Patents

Literature

92 results about "Electrical aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

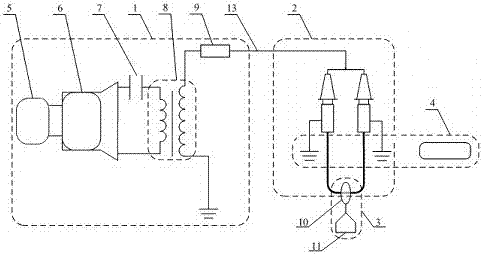

Oiled paper compound insulation electrical ageing test system

ActiveCN103954895AImplement overlay controlImprove usabilityTesting dielectric strengthCapacitanceCardboard

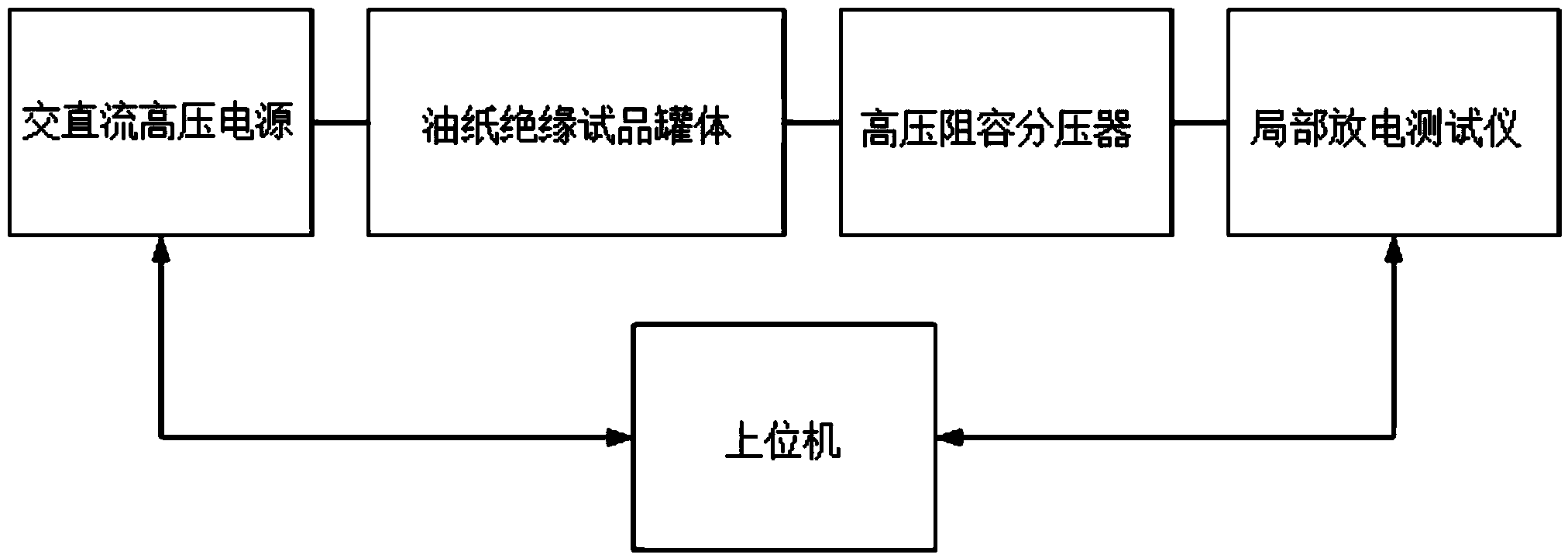

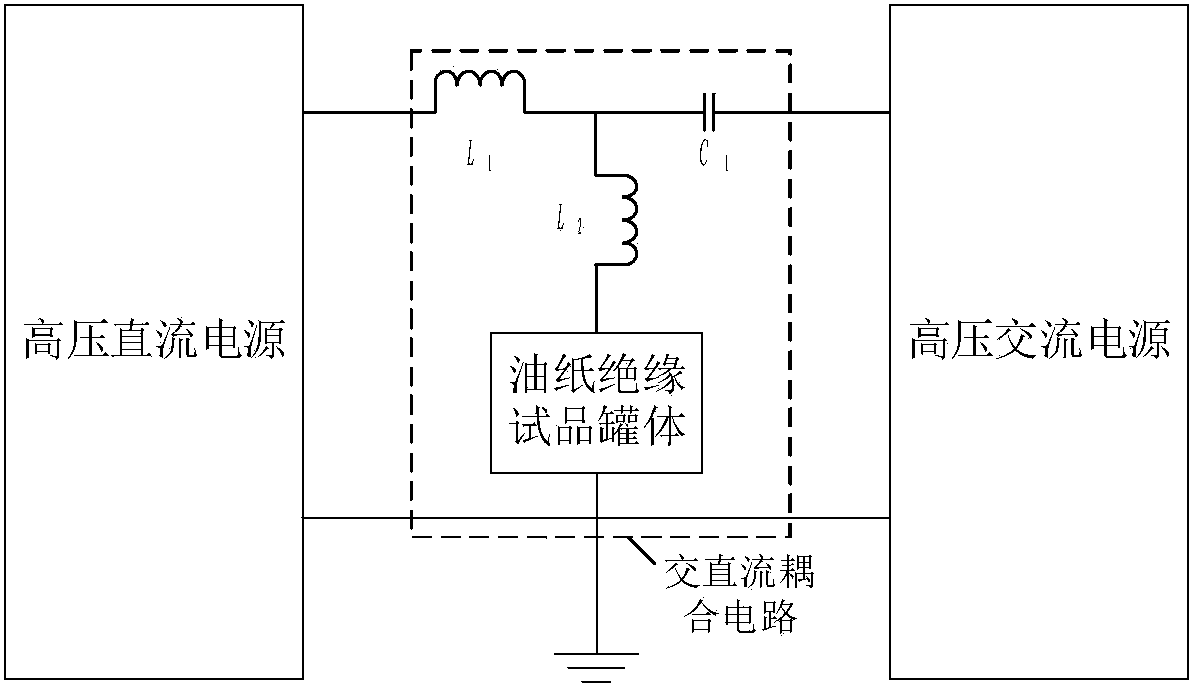

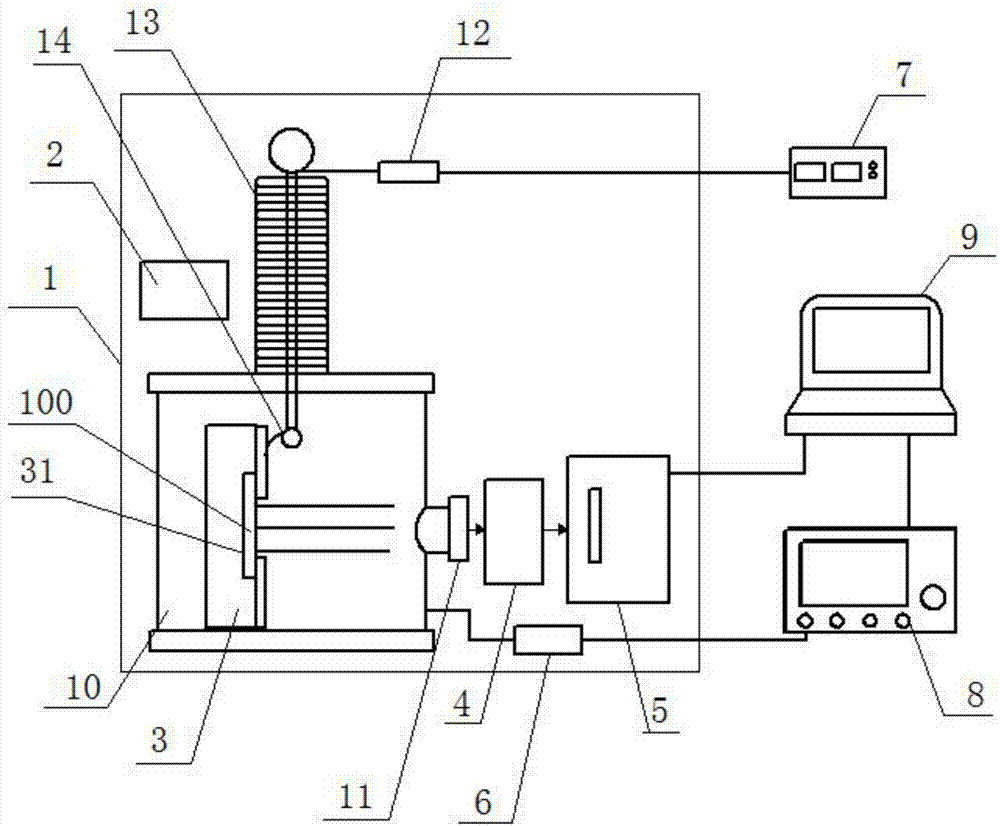

The invention discloses an oiled paper compound insulation electrical ageing test system which comprises an alternating current-direct current high voltage power supply, a high voltage capacitance-resistance divider, an oiled paper insulation sample tank, a partial discharge measuring instrument and an upper computer. The alternating current-direct current high voltage power supply is connected with the oiled paper insulation sample tank. The high voltage capacitance-resistance divider is connected with the oiled paper insulation sample tank. The partial discharge measuring instrument is connected with the oiled paper insulation sample tank, and collects partial discharge signals inside an oiled paper insulation sample. The upper computer is in two-way communication connection with the alternating current-direct current high voltage power supply and the partial discharge measuring instrument. According to the oiled paper compound insulation electrical ageing test system, alternating current-direct current compound voltage is adopted for oiled paper insulation, accurate and accelerated ageing is conducted on a solid insulation paper board, and an oiled paper insulation electrical ageing laboratory test is achieved.

Owner:STATE GRID CORP OF CHINA +3

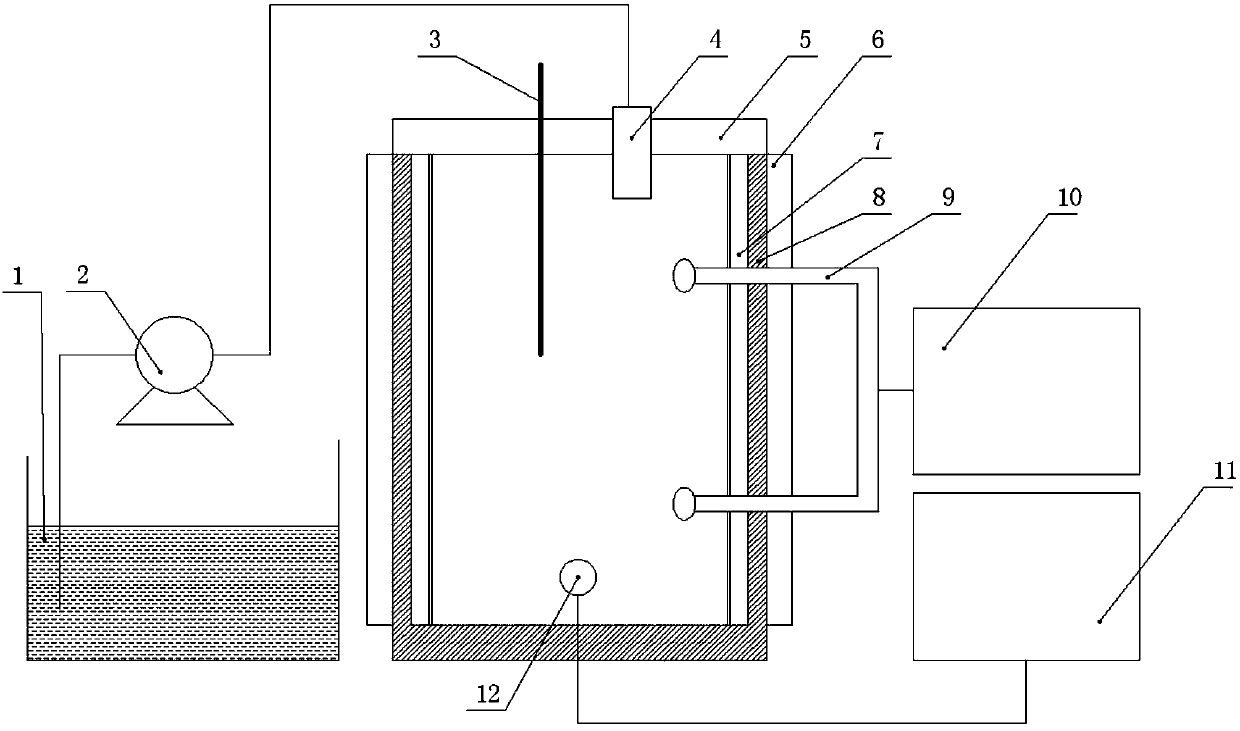

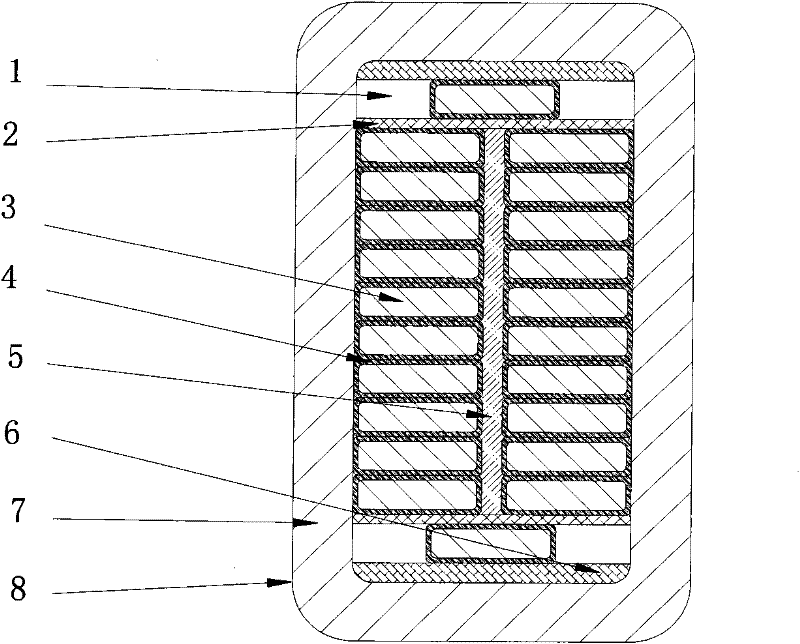

Oil paper insulation electric heating combined aging sealing system

InactiveCN105044569AGuaranteed non-proliferationEnsure safetyTesting dielectric strengthVacuum extractionSystem pressure

