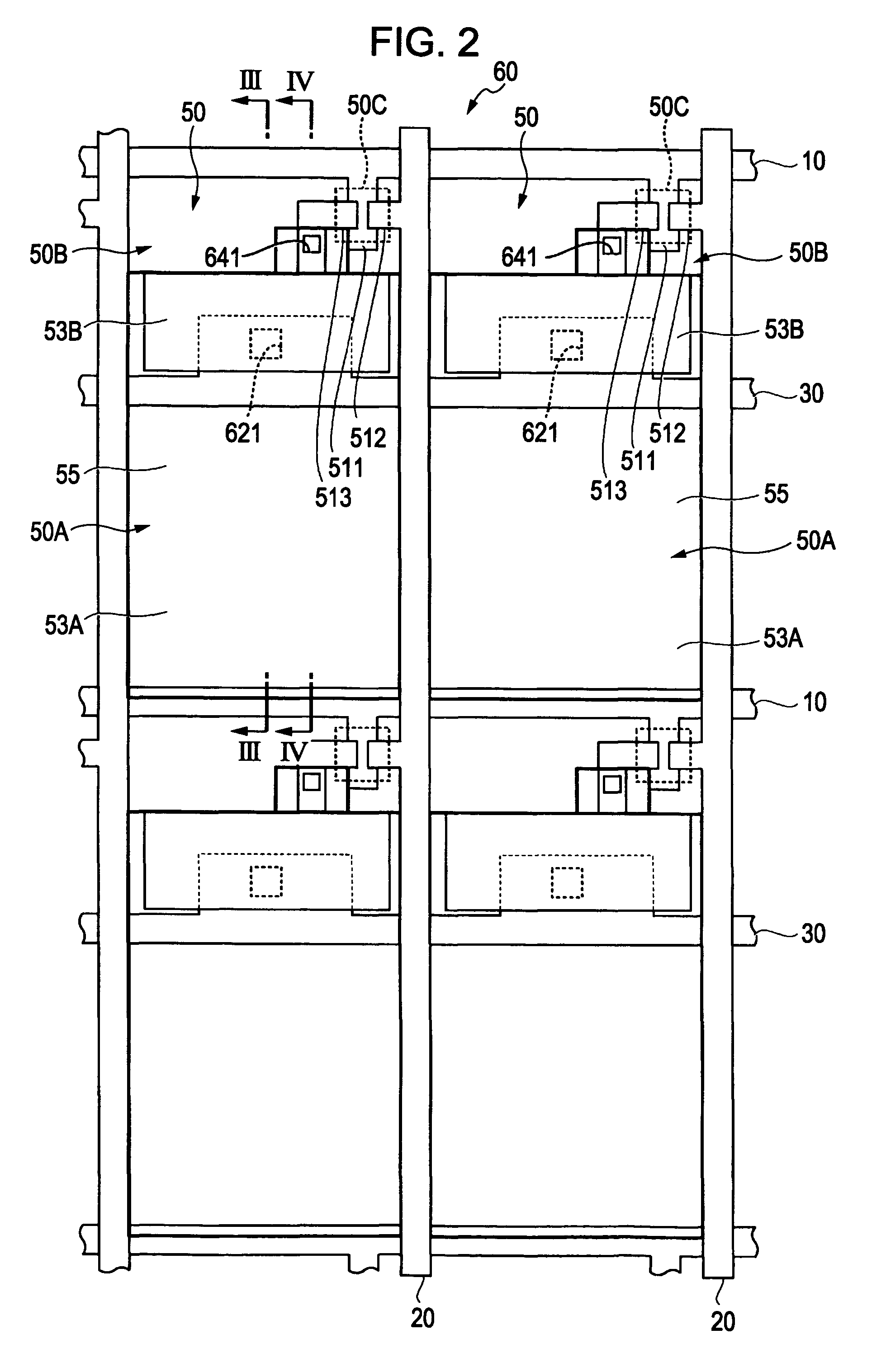

Liquid crystal display device and manufacturing method thereof

ActiveUS20070273800A1Increase the areaIncrease the aperture ratioStatic indicating devicesNon-linear opticsCapacitanceLiquid-crystal display

