Less-resin mica tape used for high voltage motor and preparation method thereof

A technology of mica tape with less glue and high-voltage motor, which is applied in mica, chemical instruments and methods, lamination, etc., can solve the problems of no longer immersion, unusable mica tape with less glue, high glue content, etc., and achieve excellent electrical aging performance and Uniformity of electrical performance, high electrical strength, and the effect of reducing the size of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

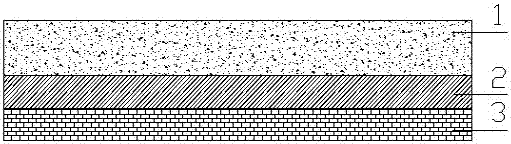

[0044] The present embodiment provides a kind of adhesive-less mica belt and its preparation method that are suitable for high-voltage motors, and its structure is as follows figure 1 Shown; In this mica tape, adhesive is solid bisphenol A type epoxy resin (softening point is 60-80 ℃); Mica paper layer 1 is made of cooked mica paper through calcining and chemical treatment, the thickness of cooked mica paper is 0.09mm, the penetration time is 41s, and the mass per unit area is 158g / m 2 (commercially purchased); the reinforcing material is electrical grade alkali-free glass fiber cloth, the thickness is 0.032mm, and the mass per unit area is 23.1g / m 2 ; The latent epoxy curing accelerator is zinc naphthenate.

[0045] The preparation method of the less rubber mica tape suitable for high-voltage motors is as follows:

[0046] (1), select cooked mica paper, adhesive and reinforcing material, the adhesive is solid bisphenol A epoxy resin (softening point is 60-80 ℃), and the rei...

Embodiment 2

[0055] The present embodiment provides a kind of adhesive-less mica belt and its preparation method that are suitable for high-voltage motors, and its structure is as follows figure 1 shown. In the mica tape, the adhesive is solid bisphenol A type epoxy resin (the softening point is 110-130°C); the mica paper layer 1 is composed of calcined and chemically treated cooked mica paper, the thickness of the cooked mica paper is 0.11mm, The penetration time is 43s, and the mass per unit area is 181g / m 2 (commercially purchased); the reinforcing material is electrical grade alkali-free glass fiber cloth, the thickness is 0.032mm, and the mass per unit area is 23.1g / m 2 ; The latent epoxy curing accelerator is zinc naphthenate.

[0056] The preparation method of the less rubber mica tape suitable for high-voltage motors is as follows:

[0057] (1), select cooked mica paper, adhesive and reinforcing material, the adhesive is solid bisphenol A epoxy resin (softening point is 110-130°...

Embodiment 3

[0066] The present embodiment provides a kind of adhesive-less mica belt and its preparation method that are suitable for high-voltage motors, and its structure is as follows figure 1 Shown; In this mica tape, adhesive is solid bisphenol F type epoxy resin (softening point is 110-130 ℃); Mica paper layer 1 is made of cooked mica paper through calcining and chemical treatment, and the thickness of cooked mica paper is 0.09mm, penetration time is 40s, mass per unit area is 162g / m 2 (commercially purchased); the reinforcing material is electrical grade alkali-free glass fiber cloth, the thickness is 0.032mm, and the mass per unit area is 23.1g / m 2 ; The latent epoxy curing accelerator is zinc isooctanoate.

[0067] The preparation method of the less rubber mica tape suitable for high-voltage motors is as follows:

[0068] (1), select cooked mica paper, adhesive and reinforcing material, the adhesive is solid bisphenol F epoxy resin (softening point is 110-130°C), and the reinfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com