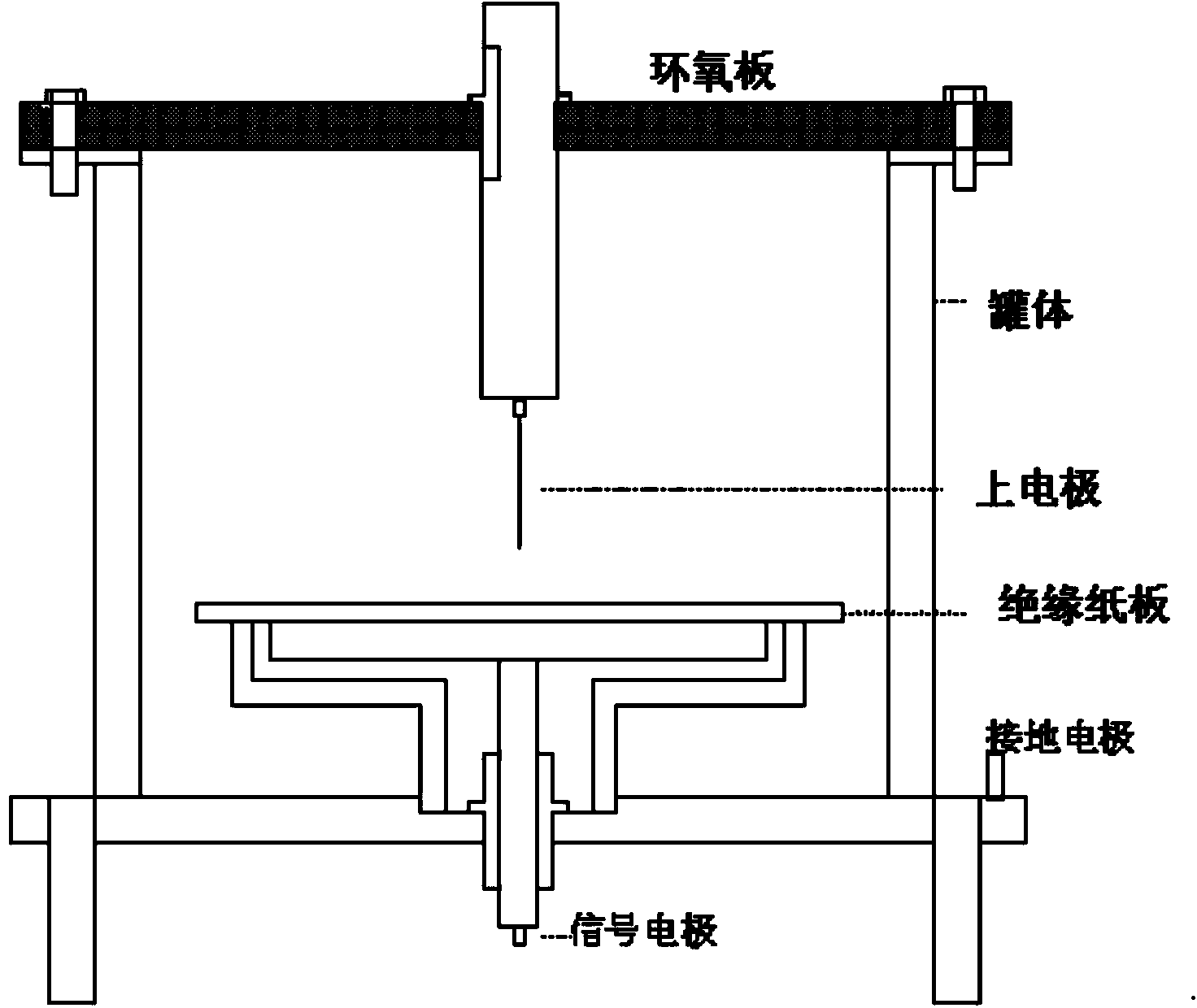

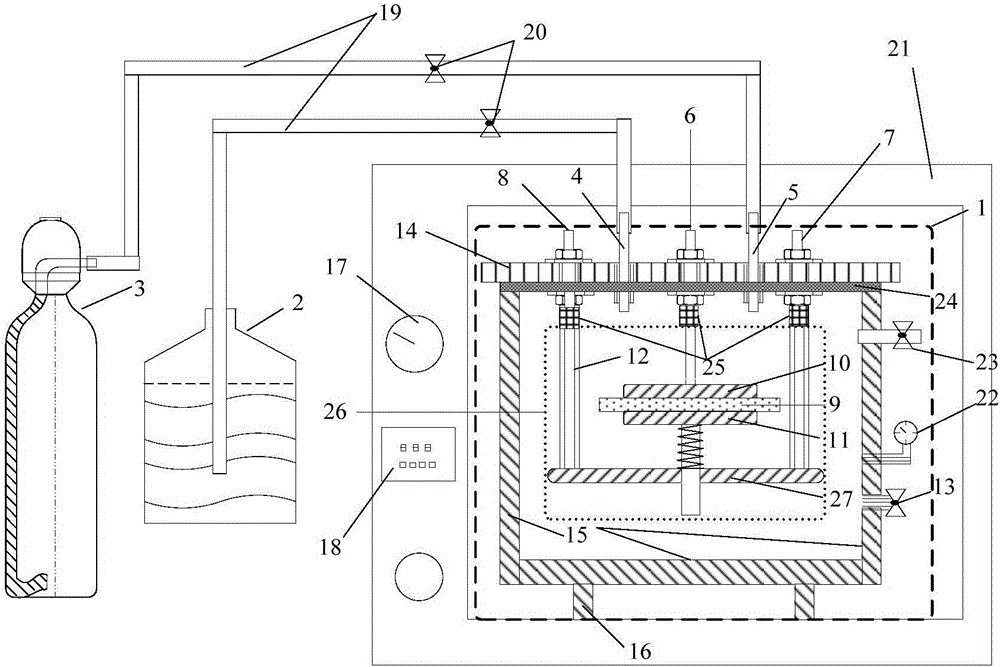

The invention discloses an oil paper insulation electric heating combined aging sealing system, is used for a strict oil paper insulation electric heating combined aging experiment, and includes an electrical aging sealing system, a thermal aging sealing system, an oil storage tank and a nitrogen gas cylinder. The thermal aging sealing system includes a sealing cavity capable of being opened, and a thermal aging system pressure gauge and a temperature control meter are arranged on a side wall of the sealing cavity; and the electrical aging sealing system is arranged in the sealing cavity of the thermal aging sealing system, and includes a cavity with an upward opening, the top of the cavity is sealed through an epoxy sealing plate, an oil filling port and an inflation inlet are arranged on the epoxy sealing plate, an electrical aging system pressure gauge and a vacuum extraction opening are arranged on a cavity wall of the cavity, the cavity is internally provided with an electrical aging electrode used for an experiment, and a high voltage end and a grounding end of the electrical aging electrode are led out through the epoxy sealing plate; and the oil storage tank and the nitrogen gas cylinder are connected to the oil filling port and the inflation inlet respectively through high temperature pipes.

Owner:XI AN JIAOTONG UNIV

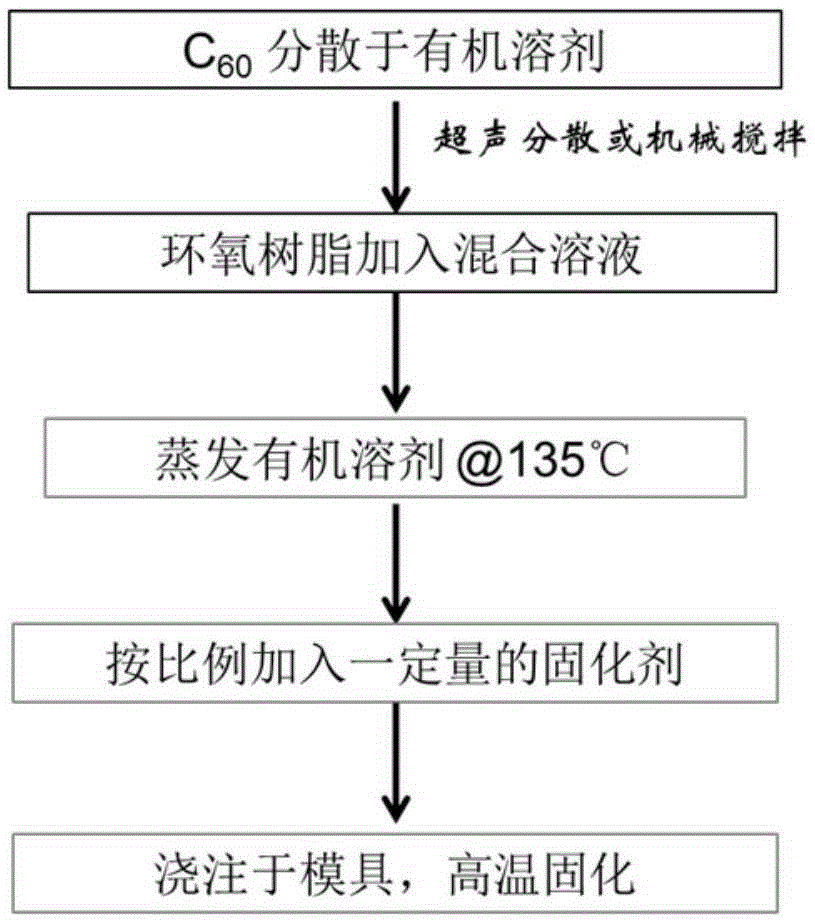

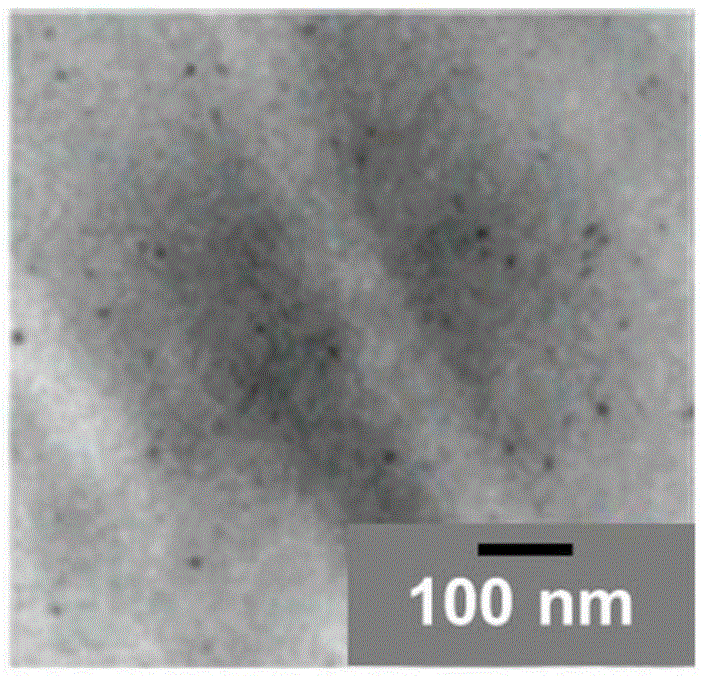

Epoxy resin fullerene composite material and preparation method thereof

The invention relates to an epoxy resin fullerene composite material and a preparation method thereof. The materials of the epoxy resin fullerene composite material include fullerene, epoxy resin and a curing agent. The epoxy resin fullerene composite material has the advantages of remarkably increasing the volume resistivity and breakdown voltage of a polymer matrix, inhibiting the injection of space charges, decreasing dielectric constant and loss, and improving the electrical aging property of the epoxy resin, and moreover, the mechanical strength and toughness of the epoxy resin are also increased to a certain degree.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

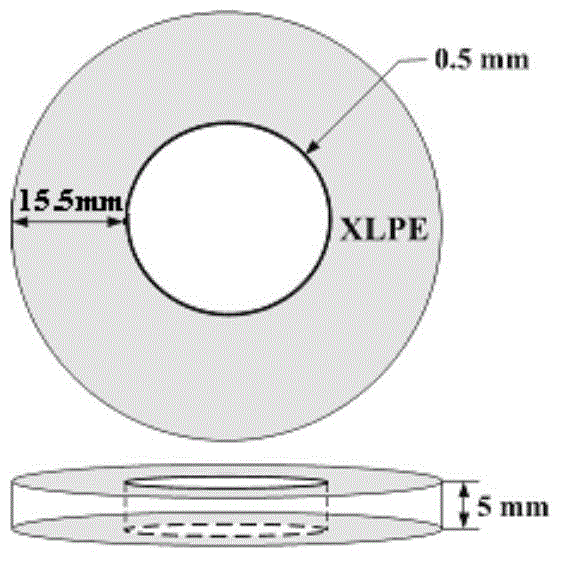

Method for determining cross-linked polyethylene insulation voltage tolerance index of alternating-current cable

InactiveCN103983902ASmall dispersionHigh precisionTesting dielectric strengthDispersityCross-linked polyethylene

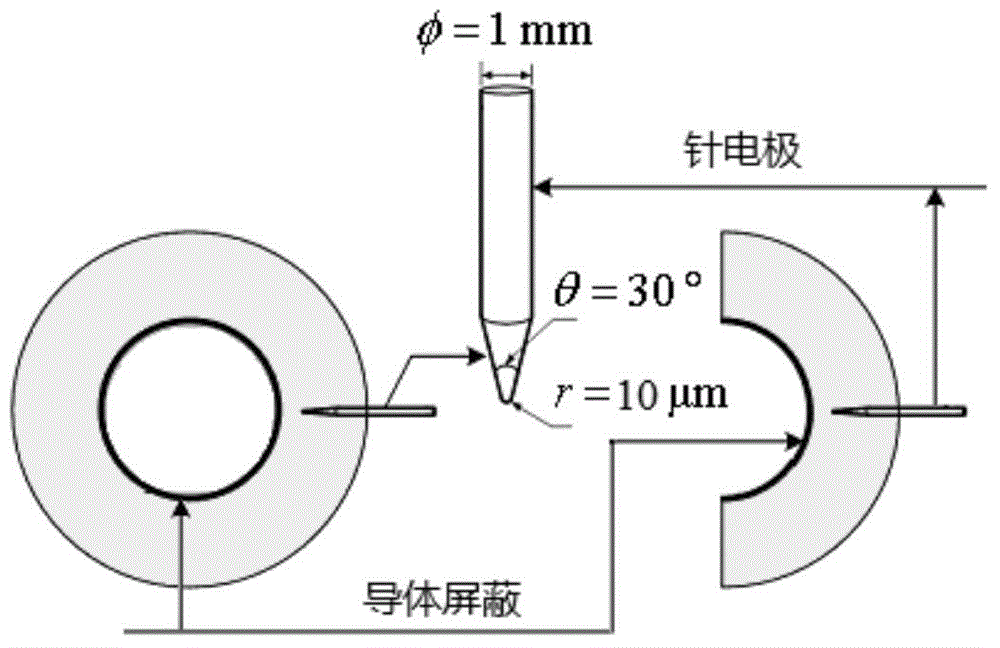

A method for determining the cross-linked polyethylene insulation voltage tolerance index of an alternating-current cable comprises the steps of preparing a cross-linked polyethylene cable insulation test block, preparing and pre-processing a pin electrode, manufacturing a sample for an electrical tree test, conducting an electrical tree triggering test, processing data, obtaining the electrical tree triggering time and voltage in a voltage stepping-up test, conducting a constant-voltage test under the same voltage, measuring the electrical tree triggering time, and obtaining the cross-linked polyethylene insulation voltage tolerance index of the alternating-current cable through calculation. The method overcomes the defects of a traditional breakdown type accelerating electrical aging test that requirements for equipment are high, operation is difficult, a large amount of time and labor is needed, and the dispersity of design parameters is high, the measured cross-linked polyethylene insulation voltage tolerance index of the high-voltage alternating-current cable is stable, reliable and low in dispersity, and short-time and long-term voltage resistance of cable insulation can be reflected truly and effectively. The method can be adopted by both insulation design of new cables and remaining life evaluation of operating cables and provides a powerful guarantee for long-term stable operation of cables.

Owner:XI AN JIAOTONG UNIV

Manufacturing process for manufacturing motor stator coil through vacuum-pressure paint dipping

ActiveCN103475174ASolve the problem of insufficient structureSolve technical problems of performanceApplying solid insulationThermodynamicsVacuum pressure

The invention relates to a manufacturing process for manufacturing a motor stator coil through vacuum-pressure paint dipping. The process includes the following steps: after an main insulating layer of a motor bearing-type coil is bandaged with a little-glue mica tape, carrying out a vacuum-pressure paint dipping process on the motor stator coil; after inter-mica air gaps are filled fully with insulating paint in advance, carrying out heat moulding curing at a temperature of 180 DEG C to 200 DEG C and then inserting the coil into a motor stator groove; and after connection, carrying out second heat moulding curing at a temperature of 155 DEG C for no shorter than 10 hours. The high-voltage motor stator coil manufactured through the vacuum-pressure paint dipping is structurally compact in insulating layer, zero in air pocket, low in dielectric loss increment, and low in partial discharge capacity and high in dielectric breakdown field intensity. Insulating performance, mechanical performance, heat resistance performance and electrical aging resistance performance of the coil are all improved significantly so that a coil quality is improved to a higher level.