Owner:JAPAN DISPLAY WEST

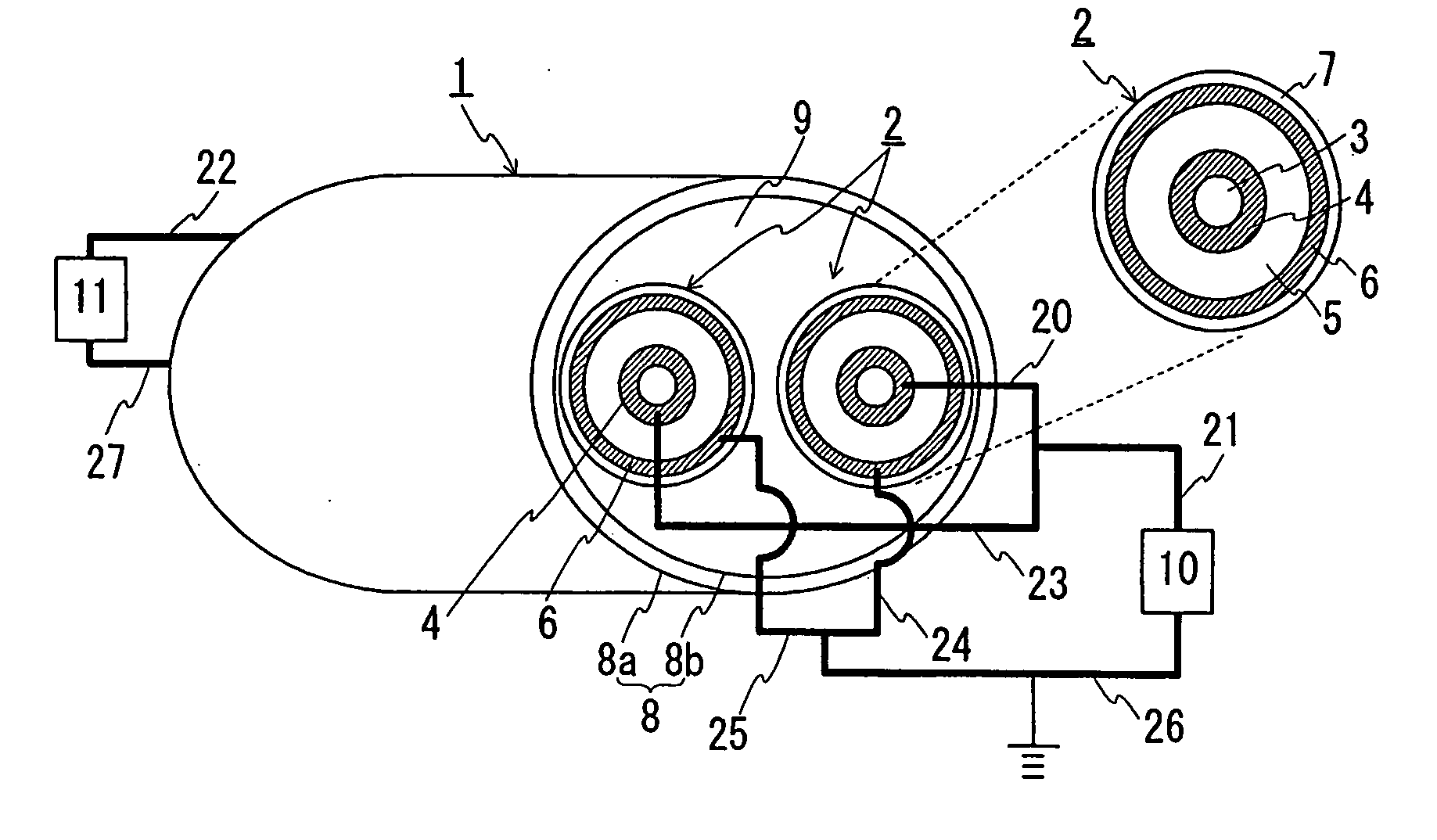

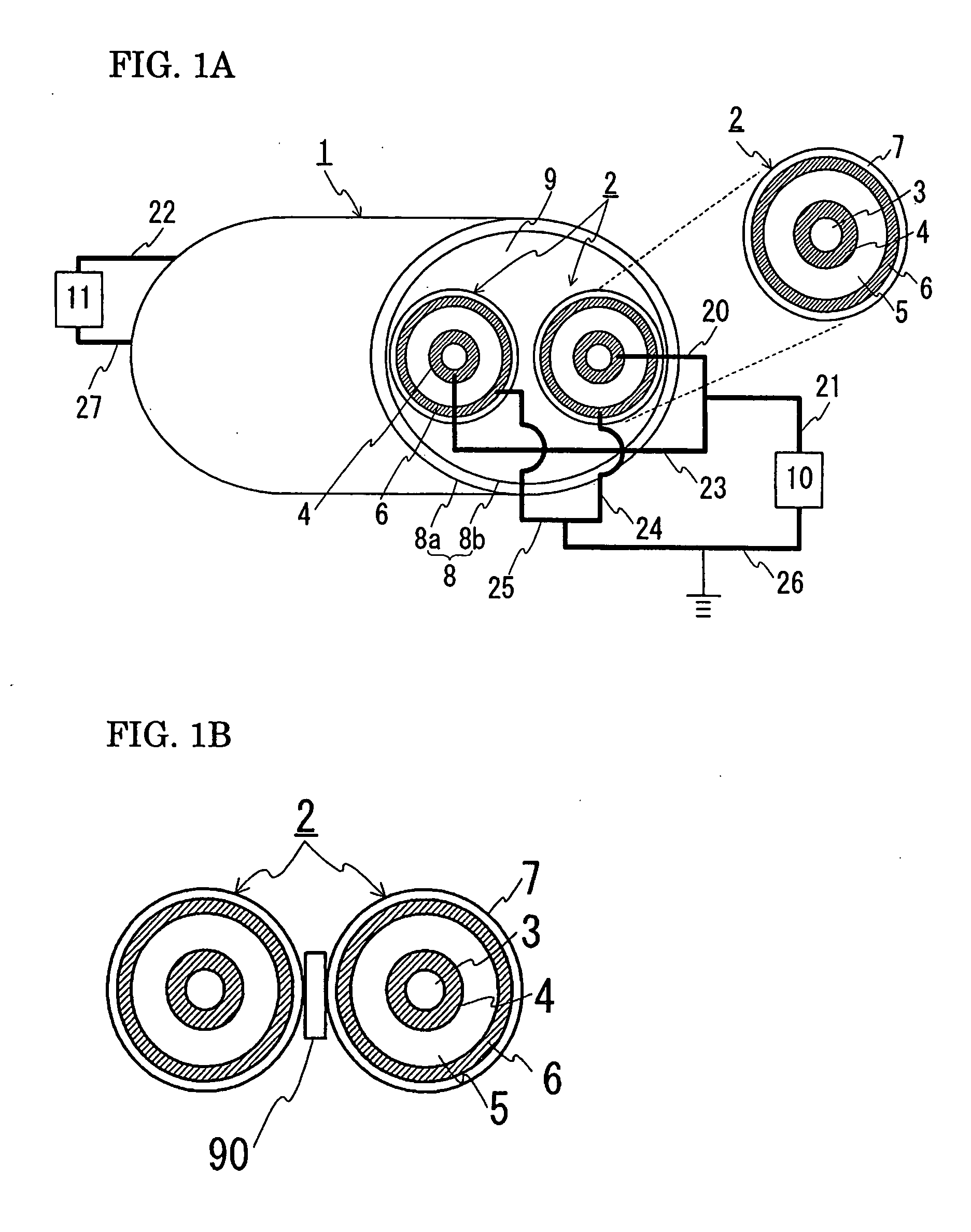

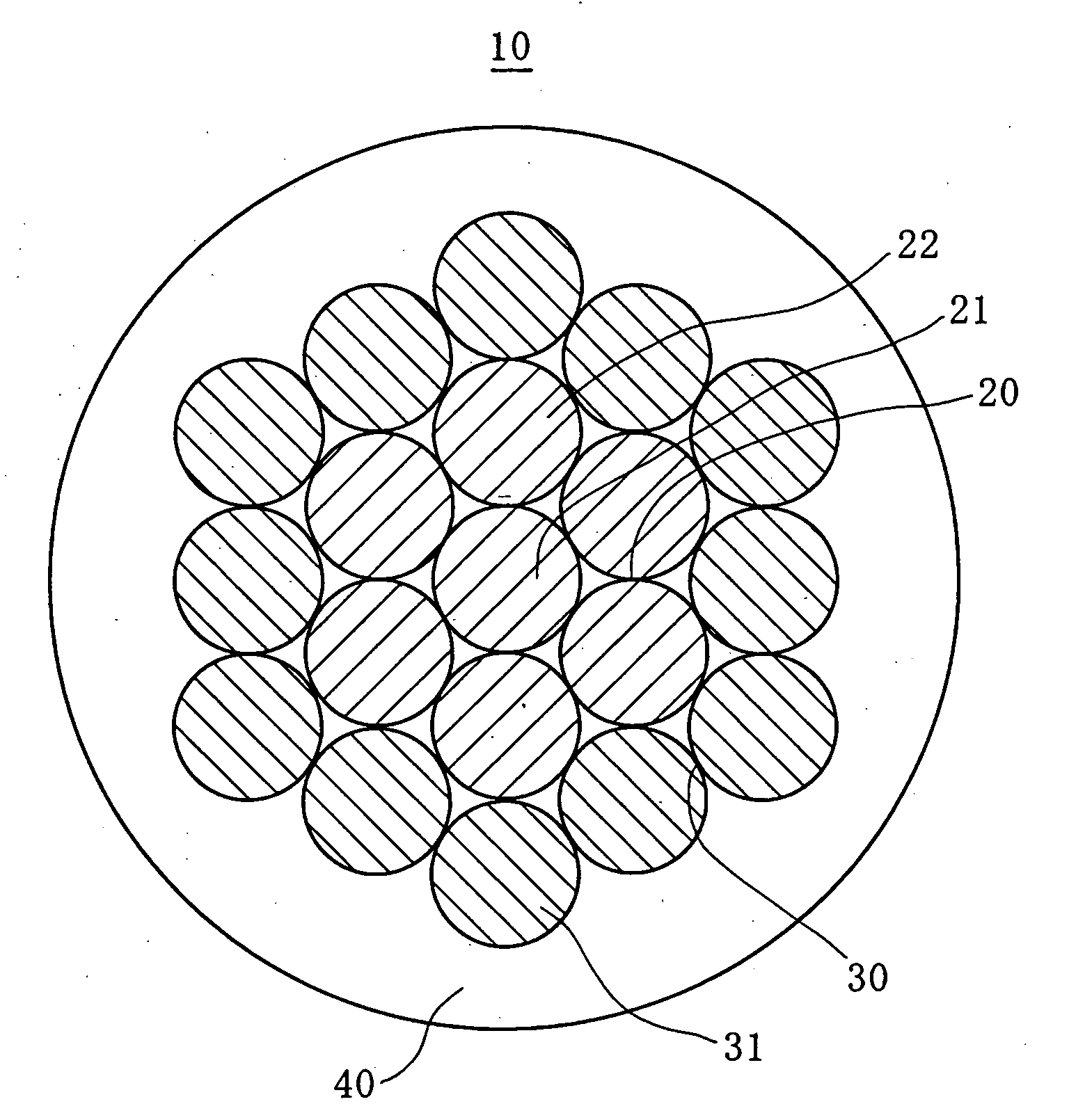

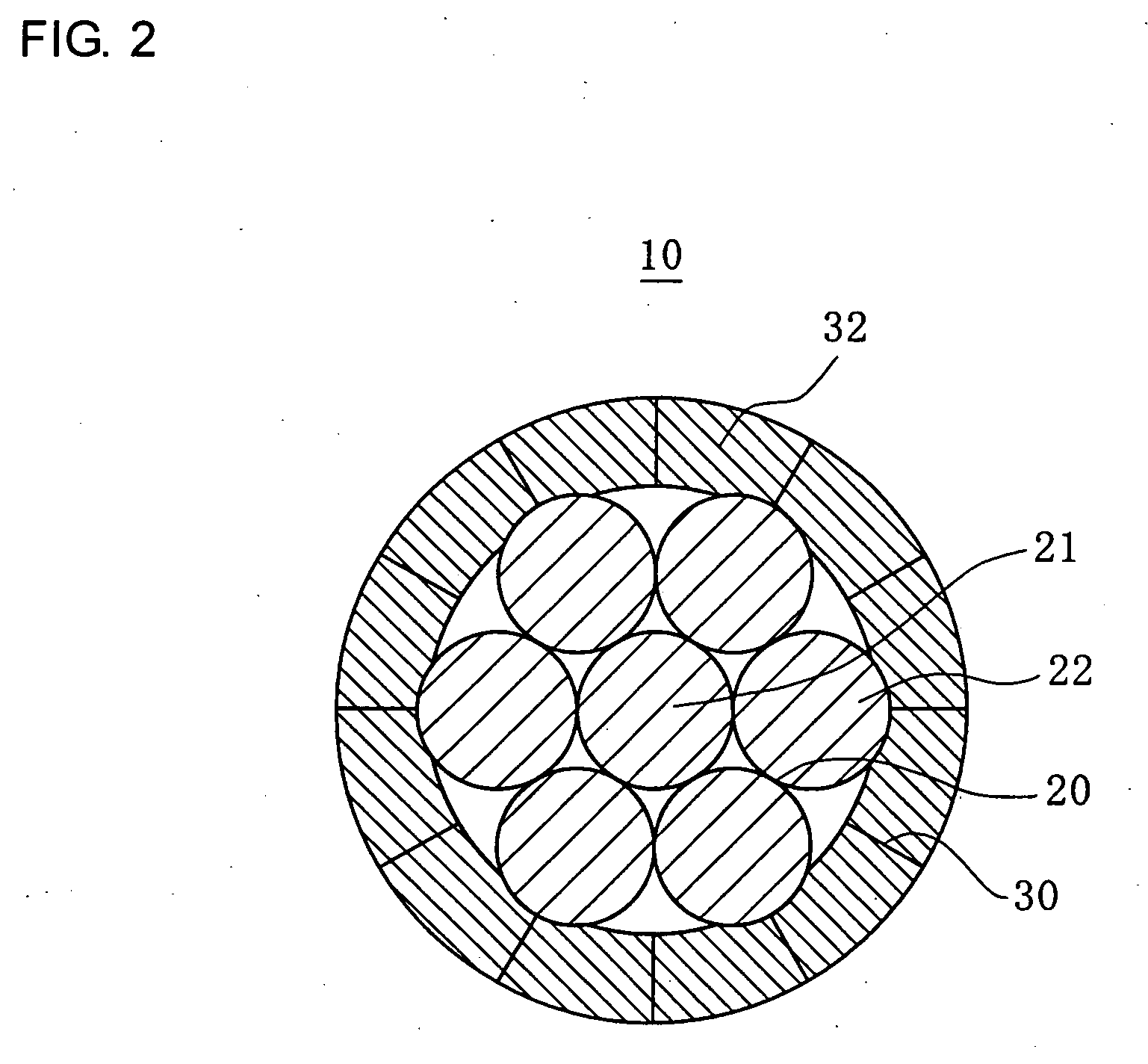

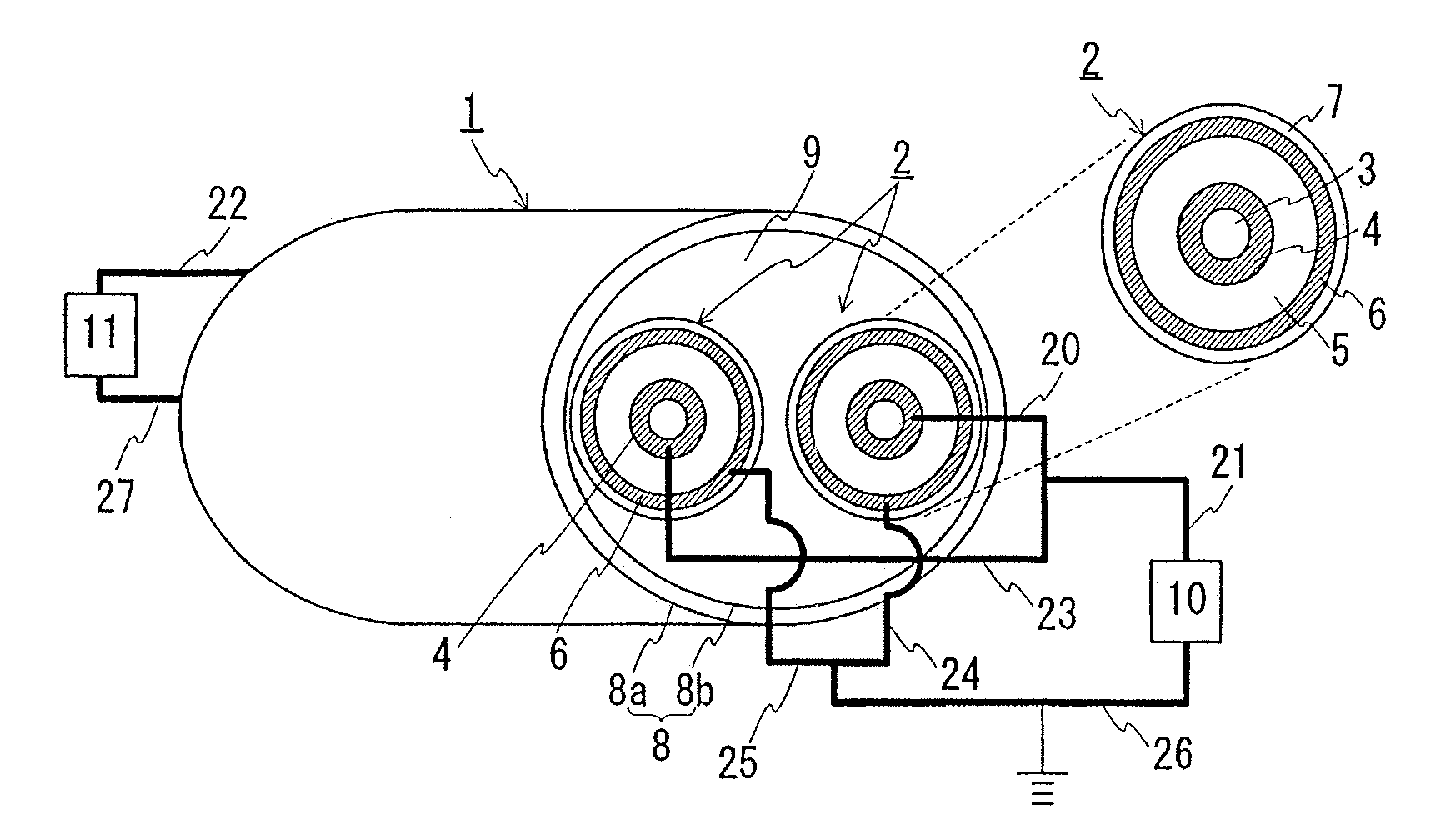

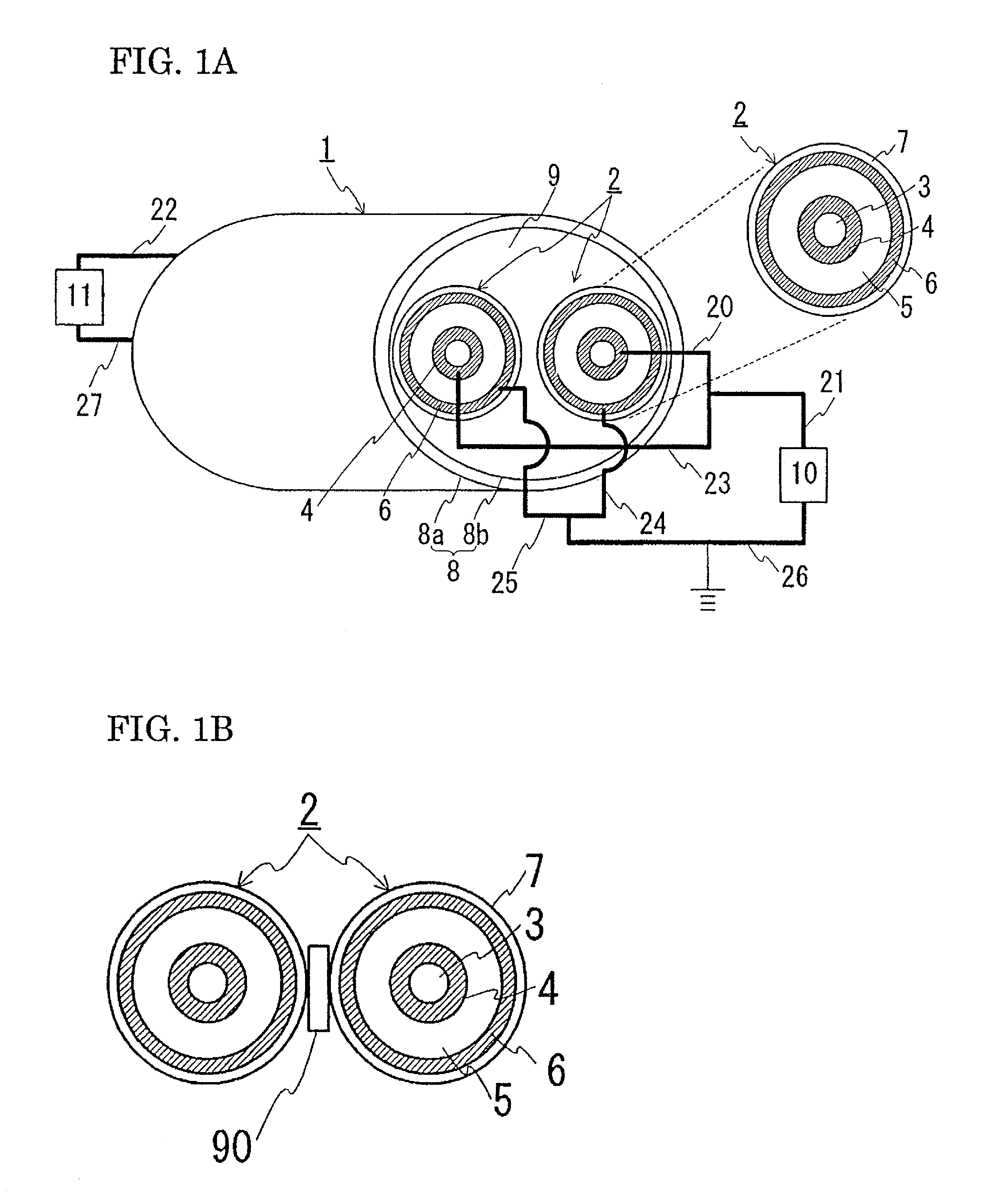

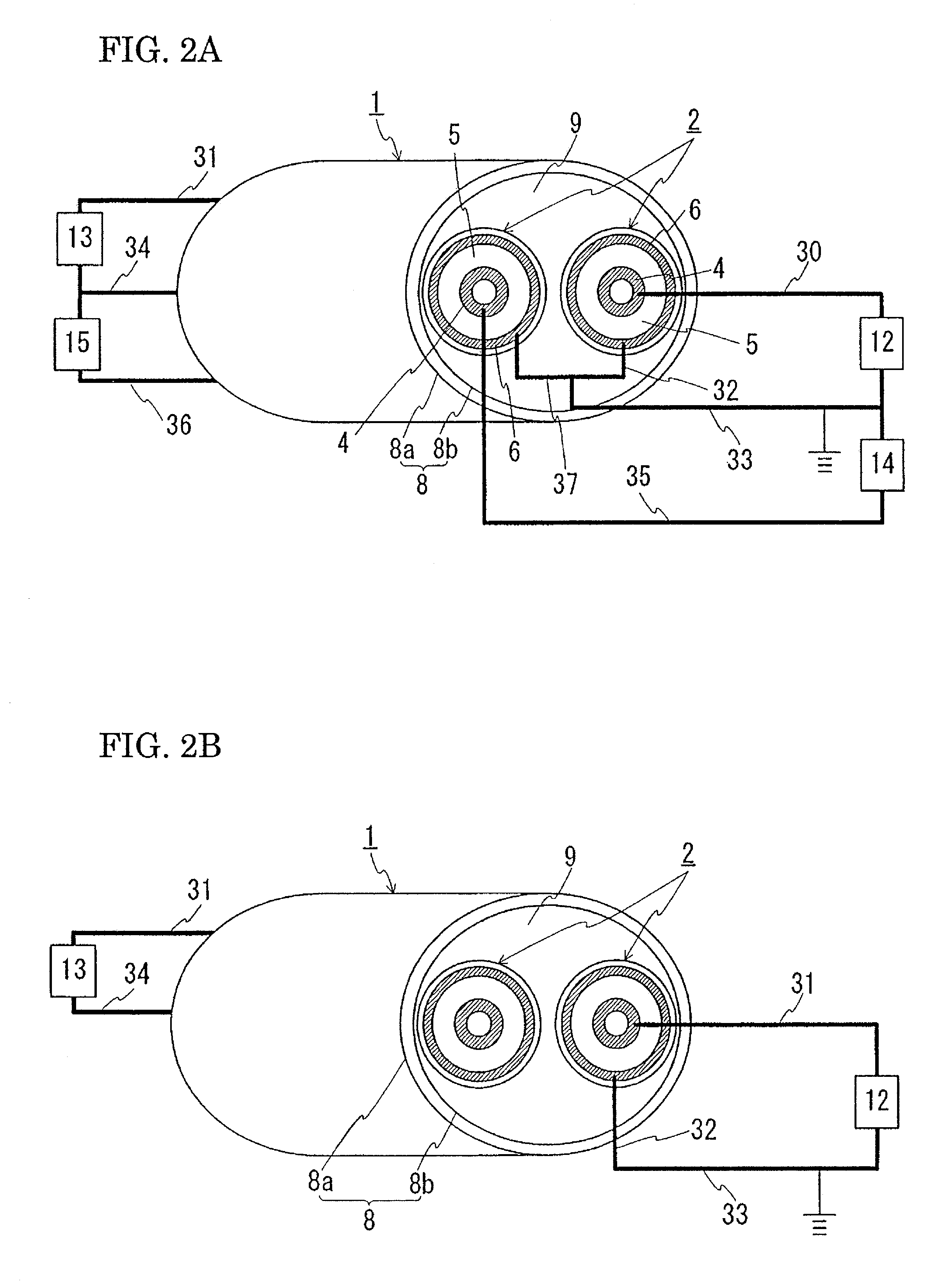

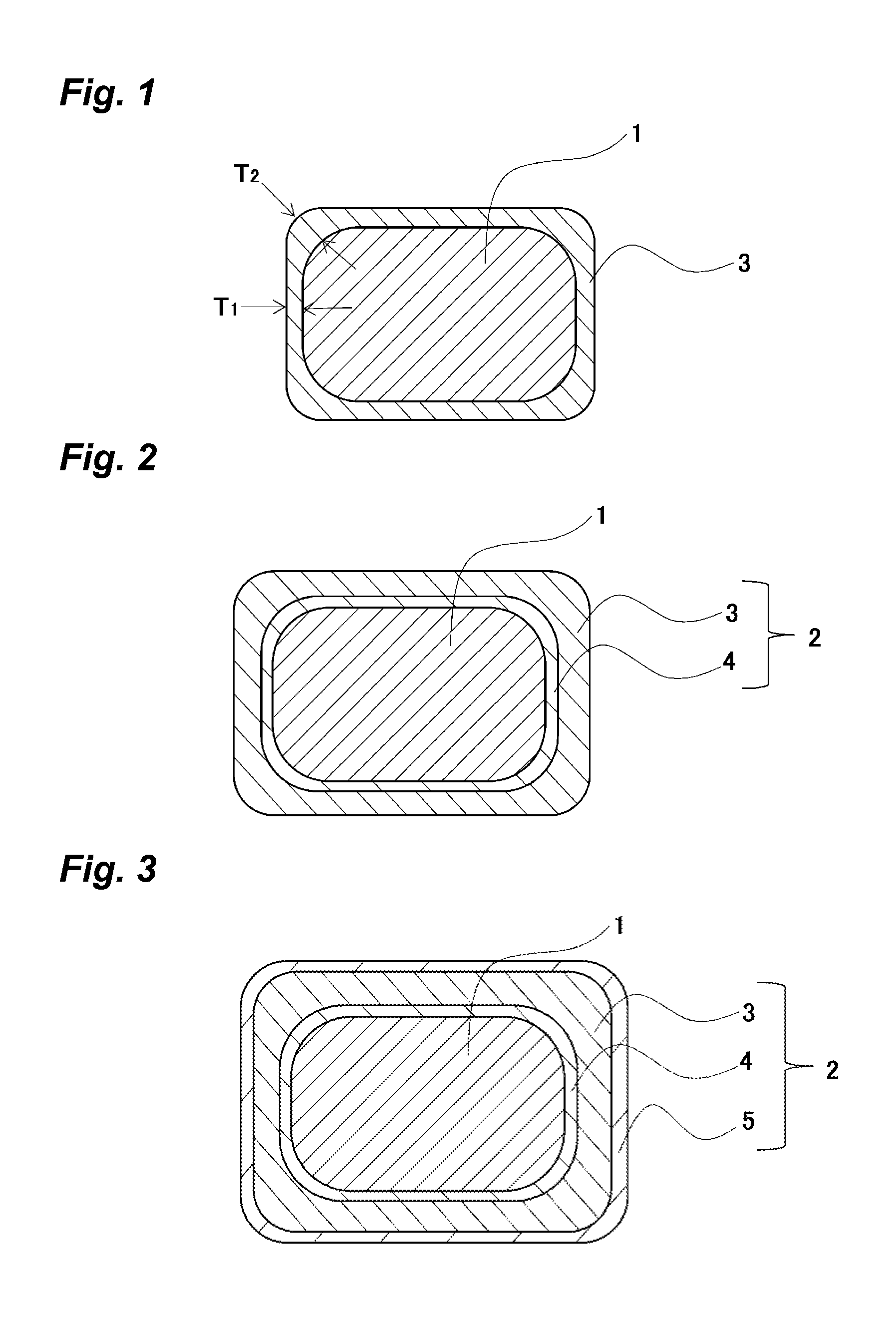

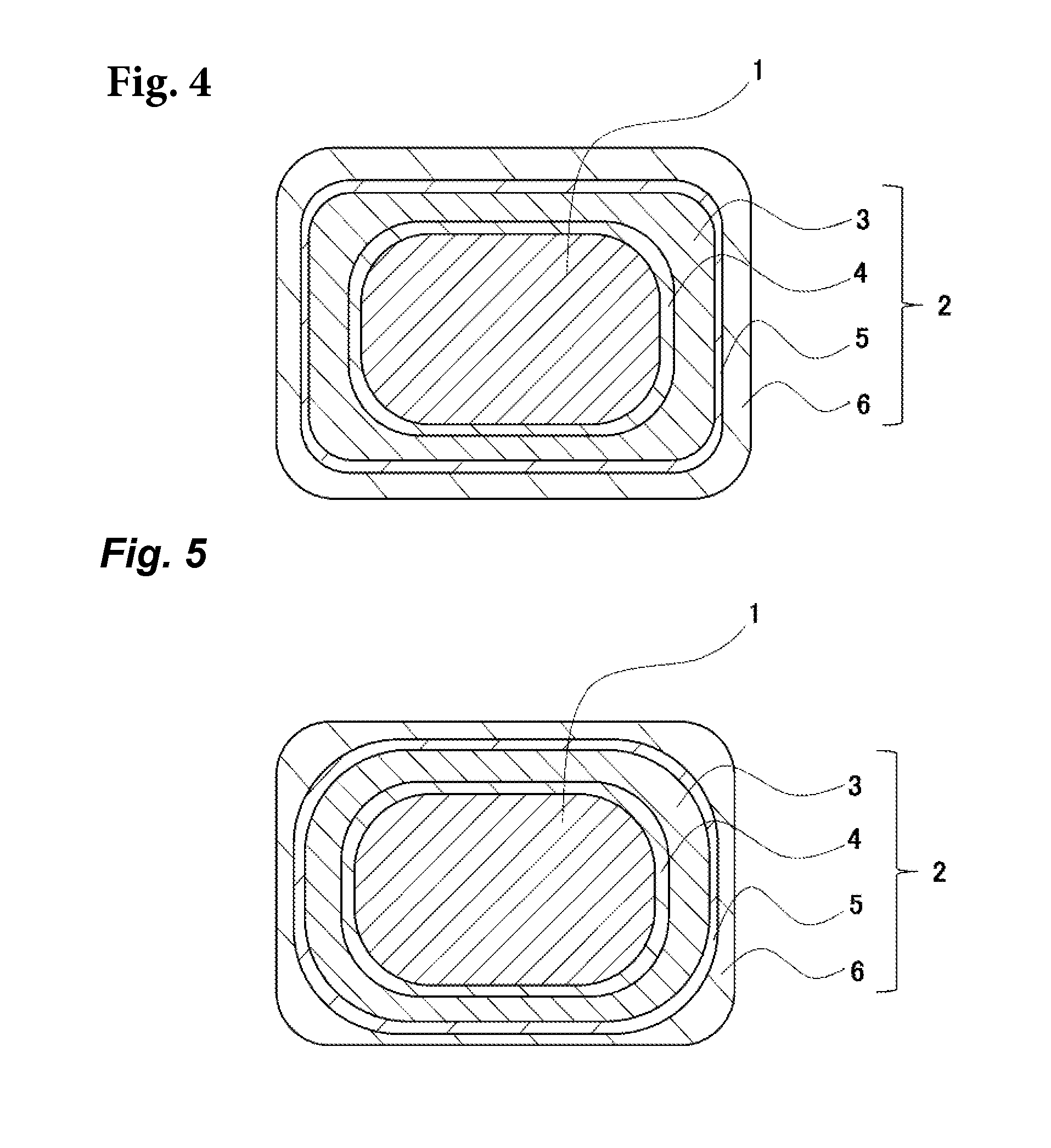

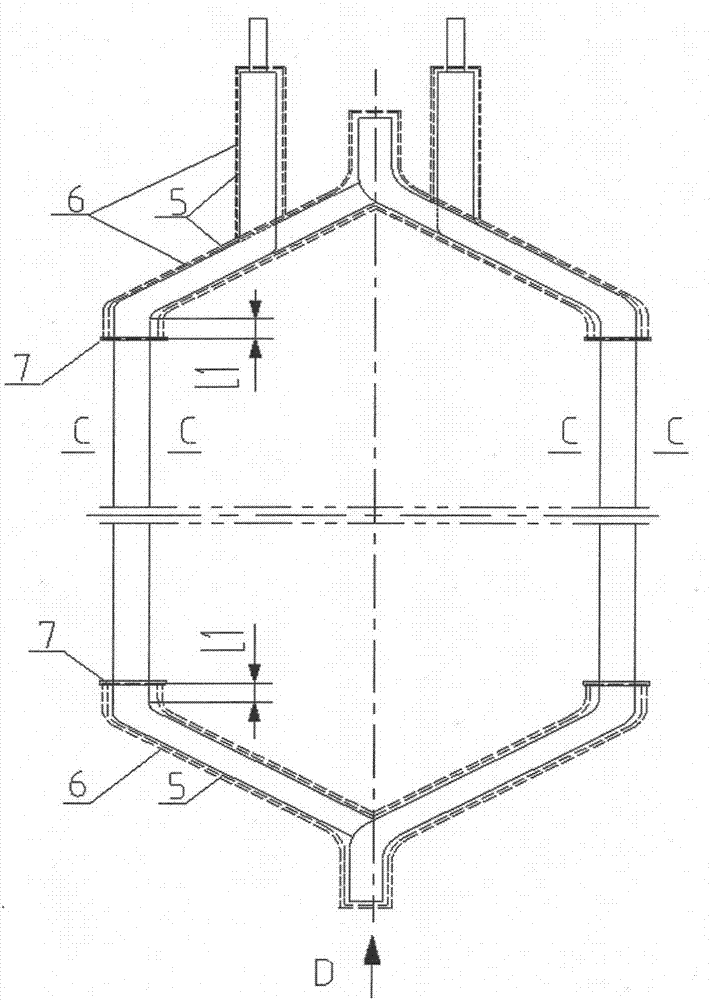

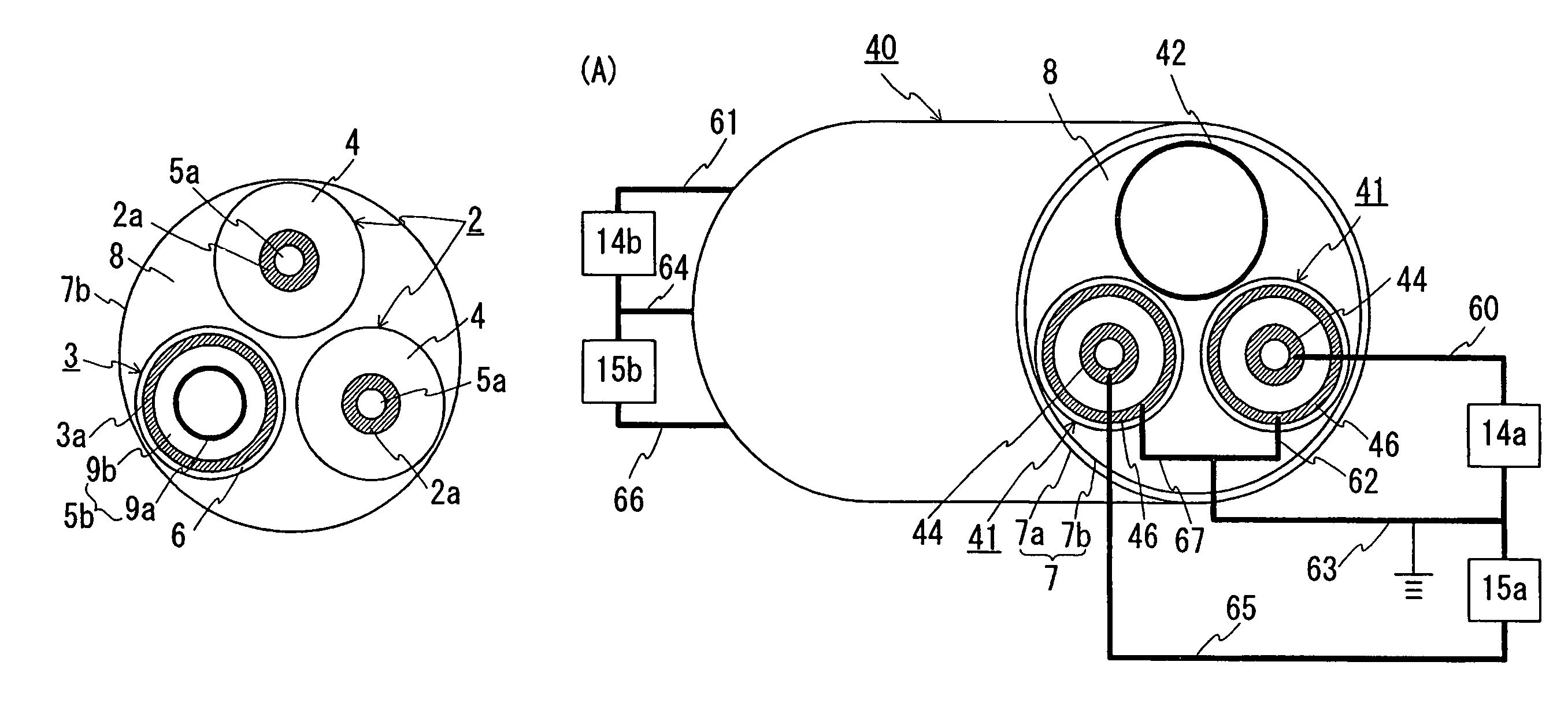

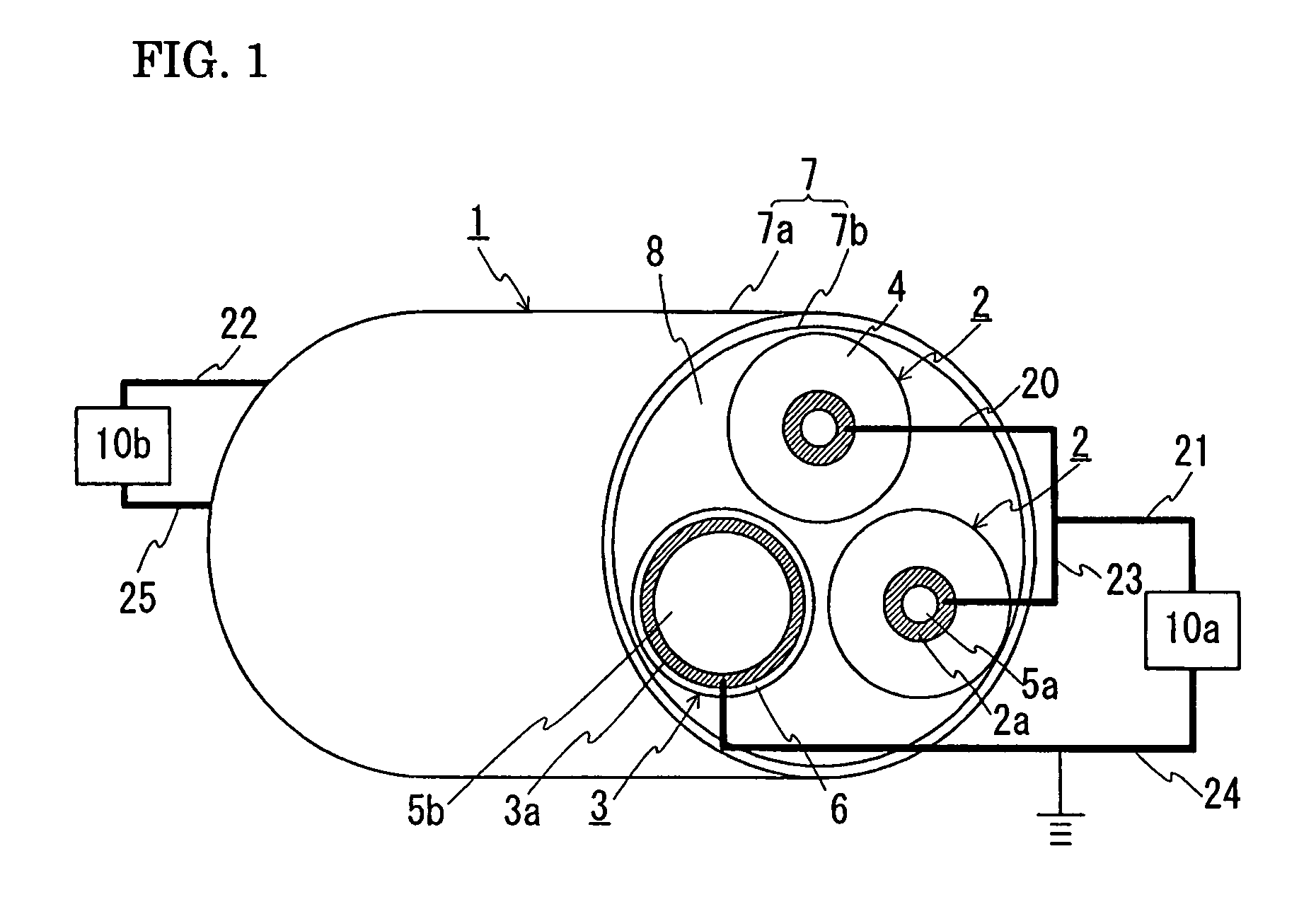

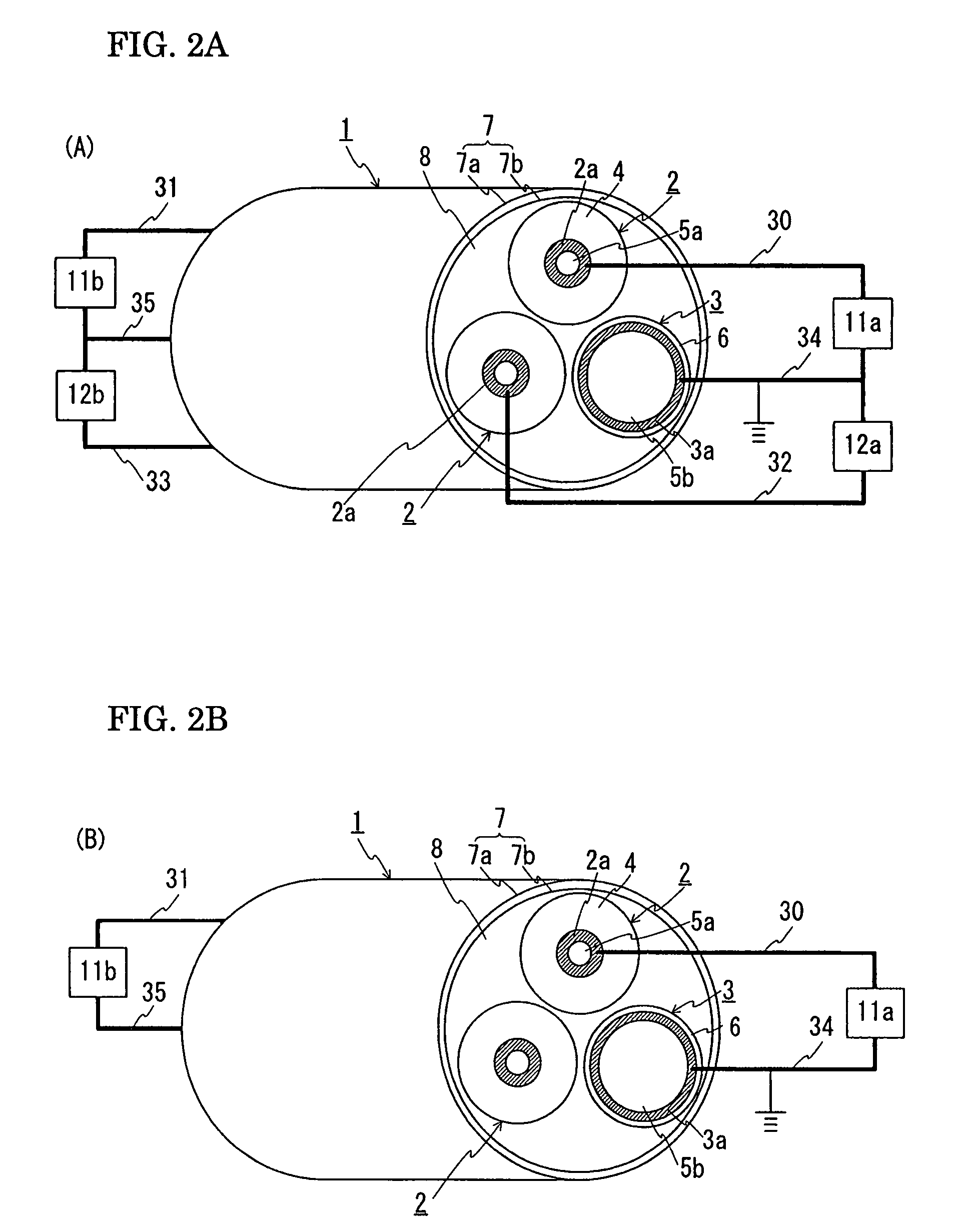

Superconducting Cable

InactiveUS20080164048A1Decreased cable diameterReduce heatBus-bar/wiring layoutsSuperconductors/hyperconductorsReturn currentEngineering

A superconducting cable having a smaller outside diameter and a DC power transmission method utilizing this superconducting cable. The superconducting cable (1) comprises two stranded cable cores (2) each having a superconductor layer (4) of a superconducting material and an external superconducting layer (6) and contained in a heat insulating pipe (8). Each cable core (2) consists of a former (3), the superconductor layer (4), an insulating layer (5), the external superconducting layer (6), and a protective layer (7) arranged sequentially from the center. In the case of unipolar transmission, the superconductor layers (4) provided to both cores (2) are fed with an unipolar current and used as a supply line and the external superconducting layers (6) provided to both cores (2) are fed with a return current and used as a return line. In the case of bipolar transmission, the superconductor layer (4) provided to one core (2) is used for positive pole transmission, the superconductor layer (4) provided to the other core (3) is used for negative pole transmission, and the external superconducting layers (6) of both cores (2) are used as a neutral line layer.

Owner:SUMITOMO ELECTRIC IND LTD

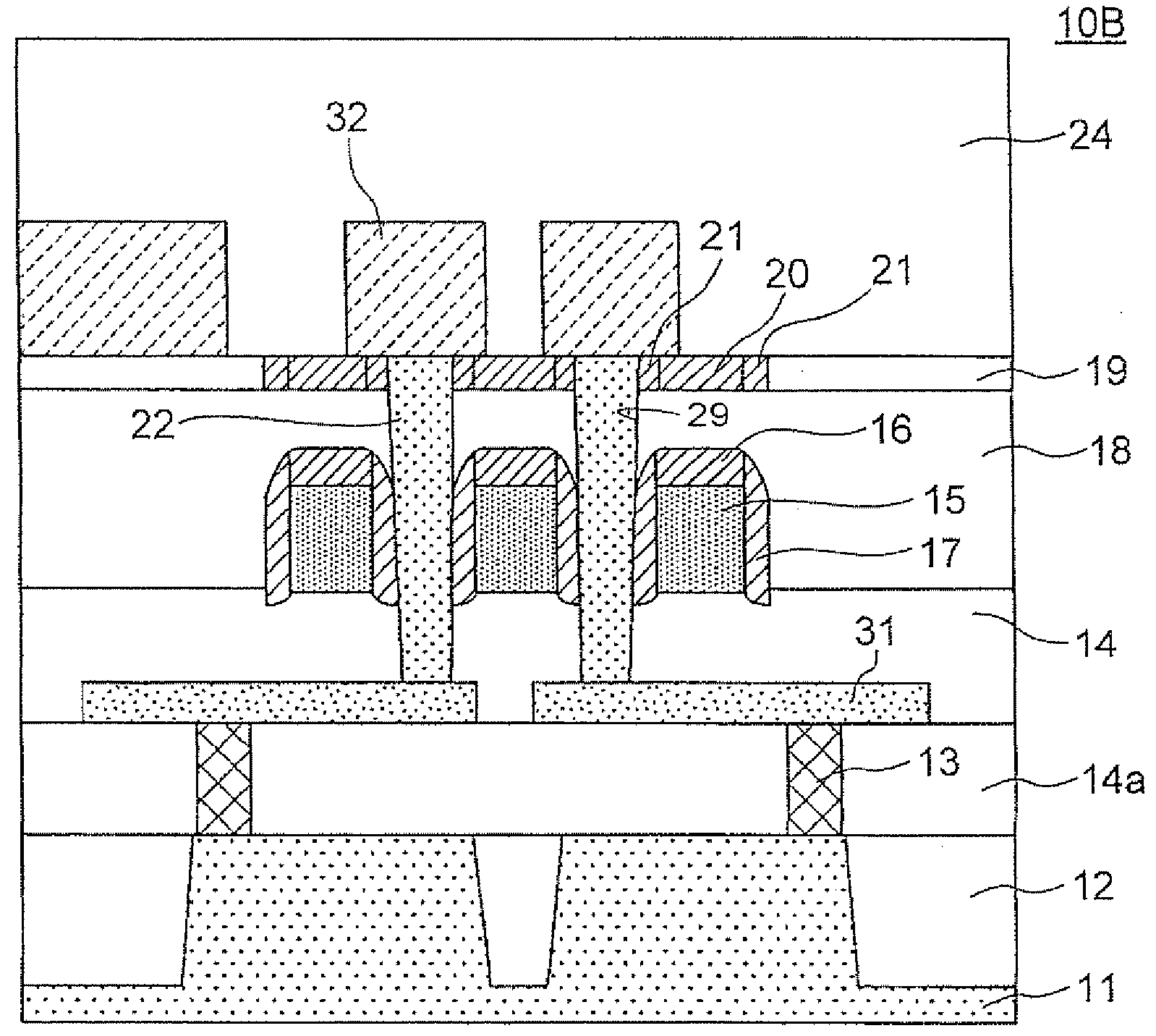

Semiconductor device, manufacturing method thereof, and data processing system

InactiveUS20090256237A1Reduce insulation thicknessSufficient resolutionTransistorSemiconductor/solid-state device detailsEngineeringData processing

A miniaturized semiconductor device is provided by reducing the design thickness of a wiring line protecting film covering the surface of a wiring layer, and reducing the distance between the wiring layer and via plugs formed by a self-aligning process. Dummy mask layers extending in the same layout pattern as the wiring layer is formed above the wiring layer covered with a protecting film composed of a cap layer and side wall layers. In the self-aligning process for forming via plugs in a self-aligned manner with the wiring layer and its protecting film, the thickness of the cap layer is reduced and the design interval between the via plugs is reduced, whereby the miniaturization of the semiconductor device is achieved.

