6 kilovolt level high-voltage motor insulation structure and manufacturing method thereof

A technology of insulation structure and high-voltage motor, applied in the shape/style/structure of winding insulation, laying solid insulation, etc., which can solve the problems of large insulation margin and mass production, short product service life and operating life, and low insulation strength of motors, etc. problem, to achieve the effect of good electric strength, insulation thickness thinning and good insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

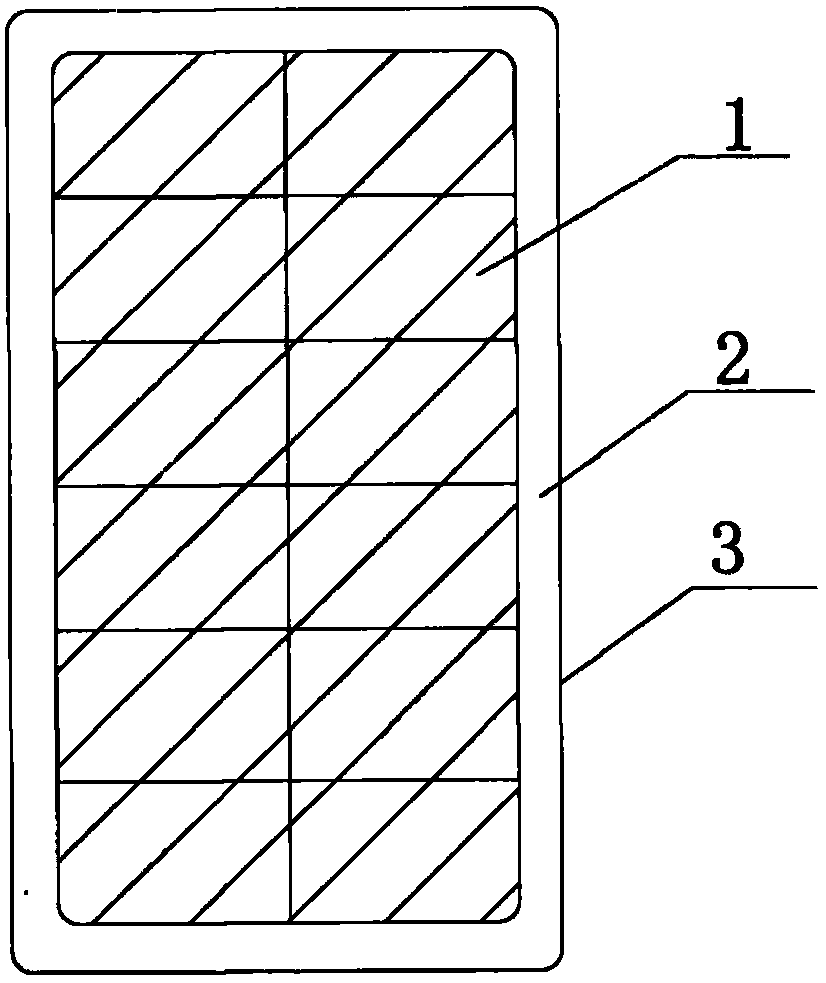

Image

Examples

Embodiment

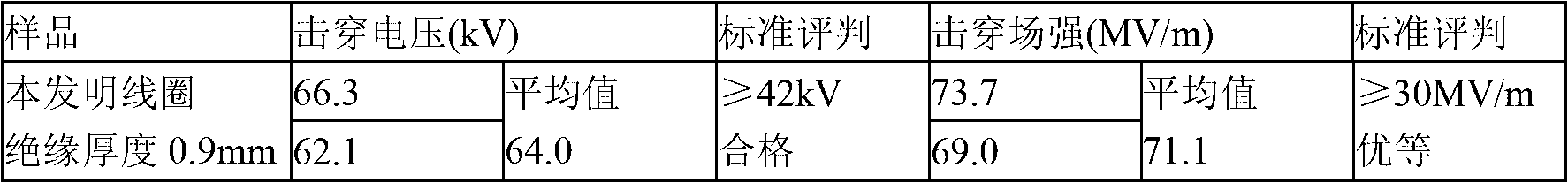

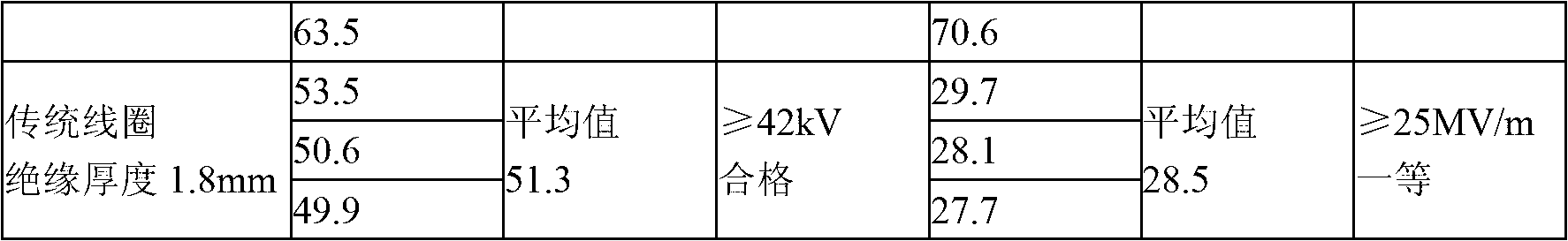

[0070] Apply the insulation structure of the present invention to make motor coils, use three-layer polyester film mica flat-wrapped copper-clad flat wire as the winding copper flat wire, the cross-sectional size of the copper conductor is 2.2×5.0mm, and the double-sided insulation thickness between turns is 0.40mm. After double-row parallel winding for 10 turns and expansion-type inter-turn gelation, 5 layers of polyester film less rubber powder mica tape with a thickness of 0.09mm are wrapped as the main insulating layer (its insulation thickness is 0.90mm), and then Including low-resistance anti-halation tape and high-resistance anti-halation tape. After vacuum pressure impregnation, baking and curing, the total size of the groove coil is 12.76mm×27.96mm, and the total cross-sectional area of the groove is about 356.8mm 2 , where the total cross-sectional area of the copper conductor is 220mm 2 , the cross-sectional area of the copper conductor accounts for 61.7% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com