Owner:HANGZHOU FUYANG HYDROPOWER EQUIP INSPECTION

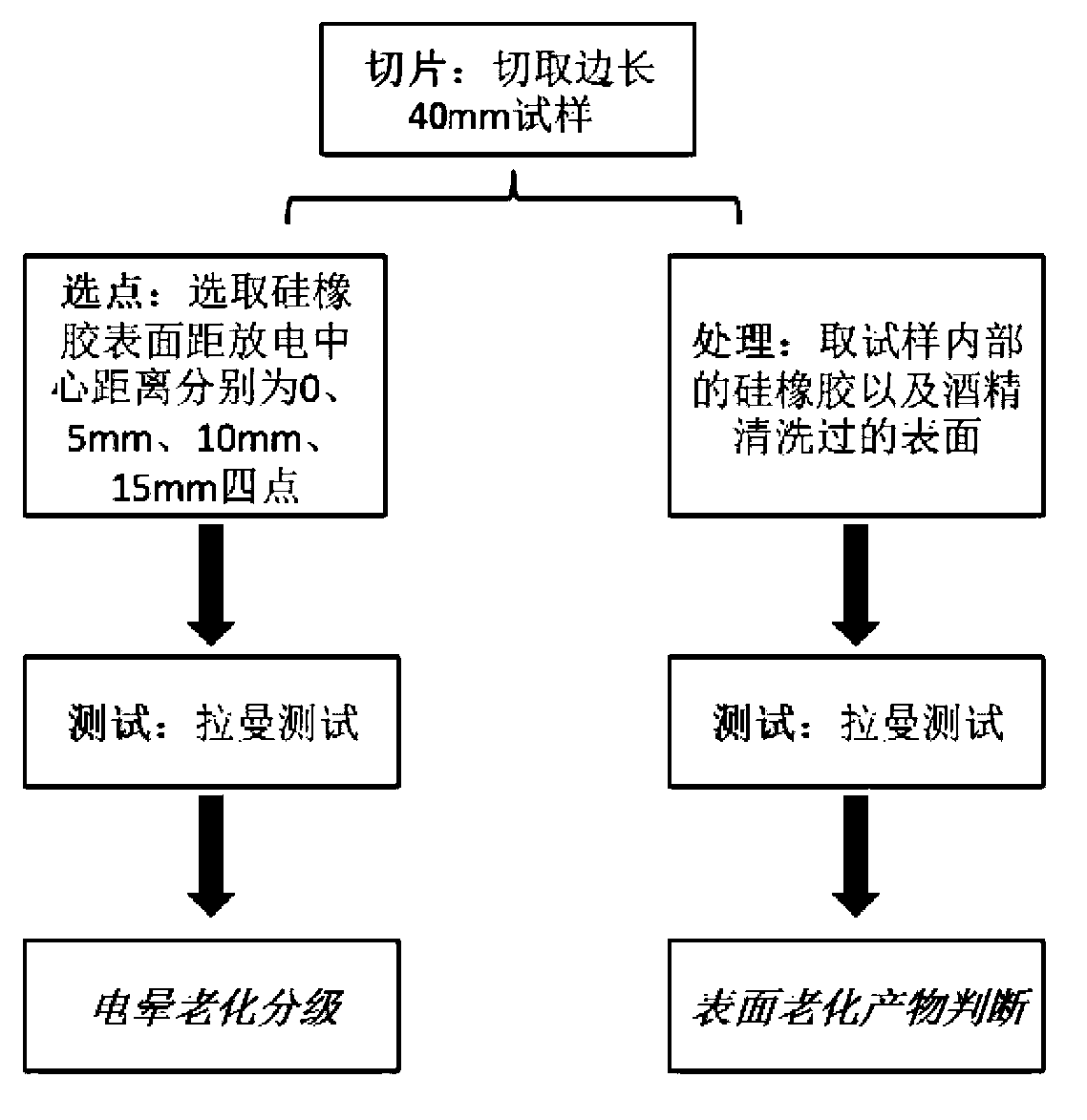

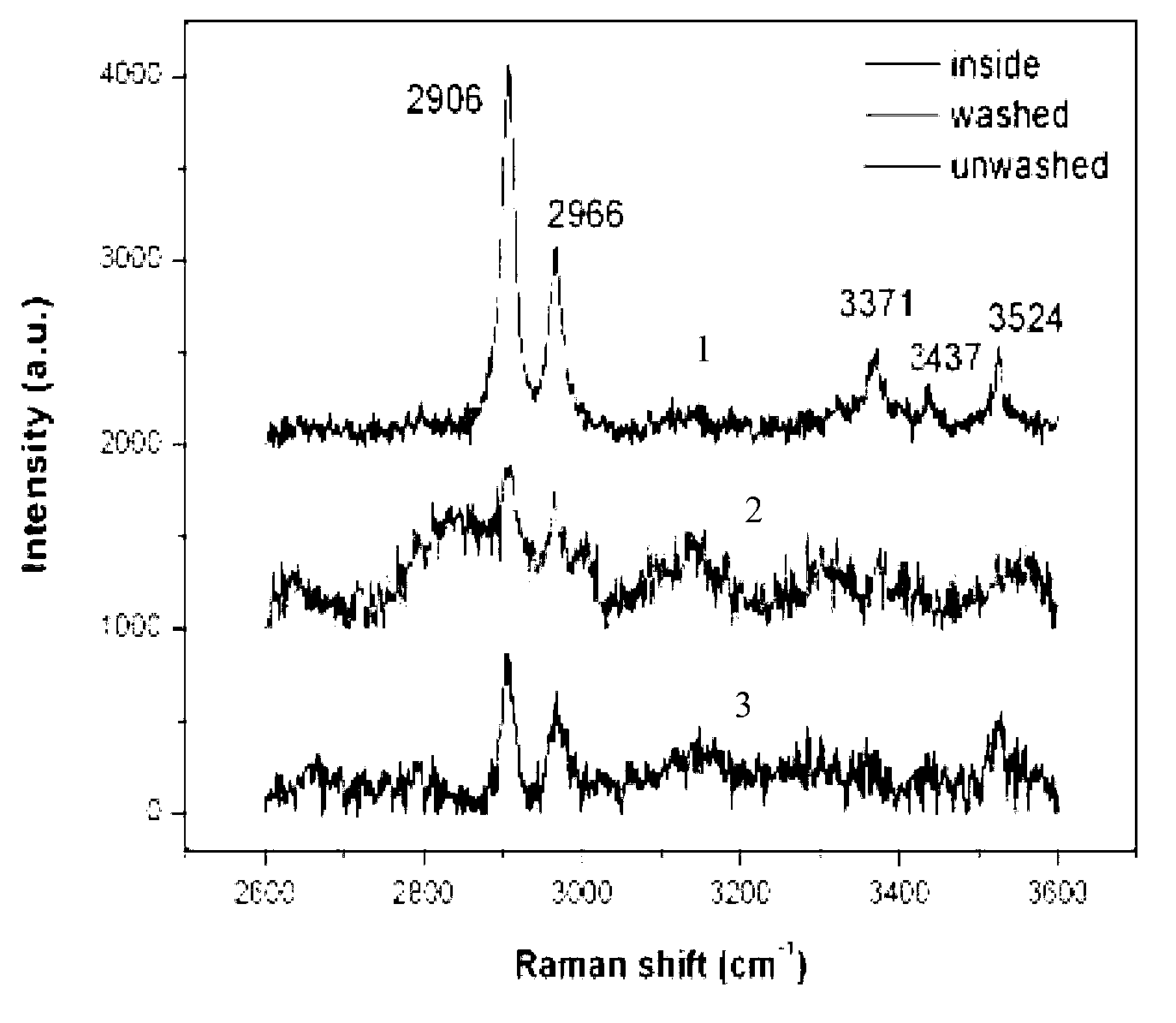

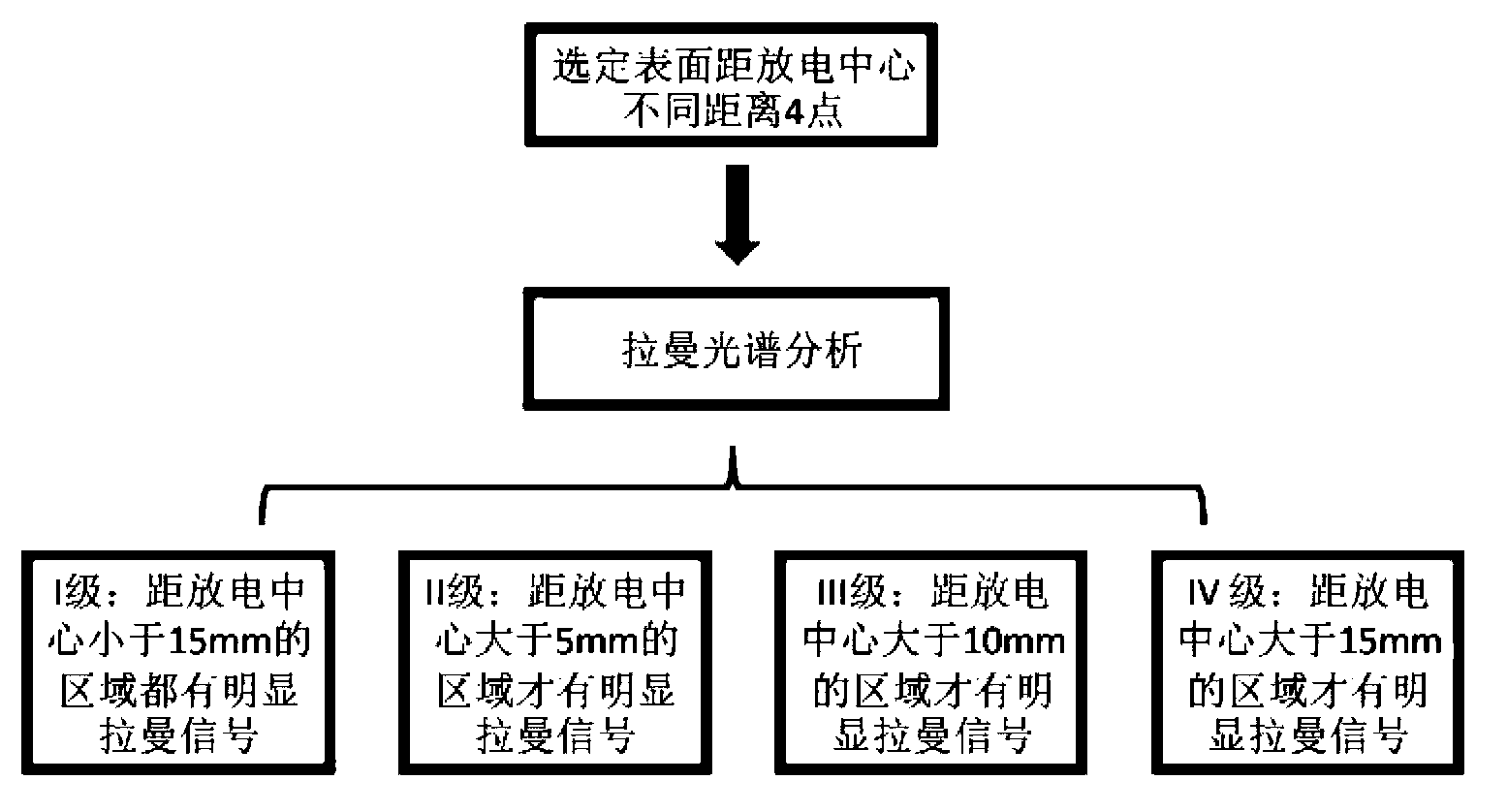

Method for detecting electrical aging of silicone rubber composite insulator

ActiveCN103267937AFew samplesShort test timeTesting dielectric strengthRaman scatteringElectricityComposite insulators

The invention discloses a method for detecting electrical aging of a silicone rubber composite insulator. The method for detecting the electrical aging of the silicone rubber composite insulator includes a first step of taking a high-voltage-side shed of the silicone rubber composite insulator of a running line as a sample, and a second step of collecting micro-Raman spectra on the surface of the sample, and judging the degree of the electrical aging of the sample according to the fact that whether an obvious Raman peak exists at the position of 2906cm-1, 2966cm-1, 3371cm-1, 3437cm-1, 3524cm-1. The method for detecting the electrical aging of the silicone rubber composite insulator has the advantages of being less in sample, short in detection time and easy and convenient to conduct. Detection can be finished without the need of complicated treatment of the sample. The Raman peak is used as a tool of analysis of the electrical aging of the silicone rubber composite insulator, so that subjective factors such as a man-made factor and an environment factor are eliminated and the accuracy is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

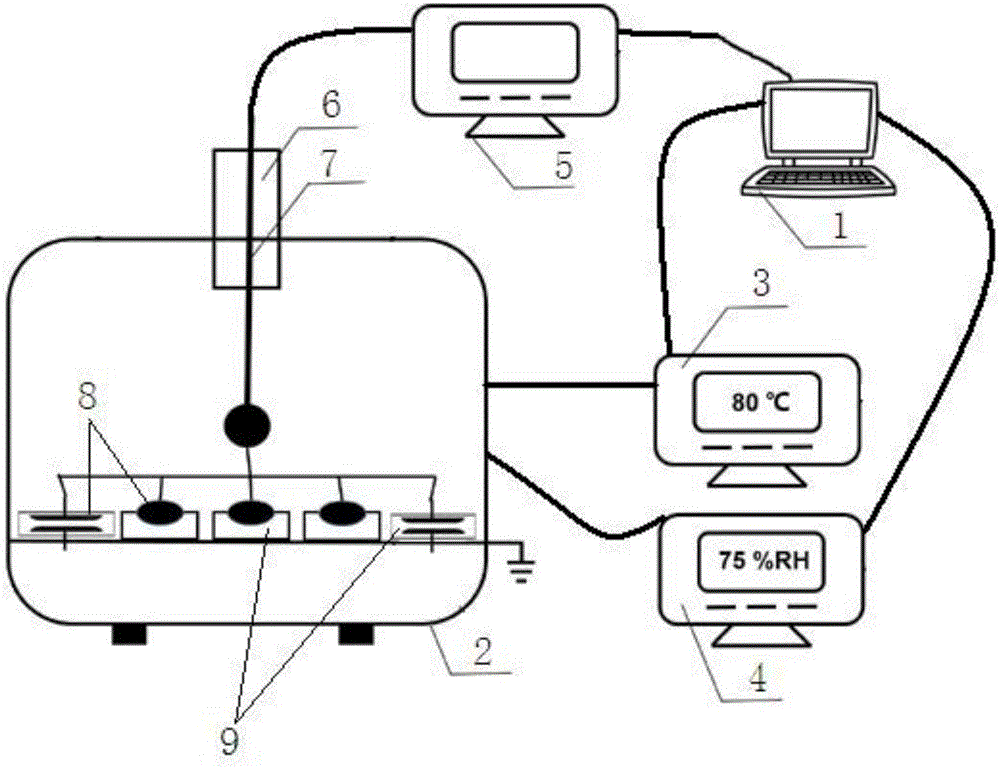

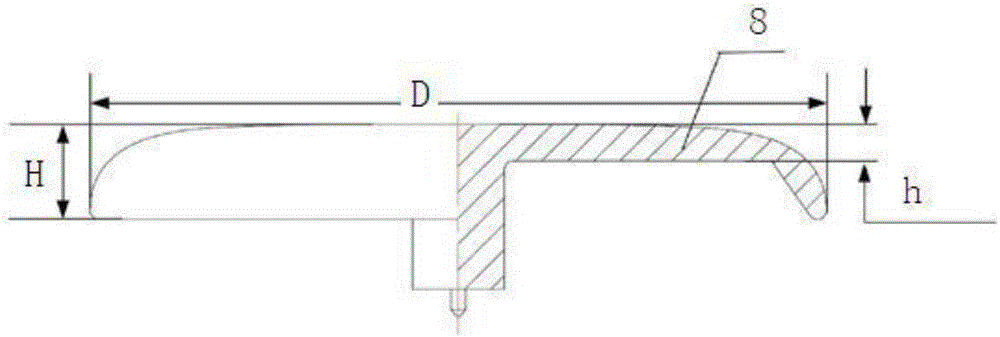

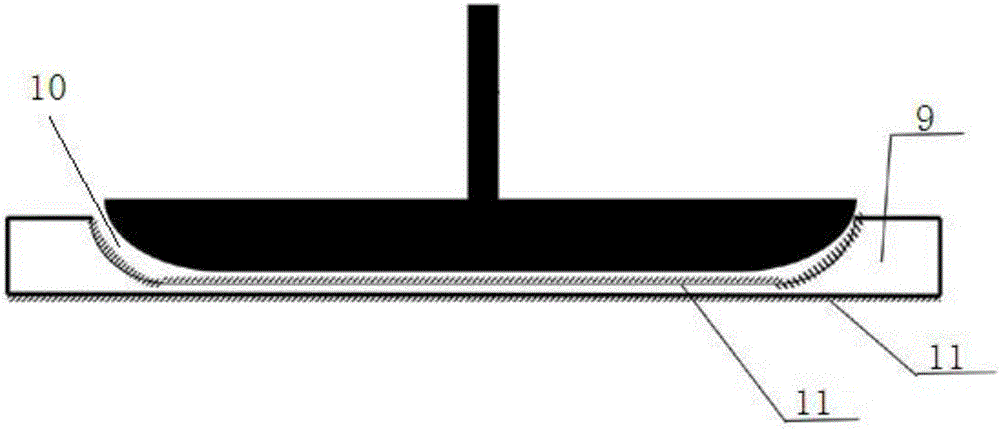

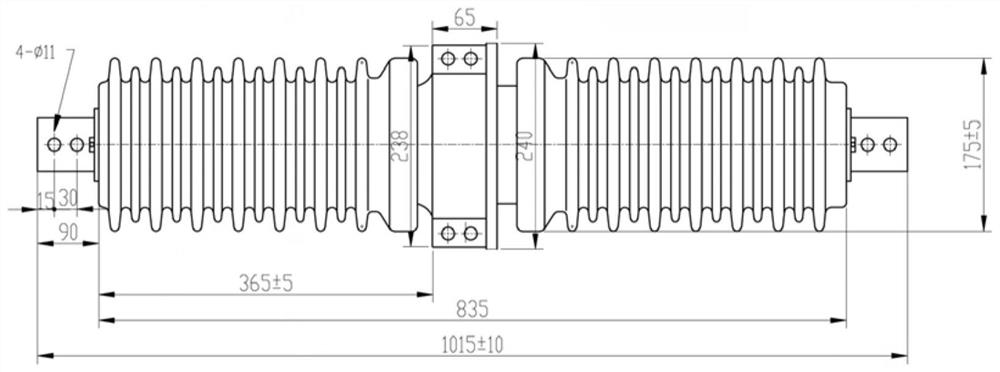

Insulating material electrical aging performance evaluation device and detection method

ActiveCN106771894ACharacterization of Electrical Aging PropertiesIncrease credibilityTesting dielectric strengthTemperature controlElectricity

The invention discloses an insulating material electrical aging performance evaluation device which comprises a control device, a voltage control device, a temperature control device, a humidity control device and a sample chamber equipped with a number of sample tools, wherein the voltage control device, the temperature control device and the humidity control device are connected with a high voltage introduction unit. The high voltage introduction unit comprises a high voltage bushing and a high voltage lead. The high voltage bushing is in sealed connection with the sample chamber. The high voltage lead successively passes through the high voltage bushing, and then is connected with electrodes which are connected with the high voltage ends of the sample tools. The control device adjusts the temperature and humidity in the sample chamber and the voltage aging samples of the sample tools through the voltage control device, the temperature control device and the humidity control device. The insulating material electrical aging performance evaluation device provided by the invention has the advantages of small space occupation, simple structure, convenient use, wide application range and high practicability. The test device and the detection method can effectively evaluate the electrical aging performance of an insulating material in working condition in actual operation, and provide an important reference for the screening of insulating materials.

Owner:NANJING NARI GROUP CORP +3

Multi-factor phase color tube aging simulation experiment method

InactiveCN104198855AImprove reliabilityShorten aging timeWeather/light/corrosion resistanceElectrical testingEtchingTransformer

The invention relates to a multi-factor phase color tube aging simulation experiment method. The multi-factor phase color tube aging simulation experiment method includes the steps that step 1, an experiment box which is provided with a heating system, a chemical etching system, a radiation system, a high voltage electrode and a data detection system is prepared; step 2, a cylindrical accessory phase color tube is placed in an inner chamber of a box body; step 3, the temperature of the inner chamber of the box body is within the range of 25 to 2500 DEG C and the humidity of the inner chamber of the box body is within the range of 0 to 10%; step 4, the chemical etching liquid is injected into the inner chamber of the box body through the chemical etching system; step 5, the 2 to 20 kV alternating current voltage is switched into the inner chamber of the box body through the high voltage electrode; step 6, the radiation system is opened in the inner chamber of the box body to form a multi-factor simulation environment. According to the multi-factor phase color tube aging simulation experiment method, multiple factors such as the chemical etching, the electricity, the heat and the ultraviolet and the combined action which cause the aging of the phase color tube are effectively evaluated and accordingly the reliability of experiment data is improved and meanwhile the aging time is effectively shortened and a simulation device is close to the actual operation situation of a transformer in comparison with a single-factor heat aging or electrical aging method and device.