Owner:ELPIDA MEMORY INC

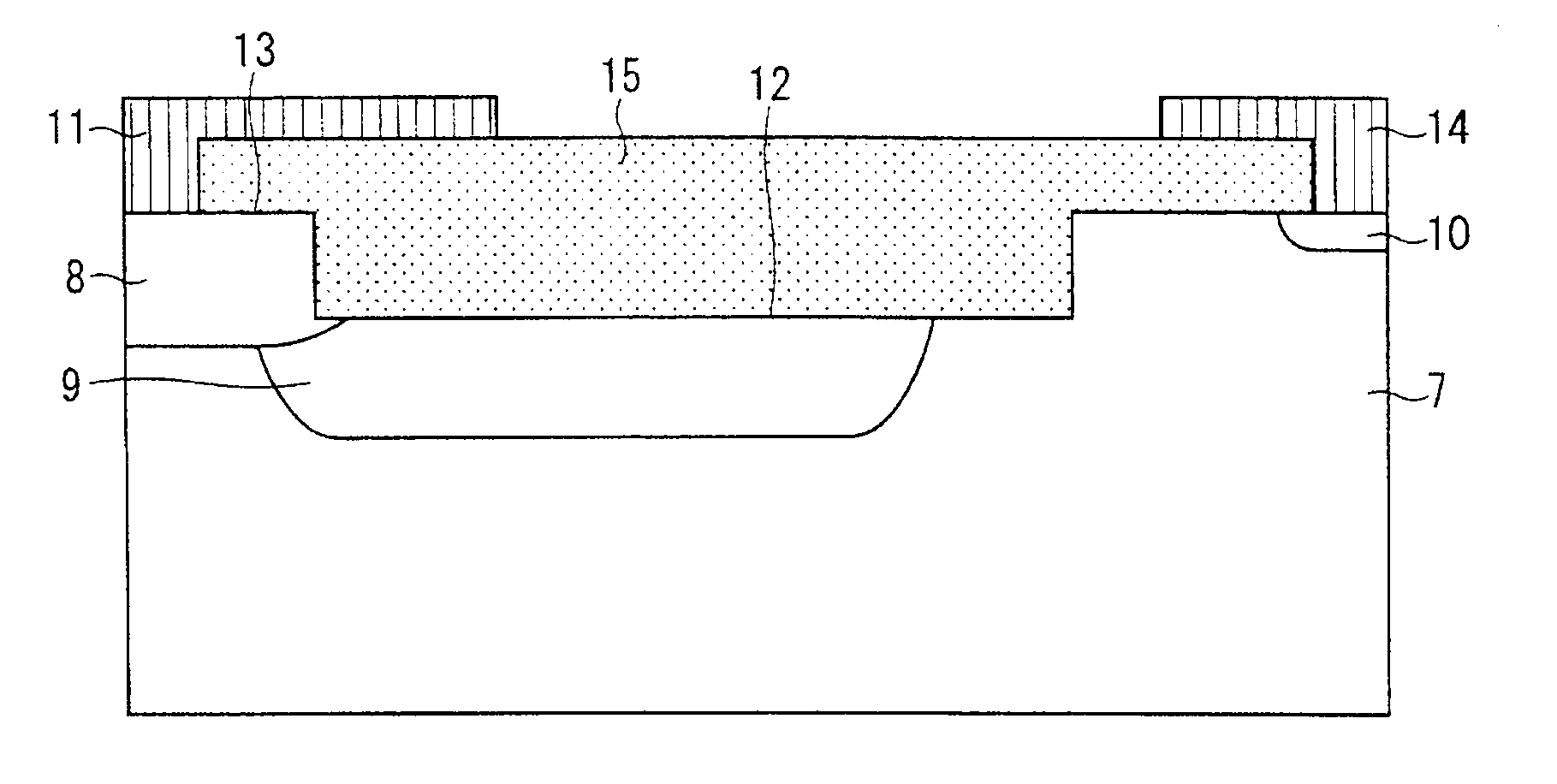

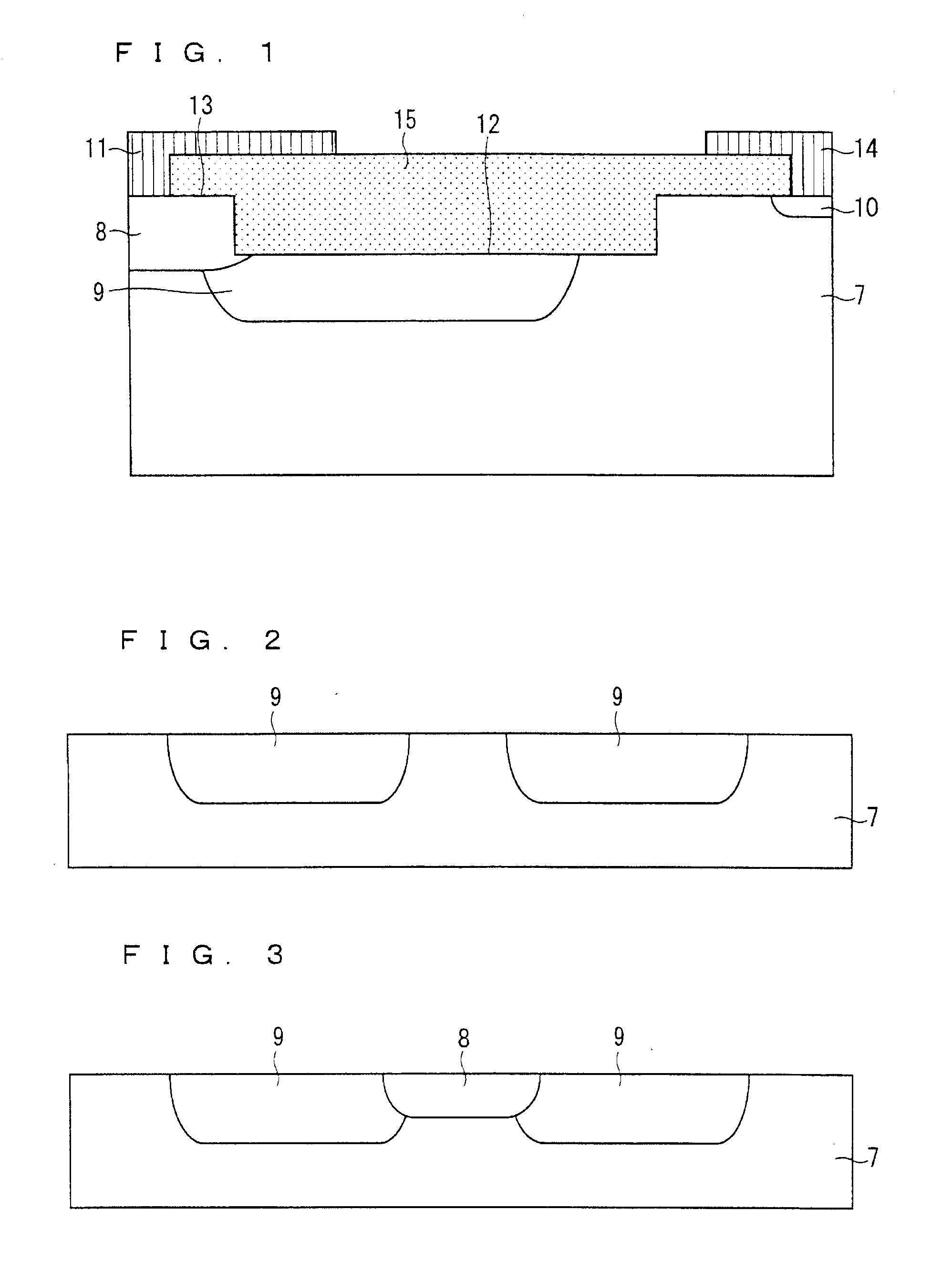

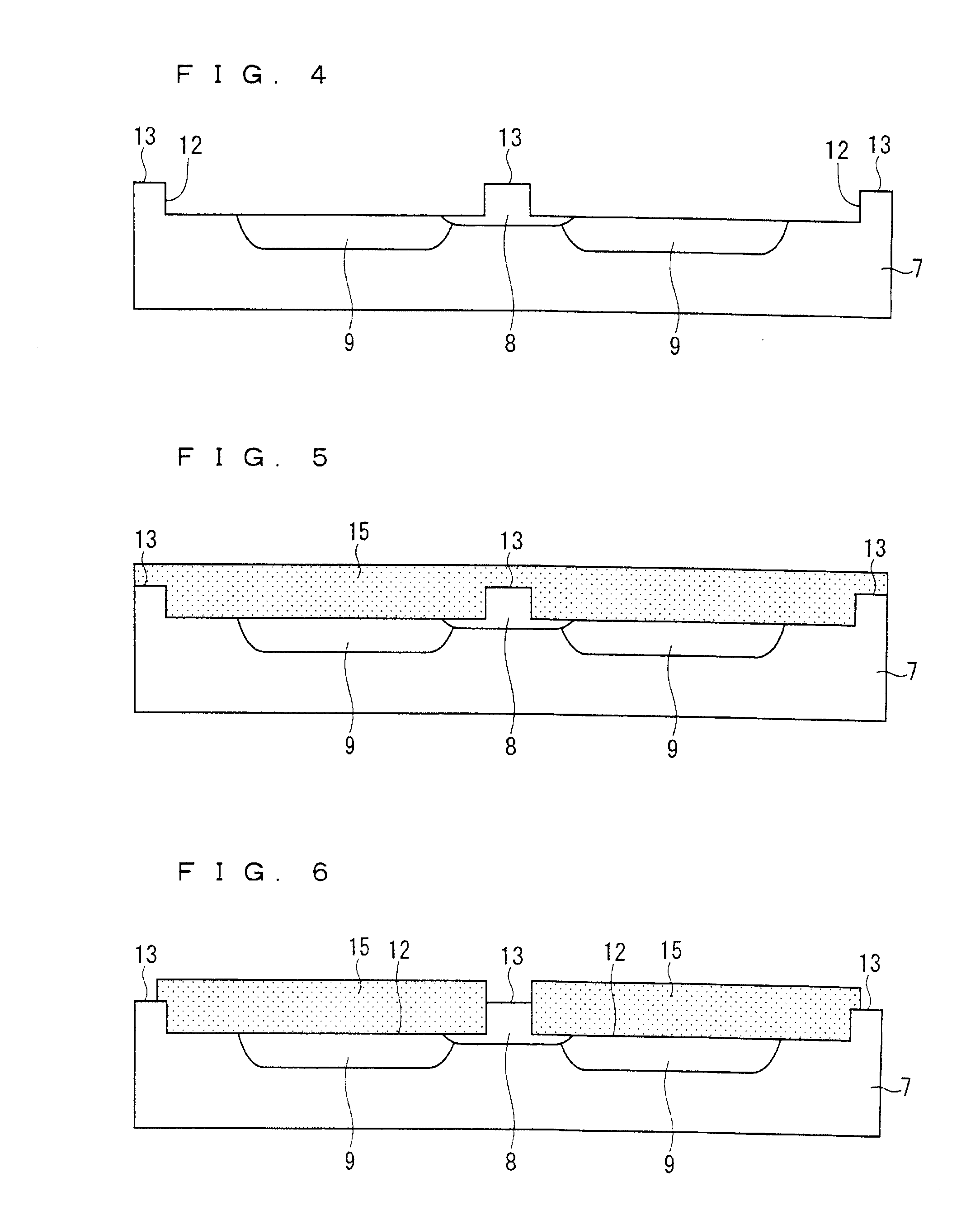

Semiconductor device and method of manufacturing a semiconductor device

ActiveUS20110084354A1Avoid it happening againImprovement in focus marginSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

In a semiconductor device according to the present invention, an electrode layer and a recessed part are formed on a surface of a semiconductor substrate. Further, in the semiconductor substrate, a RESURF layer that is in contact with a bottom surface of the recessed part and the electrode layer is formed. In addition, an insulating film is formed on an upper surface of the semiconductor substrate so as to fill the recessed part. Moreover, a field plate electrode is formed on the insulating film above the recessed part.

Owner:MITSUBISHI ELECTRIC CORP

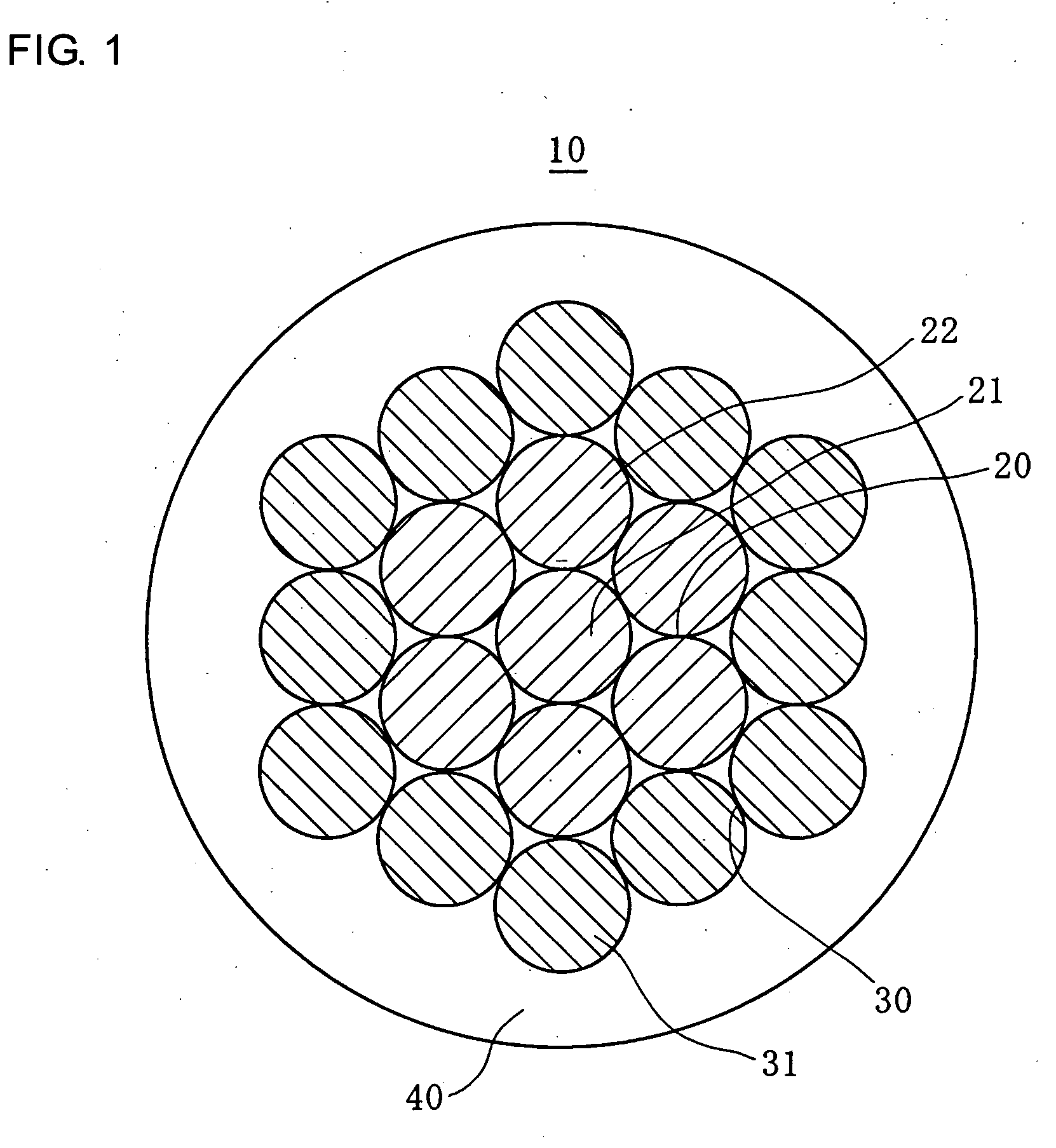

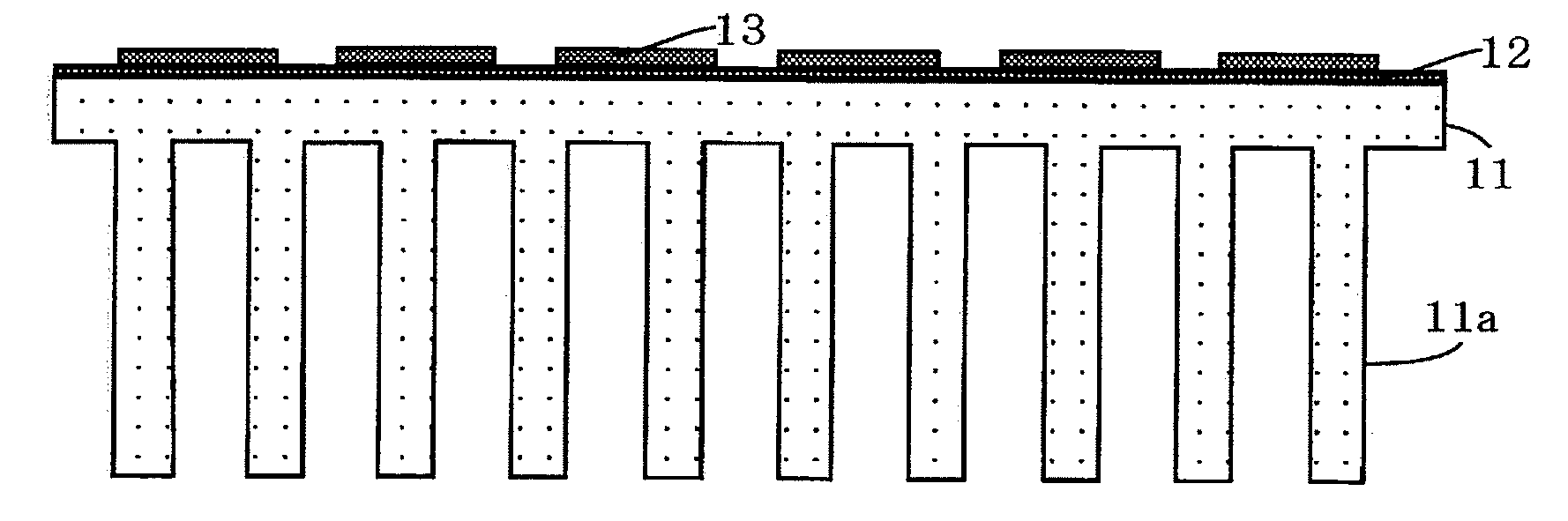

Electric Wire for Automobile

InactiveUS20090266575A1High bending fatigue strengthSmall bending stressNon-insulated conductorsPlastic/resin/waxes insulatorsCopperElectric wire

An electric wire for an automobile has a core wire section and an outer circumferential wire section. The core wire section is formed by spirally winding six element wires around one element wire, where each element wire is made of stainless steel having elongation of 30% or more and tensile strength of 920 MPa or higher and the element wires have the same diameter in the range of 0.127 mm±10%. The circumferential wire section is formed by spirally winding twelve element wires around the core wire section, where the twelve element wires are wound close to each other in a single layer, each element wire is made of copper having tensile strength of 220 MPa or higher, and the element wires have the same diameter in the range of 0.127 mm±10%. The wire is light, small, strong and has good bending characteristics.

Owner:SUMITOMO WIRING SYST LTD

Heat exchange unit

InactiveUS20100186424A1Avoid crackingAvoid fracturesThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsSurface roughnessThermoelectric element

A heat exchange unit is constituted of a thermoelectric module and a heat exchanger. The thermoelectric module includes an upper electrode, a lower electrode, and a plurality of thermoelectric elements interposed between the upper electrode and the lower electrode, wherein the heat exchanger composed of aluminum or aluminum alloy having high thermal conductivity is attached to the upper electrode and / or the lower electrode via an insulating layer. The surface roughness of the heat exchanger adjoined to the insulating layer is controlled to be less than 4.7 μm and greater than 0.1 μm. This prevents cracks and fractures from being formed in the insulating layer, which is thus improved in adhesion with the heat exchanger. Thus, it is possible to demonstrate high heat-absorption / dissipation performance and high reliability in the heat exchange unit due to a reduced thermal resistance between the thermoelectric module and the heat exchanger.

