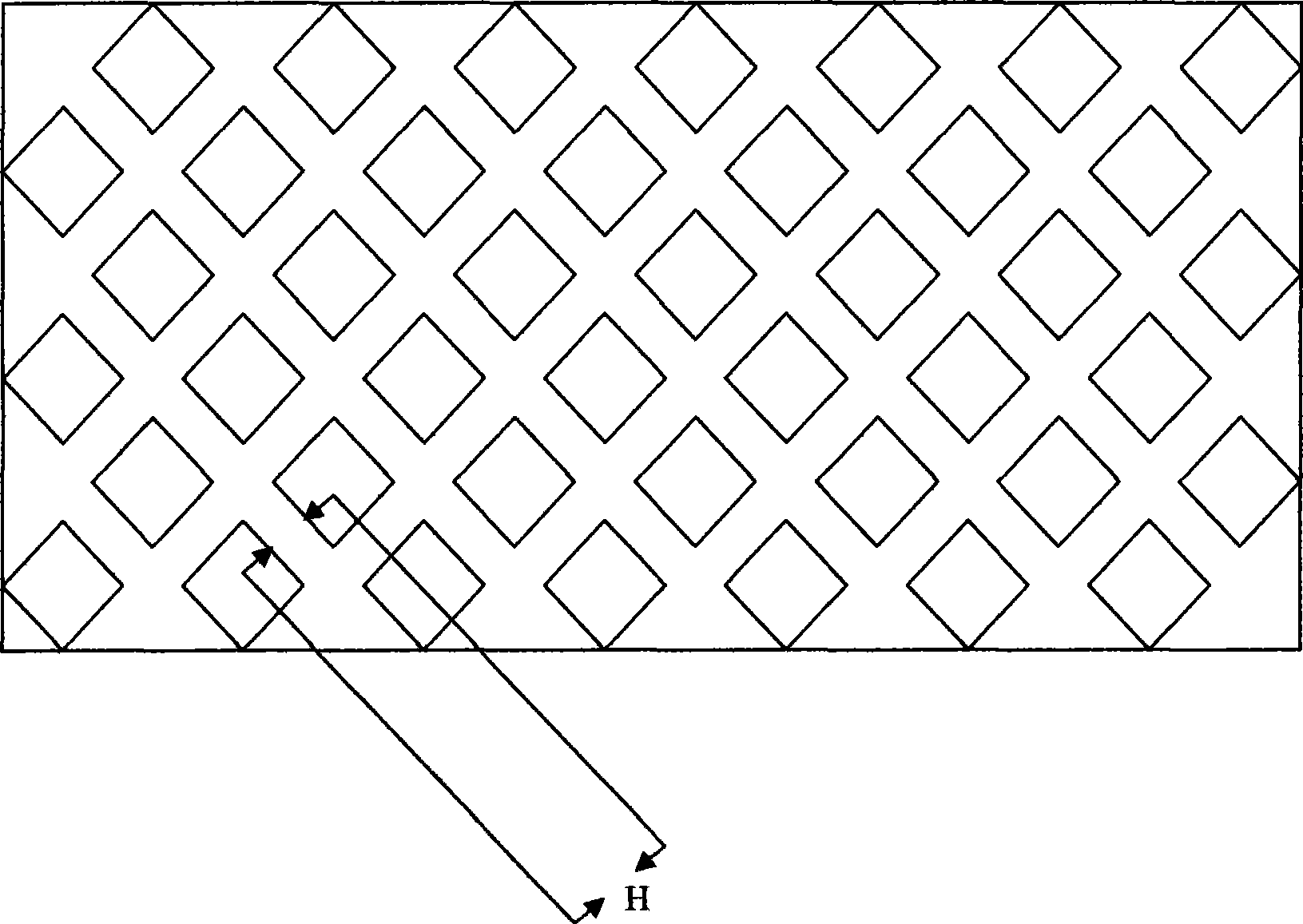

Diamond dotted glue composite dielectric paper and preparation method thereof

A composite insulation and diamond technology, applied in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of increasing the manufacturing cost of transformers, unable to meet the electrical performance of insulation, and unable to ensure insulation strength, and save manufacturing costs. , Excellent mechanical properties, high dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A rhombic dispensing composite insulating paper, consisting of a polyester film layer, a polyester fiber non-woven fabric layer for electrical insulation pasted on the upper and lower surfaces of the polyester film layer with an F-grade polyurethane adhesive, and a diamond-shaped coating on each Composition of modified epoxy resin on the surface of polyester fiber non-woven fabric layer for electrical insulation;

[0031] Described polyester film layer is the polyester film layer that thickness is 0.05mm;

[0032] The polyester fiber nonwoven fabric layer for electrical insulation is a polyester fiber nonwoven fabric layer manufactured by hot rolling for electrical insulation with a thickness of 0.025 mm;

[0033] The F-grade polyurethane adhesive is composed of 2.5 parts of the F-grade polyurethane adhesive component A and 1.0 part of the F-grade polyurethane adhesive component B as a curing agent in a weight ratio;

[0034] The modified epoxy resin is a mixture of bi...

Embodiment 2

[0049] A rhombic dispensing composite insulating paper, consisting of a polyester film layer, a polyester fiber non-woven fabric layer for electrical insulation pasted on the upper and lower surfaces of the polyester film layer with an F-grade polyurethane adhesive, and a diamond-shaped coating on each Composition of modified epoxy resin on the surface of polyester fiber non-woven fabric layer for electrical insulation;

[0050] Described polyester film layer is the polyester film layer that thickness is 0.025mm;

[0051] The polyester fiber nonwoven fabric layer for electrical insulation is a polyester fiber nonwoven fabric layer manufactured by hot rolling for electrical insulation with a thickness of 0.020 mm;

[0052] The F grade polyurethane adhesive is composed of 2.5 parts of F grade polyurethane adhesive component A and 1.2 parts of F grade polyurethane adhesive B component as curing agent in a weight ratio;

[0053] The modified epoxy resin is a mixture of bisphenol ...

Embodiment 3

[0068] A rhombic dispensing composite insulating paper, consisting of a polyester film layer, a polyester fiber non-woven fabric layer for electrical insulation pasted on the upper and lower surfaces of the polyester film layer with an F-grade polyurethane adhesive, and a diamond-shaped coating on each Composition of modified epoxy resin on the surface of polyester fiber non-woven fabric layer for electrical insulation;

[0069] The polyester film layer is a polyester film layer with a thickness of 0.10mm.

[0070] The polyester fiber nonwoven fabric layer for electrical insulation is a polyester fiber nonwoven fabric layer manufactured by hot rolling for electrical insulation with a thickness of 0.05mm;

[0071] The F-grade polyurethane adhesive is composed of 3.0 parts of the F-grade polyurethane adhesive component A and 1.5 parts of the F-grade polyurethane adhesive component B as a curing agent in a weight ratio;

[0072] The modified epoxy resin is a mixture of bisphenol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com