Owner:STATE GRID CORP OF CHINA +1

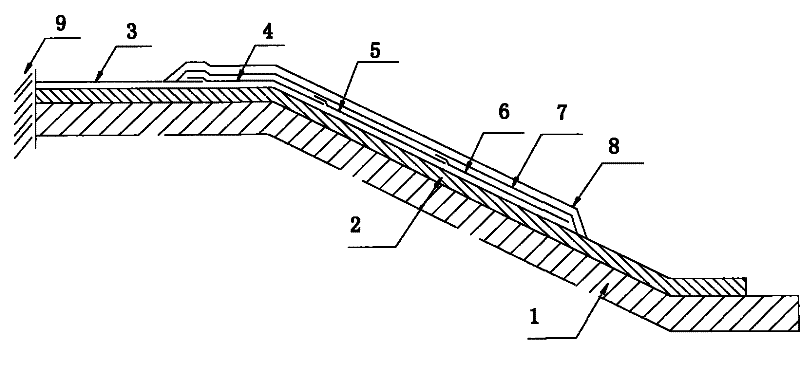

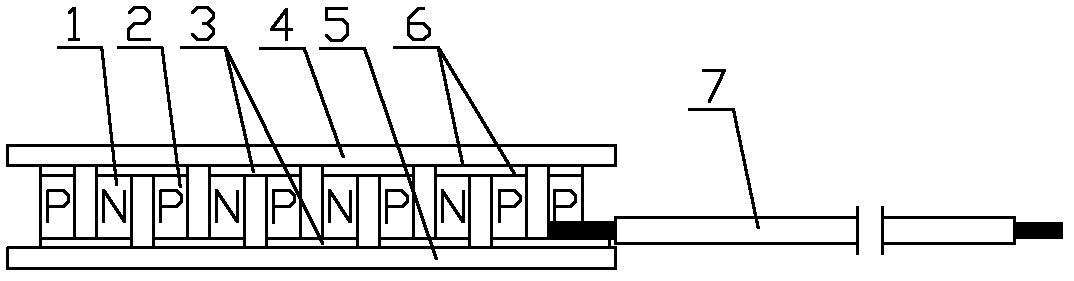

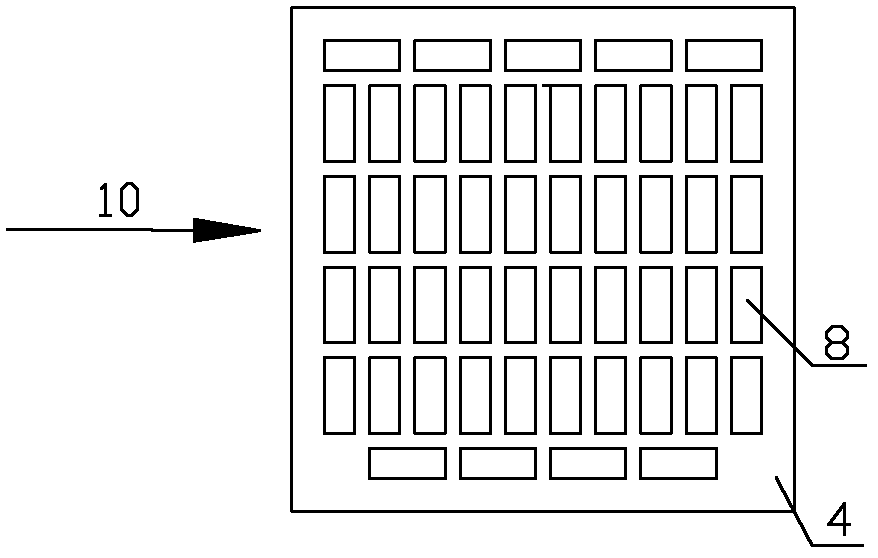

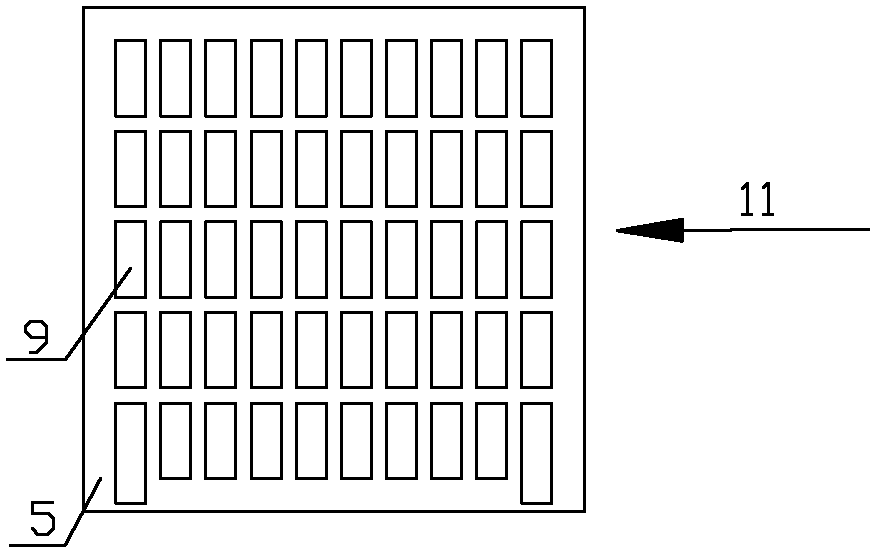

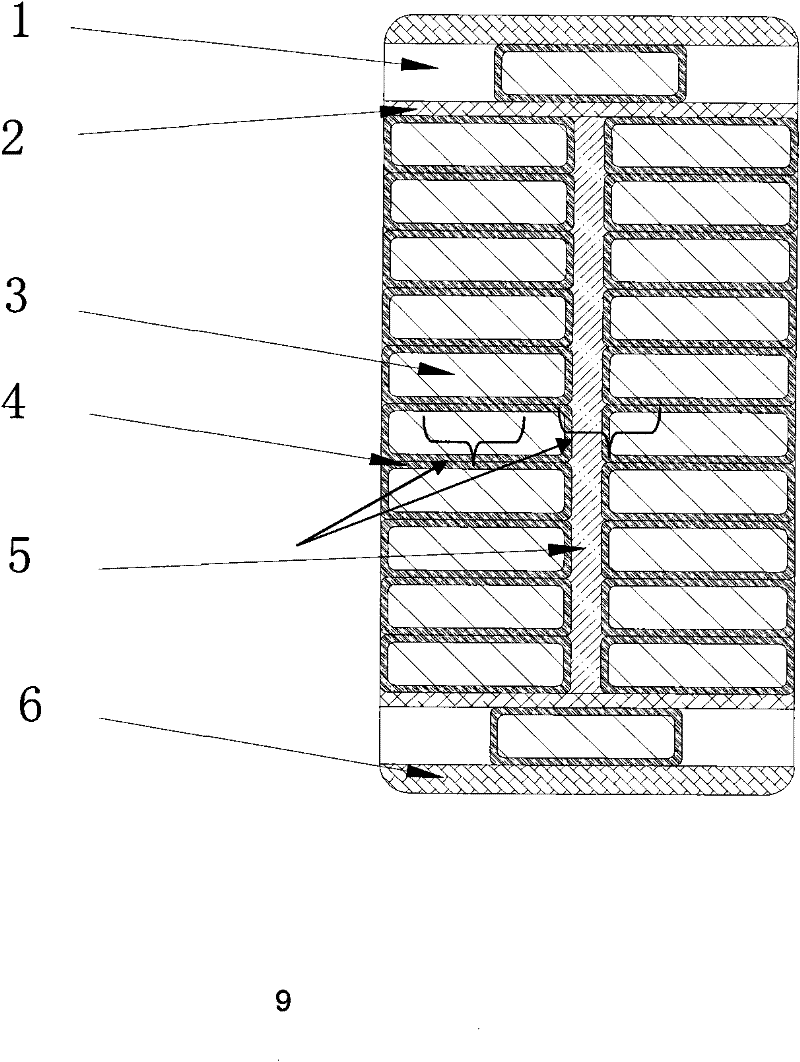

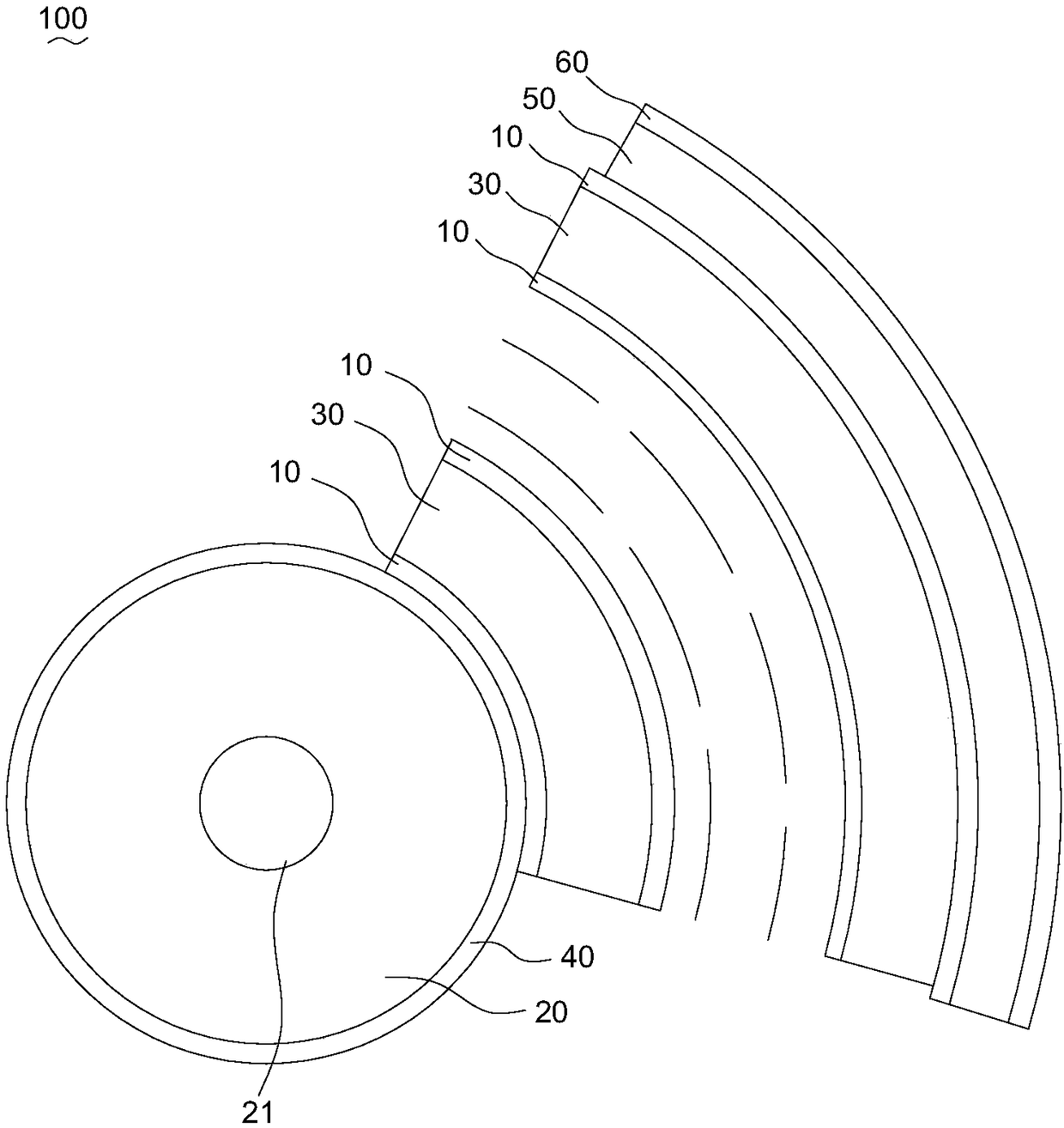

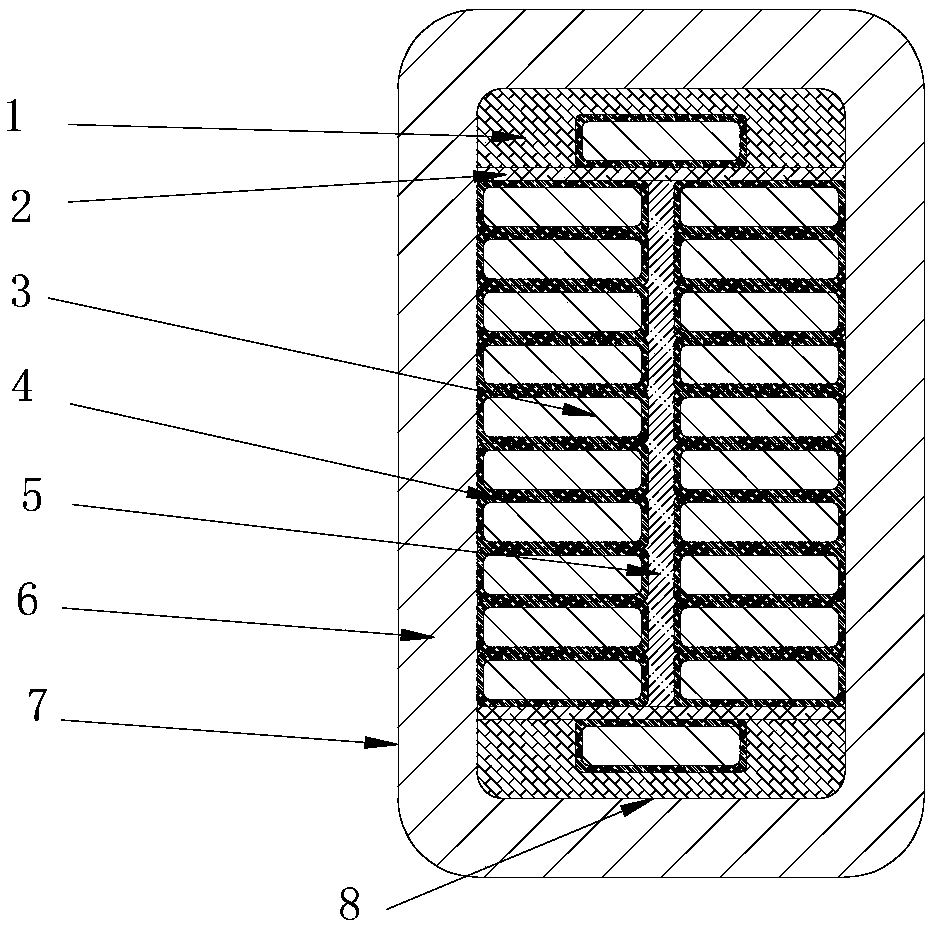

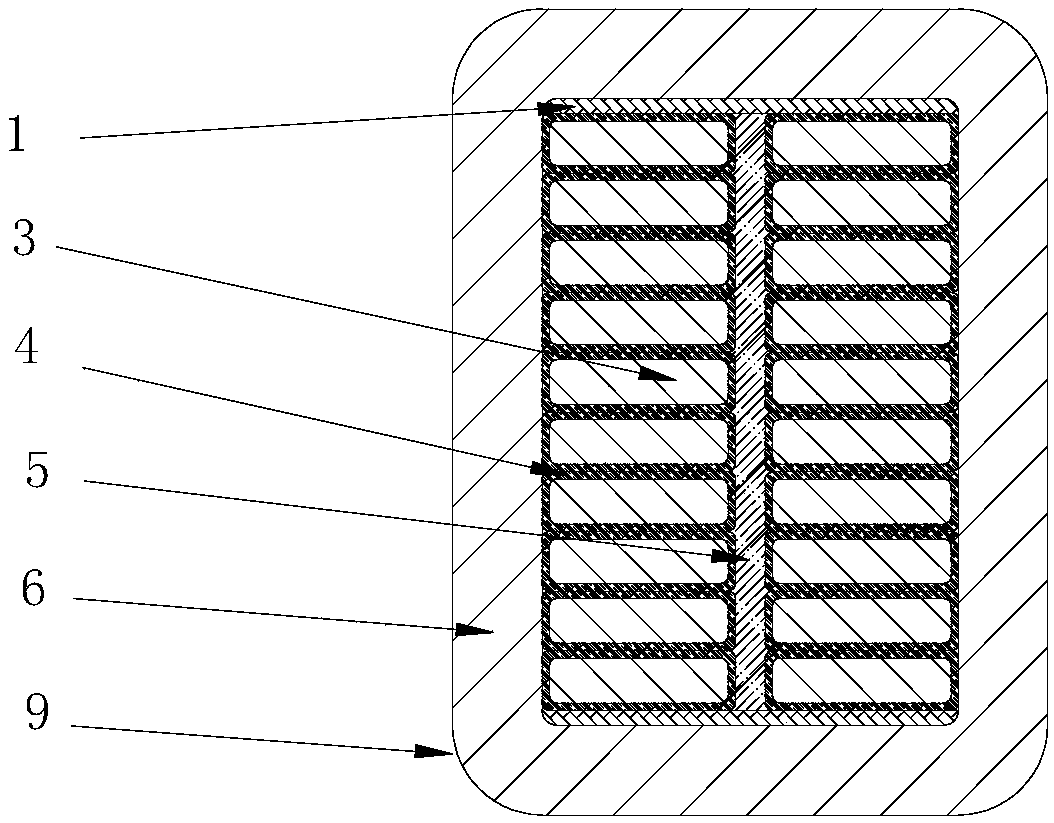

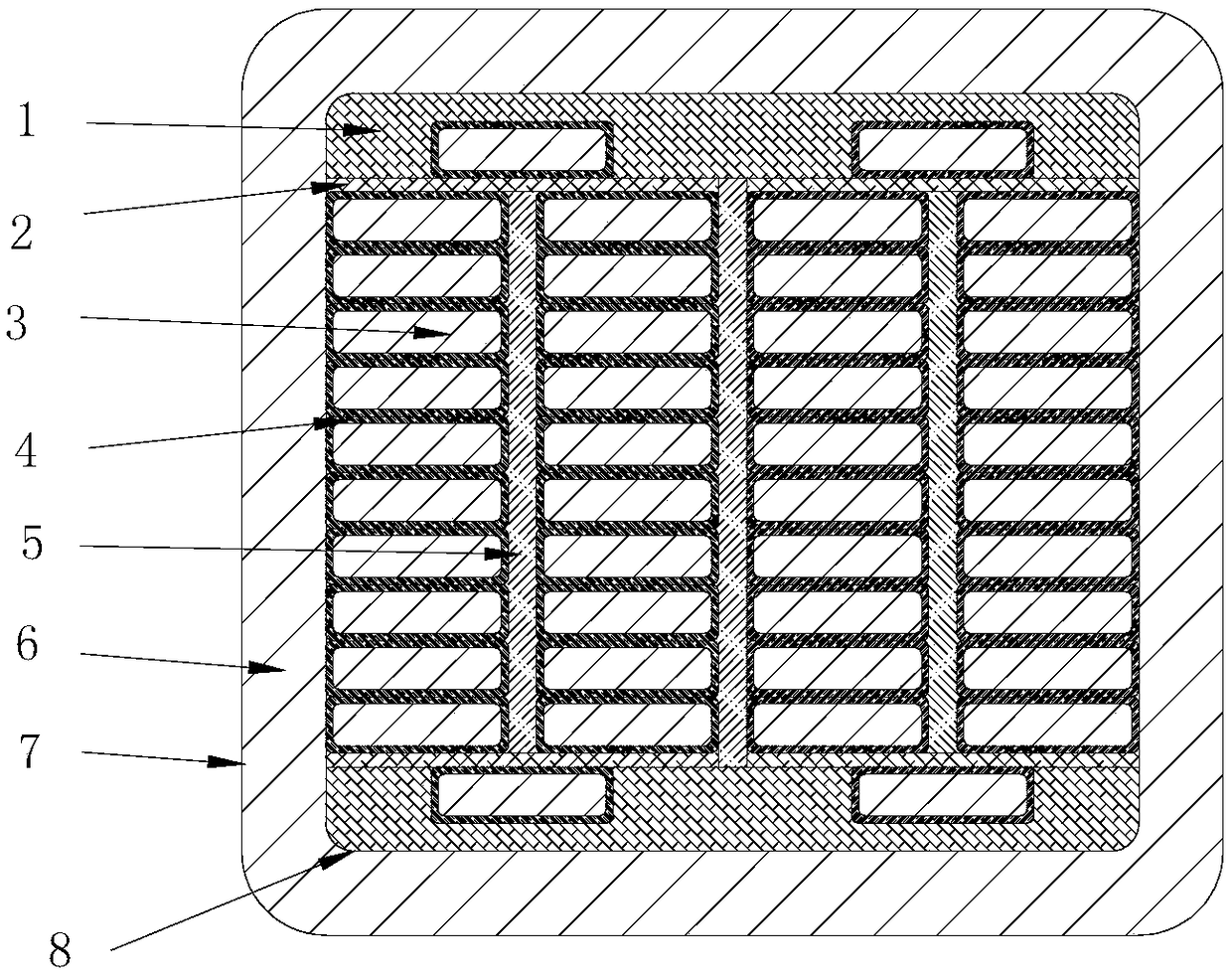

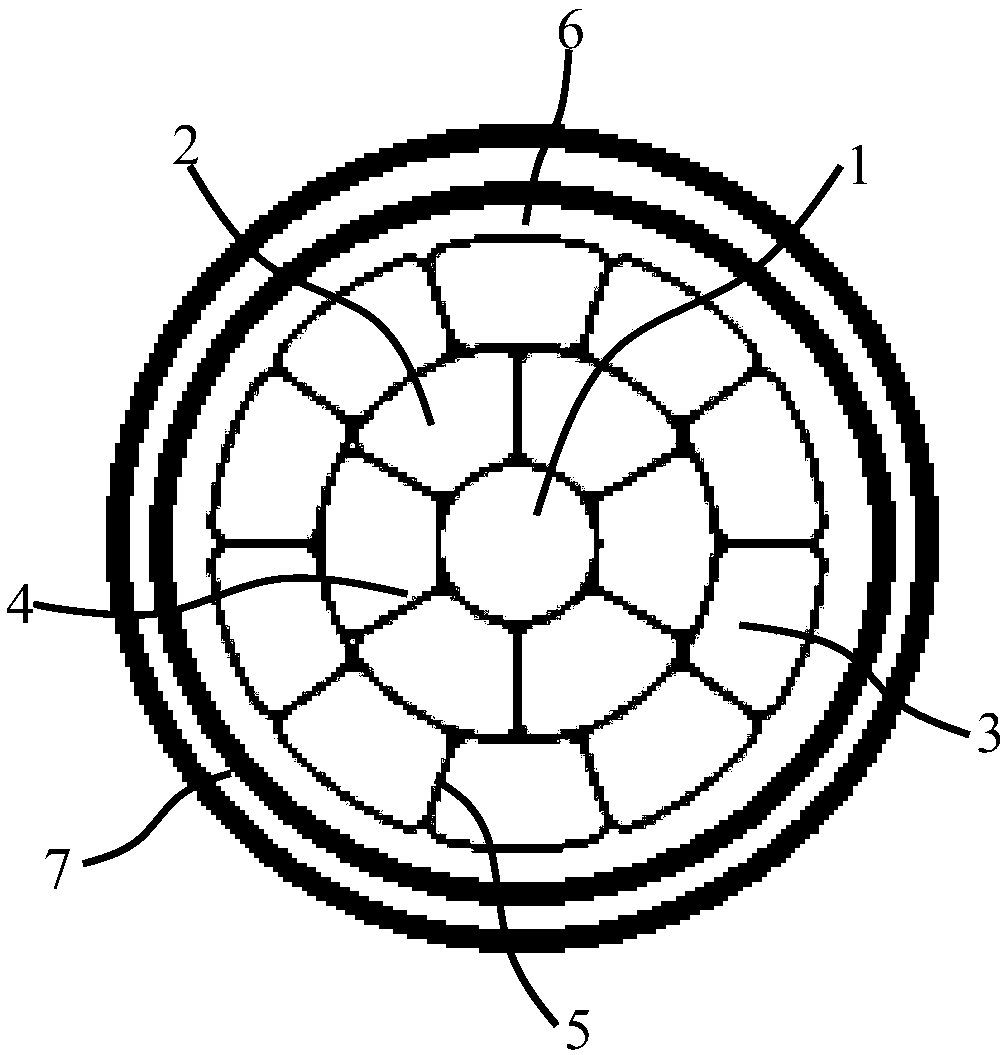

Preparation method for realizing one-time dip forming of main insulation and anticorona layer of stator coil of large-scale high voltage motor

InactiveCN102447361AImprove breathabilityHigh voltageManufacturing dynamo-electric machinesHigh resistanceCooking & baking

The invention provides a preparation method for realizing one-time dip forming of a main insulation and anticorona layer of a stator coil of a large-scale high voltage motor, aiming at solving the problem of the one-time dip forming of the main insulation and anticorona layer of a VPI (vacuum pressure impregnation) stator coil bar. The preparation method comprises the following steps of: 1) gluing a plurality of layers of a stator conductor 1 with a mica tape 2; 2) respectively wrapping a low resistance band 3, a middle resistance band 4, a middle-high resistance band 5 and a high resistance band 6 at a low resistance section, a middle resistance section, a middle-high resistance section and a high resistance section of a stator coil in a half lap winding manner; 3) respectively wrapping an additional insulation layer 7 on the outer surfaces of the middle resistance band, the middle-high resistance band and the high resistance band in the half lap winding manner; 4) then respectively wrapping a high resistance band 8 outside the additional insulation layers 7 in the half lap winding manner; 5) wrapping a demoulding band provided with holes on the surface of the whole stator coil; and 6) placing the stator coil into a VPI paint tank, mounting the stator coil into a mould after the stator coil is dipped by paint, placing the mould into a baking oven, and carrying out hot-pressing curing and moulding, thus the finished product VPI stator coil is obtained. Critical coronal voltage of the stator coil of a generator is more than 2UN, UN is rated voltage, flashover breakdown voltage is more than 2UN, and electrical aging life is more than 1500 hours.

Owner:HARBIN ELECTRIC MASCH CO LTD +1

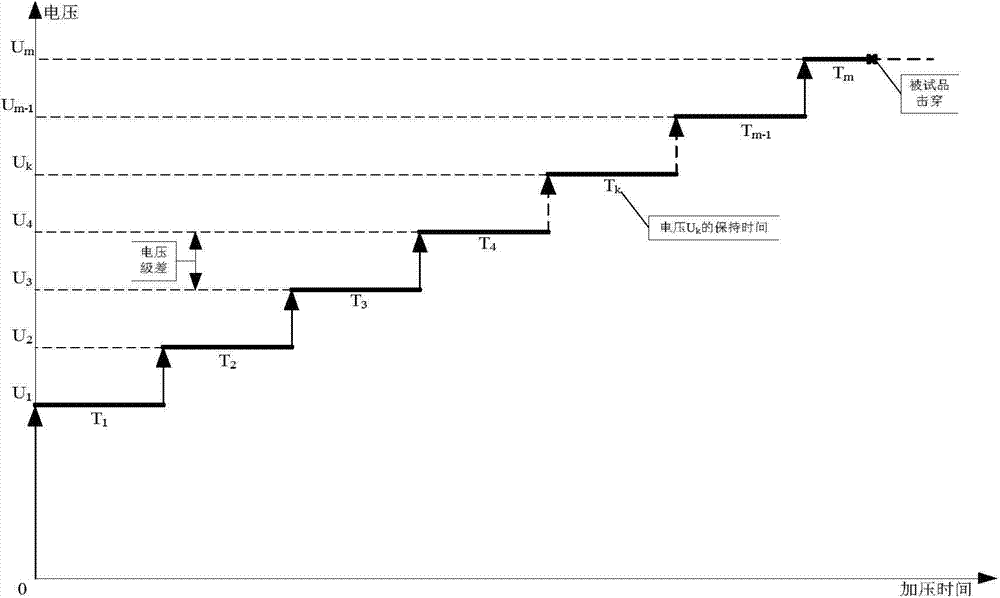

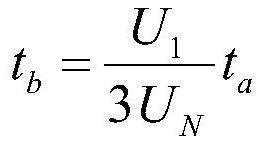

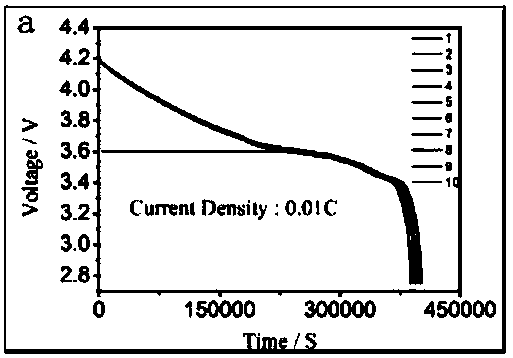

Method for solving solid-insulator electrical aging life

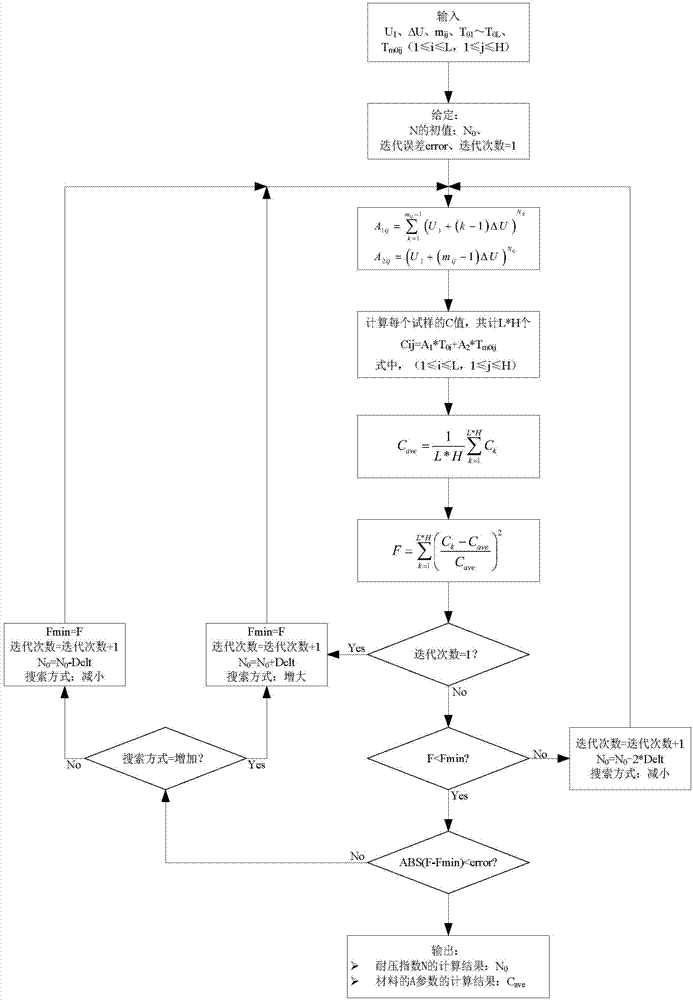

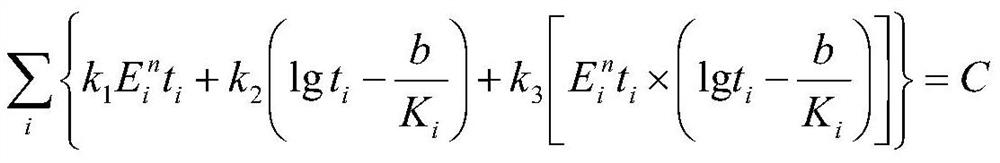

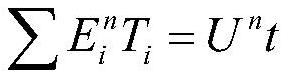

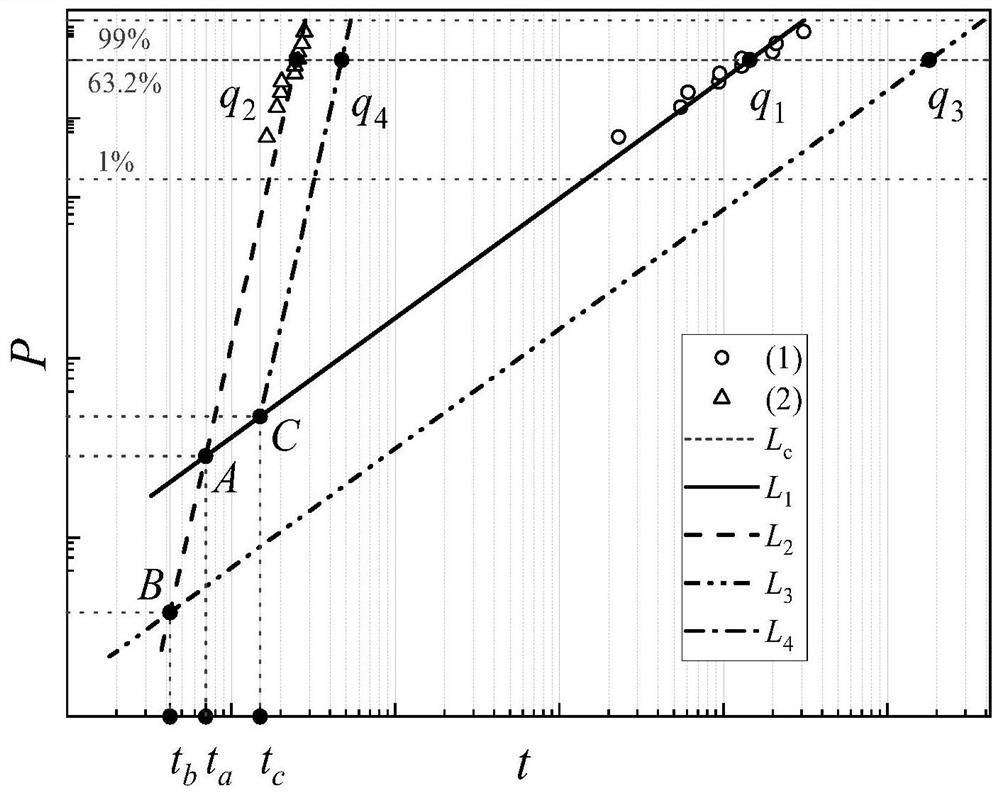

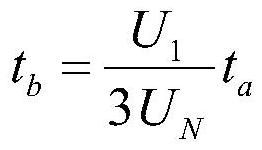

ActiveCN104764949AThe method of N value is simpleIntuitive physicsElectrical testingSpecial data processing applicationsElectricityEngineering