Owner:YAMAHA CORP

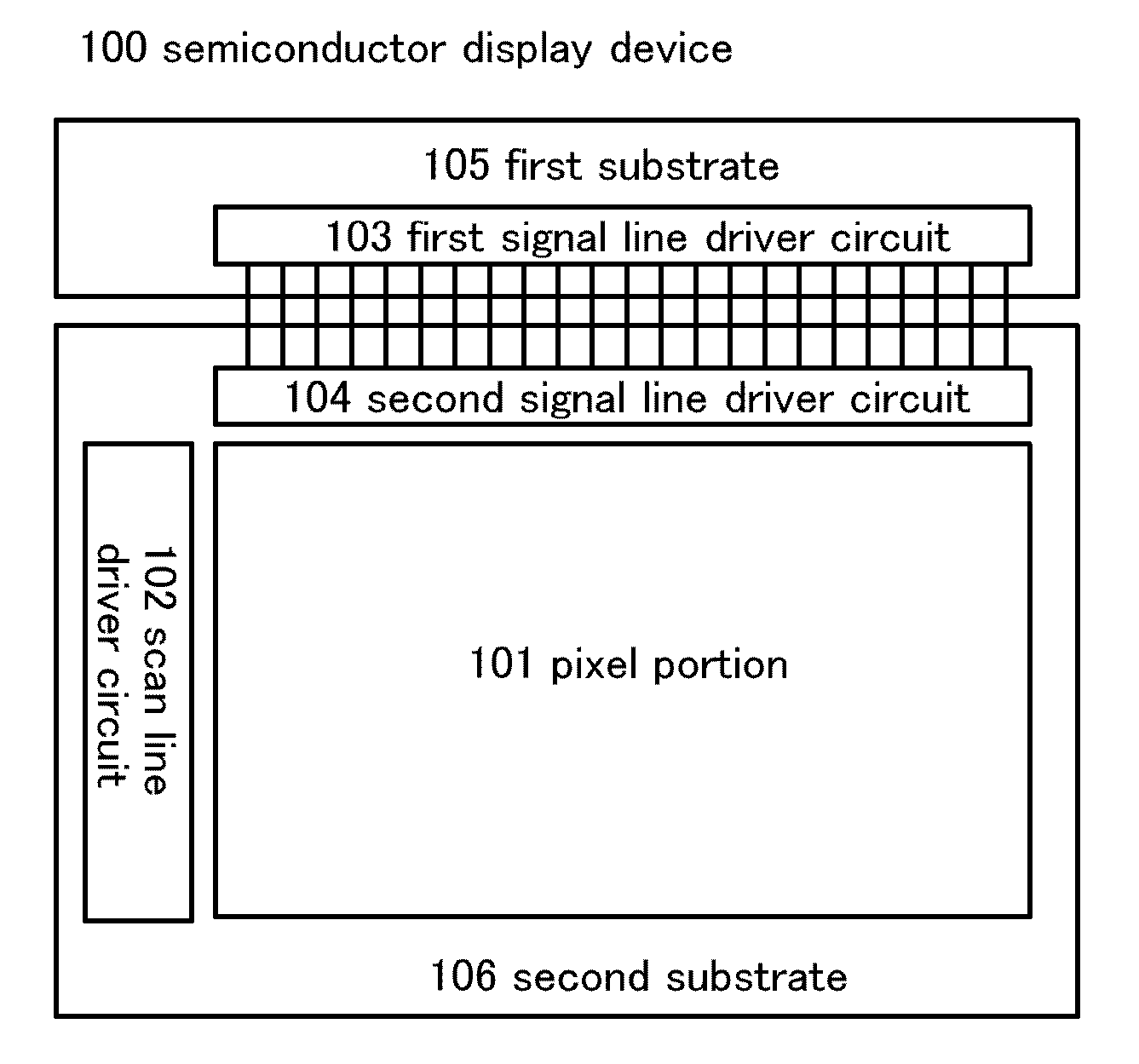

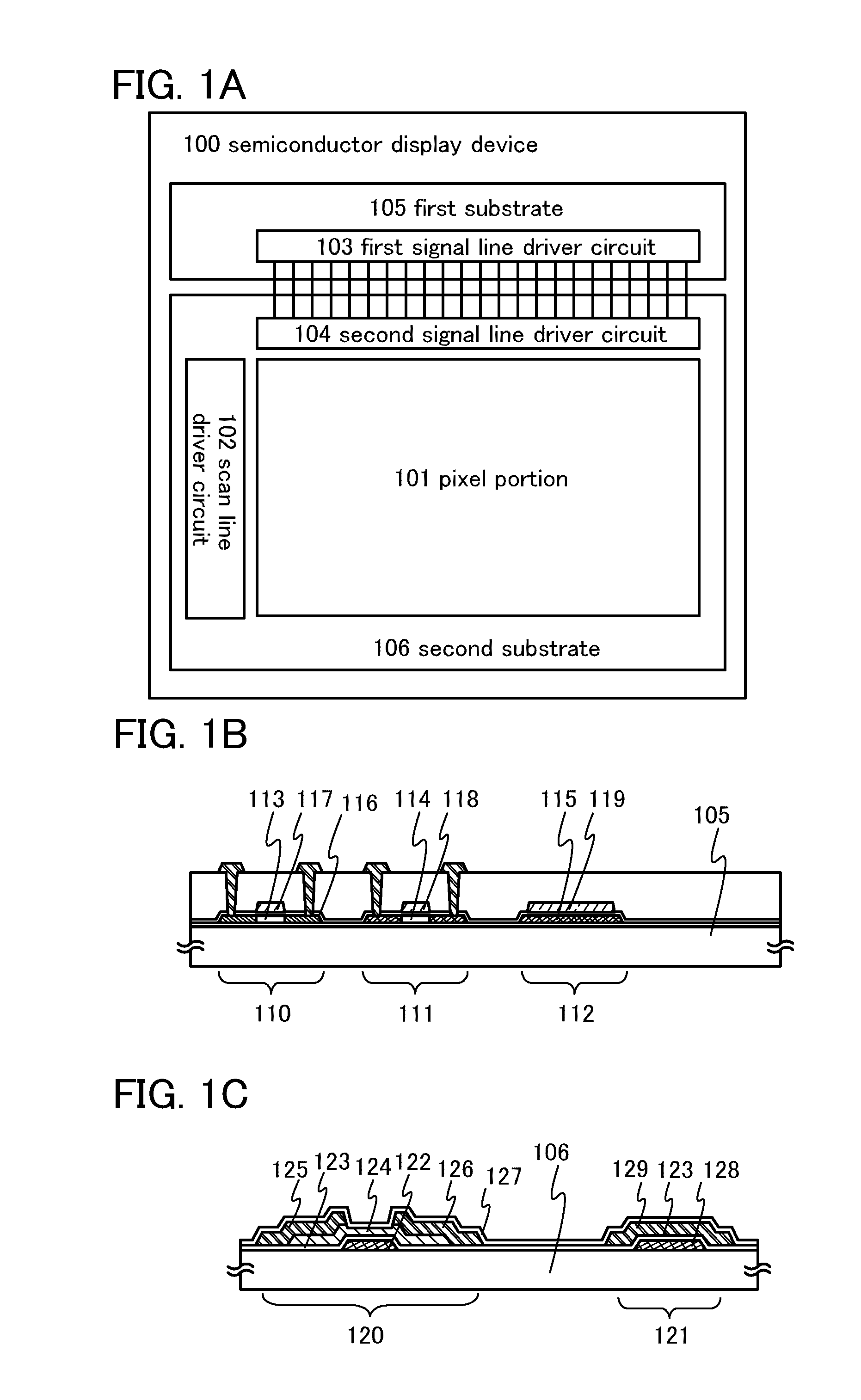

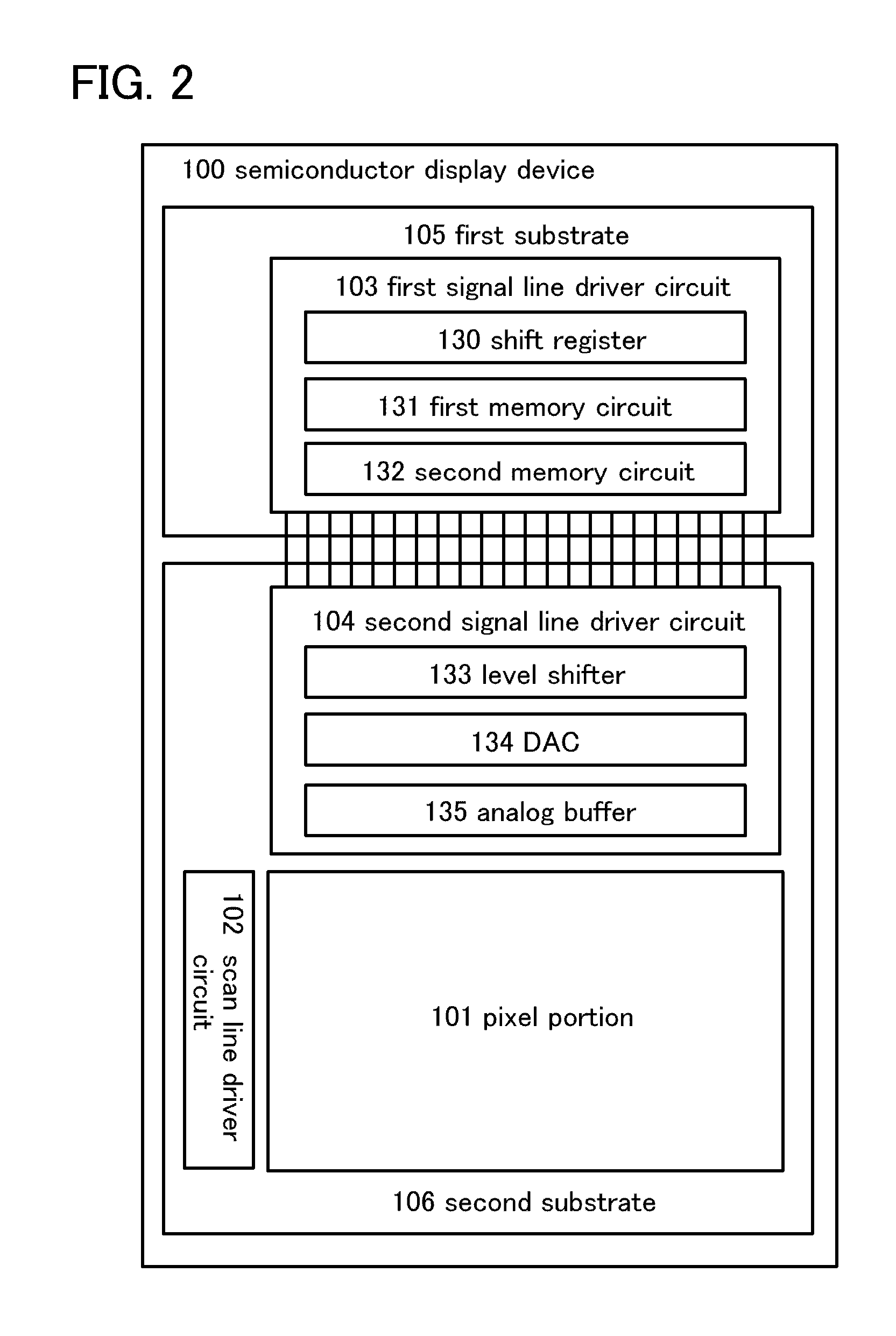

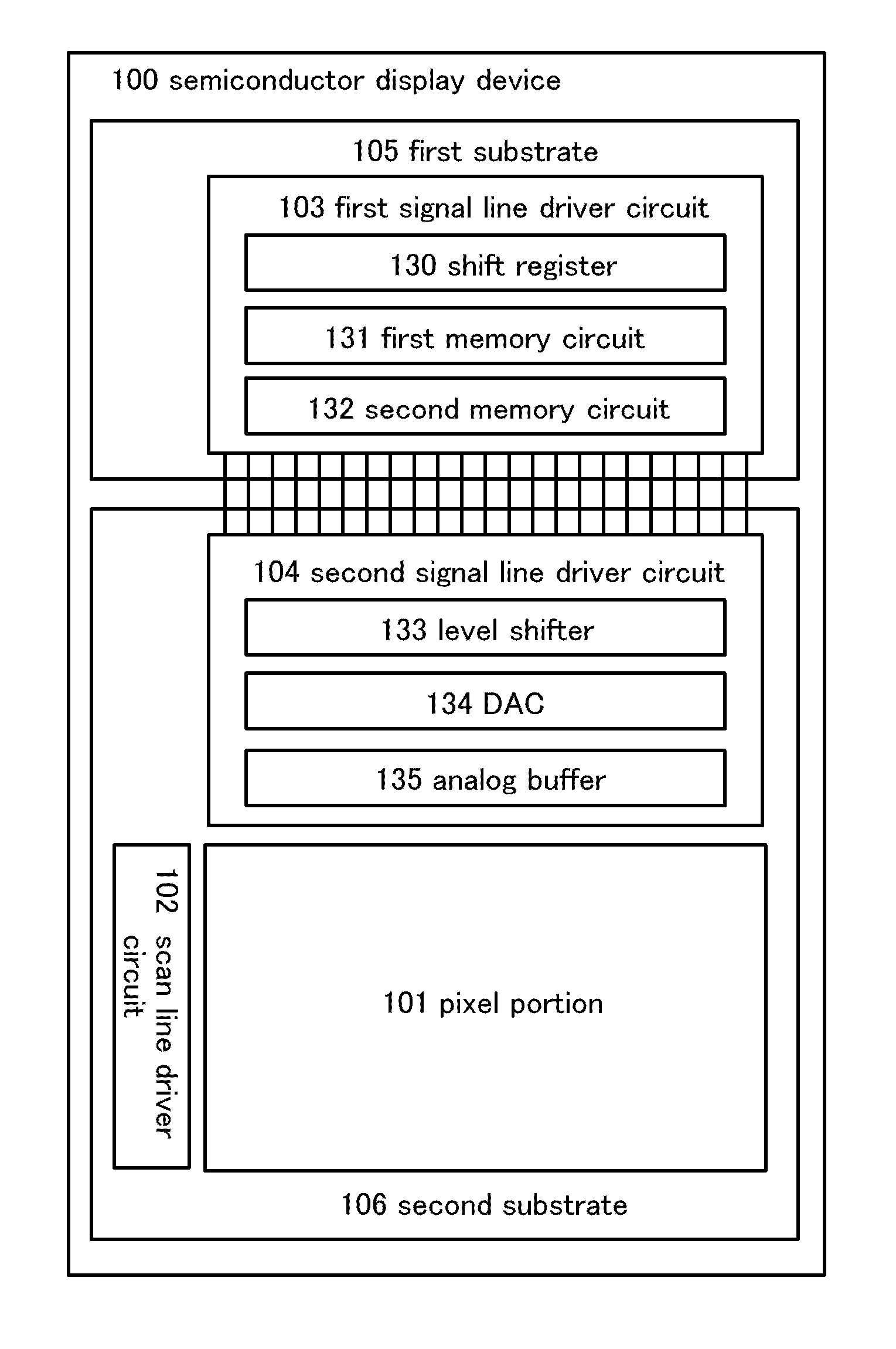

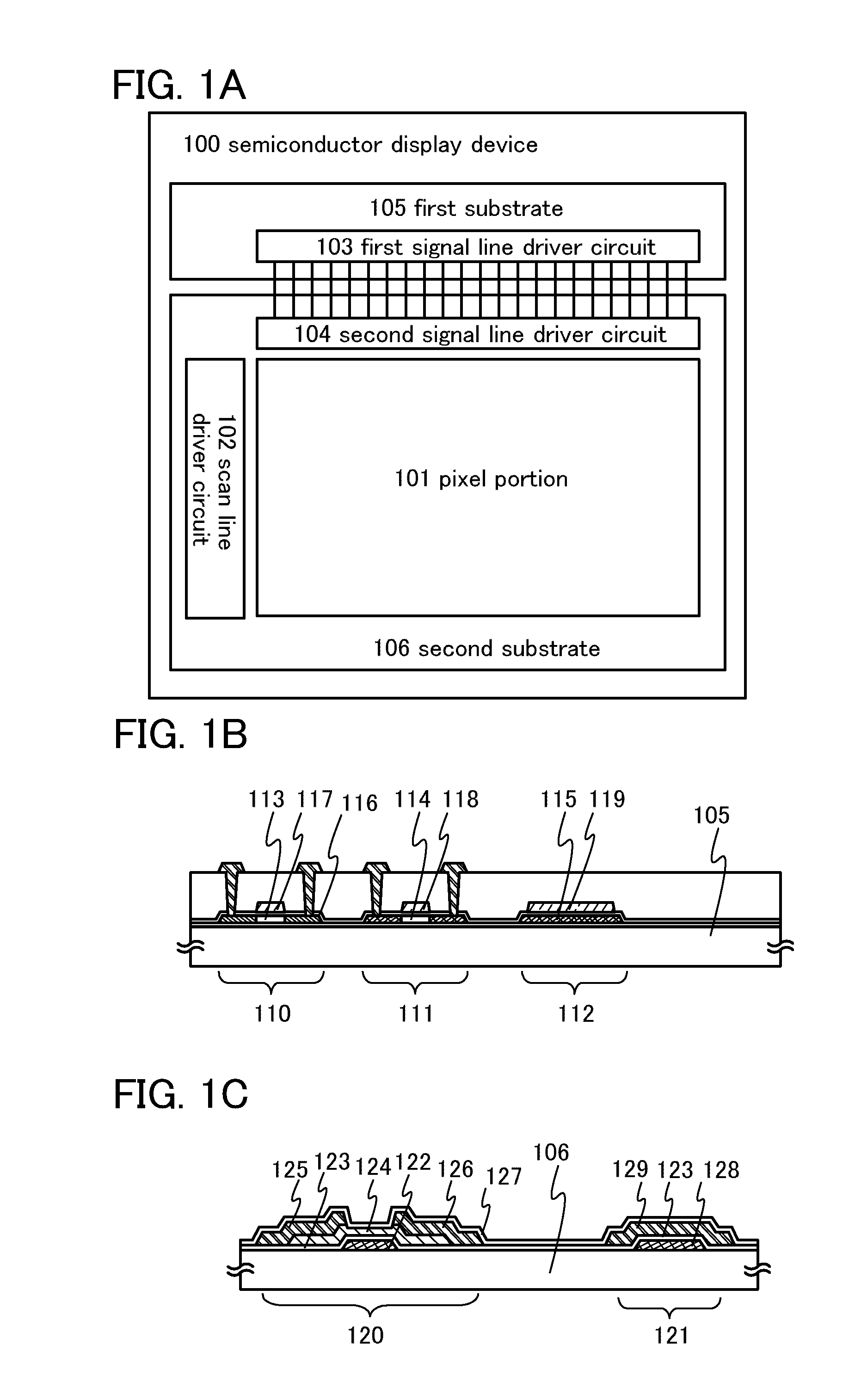

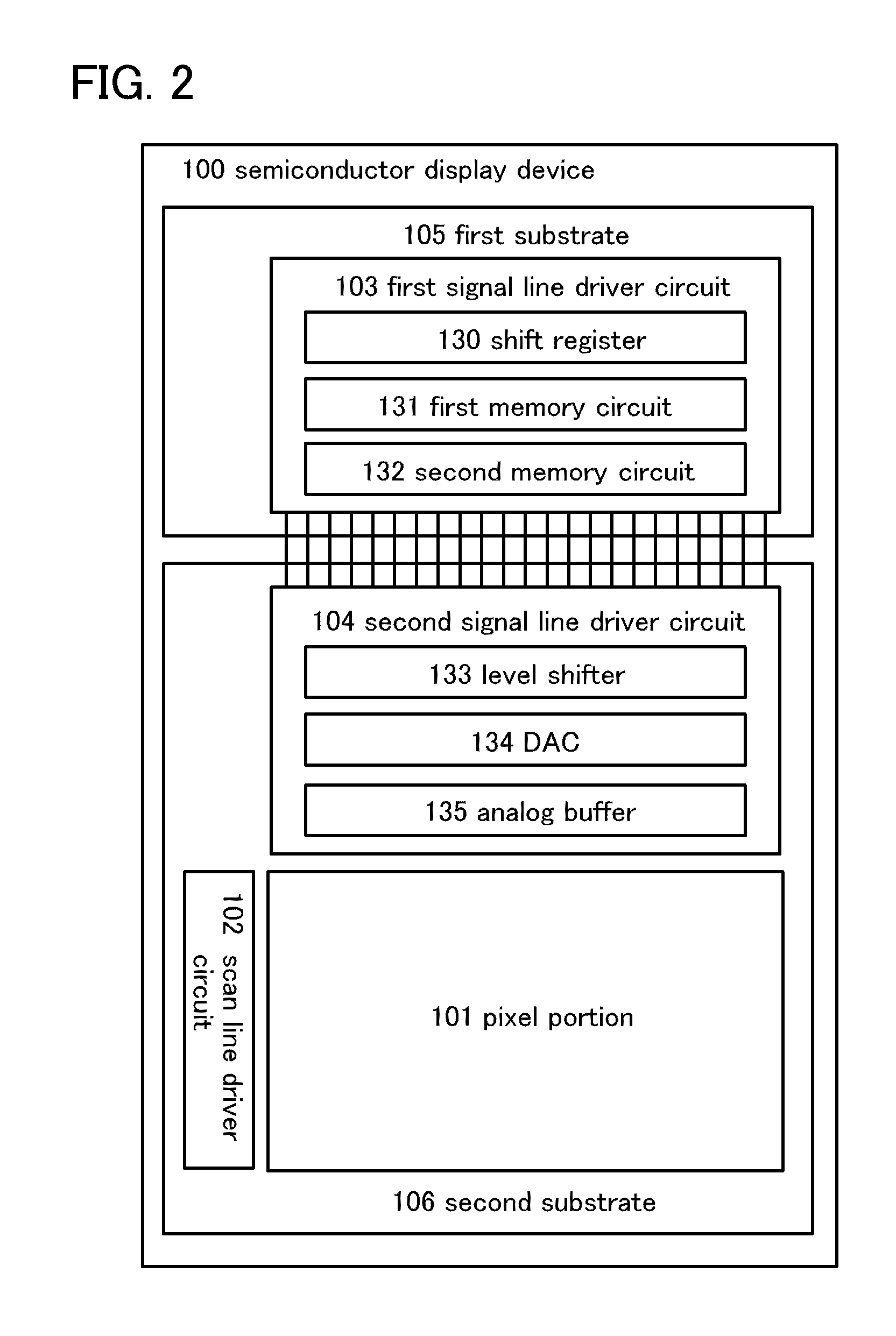

Semiconductor display device

ActiveUS20110242070A1Run at high speedImprove pressure resistanceTelevision system detailsTelevision system scanning detailsDriver circuitElectrical conductor

A semiconductor display device comprising a pixel portion and a signal line driver circuit comprising a first circuit, a second circuit configured to control timing of the sampled serial video signals by the first circuit, and a third circuit configured to perform signal processing on the parallel video signals, wherein the second circuit comprises a first semiconductor element formed over a first substrate, the first semiconductor element including a first semiconductor layer, wherein the third circuit comprises a second semiconductor element formed over a second substrate, the second semiconductor element including a second semiconductor layer, wherein the pixel portion comprises a third semiconductor element formed over the second substrate, the third semiconductor element including a third semiconductor layer, wherein the first semiconductor layer comprises silicon or germanium, and wherein each the second semiconductor layer and the third semiconductor layer has a wider bandgap than the first semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

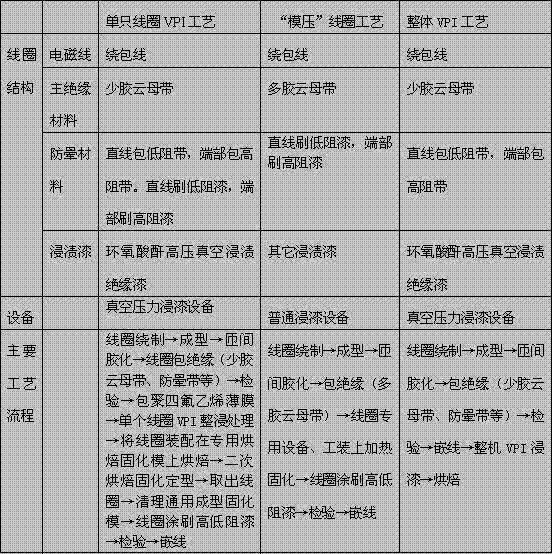

Technology for compatibilizing middle-minihydraulic turbine generator

InactiveCN101075764AReduce insulation thicknessSave spaceWindings insulation materialWindings insulation shape/form/constructionEpoxyInsulation layer

The invention comprises: a stator, a rotor and coil. The coil of said rotator and stator uses the copper flat wire made of the tong-ma epoxy glass mica and the non-coated Dacron glass copper flat wire. The capacity-increased modification technology comprises the stator modification technology and rotator medication technology. The F class stator coil insulation structure provided by the invention has an insulation layer made by means of integral hot-embossing, and its lower and upper edge is everted 90degree so as to reduce the space occupied by the coil; the thickness of the insulation between coil interturns is reduced.

Owner:吴玉泉

Semiconductor display device

ActiveUS8519990B2Secure high quality of display imageReduce insulation thicknessTelevision system detailsTelevision system scanning detailsDriver circuitElectrical conductor