The invention discloses a method for solving the solid-insulator electrical aging life. The method includes the steps of S1, assuming that the solid-insulator electrical aging life obeys the inverse power rules (1) and (2) (please see the specification); S2, carrying out a solid-insulator acceleration electrical aging test with a step-by-step boosting method, wherein as for different voltages Uk and voltage keeping times Tk, the value of the following equation (3) (please see the specification) keeps unchanged; when the material accelerated life test is carried out with the step-by-step boosting method, the Tks in the equation (3) are the same and are assumed to be T0s, and the equation (3) becomes the equation (4) (please the specification); when the test is carried out, the multiple different T0s are selected for testing, and testing of multiple samples is carried out under each T0; multiple sets of known T0s, multiple sets of known Tms, multiple sets of Uks and multiple sets of Ums are obtained after the test is completed; S3, processing the test data with the maximum likelihood method; S4, calculating the insulation life L of a solid insulator under E according to the equation (1) or the equation (2). The method is simple, convenient and rapid, and the physical sense and the mathematical sense are visual.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Preparation method of thermoelectric refrigerator for high orbit space

InactiveCN102425879AStrong impact resistanceStrong vibration performanceMachines using electric/magnetic effectsFailure rateThermoelectric materials

The invention relates to a preparation method of a thermoelectric refrigerator for high orbit space; the preparation method comprises the following steps of: preparing a thermoelectric material sheet, a thermoelectric element, a metallization pattern and a flow deflector, integrally welding, grinding, carrying out ultrasonic cleaning, welding outgoing lines, and carrying out temperature and mechanics aging test of 'electrical aging and temperature cycle as well as variable frequency vibration'; the preparation method is characterized in that two layers of nickel are respectively plated on two end surfaces of the thermoelectric material sheet; a layer of nickel is plated on the metallization pattern; and a layer of nickel and a layer of tin are plated on exposed parts of the flow deflector through barrel plating. Through nickel plating of the thermoelectric material sheet and the metallization graph and nickel plating and tin plating of the flow deflector together with material optimization, welding, grinding, ultrasonic cleaning and screening of destructive tests, the thermoelectric refrigerator prepared by the method has the advantages that the space radiation resistant capacity reaches 300 Krad (Si), the failure rate reaches 200fit, the temperature difference is large, the refrigeration power is high, has the characteristics of strong impact resistance and vibration mechanical property, high reliability, small volume and the like and is particularly suitable for being applied to the high orbit space.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

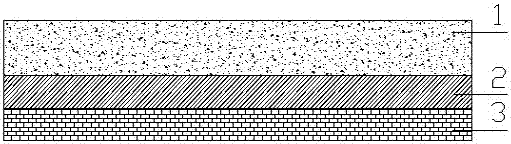

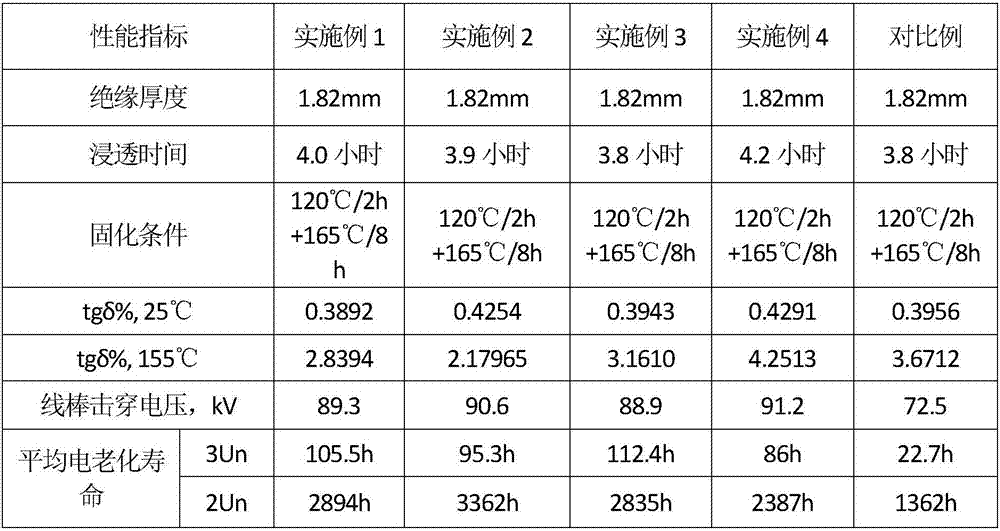

Less-resin mica tape used for high voltage motor and preparation method thereof

ActiveCN106960705AImprove electrical strengthRetain poresLamination ancillary operationsLaminationSemi solidSolvent free

The invention discloses a less-resin mica tape used for a high voltage motor and a preparation method thereof. The less-resin mica tape comprises a mica paper layer, a reinforced material layer, and an adhesive layer. The mica paper layer is formed by a piece of prepared mica paper. The preparation method comprises steps that step1, the prepared mica paper, the adhesive, and the reinforced material are selected; step2, uniform printing, spraying, or frictioning of solvent-free solid adhesive or semi-solid resin adhesive on the prepared mica paper or the reinforced material is carried out; step3, the hot pressing synthesis of the prepared mica paper and the reinforced material is carried out to form a mica tape blank material; step 4, cure accelerator prepared into solution is sprayed on the mica tape blank material, and permeates in the mica tape blank material. The less-resin mica tape has advantages of enhanced electrical intensity, excellent electrical aging performance, electrical performance uniformity, and ability of satisfying requirements of advanced less-resin VPI technology on permeability of mica tapes.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

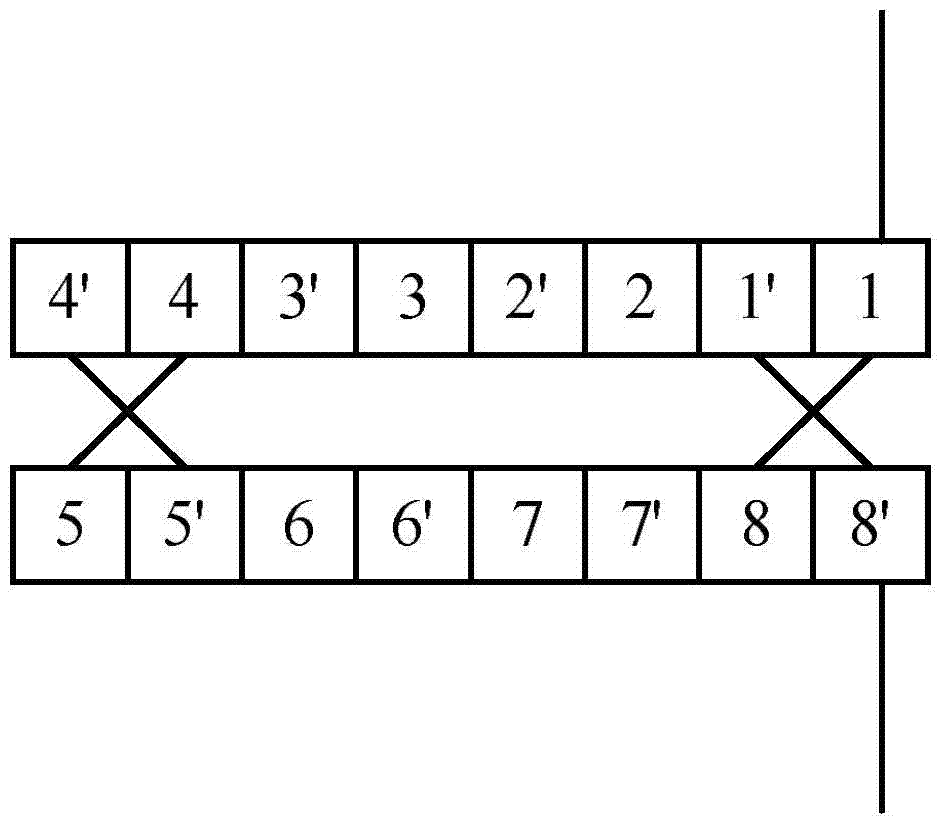

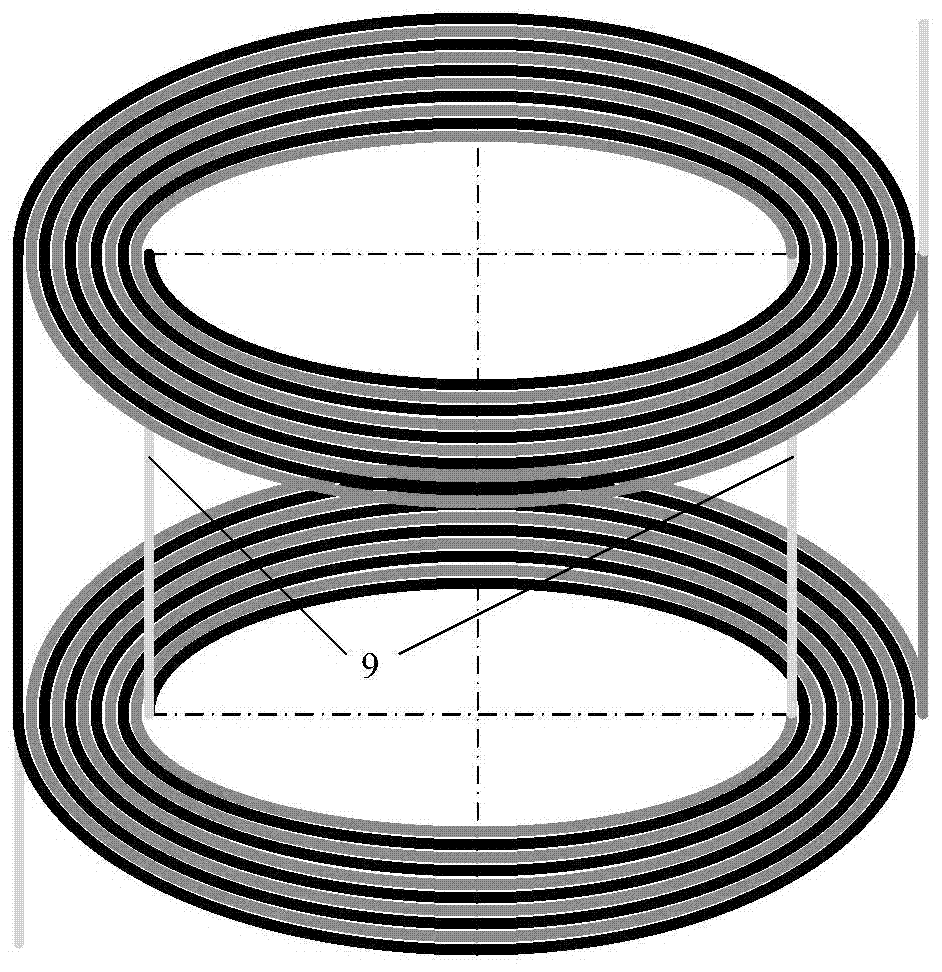

Model coil of interturn insulation test of oil-immersed power transformer and manufacturing method of model coil

ActiveCN104777406AEffective analog characteristicsEffectively simulate the development process of electrical and thermal agingTesting dielectric strengthTransformers/inductances coils/windings/connectionsTransformerEllipse

The invention relates to a model coil of an interturn insulation test of an oil-immersed power transformer and a winding method of the model coil. Specification parameters of the coil and a category of insulation paper are the same as those of the transformer. The coil is divided into an upper cake and a lower cake, wherein each cake is subjected to parallel winding by two paper wrapped wires A and B; two first tangling positions of a connecting part of the two cakes are wrapped with at least six layers of insulation paper; the two first tangling positions are located on an inner ring of the coil; a distance between the two first tangling positions is half perimeter of a lead wire of the inner ring; the head end and the tail end of each paper wrapped wire are connected together; the two paper wrapped wires serve as a high-voltage outgoing wire and a low-voltage outgoing wire respectively; an ellipse is defined by four leading-out terminals of the paper wrapped wires; the high-voltage outgoing wire and the low-voltage outgoing wire of the coil are arranged at the two ends of a long axis respectively; a short axis is coincided with a straight line formed by the two first tangling positions of the two paper wrapped wires and is equal to the diameter length of an excircle of the coil; and each of the paper wrapped wires from tangent points to end points of the leading-out terminals is additionally wrapped with at least six layers of crepe paper to reinforce insulation. The coil can effectively simulate breakdown characteristics of an interturn oil paper compound insulation system and a development process of electrical aging and thermal aging under a working condition of the large transformer, and is simple to manufacture.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

High-frequency voltage and superposed power-frequency current type cable accessory aging test device

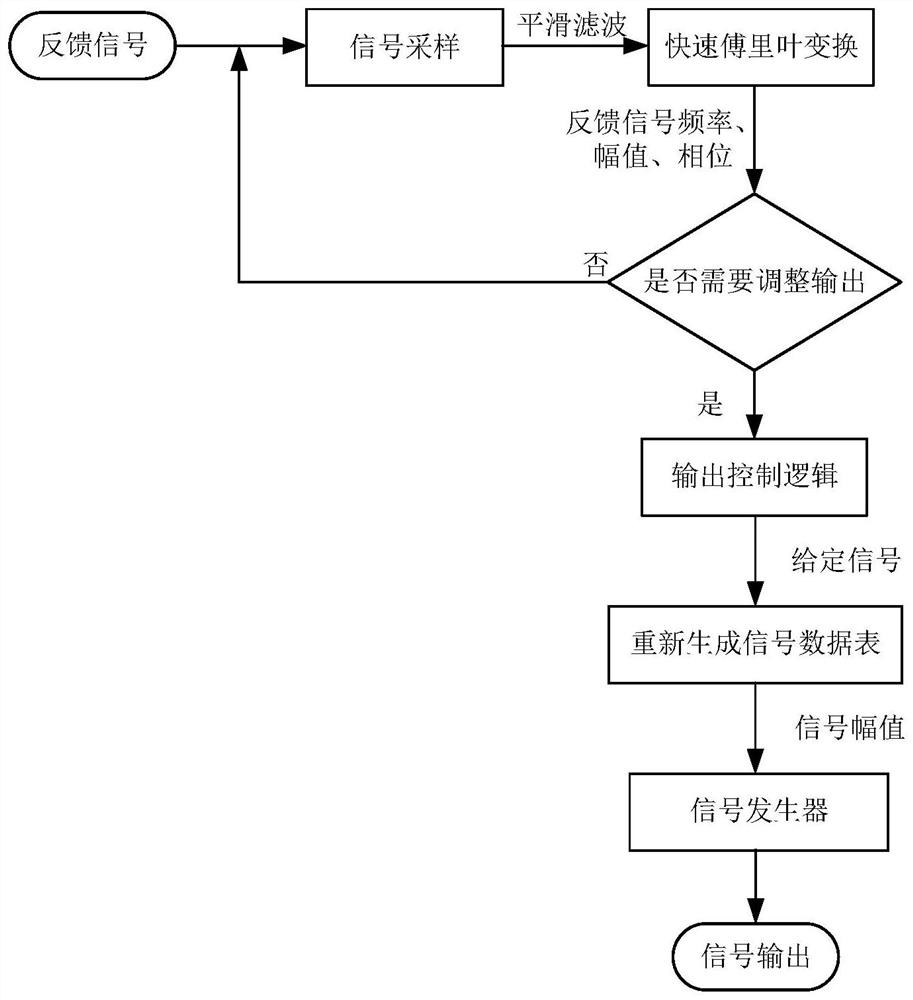

PendingCN107064691AReduce difficultyMeasure securityTesting dielectric strengthEnvironmental/reliability testsPower cableControl theory

The invention discloses a high-frequency voltage and superposed power-frequency current type cable accessory aging test device and relates to the technical field of power cable aging and detection techniques thereof. The cable accessory aging test device comprises a high-frequency test voltage generating unit, a high-frequency voltage test loop unit, a power-frequency load current simulation and generation unit and an insulating information monitoring unit. The high-frequency test voltage generating unit generates a high-frequency strong electrical field, and then an XLPE cable accessory is subjected to the high-frequency electrical aging treatment. The power-frequency load current simulation and generation unit generates heat in the high-frequency voltage test loop unit, and then the XLPE cable accessory is subjected to the thermal aging treatment. The above two units work simultaneously to simulate the actual operating condition of the XLPE cable accessory. The insulating information monitoring unit adopts the non-invasive monitoring method, so that the state monitoring for the insulating characteristic parameters of the medium-voltage XLPE cable accessory is realized.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

High-thermal conductivity insulation structure of stator bar of insulation system

InactiveCN102447331ANo reduction in technical performance indicatorsPerformance indicators do not degradeWindings insulation materialWindings insulation shape/form/constructionFiberInsulation system

The invention relates to a high-thermal conductivity insulation structure of a stator bar of an insulation system. An insulating layer on the outer surface of an electromagnetic wire contains high-thermal conductivity ceramic fibers; reinforcing materials in transposition pit insulation, inter-row insulation, narrow surface filler strip, main insulation and anti-corona materials contain high-thermal conductivity ceramic fibers; and resin adhesives in transposition pit insulation, transposition insulating layer, inter-row insulation, main insulation and anti-corona materials contain high-thermal conductivity ceramic fibers. The stator bar made by adopting the high-thermal conductivity insulation structure has the following main technical performance indexes that: (1) the bar thermal conductivity reaches 0.5W / mK; (2) in the normal state and at a voltage of 0.2UN, tg delta is less than 1 percent; (3) the stator bar has no visual corona mark in 60 seconds at a voltage of 1.5UN; (4) a breakdown voltage of the finished product bar reaches 5.5UN; and (5) an electrical aging resistance test of the bar proves that the service life of the stator bar at a voltage of 3.0UN is longer than 10 hours and the service life of the stator bar at the voltage of 2.0UN is longer than 1,100 hours. The stator bar is suitable for a VPI (vacuum pressure impregnation) insulation system.

Owner:HARBIN ELECTRIC MASCH CO LTD +1

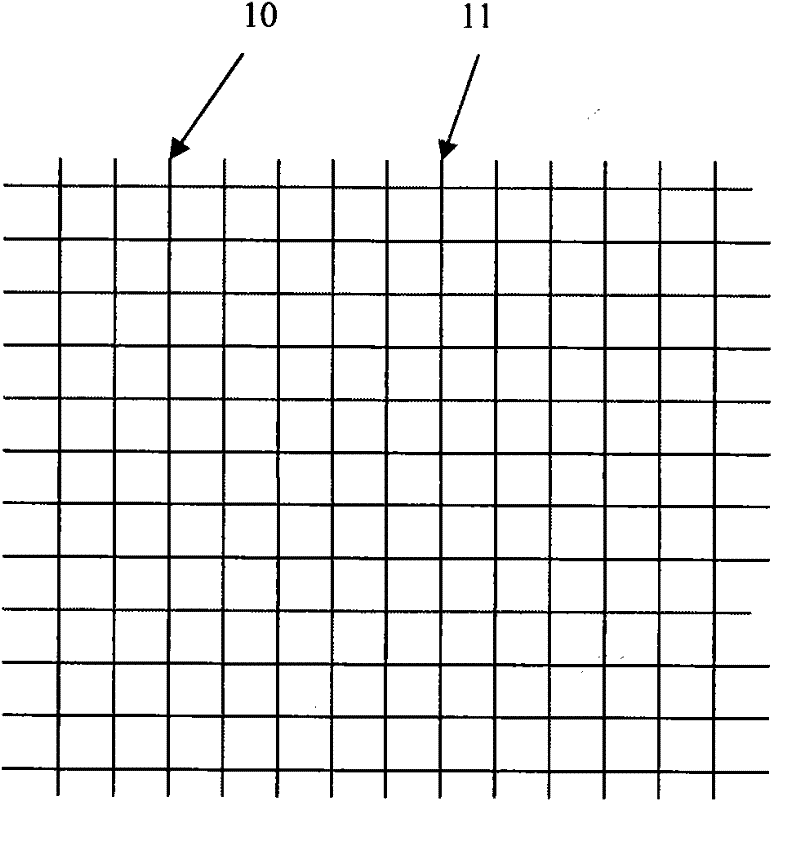

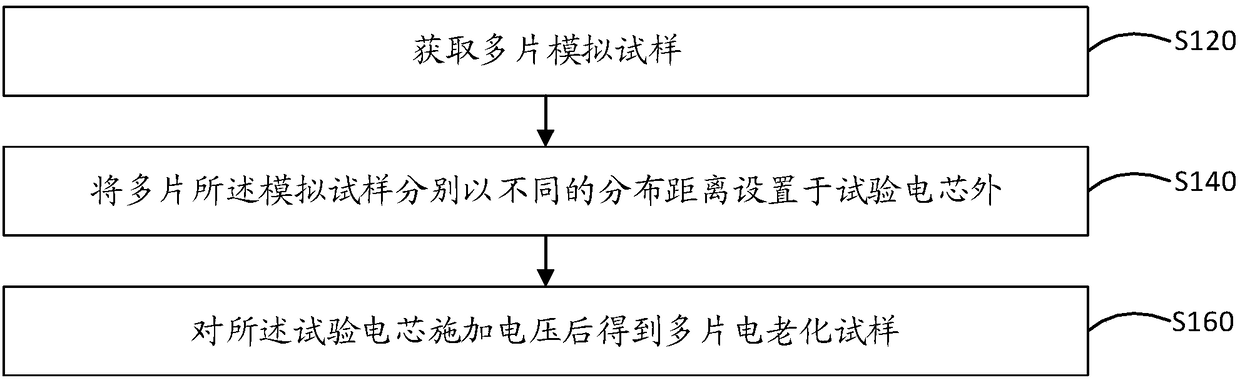

Electric aging test method and test device for cable insulation layer

The invention relates to an electric aging test method for a cable insulation layer. The method comprises the steps that a number of simulation samples are acquired; a number of simulation samples arearranged outside a test cell at different distribution distances; and after the test cell is applied with voltage, multiple electrically aged samples are acquired. According to the electric aging test method for the cable insulation layer, after voltage is applied to the test cell, a number of simulation samples arranged outside the test cell are electrically aged in a magnetic field generated bythe test cell; in the later period, multiple electrically aged samples are directly analyzed and detected to determine the degree of electrical aging of the electrically aged samples, and the degreeof aging of a to-be-tested insulation layer in a cable to be tested can be determined; the slice of the to-be-tested insulation layer electrically aged in the cable to be tested is not needed; the microstructure of the electrically aged samples is not damaged; the subsequent research of the electrically aged samples is not affected; and the accuracy of the electric aging test result of the cableinsulation layer is improved.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

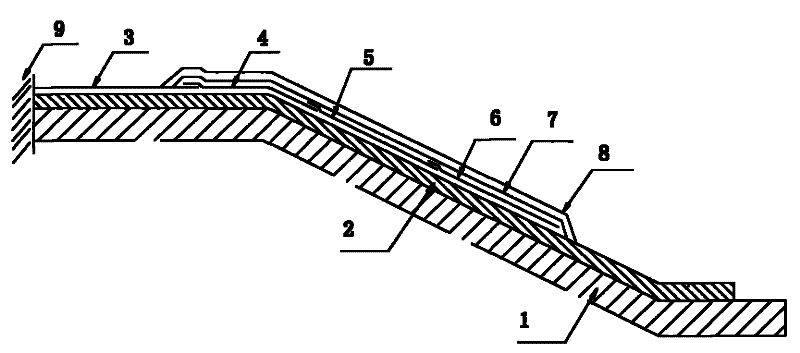

Manufacturing method of air-cooled hydrogenerator VPI (Vacuum Pressure Impregnating) stator coil bar

The invention relates to a manufacturing method of an air-cooled unit capacity hydrogenerator VPI (Vacuum Pressure Impregnating) stator coil bar. An inner shielding layer on the surface of a wire canreduce an internal local discharge probability of the wire. After the coil bar is bound with a VPI main insulation layer, a straight-line segment is bound in a half-lapping mode with a layer of low-resistance anti-corona material, then VPI of epoxy anhydride resin is carried out, after impregnation is ended, the end part is respectively bound in a half-lapping mode with medium resistance, medium-high resistance and high resistance segments, and the surface of an anti-corona segment of the end part is bound with two layers of additional insulation layers; after an anti-corona layer is processedwell, the coil bar is assembled into a hot-pressing die, pressurization is carried out, and the coil bar is placed into a baking oven to carry out heating, curing and forming; and after the main insulation layer is cured and formed, a protection layer is brushed with a high-resistance anti-corona paint and a surface coating varnish so as to obtain the finished product VPI stator coil bar. The air-cooled unit capacity hydrogenerator VPI stator coil bar has the main technical performance indexes that: (1) a breakdown voltage of the finished product coil bar is greater than or equal to 5.5UN; and (2) an electrical aging resistance experiment of the coil bar shows that the service life under a voltage of 3.0UN is greater than 40H, and the service life under a voltage of 2.0UN is greater than1,100h.