Owner:SEMICON ENERGY LAB CO LTD

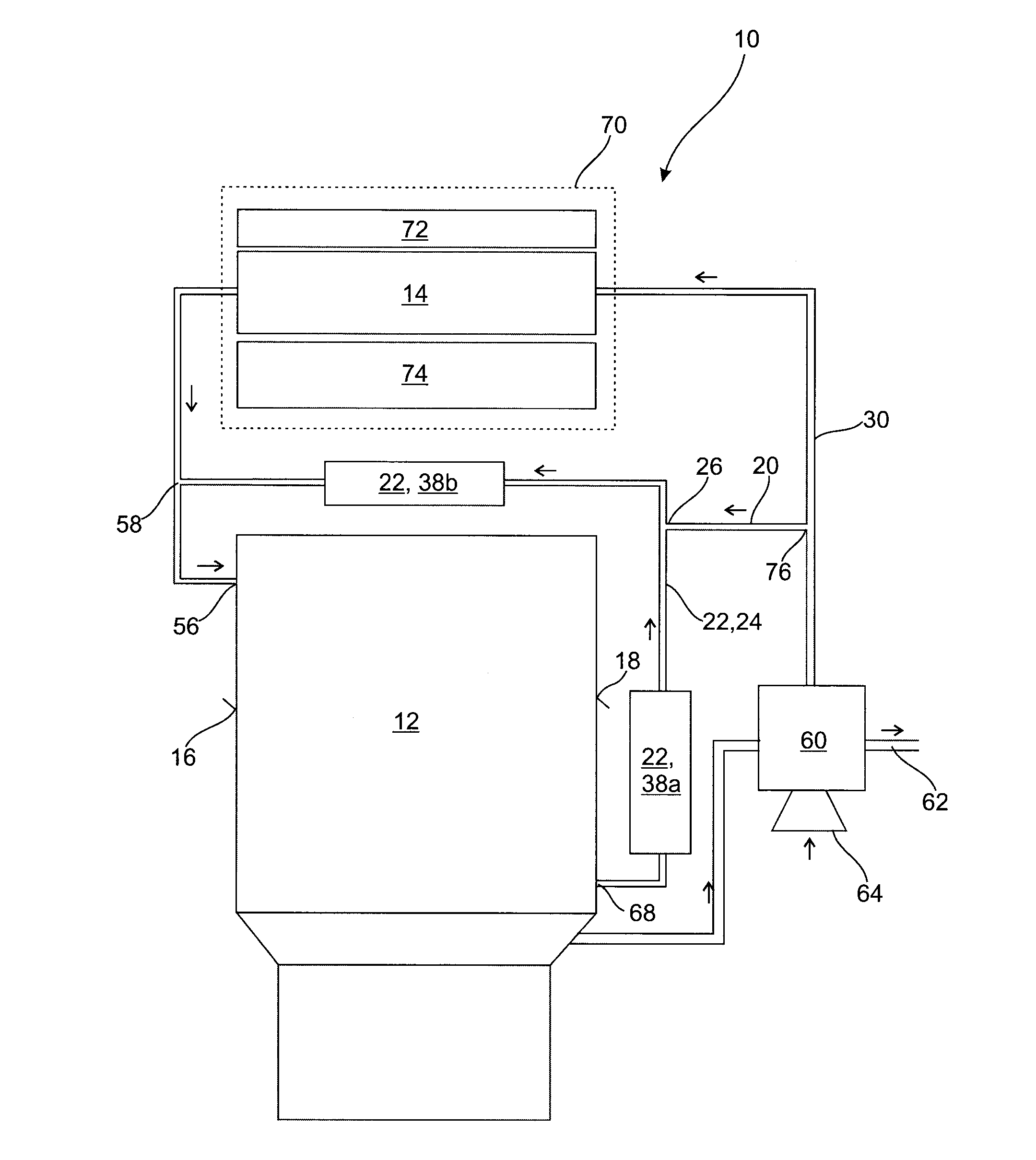

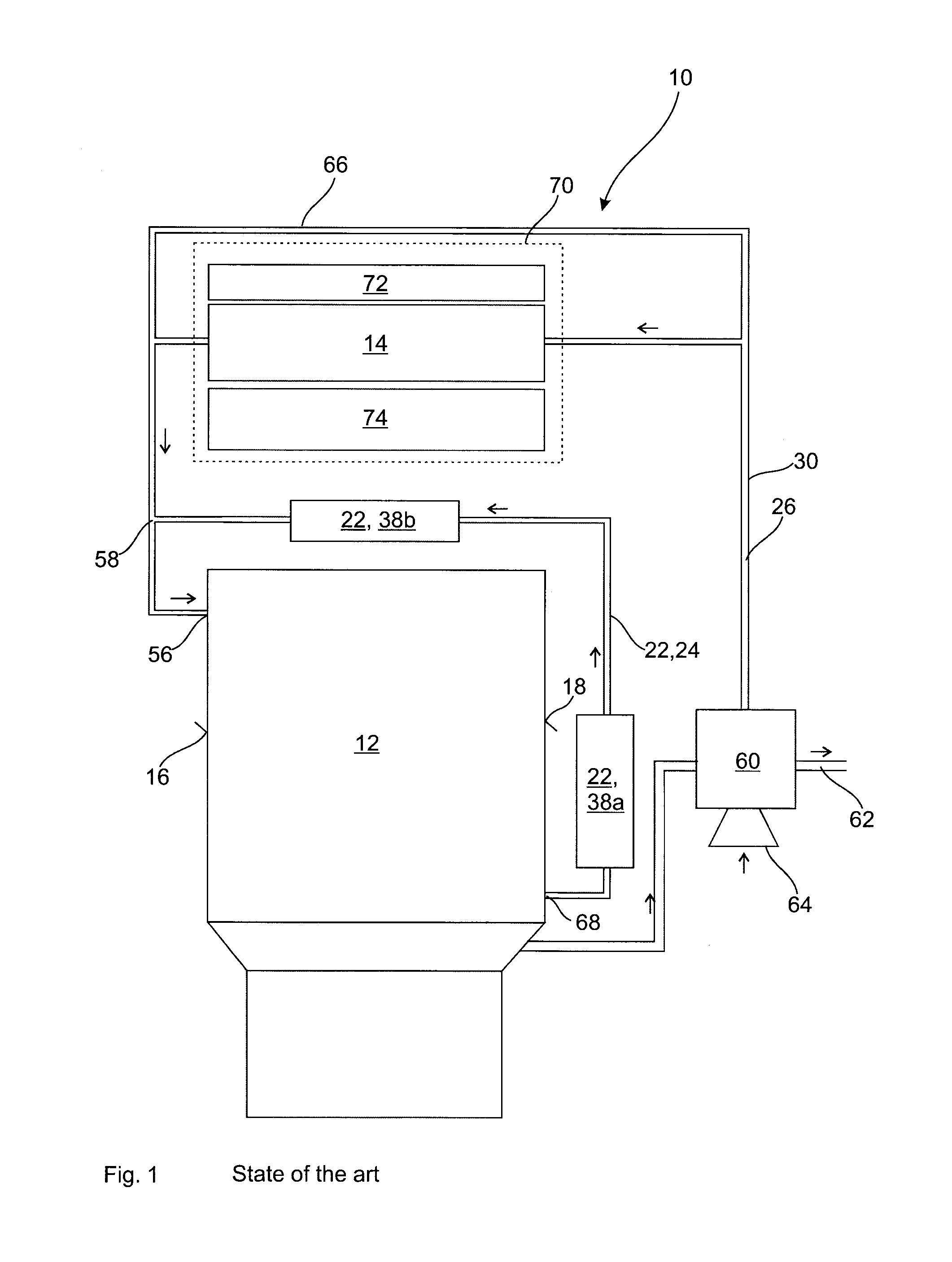

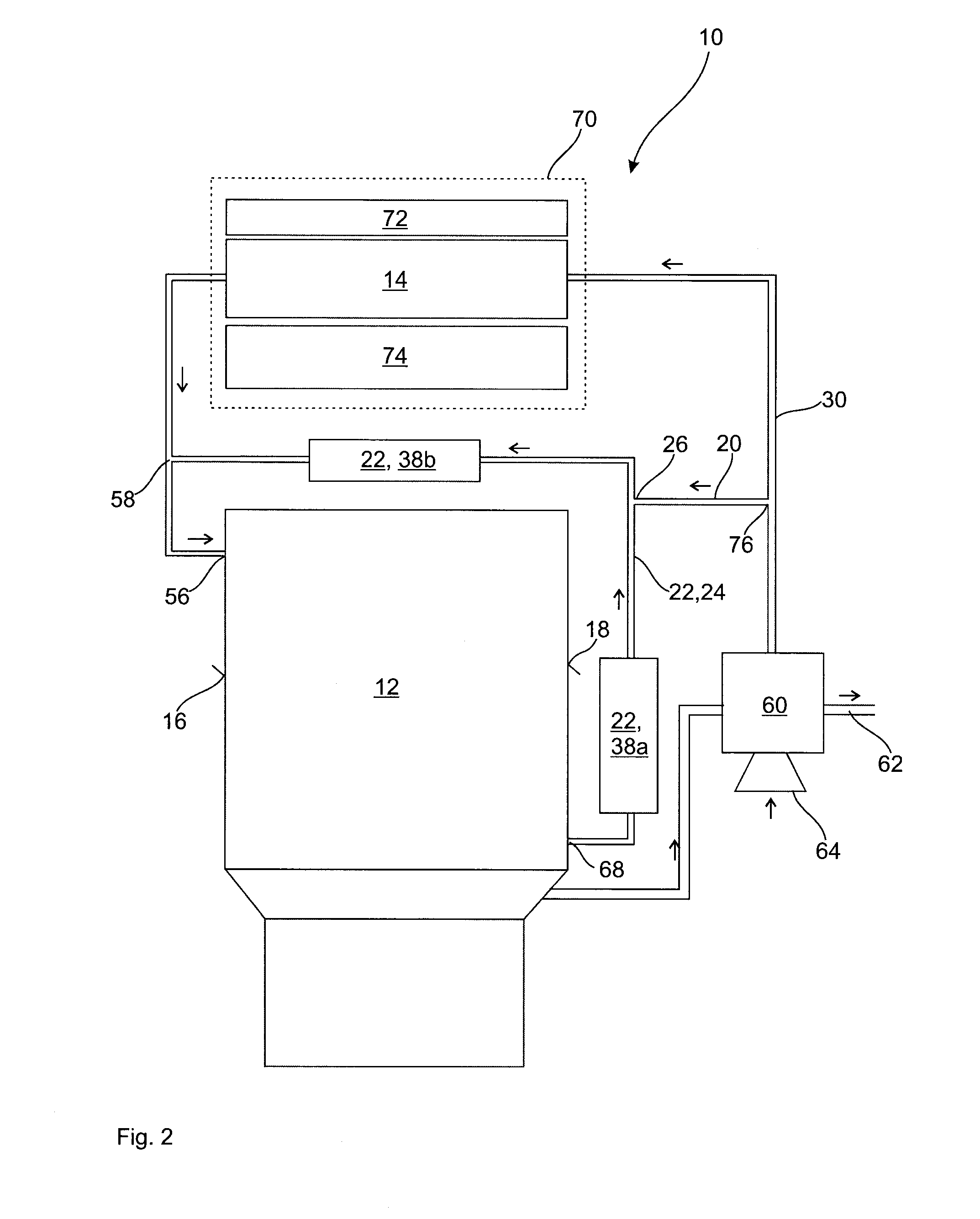

Engine arrangement with charge air cooler and egr system

ActiveUS20140318513A1DimensionReduce insulation thicknessInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gasInlet temperature

An engine arrangement includes an engine, a charge air cooler connected to an engine inlet side of the engine, an air bypass for bypassing the charge air cooler, and including an EGR system connected between engine outlet side and an engine inlet side of the engine via one or more EGR lines. The air bypass enters the EGR system at an air-bypass port of an EGR line for mixing air with exhaust gas at the engine outlet side of the EGR system and / or upstream of an EGR cooler. An engine arrangement can also comprise an engine, a charge air cooler connected via an air line to an engine inlet side of the engine, an air bypass for bypassing the charge air cooler, and including an EGR system connected between an engine outlet side and an engine inlet side of the engine via one or more EGR lines. A control device is provided for controlling an engine inlet temperature of an air / exhaust gas mixture by controlling a ratio of cooled / uncooled air and / or cooled / uncooled exhaust gas in the air / exhaust gas mixture.

Owner:VOLVO LASTVAGNAR AB

Superconducting cable

InactiveUS7943852B2Decreased cable diameterReduce heatBus-bar/wiring layoutsSuperconductors/hyperconductorsElectrical conductorEngineering

A superconducting cable has a further decreased diameter, and a DC transmission system incorporates the cable. The superconducting cable has a structure in which two cable cores, each having a superconducting conductor layer and an outer superconducting layer, are twisted together and housed in a heat-insulated pipe. Each cable core has a former, superconducting conductor layer, insulating layer, outer superconducting layer, and a protecting layer in this order from the center. In unipolar transmission, the superconducting conductor layers of both cores are used as the outward line and the outer superconducting layers of both cores as the return line. In bipolar transmission, the superconducting conductor layer of one core is used for the transmission for the positive pole, the superconducting conductor layer of the other core is used for the transmission for the negative pole, and the outer superconducting layers of both cores are used as the neutral-line layers.

Owner:SUMITOMO ELECTRIC IND LTD

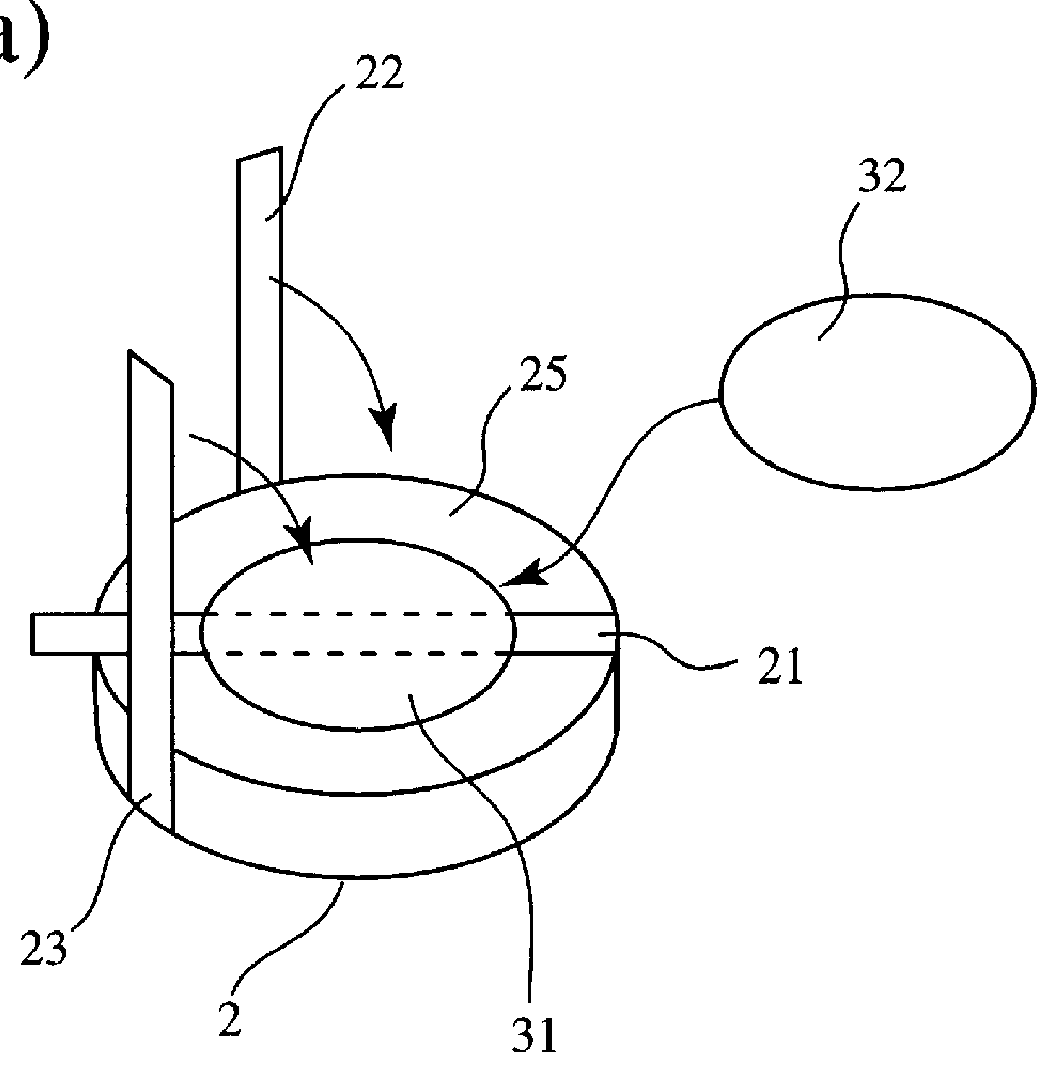

Non-reciprocal circuit element

InactiveUS6121851AImprove electrical performanceMinimize changesWaveguide type devicesCapacitorElectrical and Electronics engineering

A non-reciprocal circuit element for transmitting a high-frequency signal of microwave band in one direction. The electrical characteristics of the non-reciprocal circuit element have been improved by using an insulating sheet having a thickness within a specific range thereby to regulate the distance between vertically adjacent strip electrodes within a specific range. Also, the product-to-product variation in the electrical characteristics of the non-reciprocal circuit element has been minimized by shaping the end portion of the strip electrode so as to extend in coplanar relationship to the top surface of the capacitor to be connected.

Owner:HITACHI METALS LTD

Liquid crystal device, manufacturing method thereof, and electronic apparatus

InactiveUS20070052890A1Solve insufficient capacityPreventing the cross talk from occurringNon-linear opticsCapacitanceEngineering

A liquid crystal device includes: a first substrate including a scanning line, a data line intersecting with the scanning line, a switching element, a pixel electrode and a storage capacitor which are provided in association with an intersection of the scanning line and the data line; a second substrate opposing the first substrate; and liquid crystal interposed between the first substrate and the second substrate. A region where the pixel electrode is provided includes a reflective region and a transmissive region. An insulation layer is provided in the reflective region and the transmissive region to cover the switching element. A liquid crystal thickness adjustment layer is provided on the insulation layer in the reflective region. The pixel electrode is provided on the insulation layer in the transmissive region and on the liquid crystal thickness adjustment layer in the reflective region. Further, the storage capacitor includes a first capacitance electrode which is disposed on the insulation layer in the reflective region and is electrically connected to the pixel electrode, and a second capacitance electrode opposing the first capacitance electrode with the insulation layer disposed therebetween.

Owner:EPSON IMAGING DEVICES CORP

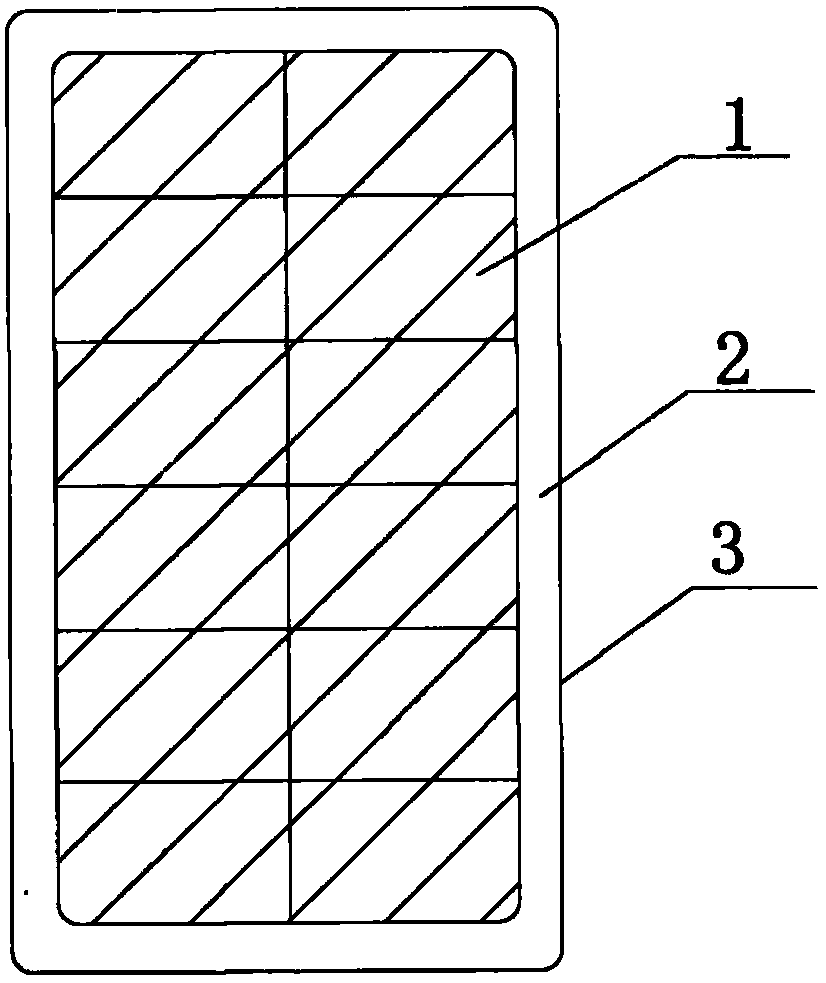

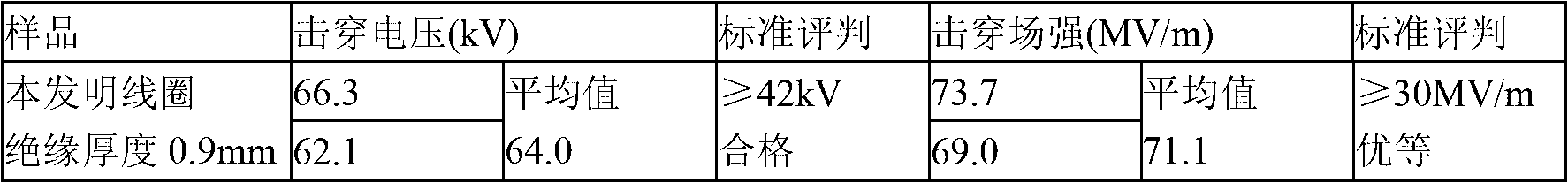

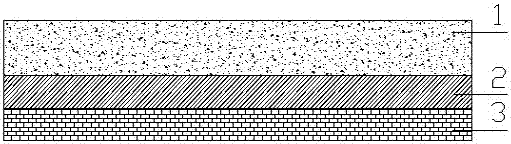

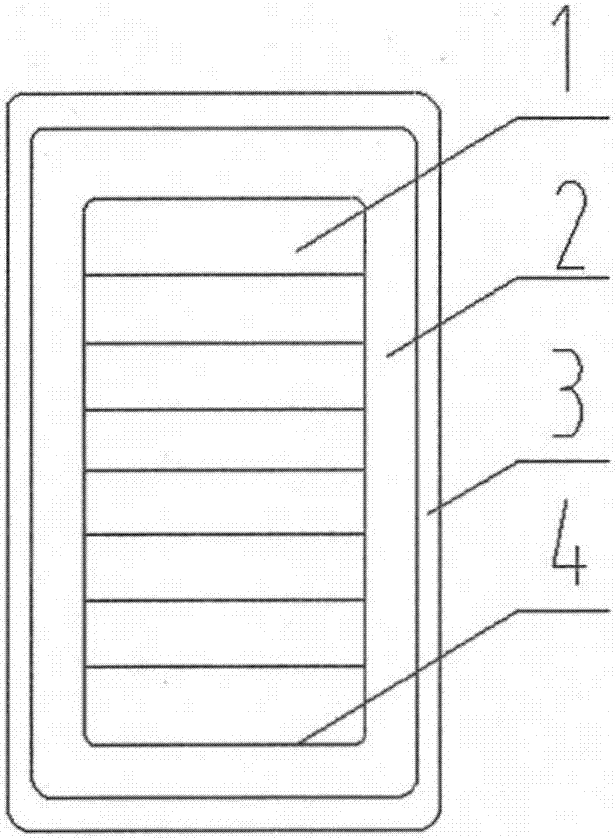

6 kilovolt level high-voltage motor insulation structure and manufacturing method thereof

InactiveCN102983654AHigh dielectric strengthReduce insulation thicknessWindings insulation shape/form/constructionApplying solid insulationMotor insulationEngineering

The invention discloses a 6 kilovolt level high-voltage motor insulation structure and a manufacturing method of the insulation structure. The insulation structure comprises an electromagnetic coil provided with a guide line insulating layer, and a main insulating layer manufactured on the electromagnetic coil in a winding mode. Epoxy acid anhydride type impregnating resin condensates are arranged in a gap between the guide line insulating layer on the electromagnetic coil and the main insulating layer. The 6 kilovolt level high-voltage motor insulation structure and the manufacturing method of the insulation structure have the advantages that insulating strength of the guide line insulating layer and the main insulating layer are both greatly promoted, but insulating thickness of the guide line insulating layer and the main insulating layer are obviously thinned.

Owner:上海同立电工材料有限公司

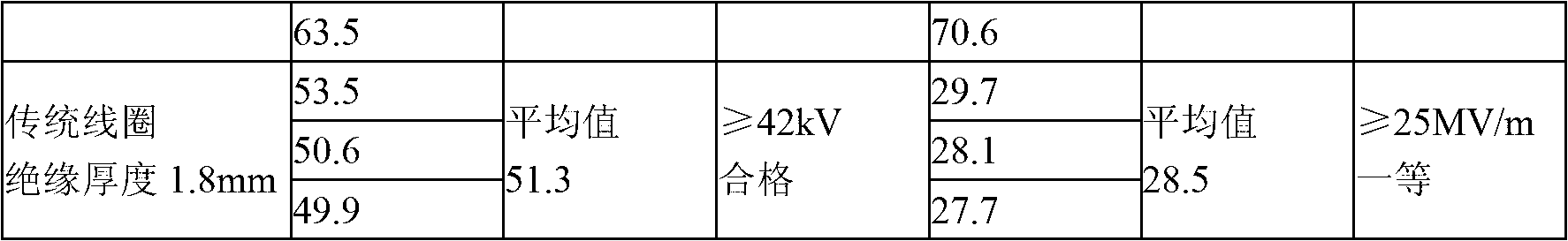

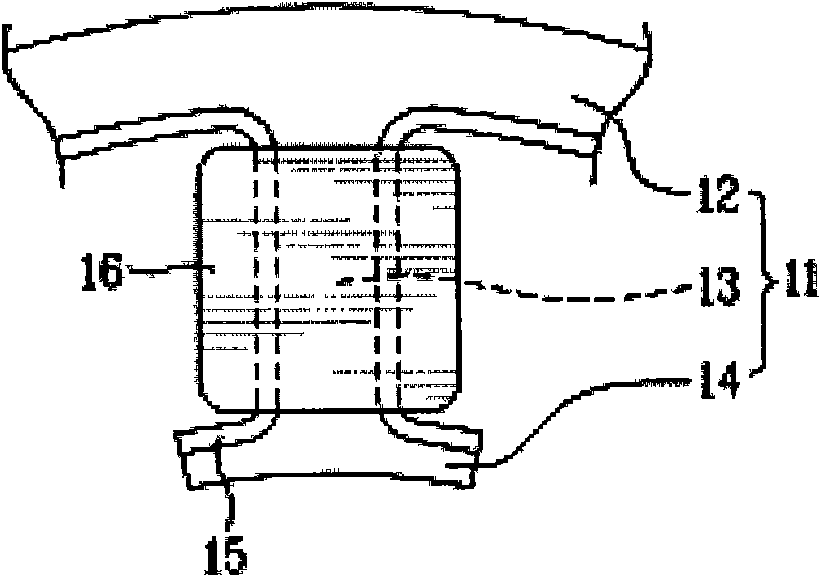

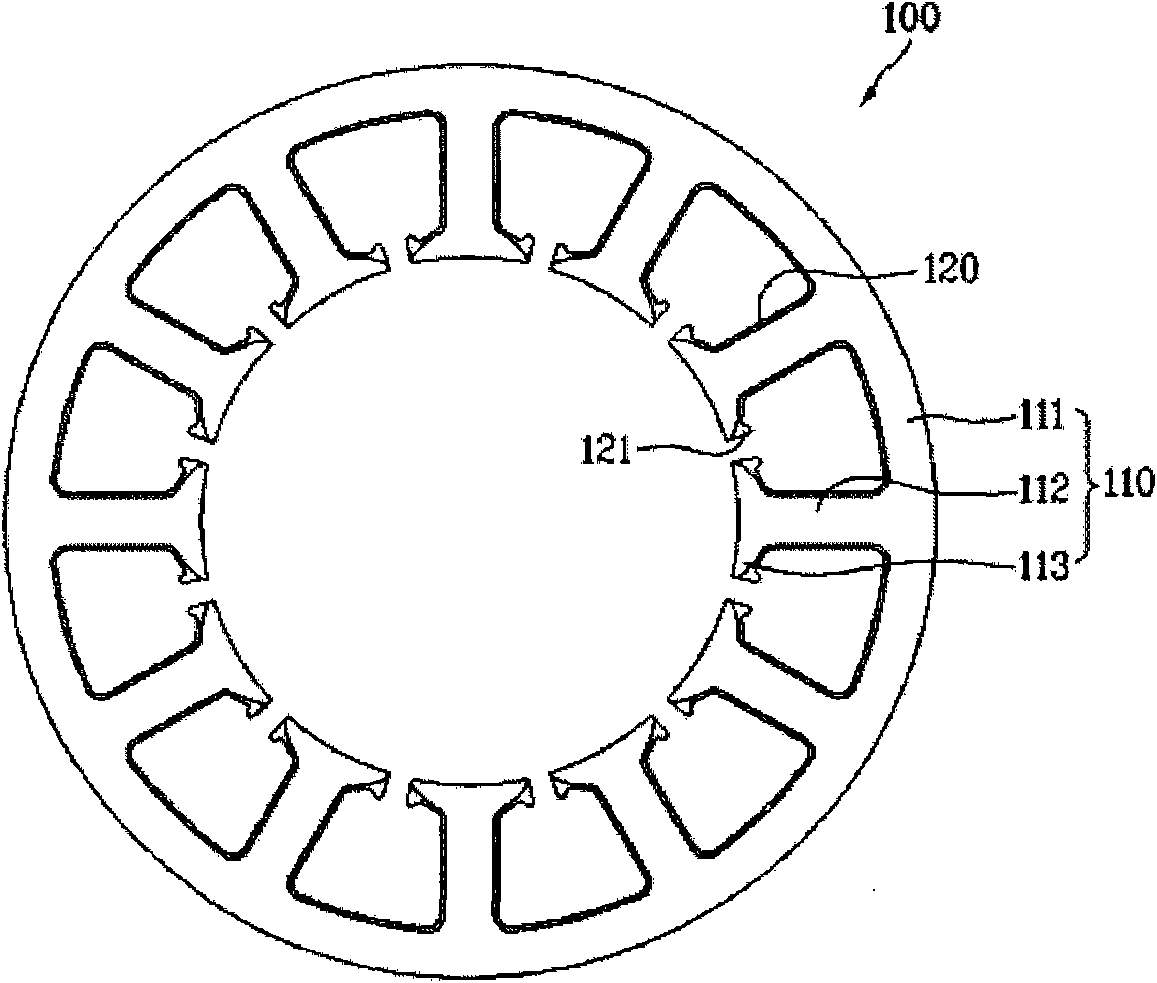

Motor

InactiveCN101572446AMaximum winding areaReduce insulation thicknessWindings insulation shape/form/constructionMagnetic circuit stationary partsPole pieceConductor Coil

The invention discloses a motor which comprises a stator iron core. The stator iron core comprises a plurality of T-shaped parts, pole shoes, inclined parts, insulators and a stator winding, wherein the T-shaped parts protrude from a basal part towards a center direction along the radial direction and are formed in the circumference direction, and the pole shoes are formed by extending the end parts of the T-shaped parts from the circumference direction towards both sides; each inclined part at the tail end of each pole shoe is formed by the gradual reduction of an inner peripheral surface of each pole shoe towards the end part of each T-shaped part; each insulator covers each T-shaped part, at least part of each inclined part and at least part of the basal part; and the stator winding is wound on the T-shaped parts covered by the insulators and is insulated from the stator iron core. The motor maximizes the winding area of a stator wound on the stator iron core and keeps the inner peripheral surfaces of the pole shoes in an insulation distance from the stator winding by insulated protrusions so as to reduce the insulation thickness of the insulators and save the material cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

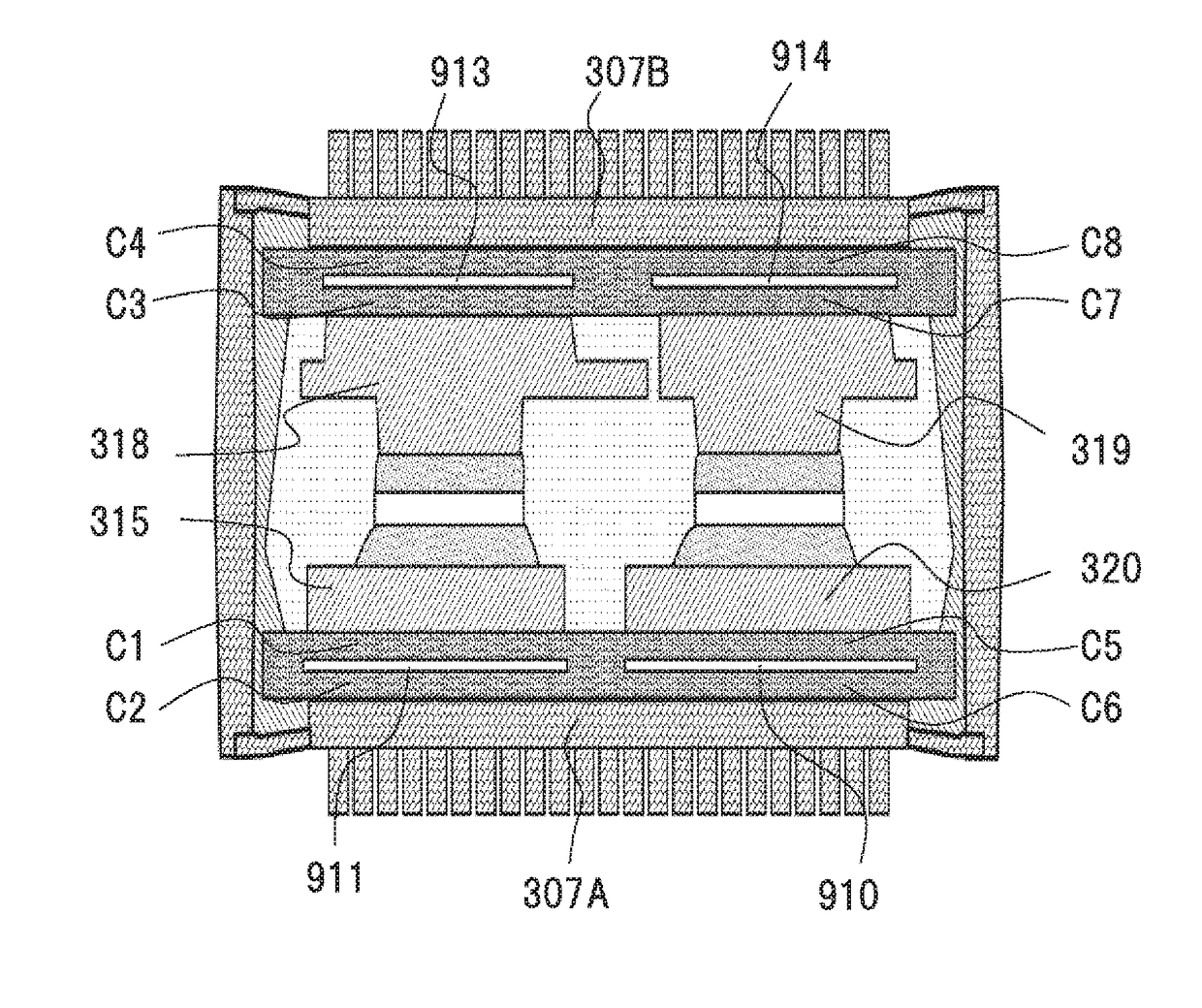

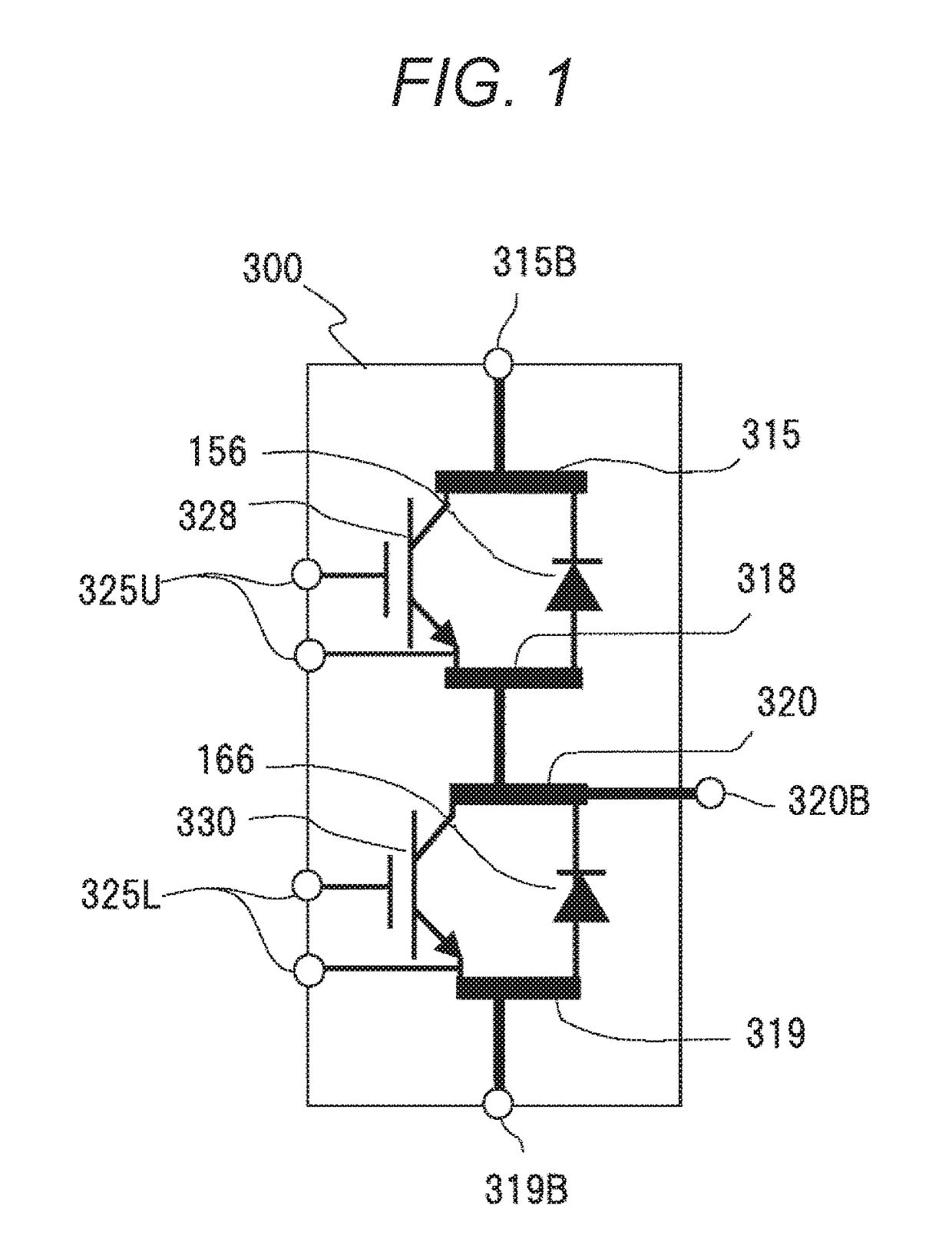

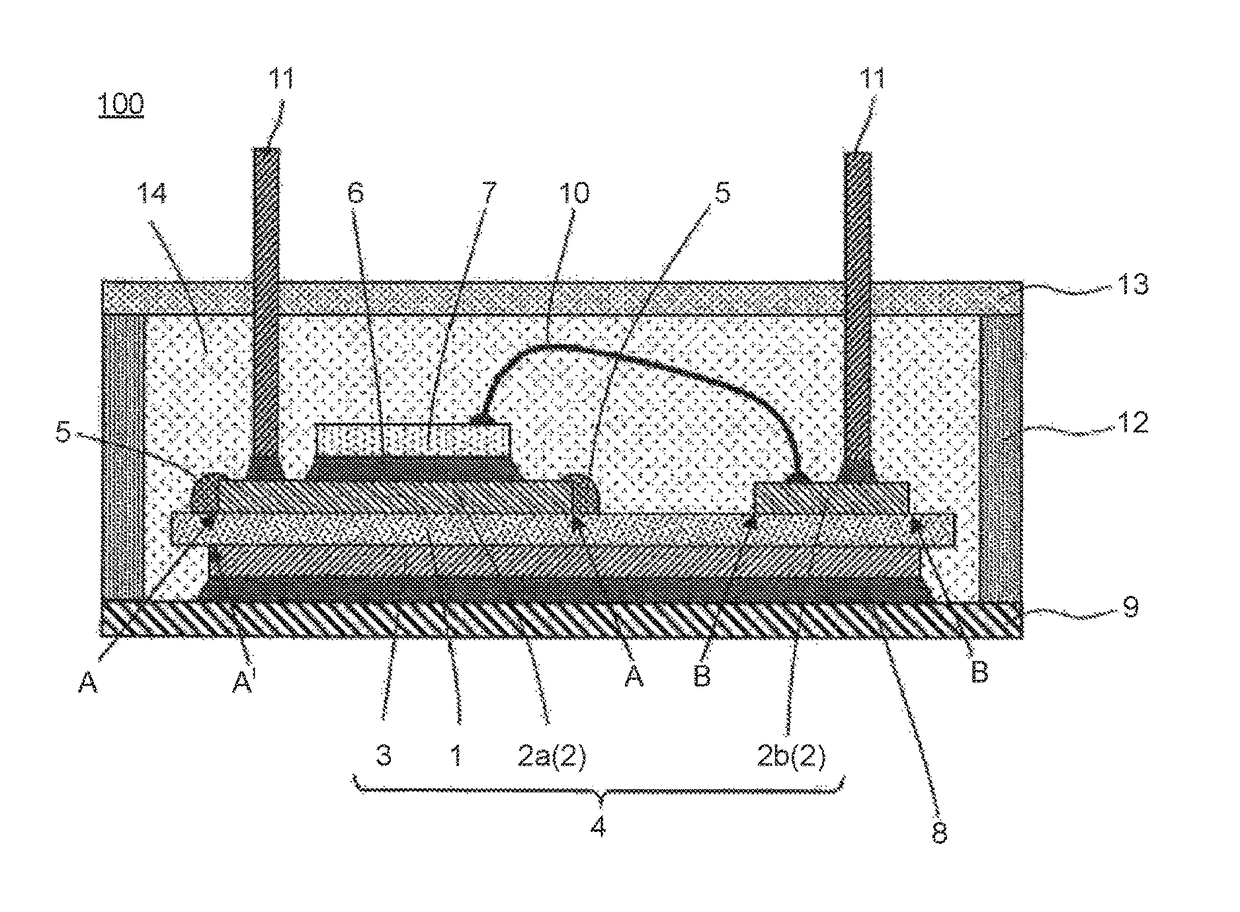

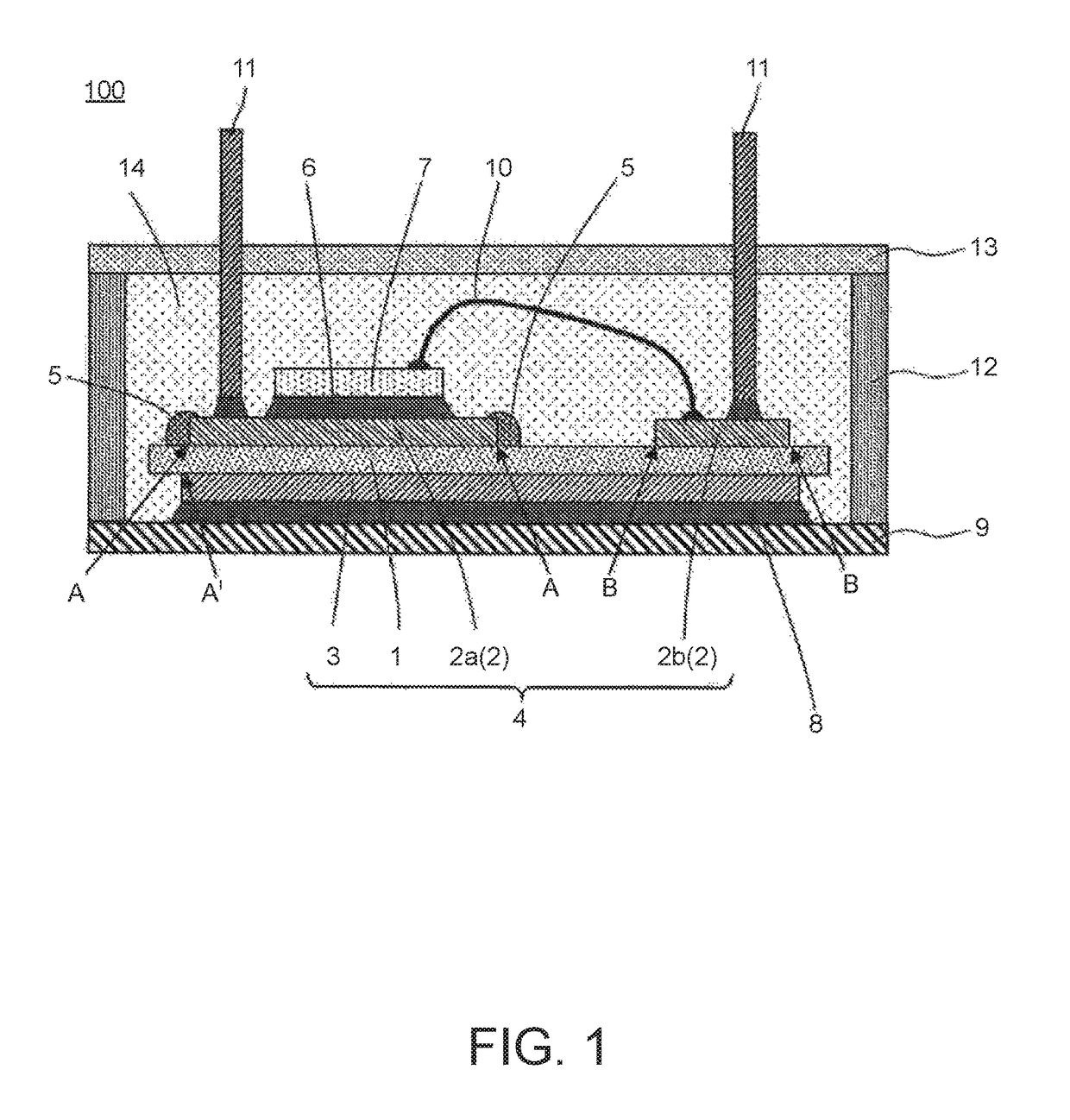

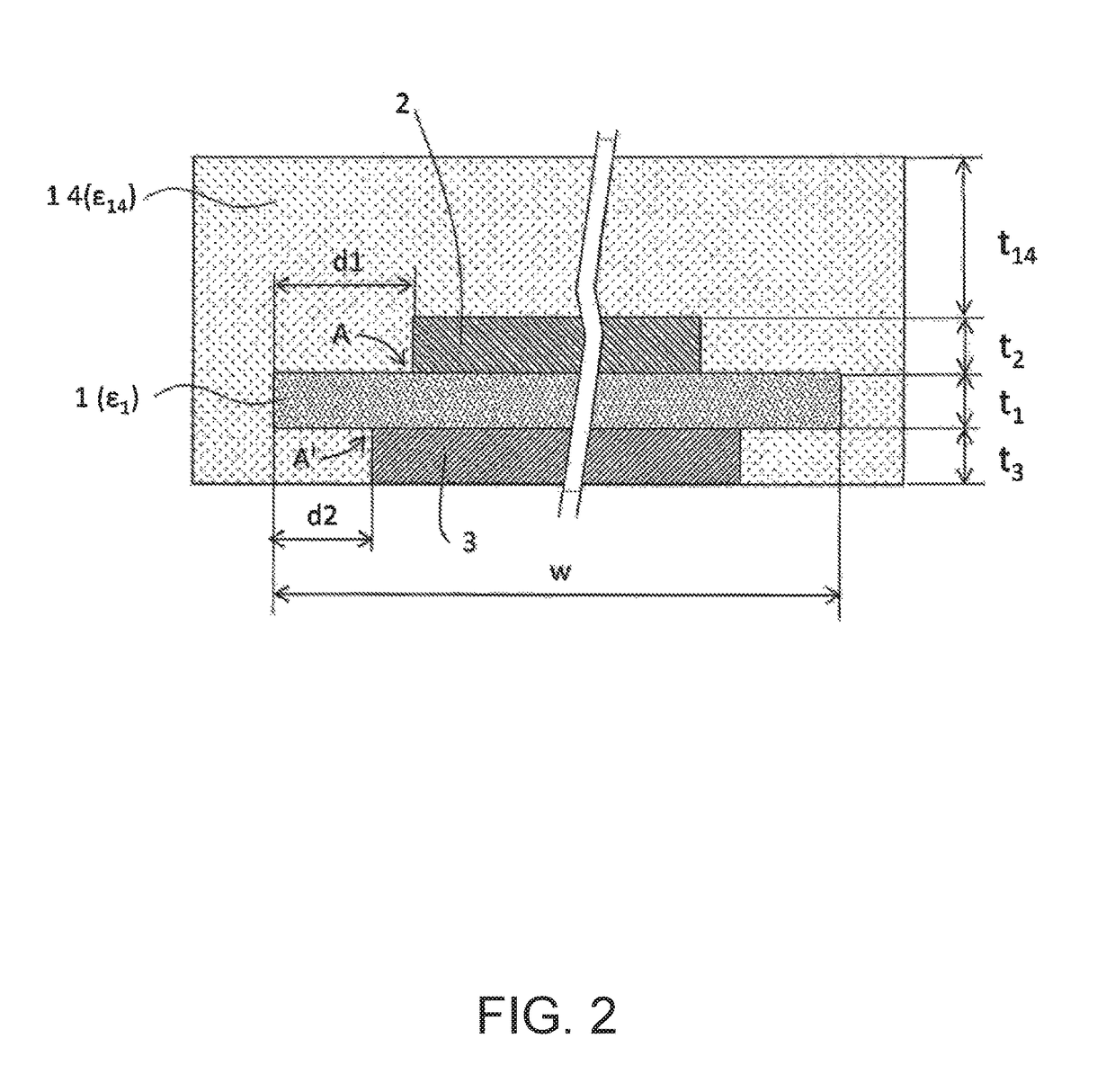

Power Module

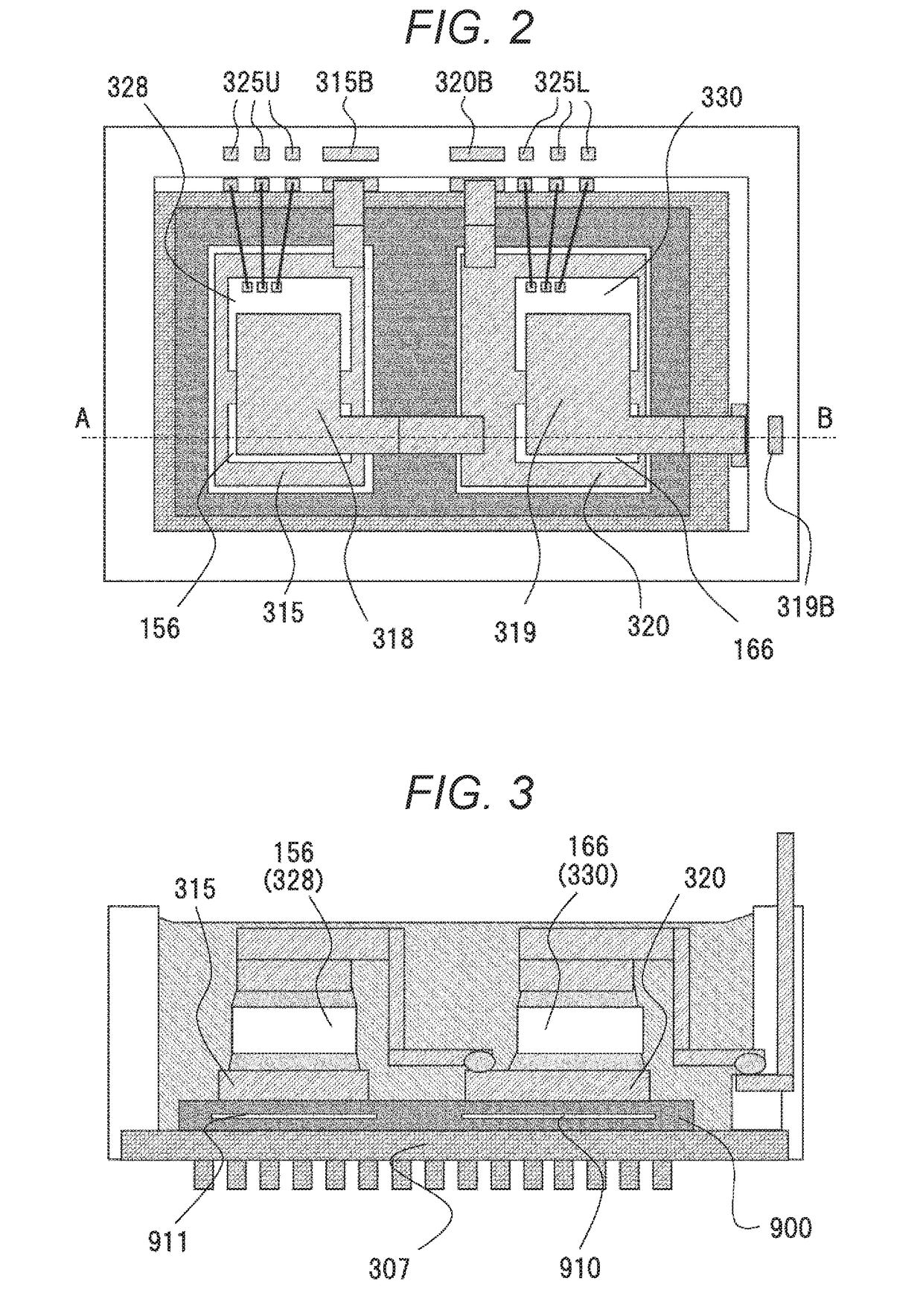

ActiveUS20180211938A1Reduce insulation thicknessMuch is dissipated as heatConversion constructional detailsSemiconductor/solid-state device detailsElectrical conductorComputer module

It is an object of the present invention to provide a power module which can withstand a high voltage with a thin insulating layer. A power module of the present invention is provided with a first power semiconductor element 328 of an upper arm side constituting an inverter circuit, a second power semiconductor element 330 of a lower arm side, a first conductor part 320 which transmits an alternating current, a second conductor part 315 which transmits a direct current, an electrically-conductive heat dissipating part 307, a first intermediate conductor layer 910 disposed between the first conductor part 320 and the heat dissipating part 307 via an insulating layer 900, and a second intermediate conductor layer 911 disposed between the second conductor part 315 and the heat dissipating part 307 via the insulating layer 900, wherein, the second intermediate conductor layer 911 is formed to be separated from the first intermediate conductor layer 910, and the first intermediate conductor layer 910 forms a capacity circuit which shares the voltage between the first conductor part 320 and the heat dissipating part 307.

Owner:HITACHI ASTEMO LTD

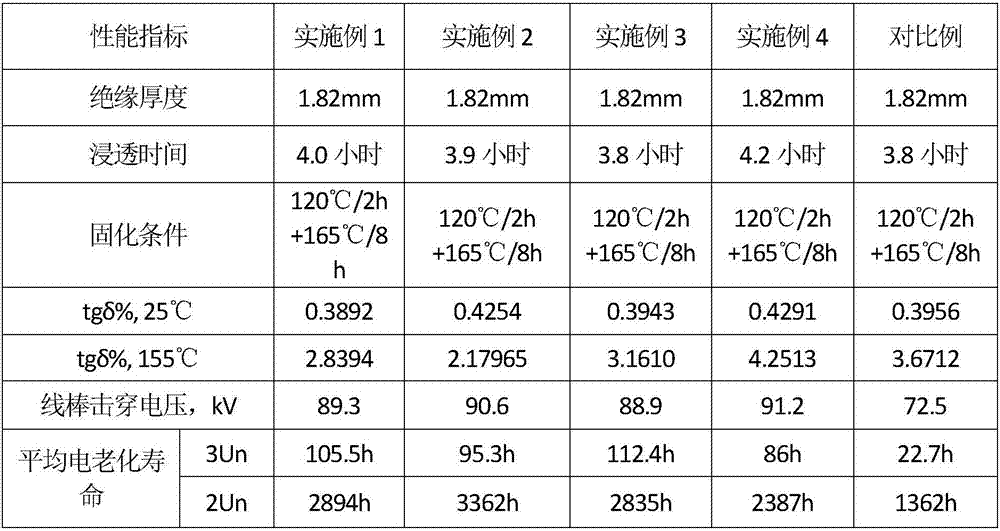

Less-resin mica tape used for high voltage motor and preparation method thereof

ActiveCN106960705AImprove electrical strengthRetain poresLamination ancillary operationsLaminationSemi solidSolvent free

The invention discloses a less-resin mica tape used for a high voltage motor and a preparation method thereof. The less-resin mica tape comprises a mica paper layer, a reinforced material layer, and an adhesive layer. The mica paper layer is formed by a piece of prepared mica paper. The preparation method comprises steps that step1, the prepared mica paper, the adhesive, and the reinforced material are selected; step2, uniform printing, spraying, or frictioning of solvent-free solid adhesive or semi-solid resin adhesive on the prepared mica paper or the reinforced material is carried out; step3, the hot pressing synthesis of the prepared mica paper and the reinforced material is carried out to form a mica tape blank material; step 4, cure accelerator prepared into solution is sprayed on the mica tape blank material, and permeates in the mica tape blank material. The less-resin mica tape has advantages of enhanced electrical intensity, excellent electrical aging performance, electrical performance uniformity, and ability of satisfying requirements of advanced less-resin VPI technology on permeability of mica tapes.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

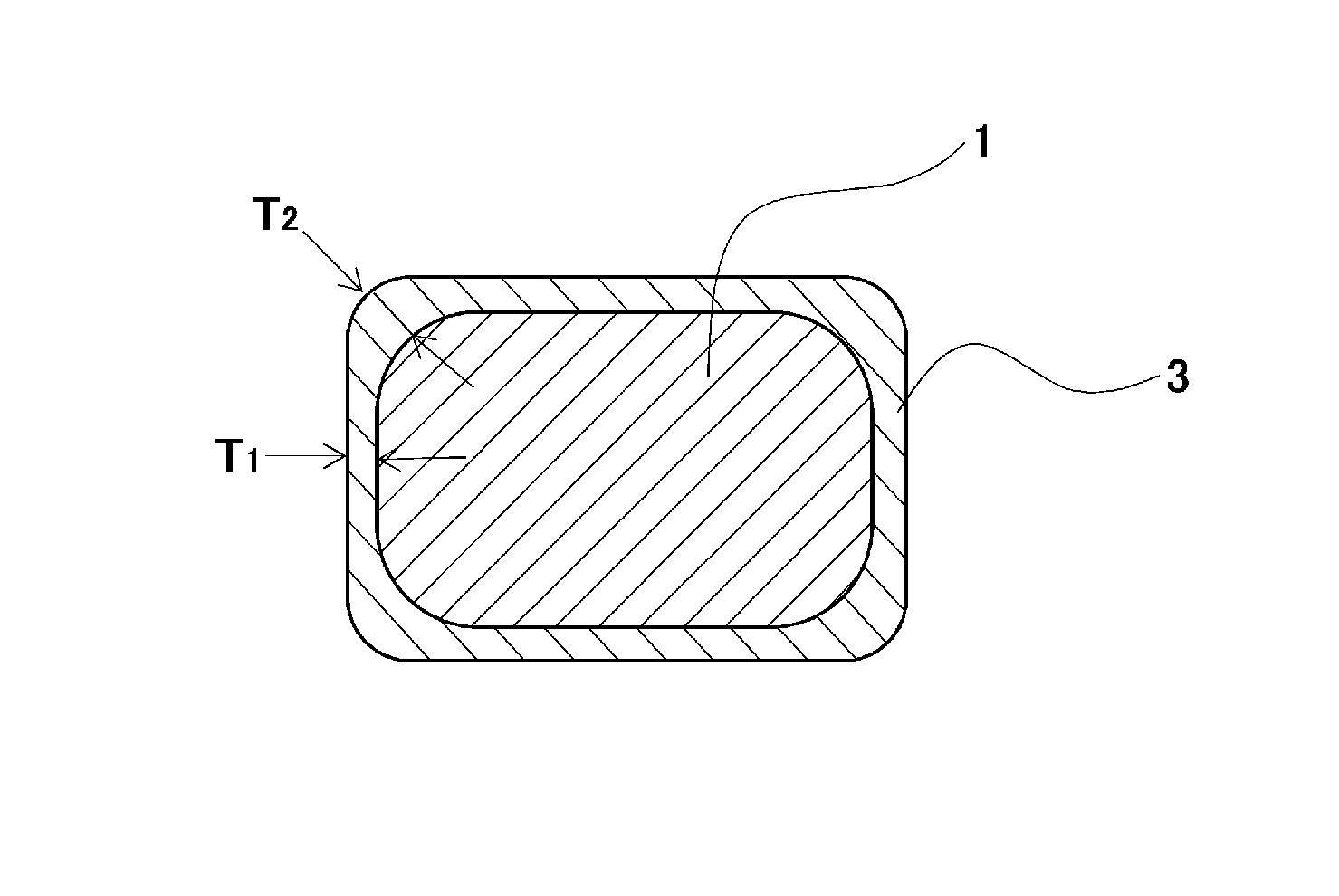

Insulated wire, and electric/electronic equipments, motor and transformer using the same