Owner:HARBIN ELECTRIC MASCH CO LTD

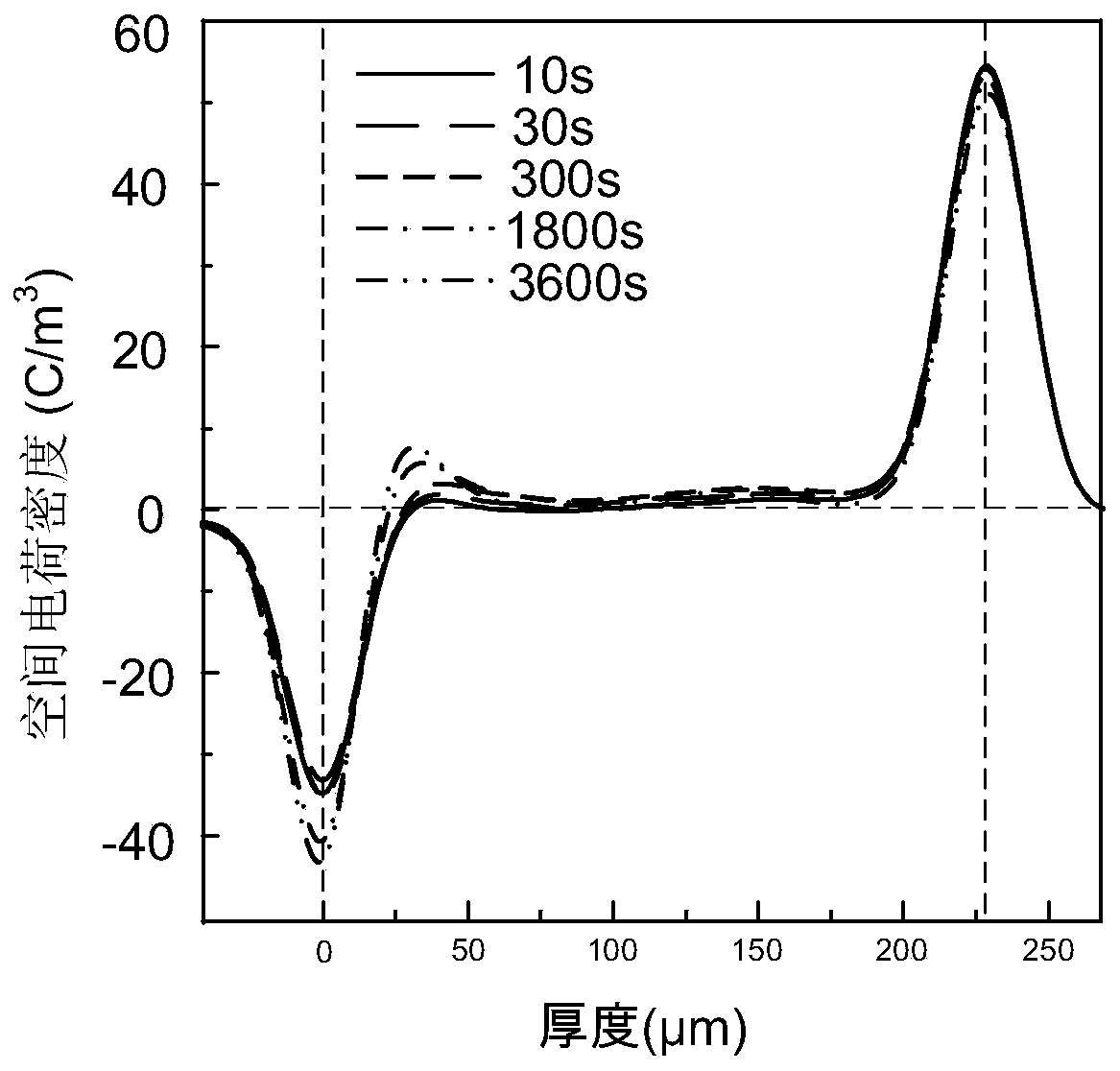

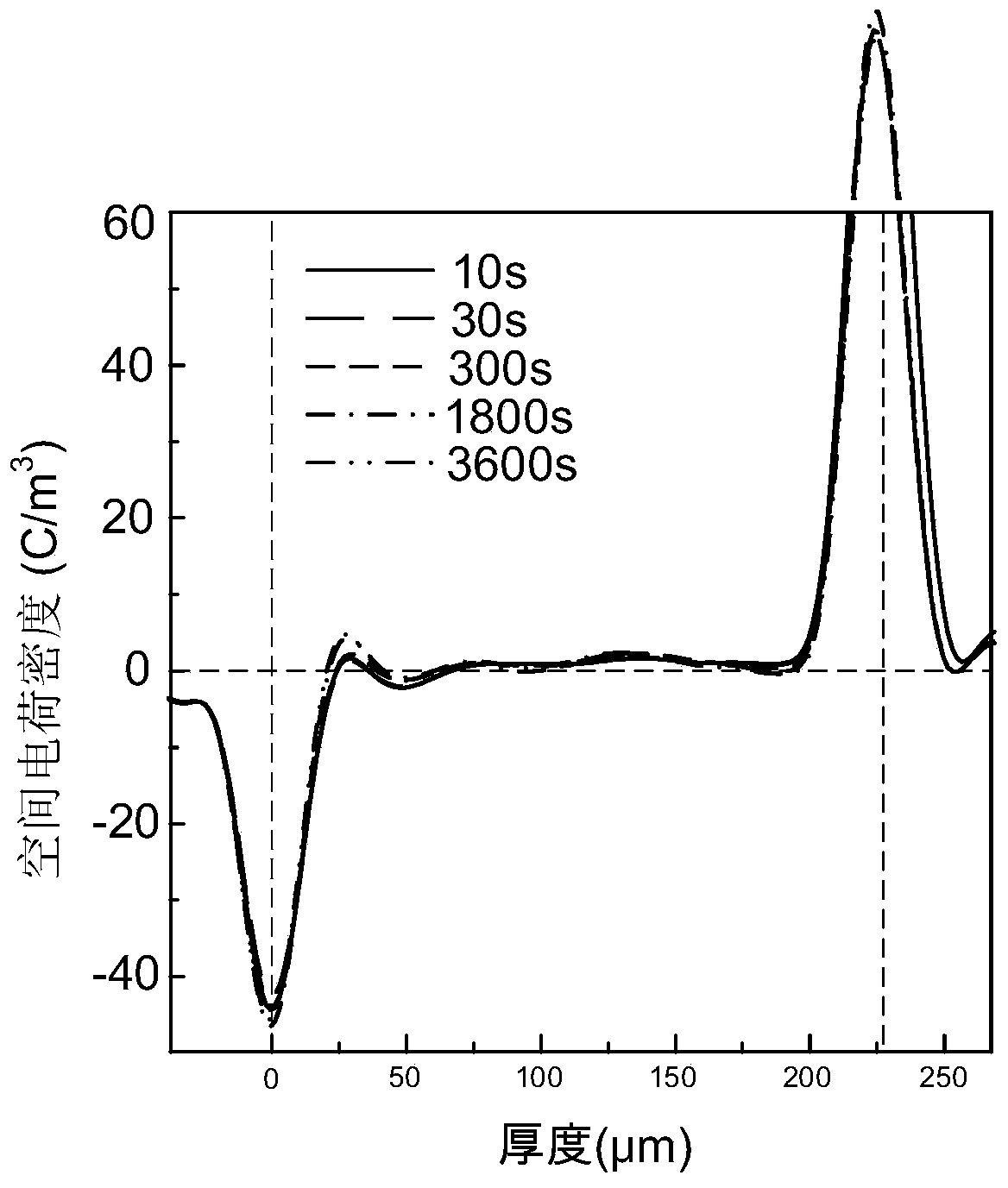

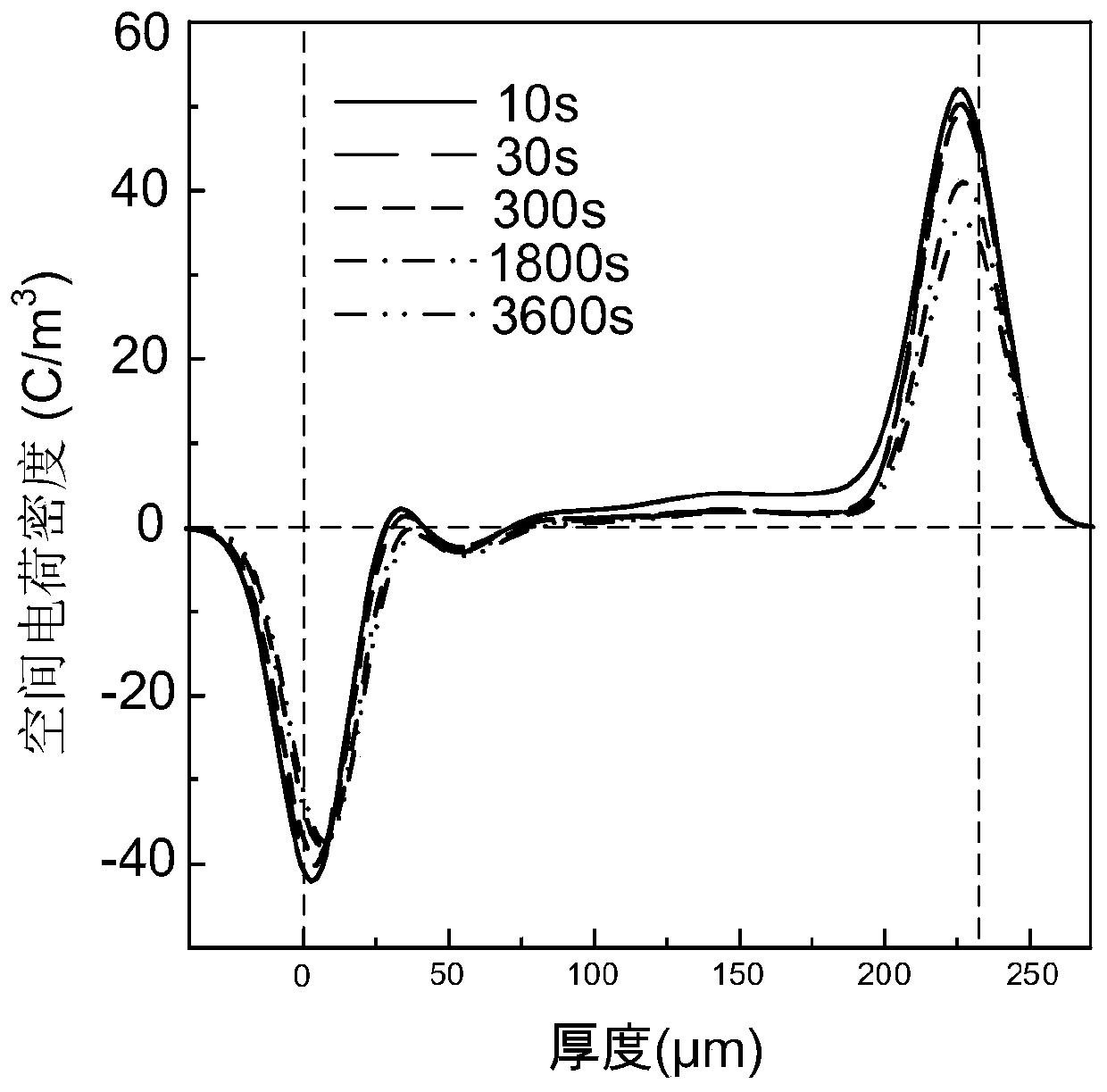

Method for improving insulation space charge characteristics of polypropylene high-voltage direct-current cable

InactiveCN110894320AImproved insulating space charge characteristicsPromote accumulationLow-density polyethyleneHigh-voltage direct current

The invention belongs to the technical field of high-voltage direct-current power transmission equipment and discloses a method for improving the insulation space charge characteristics of a polypropylene high-voltage direct-current cable. The method comprises the step of carrying out melt blending and extrusion granulation on a polypropylene composite base material, ultra-low density polyethyleneand a free radical scavenger in a certain mass ratio to prepare a polypropylene-based high-voltage direct-current cable insulation material for improving the space charge characteristics by capturingfree radicals. According the invention, traps with different energy level depths and densities are introduced into the insulation material by utilizing the steric hindrance effect of the free radicalscavenger, so space charges injected by an external electric field are inhibited, and space charge accumulation is improved; and therefore, the insulating strength and the electrical aging resistanceof the polypropylene composite material are improved.