ActiveUS9424961B2Increase spacingReduce insulation thicknessWindings insulation materialWindings insulation shape/form/constructionElectrical conductorTransformer

Owner:ESSEX FURUKAWA MAGNET WIRE LLC

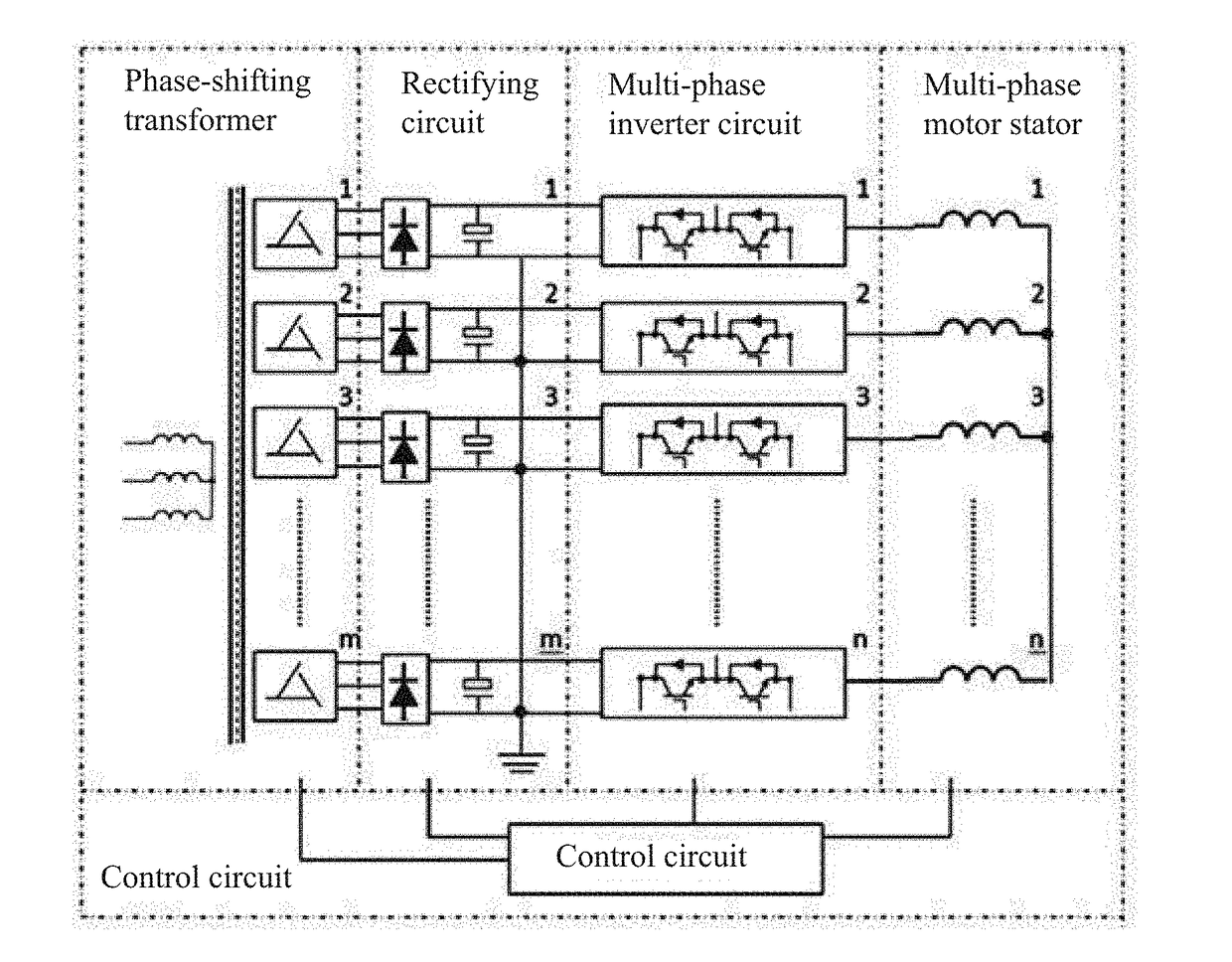

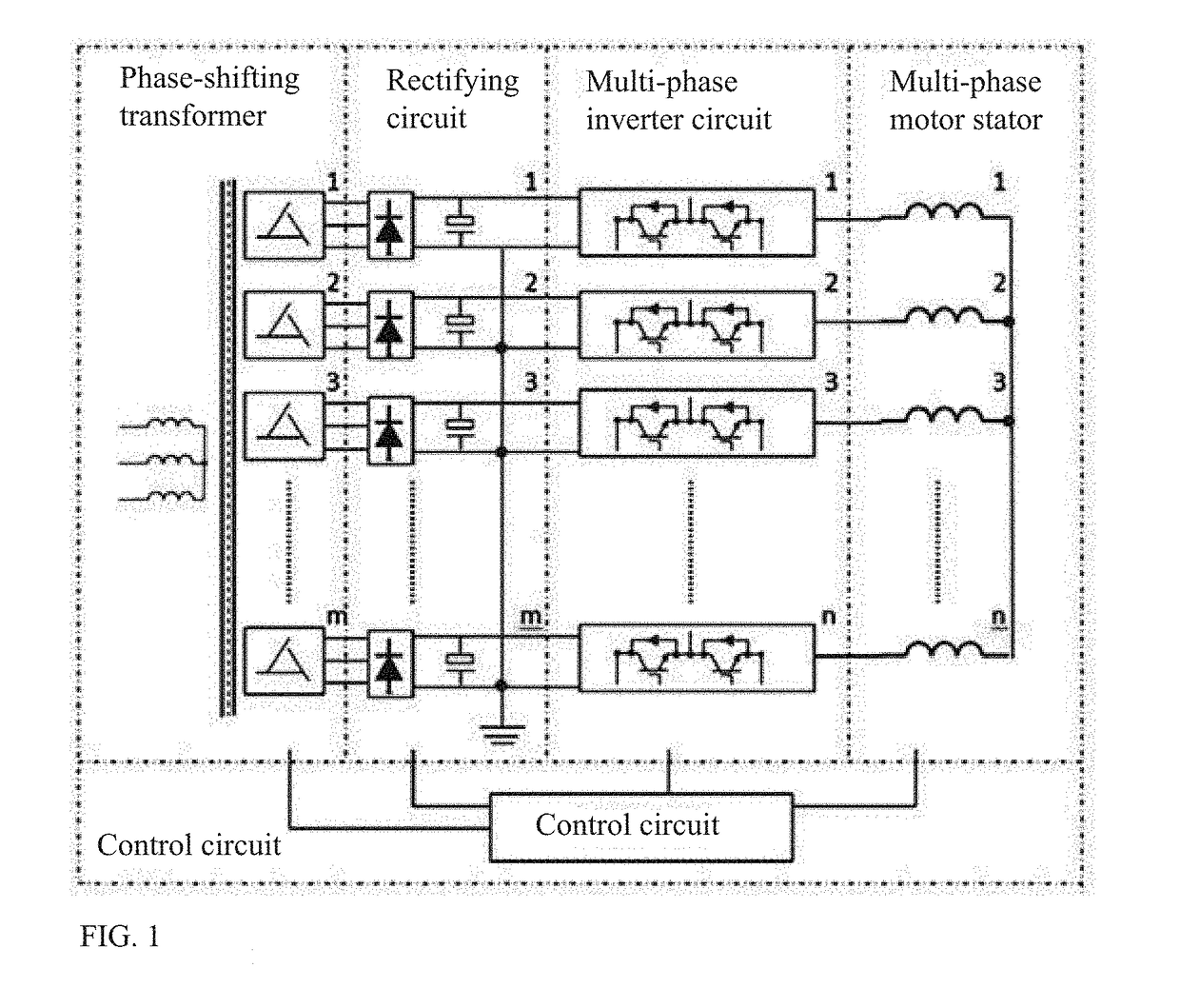

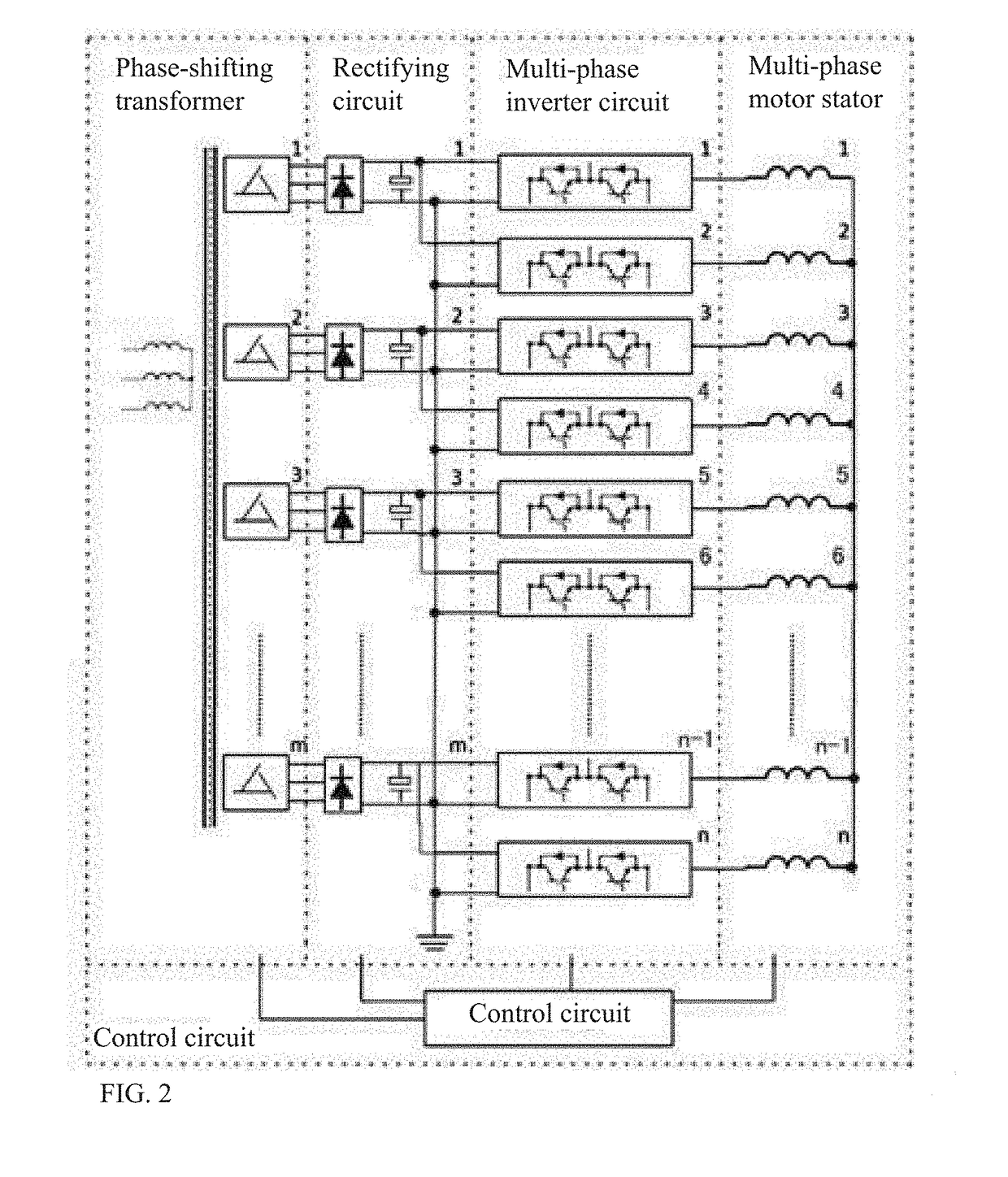

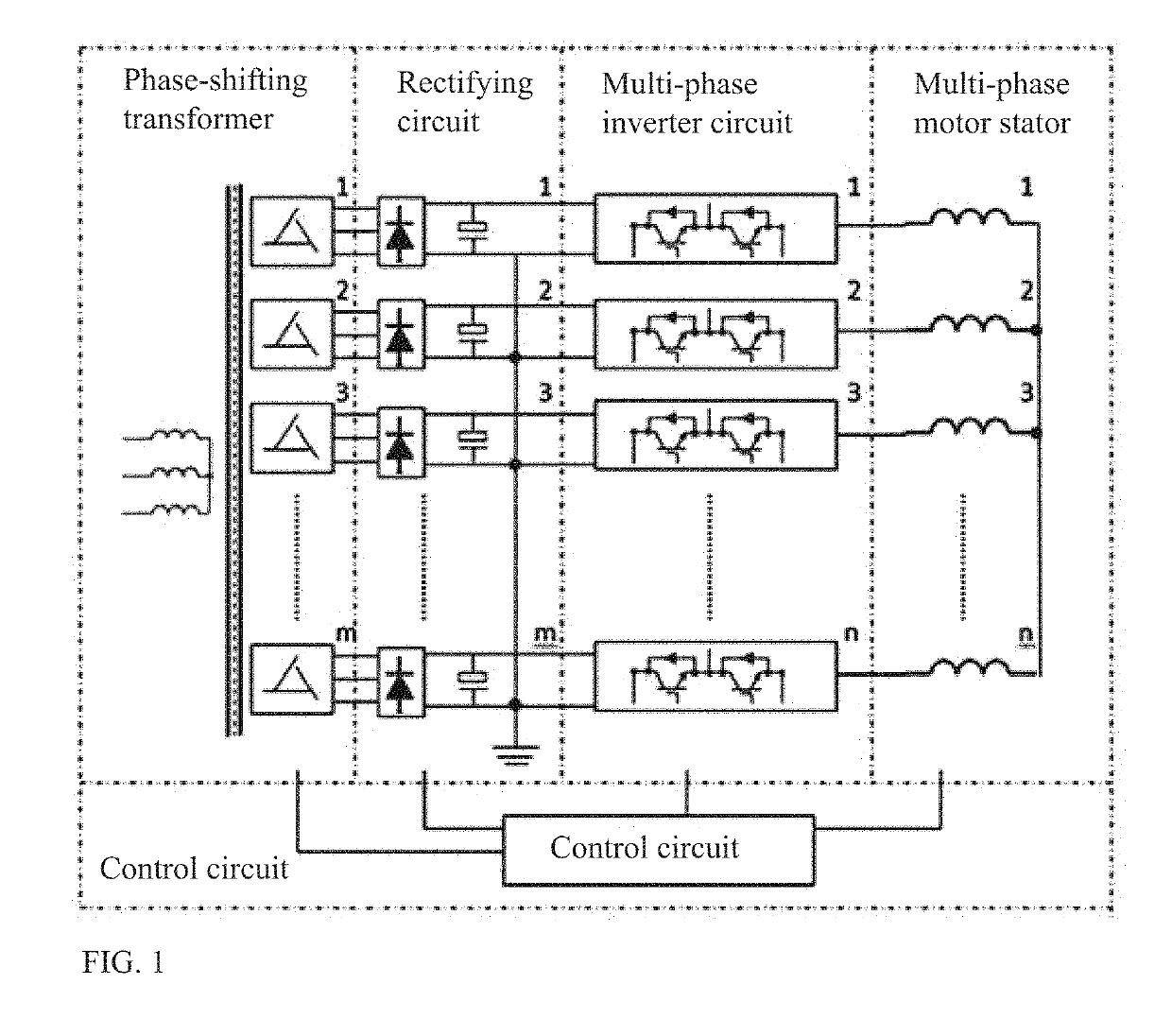

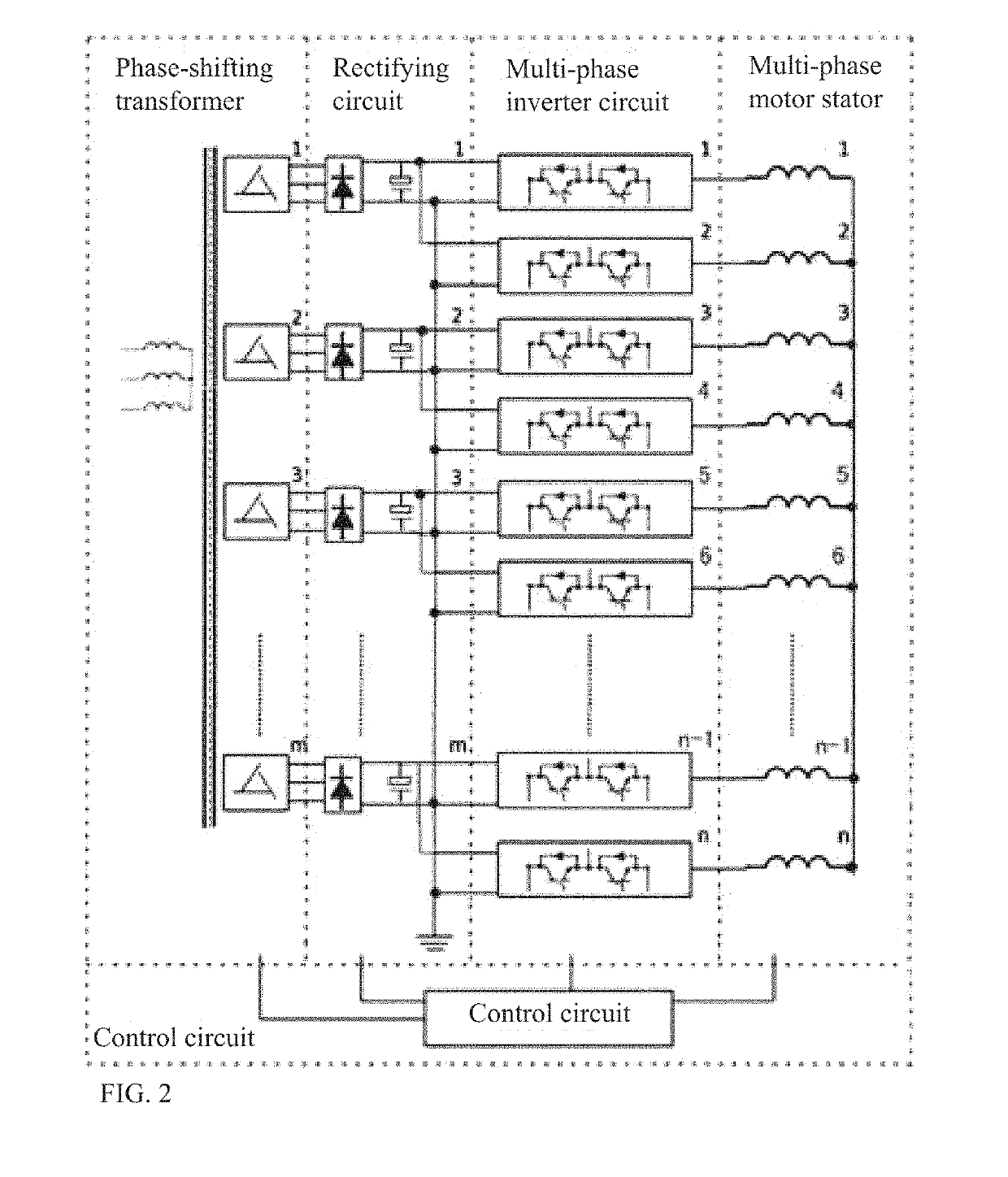

High-low-voltage conversion star multi-phase variable-frequency drive system

ActiveUS20180287541A1Reduce pollutionEasy to optimizeElectric motor controlAc-dc conversionFrequency changerTransformer

The present invention provides a high-low-voltage conversion star multi-phase variable-frequency drive system and relates to a high-voltage high-power motor and drive control thereof. The variable-frequency drive technical solution which is commonly used at present mainly has the disadvantages that a frequency converter is added to a common motor, the insulation life of the motor is short and the heat dissipating ability of the motor is poor. The system comprises a phase-shifting transformer, rectifying circuits, inverter circuits, a multi-phase motor, and a control circuit connected with the phase-shifting transformer, the rectifying circuits, the inverter circuits and the multi-phase motor, wherein primary windings of the phase-shifting transformer are connected with an alternating-current power source, and secondary windings of the phase-shifting transformer are connected with the rectifying circuits; and is characterized in that the number of the secondary windings is the same as the number of the rectifying circuits, one secondary winding is connected with one rectifying circuit, all rectifying circuits are in common-ground connection to form a common-ground direct-current power source, and output ends of the rectifying circuits are connected with the inverter circuits. By adopting the technical solution, high voltage and large currents are realized, simultaneously the structure is simple, the insulation requirement is lowered, the heat dissipating ability of the motor is improved and the power density is increased.

Owner:WOLONG ELECTRIC GRP CO LTD

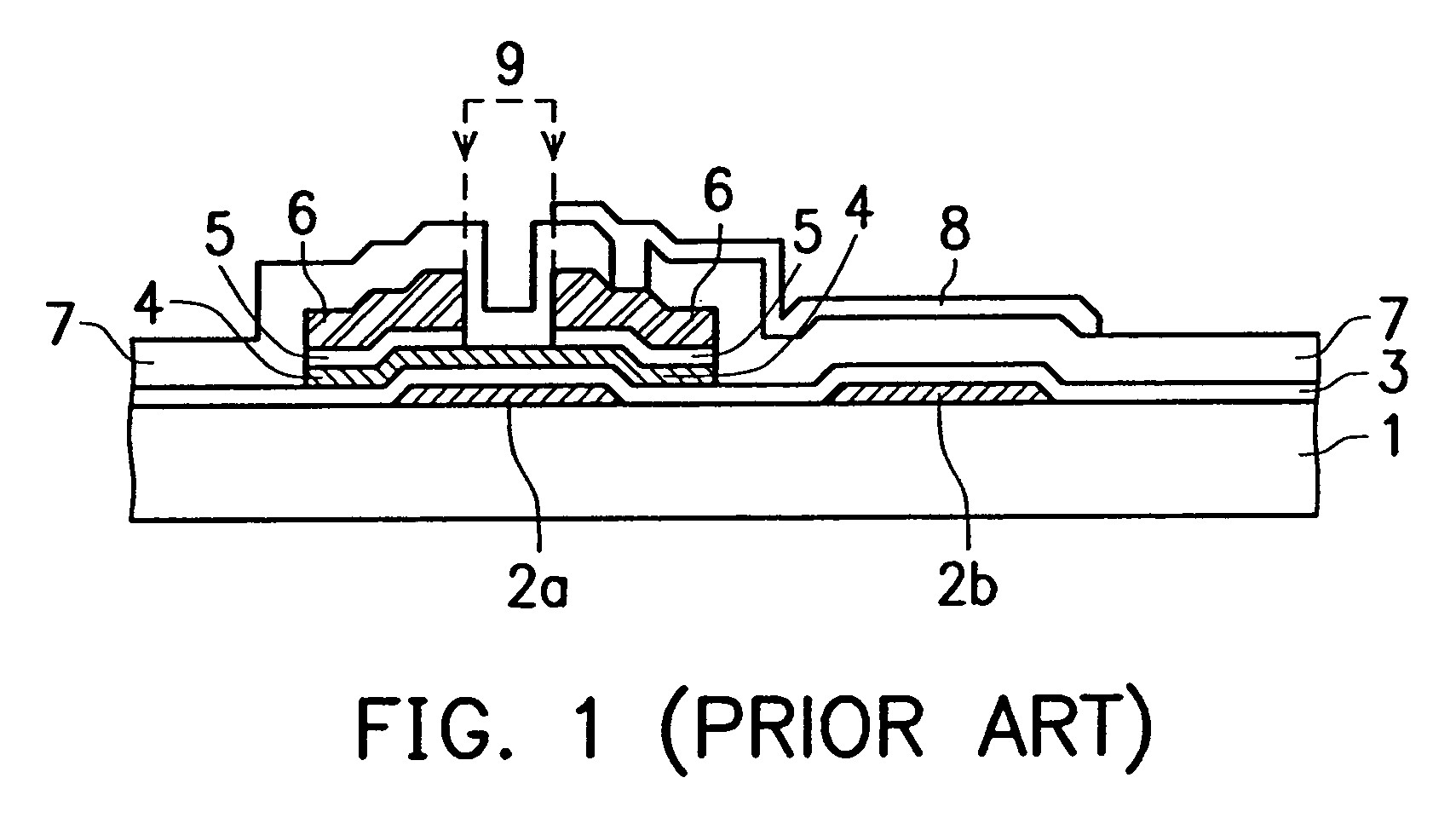

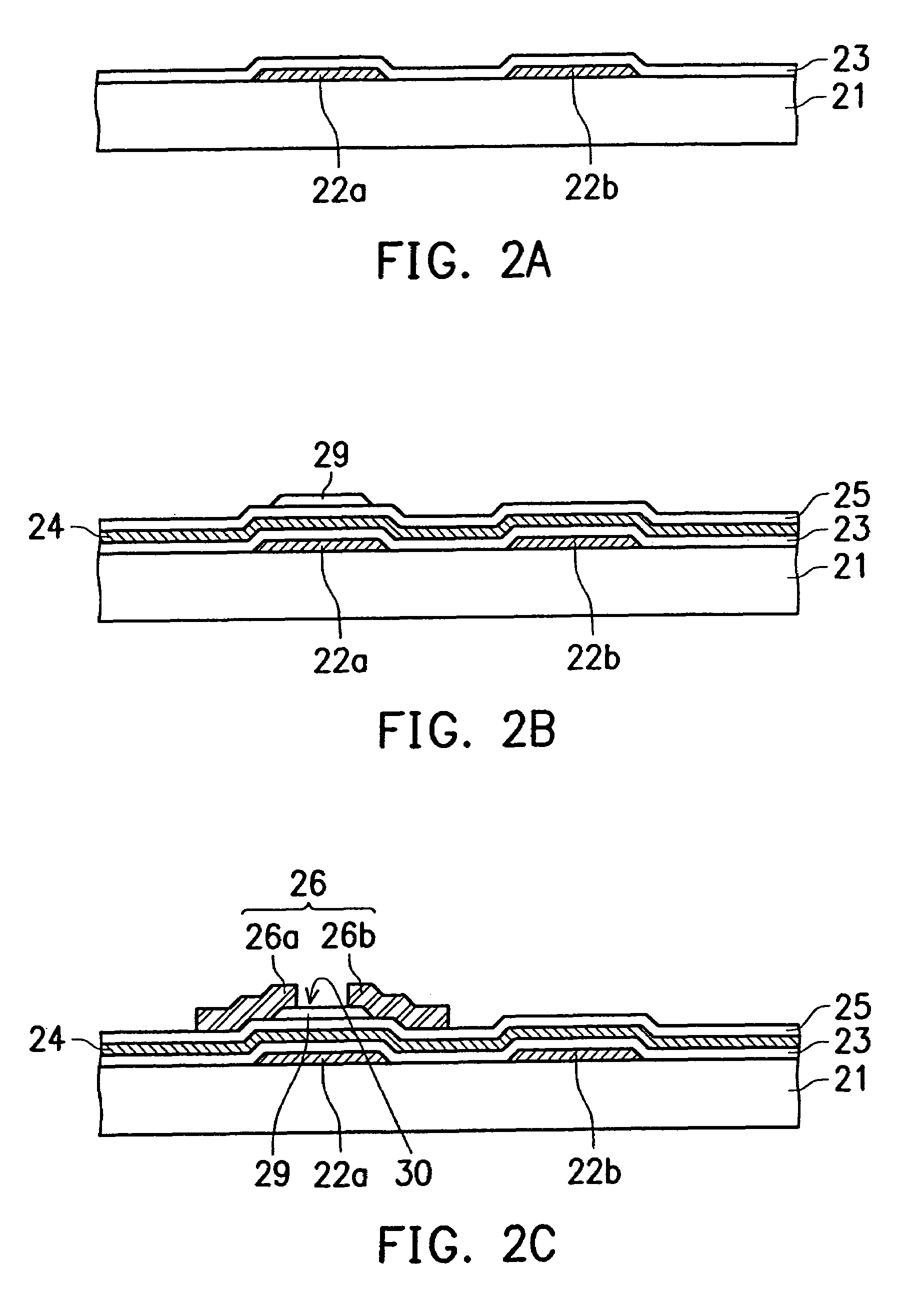

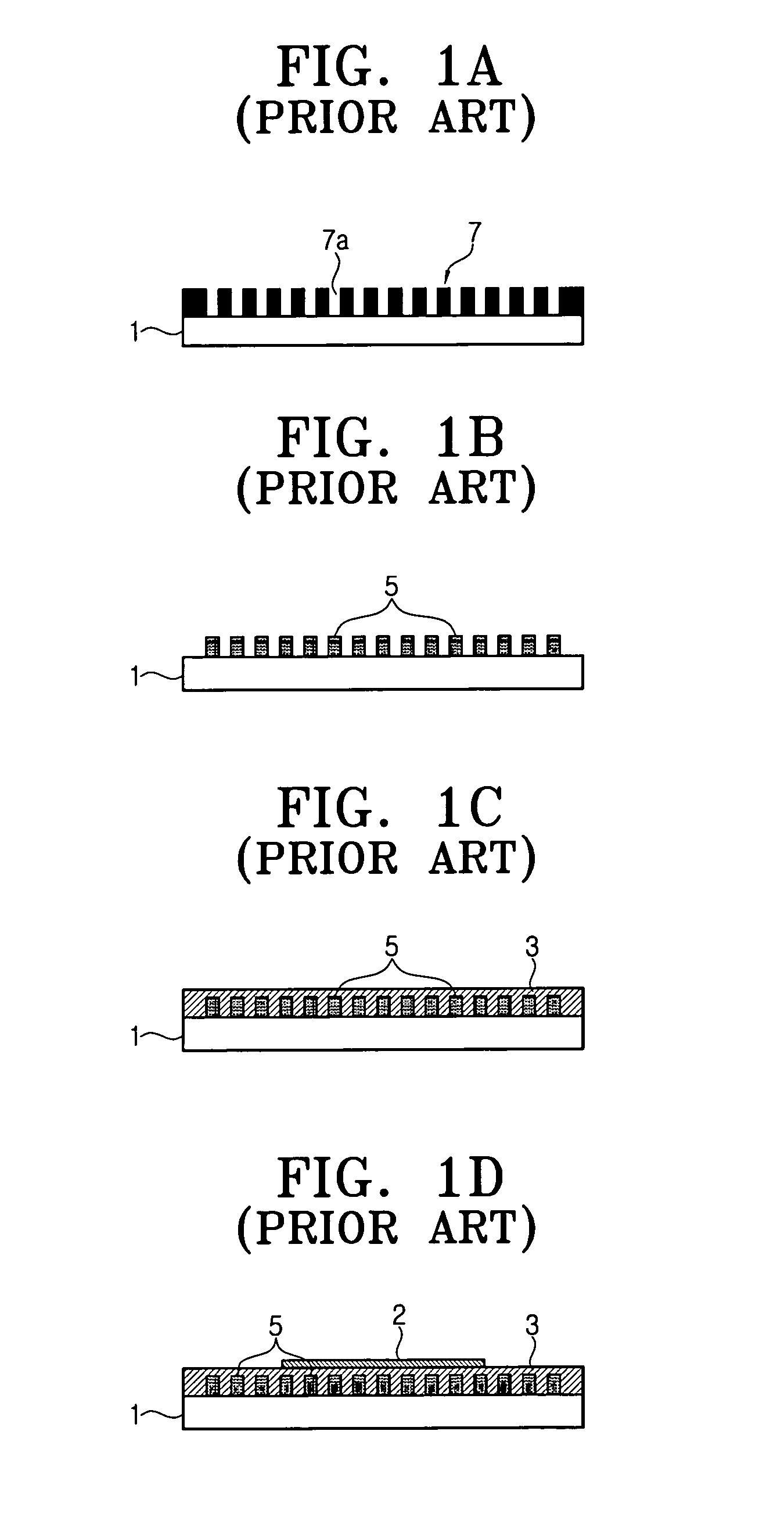

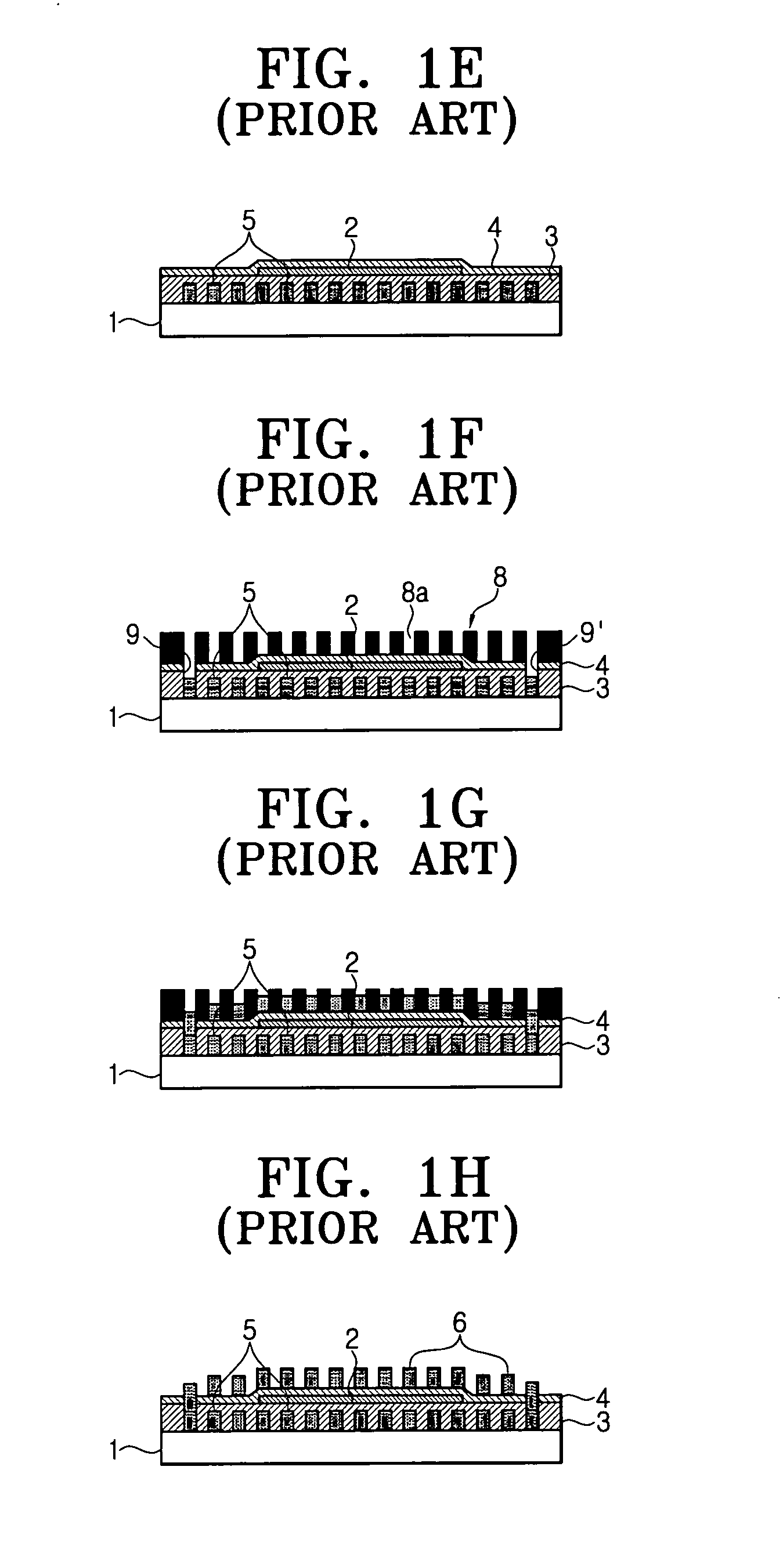

Thin film transistor liquid crystal display and manufacturing method thereof

InactiveUS7423289B2Quality improvementAvoid problemsTransistorSolid-state devicesLiquid-crystal displayEngineering

Owner:AU OPTRONICS CORP

Single coil VPI process

InactiveCN103840612AReduce insulation thicknessReduce product costManufacturing dynamo-electric machinesSingle coilElectrical and Electronics engineering

The invention discloses a single coil VPI process so as to solve the problem that a large water power generator carries out the VPI process difficultly in the prior art. The single coil VPI process sequentially comprises the following steps that VPI and baking are carried out on a single coil, and the coil is embedded. According to the scheme, the single coil VPI process has the advantages that the whole machine coil embedding is carried out after the single coil is manufactured in a VPI mode, the size of an iron core is large, operation is not easy, the insulation thickness can be decreased, the product cost is lowered, and the insulation quality of a motor is promoted to be a high level, the service life of the motor is prolonged, and the difficult problem of manufacturing of a stator coil in a medium-type water power generator is solved.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

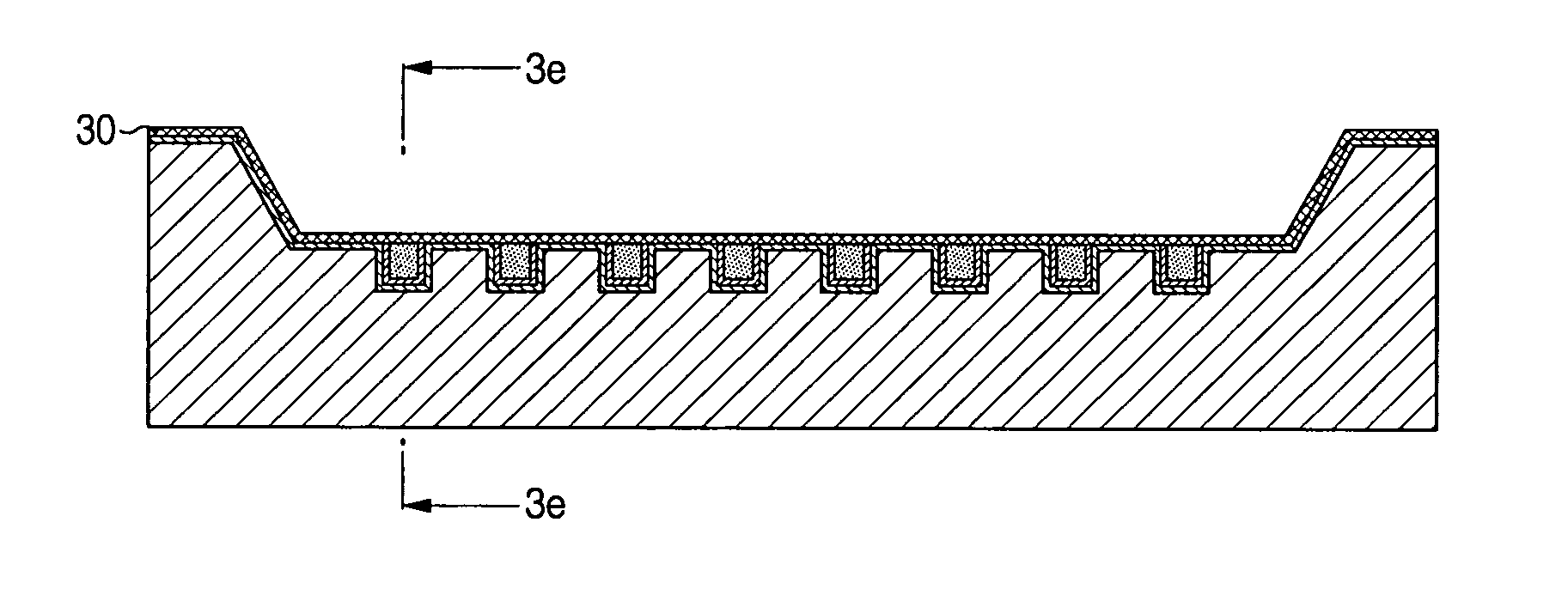

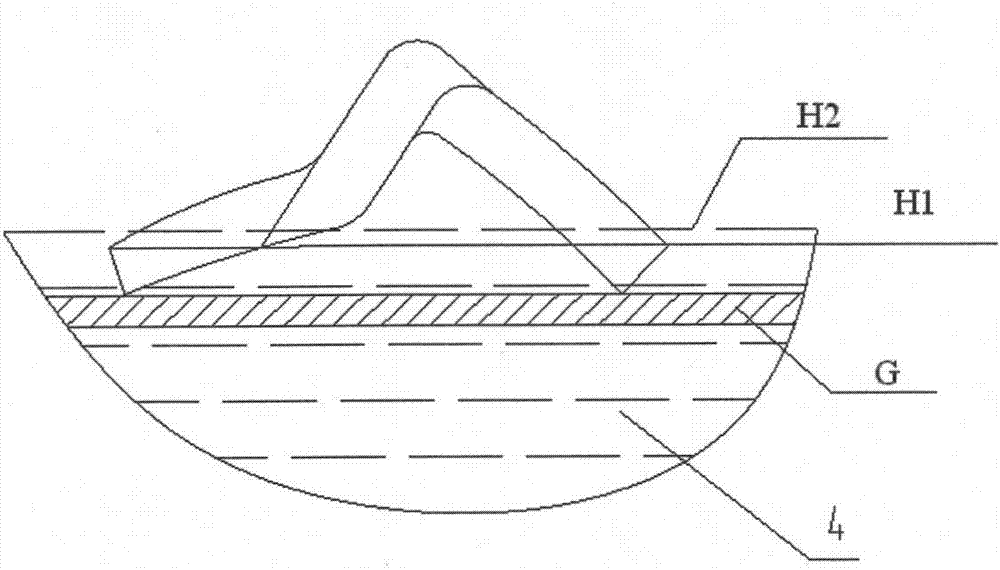

Magnetic field sensing device and a fabricating method of the same

ActiveUS20060164757A1Easy to flattenWell formedConstruction of head windingsMagnetic measurementsElectrical and Electronics engineeringMagnetic field

A magnetic field sensing device and a fabrication method of the same featuring an easy planarization profess for a substrate and a simplified procedure by the benefit of a slim planarizing substance. The magnetic field sensing device includes a substrate with a well of a predetermined depth and a plurality of grooves being formed thereon and a magnetic substance formed on an inner surface of the well to be located on an upper portion of the grooves. A first coil is formed in the grooves, a second coil is formed on an upper portion of the magnetic substance and is electrically connected to the first coil and insulating films are interposed between the first and the second coil and the magnetic substance for insulating the first and the second coil from the magnetic substance.

Owner:SAMSUNG ELECTRONICS CO LTD

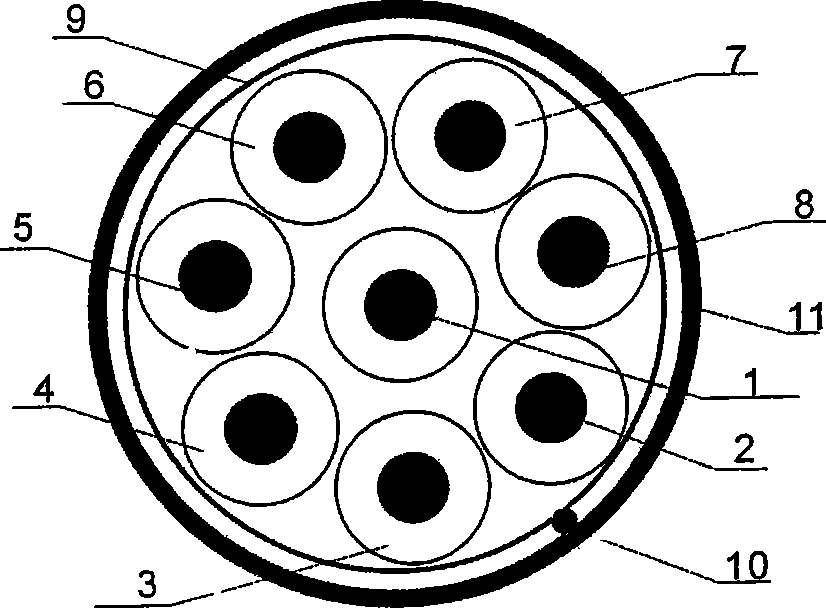

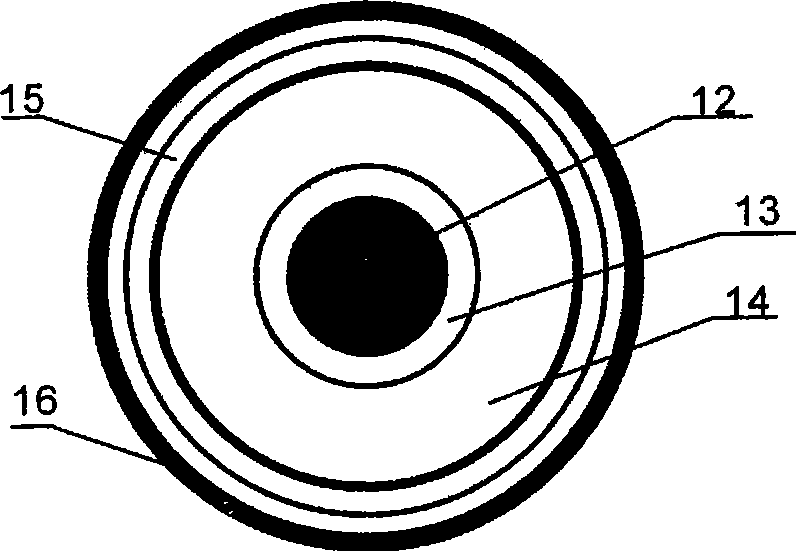

Coaxial cable for ultramicro signal transmission

InactiveCN101383203ALow costStructural stability exceedsCoaxial cables/analogue cablesInsulated cablesPolyesterElectrical conductor

The invention belongs to a cable, in particular relates to an ultramicro signal transmission coaxial cable which comprises a cable forming layer and a jacket. The ultramicro signal transmission coaxial cable is characterized in that the cable forming layer comprises one or a plurality of coaxial core wires, an insulating layer is arranged outside each core wire conductor, a shielding layer which is formed by knitting tinning copper wires is arranged outside the insulating layer, a low smoke and zero halogen inner jacket is arranged outside the shielding layer, a polyester film is wrapped outside the cable forming layer with one or a plurality of coaxial core wires, and a low smoke and zero halogen outer jacket is arranged outside the polyester film. Compared with the prior art, the invention has the advantages of stable structure, reliable performance, compact volume, environmental protection, no pollution and lower industrial manufacturing cost.

Owner:TIANJIN YXT TECH

Motor forming coil insulation thinning method

InactiveCN107154711AReduce the size of the motorHigh powerApplying solid insulationMicaVacuum pressure

The invention provides a motor forming coil insulation thinning method comprising the following steps: selecting an insulating material to wrap a copper flat wire to make a coil; half-lapping the coil with an insulating tape to form a coil mica insulation; binding up an insulating protective tape outside the coil mica insulation to form a protective insulation; sealing and binding up the end of the coil; and placing the coil bound up tightly on a lacquer dipping tool, taking solvent-free impregnating resin as impregnating resin, removing the seal and bandage at the end of the coil after the coil is impregnated at vacuum pressure, baked and cured, carrying out winding stator line embedding and arranging work, and after that, impregnating the winding-containing stator core at vacuum pressure and baking and curing the stator core. The coil mica insulation and the protective insulation constitute a coil main insulation of which the single-side thickness is less than or equal to 0.98mm. Through the method provided by the invention, the insulation thickness of the motor forming coil is reduced. The motor size is reduced under the condition of same power, and the power is increased and energy saving and consumption reducing are achieved under the condition of same size.

Owner:SHANGHAI DIANJI UNIV

Liquid crystal device, manufacturing method thereof, and electronic apparatus

InactiveUS7492425B2Solve insufficient capacityPreventing the cross talk from occurringNon-linear opticsEngineeringElectron

A liquid crystal device includes: a first substrate including a scanning line, a data line, a switching element, a pixel electrode and a storage capacitor associated with an intersection of the scanning line and the data line; a second substrate; and liquid crystal interposed between the substrates. A region where the pixel electrode is provided includes a reflective region and a transmissive region. An insulation layer is provided in the reflective region and the transmissive region to cover the switching element. A liquid crystal thickness adjustment layer is provided on the insulation layer in the reflective region. The pixel electrode is provided on the insulation layer in the transmissive region and on the liquid crystal thickness adjustment layer in the reflective region. Further, the storage capacitor includes an electrode disposed on the insulation layer in the reflective region and electrically connected to the pixel electrode.

Owner:EPSON IMAGING DEVICES CORP

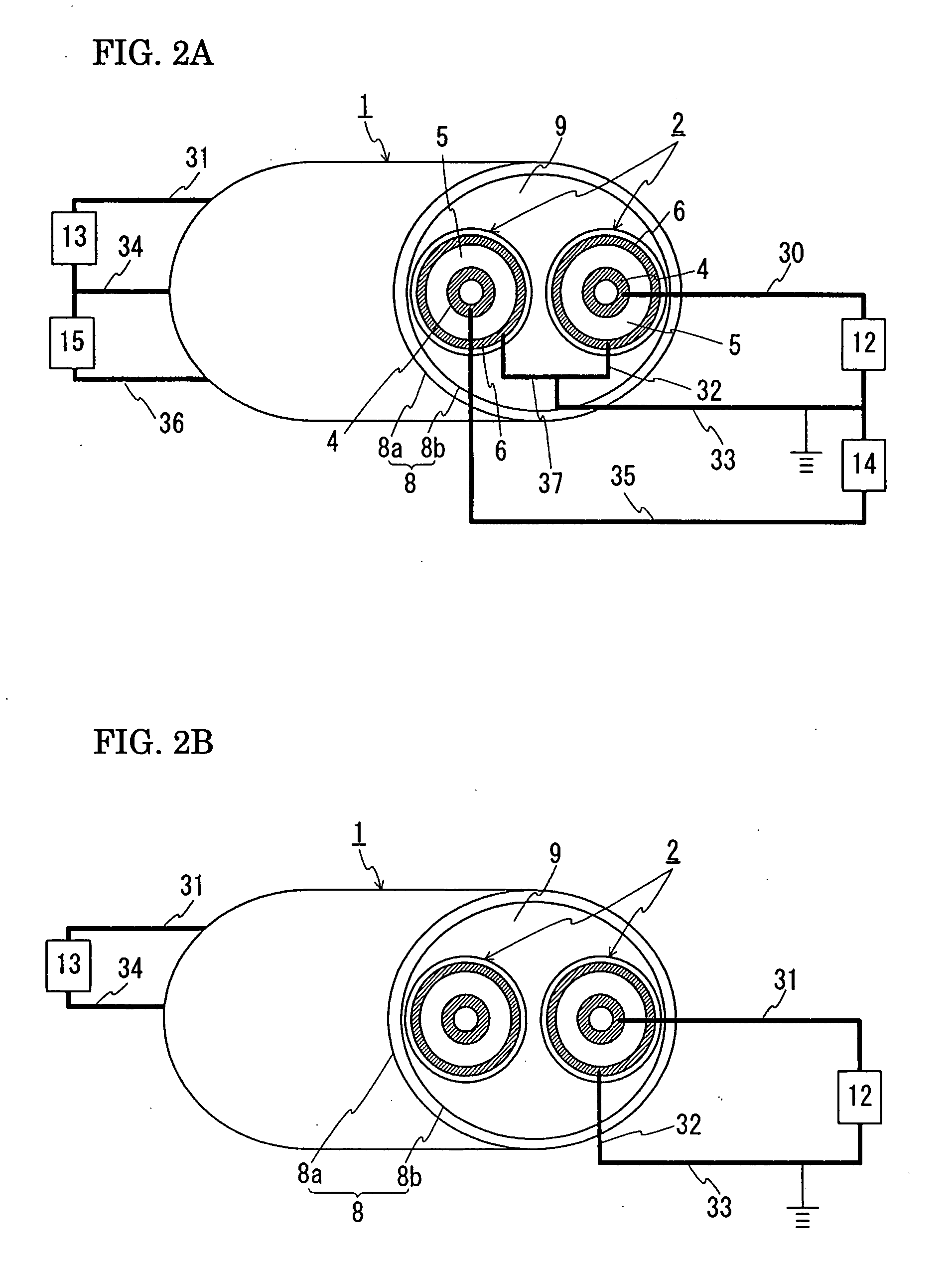

Superconducting cable and DC transmission system incorporating the superconducting cable

InactiveUS7723616B2Well formedReduce in quantitySuperconductors/hyperconductorsCable fittings for cryogenic cablesNeutral lineTransmission system

The invention offers a superconducting cable easy to form a twisted structure even when a plurality of cable cores are used and a DC transmission system incorporating the superconducting cable. A superconducting cable 1 has a structure formed by twisting together two types of cable cores (two first cores 2 and one second core 3) having different structures and then housing them in a heat-insulated pipe 7. The first cores 2 each have a first superconducting layer 2a, to be used either as an outward line or for the transmission for a pole in DC transmission, and have no superconducting layer other than the first superconducting layer 2a. The second core 3 has a second superconducting layer 3a, to be used as a return line or neutral line in DC transmission, and has no superconducting layer other than the second superconducting layer 3a. The second superconducting layer 3a has an inner diameter larger than the outer diameter of the first superconducting layer 2a.

Owner:SUMITOMO ELECTRIC IND LTD

High-low-voltage conversion star multi-phase variable-frequency drive system

ActiveUS10305409B2Reduce Harmonic PollutionMotor windings can be obviously reducedElectric motor controlAc-dc conversionFrequency changerLow voltage

The present invention provides a high-low-voltage conversion star multi-phase variable-frequency drive system and relates to a high-voltage high-power motor and drive control thereof. The variable-frequency drive technical solution which is commonly used at present mainly has the disadvantages that a frequency converter is added to a common motor, the insulation life of the motor is short and the heat dissipating ability of the motor is poor. The system comprises a phase-shifting transformer, rectifying circuits, inverter circuits, a multi-phase motor, and a control circuit connected with the phase-shifting transformer, the rectifying circuits, the inverter circuits and the multi-phase motor, wherein primary windings of the phase-shifting transformer are connected with an alternating-current power source, and secondary windings of the phase-shifting transformer are connected with the rectifying circuits; and is characterized in that the number of the secondary windings is the same as the number of the rectifying circuits, one secondary winding is connected with one rectifying circuit, all rectifying circuits are in common-ground connection to form a common-ground direct-current power source, and output ends of the rectifying circuits are connected with the inverter circuits. By adopting the technical solution, high voltage and large currents are realized, simultaneously the structure is simple, the insulation requirement is lowered, the heat dissipating ability of the motor is improved and the power density is increased.

Owner:WOLONG ELECTRIC GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com