Owner:TIANJIN UNIV

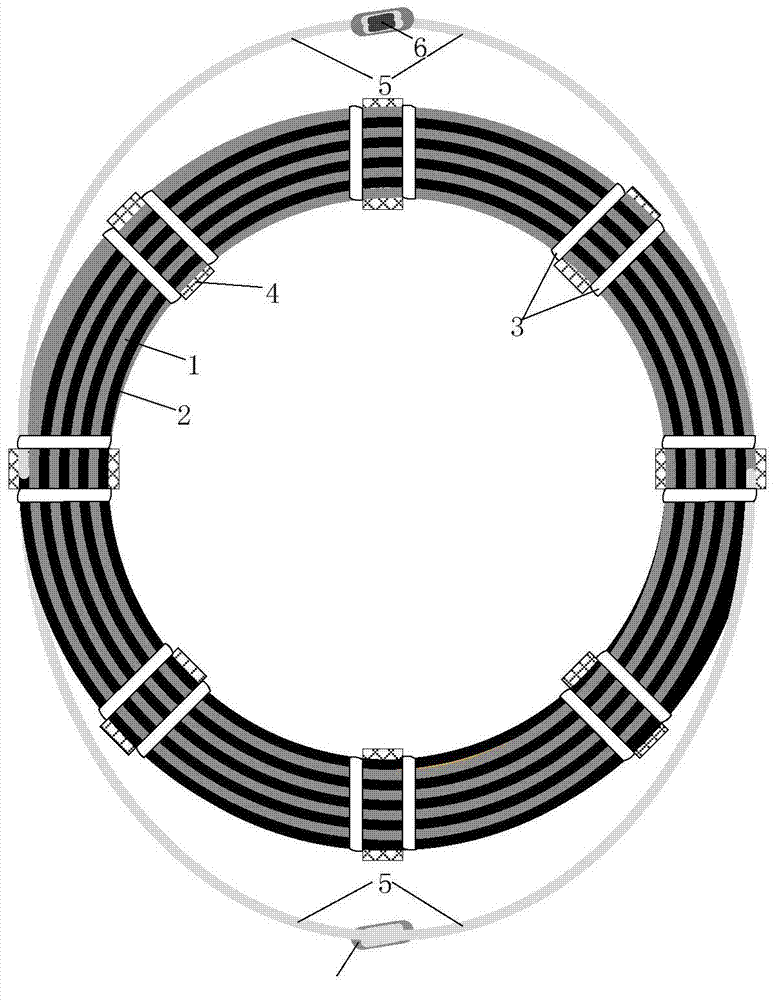

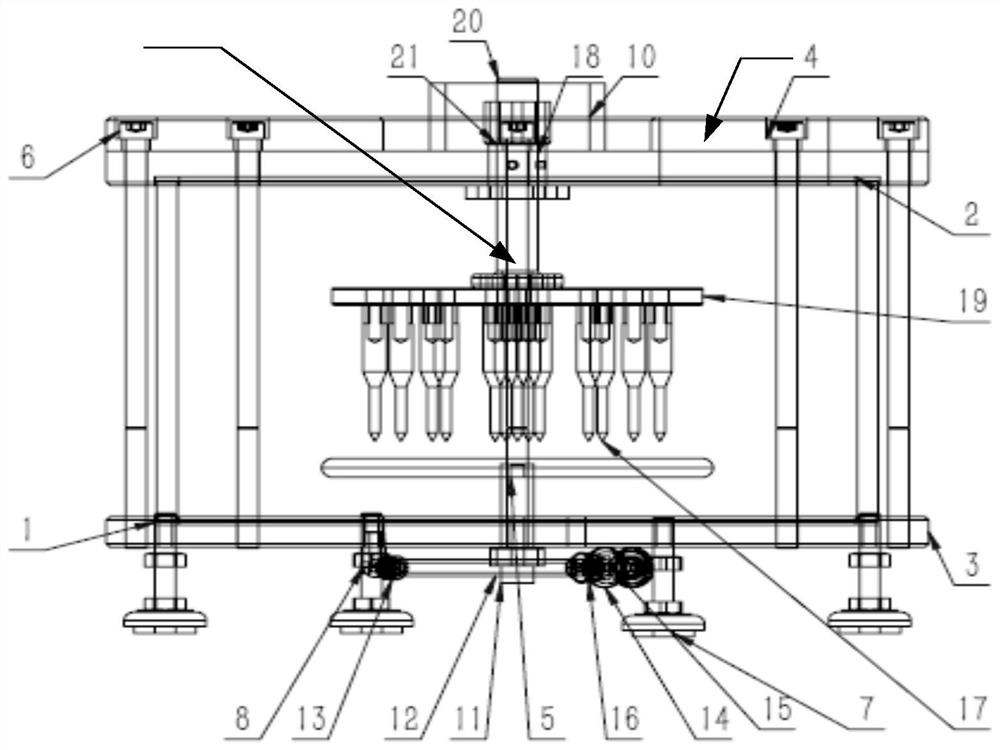

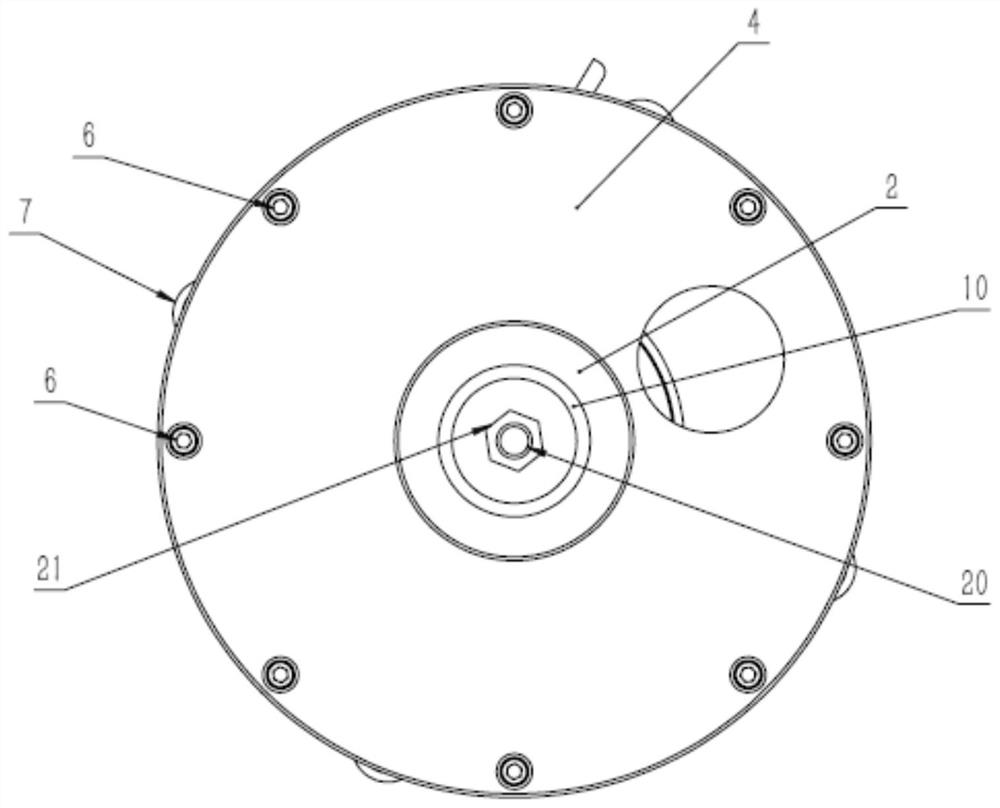

Multi-channel discharge device for accelerating electrical aging of insulating silicone oil

PendingCN112072474AEasy to adjustShorten the timeTesting dielectric strengthSpark gap detailsThermodynamicsLow voltage

The invention relates to a multi-channel discharge electrical aging device for accelerating aging of insulating silicone oil. The device comprises an upper cover plate, a lower cover plate, a pressingflange, a pin electrode, a plate electrode, a tank body, an insulating sleeve, a connecting rod and a pin mounting plate. An external power supply is connected with the connecting rod to introduce required voltage to the pin electrode; the ground electrode is connected with the plate electrode, the pin electrode and the plate electrode are arranged in the glass tank body, the insulating siliconeoil is placed in the tank body, the cover plate and the tank body are fixed into a whole through the long bolts, and the whole device can contain the insulating silicone oil with the large size. An oil taking hole is formed in an upper cover plate for oil filling and taking operation, and an extension pipe is mounted at a lower cover plate. And oil extraction operation is carried out through the pipeline. 13 pins are mounted on the pin mounting plate, and the connecting rod is moved up and down by rotating the high-pressure guide rod positioning sleeve, so that the pin plate gap is controlled.The multi-pin electrode structure adopted by the invention can greatly shorten the time required for electrical aging at a relatively low voltage level.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +3

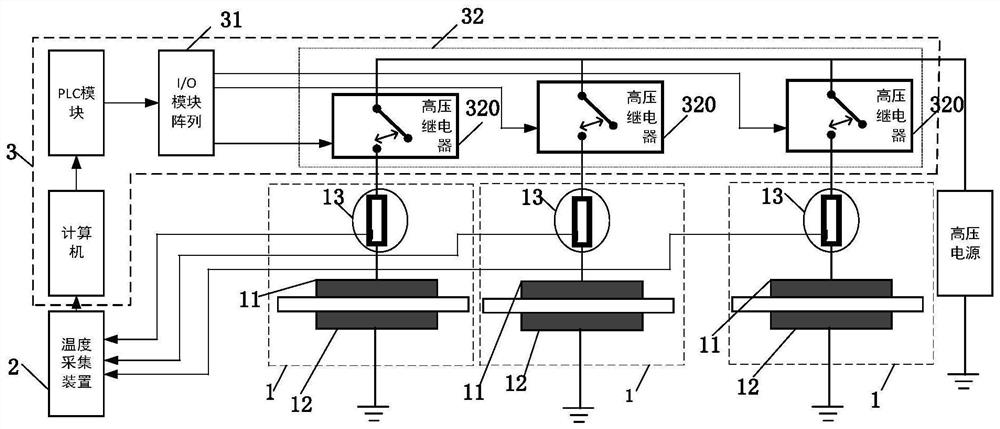

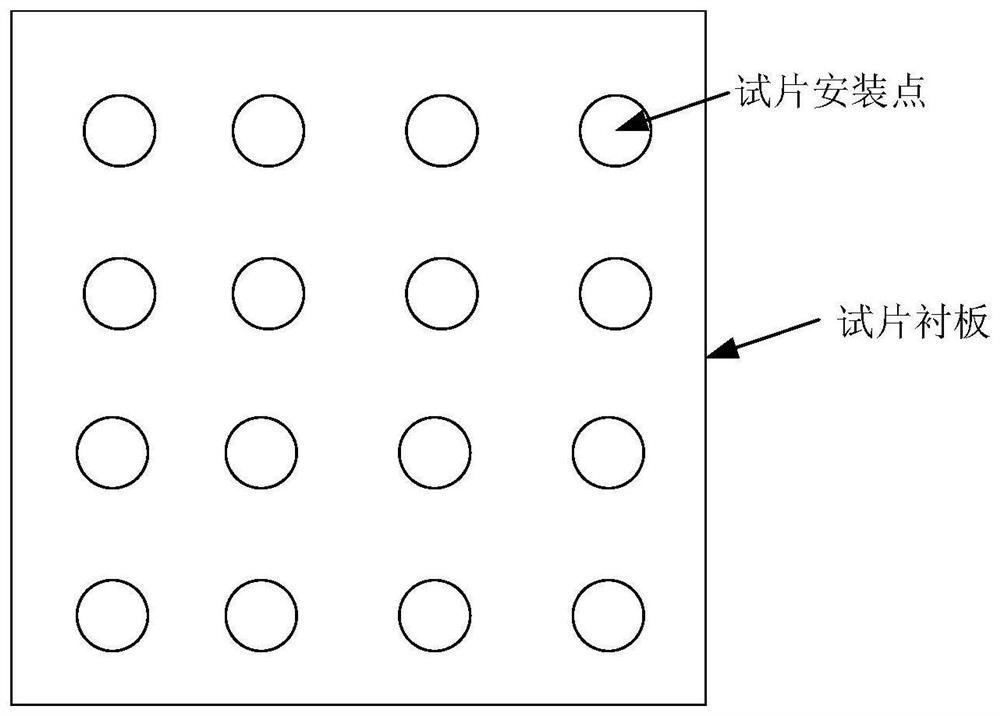

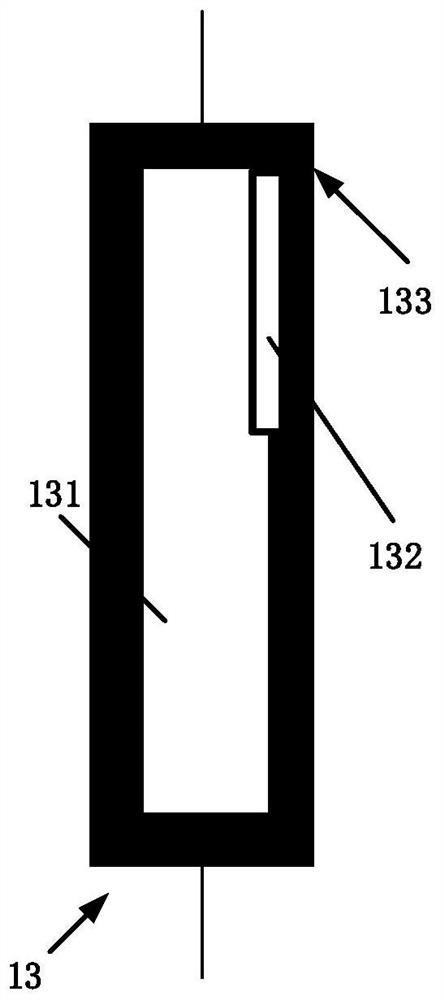

Insulating material electrical aging test system

ActiveCN112578236AAccurate and reliable aging life testAvoid frequent cutsThermometers using physical/chemical changesTesting using optic methodsElectrical resistance and conductanceEngineering

The invention discloses an insulating material electrical aging test system, which comprises a control device, a temperature acquisition device and a plurality of aging sample measurement devices. Theaging sample measurement devices are used for connecting a high-voltage power supply to test the temperature of a resistor corresponding to an insulating material sample in real time and sending thetemperature to the temperature acquisition device; the temperature acquisition device is used for acquiring the temperature fed back by each aging sample measurement device in real time; the control device is used for controlling the aging test sample measuring device to disconnect from a high-voltage power supply when the temperature change value between the temperature of any aging test sample measuring device at the current moment and the temperature of the aging test sample measuring device at the previous moment is greater than or equal to a preset temperature change threshold value. Thus, an electrical aging test loop for a plurality of insulating material samples is formed. According to the electrical aging test system for the insulating material, provided by the invention, the electrical aging field intensity can be prevented from being frequently cut off, so that the electrical aging performance test result of each insulating material sample is more accurate.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

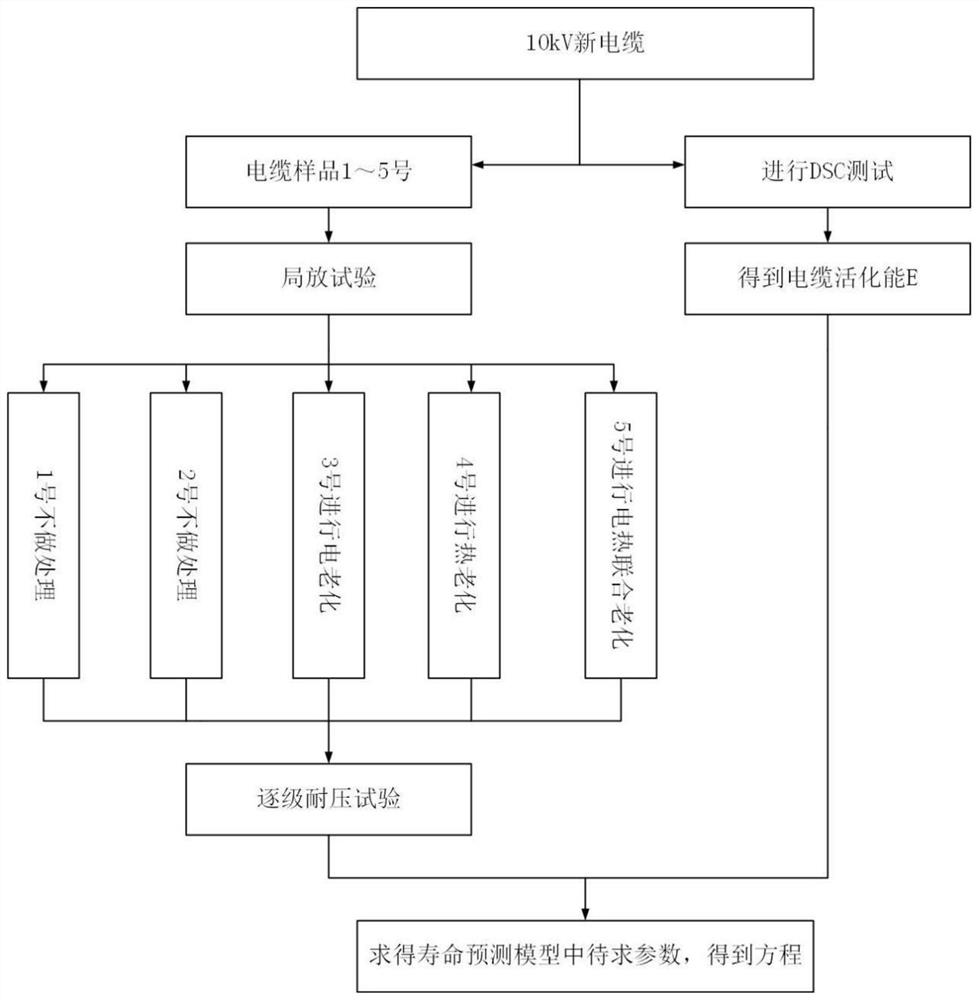

Mathematical model for predicting electric heating combined aging life of crosslinked polyethylene cable

ActiveCN112949099AProtectGuaranteed safe operationForecastingDesign optimisation/simulationThermal ageingPower cable

The invention discloses a mathematical model for predicting the electric heating combined aging life of a crosslinked polyethylene cable. The invention belongs to the technical research field of power cables. Based on a DSC method and a step-by-step boosting method, on the basis of an electric aging model and a thermal aging equation of an original inverse power law, step-by-step boosting breakdown experiments are carried out on five groups of cables with different aging degrees. According to experimental data, while respective effects of electric aging and thermal aging and interaction between the electric aging and the thermal aging are considered, a power cable life prediction equation capable of simultaneously representing the electric aging life, the thermal aging life and the combined effect between the electric aging life and the thermal aging life is given. According to the invention, the residual life of the cable can be obtained through the life prediction equation when the thermal historical data and the power-on voltage of the cable in normal operation are given, and the effect of evaluating the life of the power cable at any time on the premise of not carrying out a destructive experiment is achieved.

Owner:HARBIN UNIV OF SCI & TECH

Manufacturing process of motor stator coils by vacuum pressure impregnation

ActiveCN103475174BSolve the problem of insufficient structureSolve technical problems of performanceApplying solid insulationVacuum pressureElectric machine

The invention relates to a manufacturing process for manufacturing motor stator coils by vacuum pressure impregnation, which comprises the following steps: after wrapping the main insulating layer of the motor bearing coil with less glue mica tape, the motor stator coils are subjected to vacuum pressure impregnation process, Fill the air gap between the micas with insulating varnish in advance, then carry out hot molding curing at 180°C to 200°C, and then insert them into the stator slot of the motor. After the connection is completed, perform a second hot molding curing at 155°C. The time for secondary thermal molding curing is not less than 10 hours. The high-voltage motor stator coil manufactured by vacuum pressure impregnation has a tight insulating layer structure, no air pockets, low dielectric loss increment, small partial discharge, and high dielectric breakdown field strength. The insulation performance, mechanical performance, temperature resistance and electrical aging resistance of the coil have been significantly improved, which has raised the coil quality to a higher level.

Owner:HANGZHOU FUYANG HYDROPOWER EQUIP INSPECTION

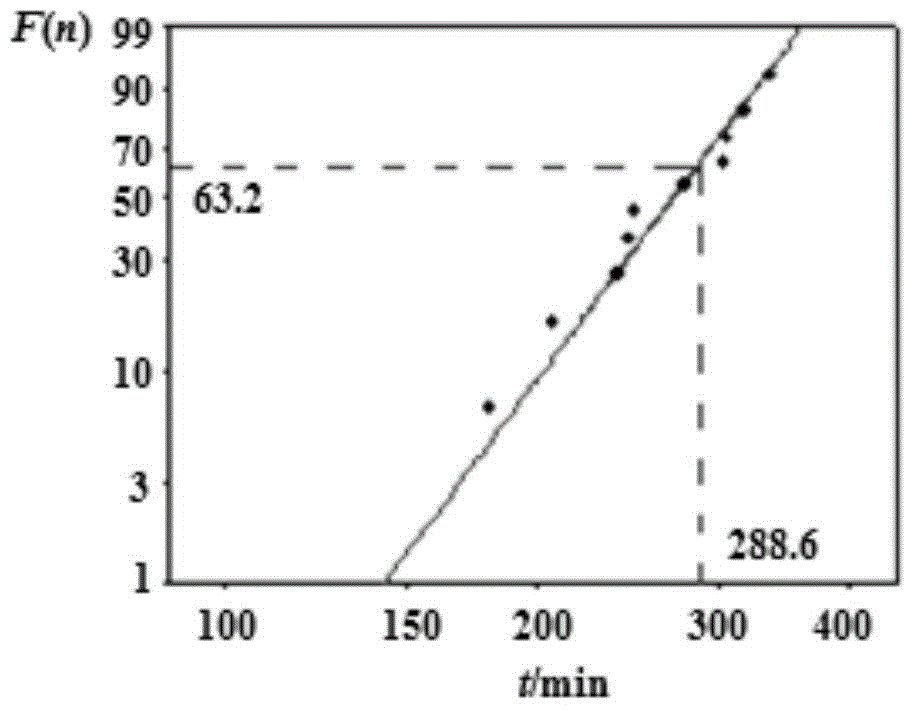

Method for quickly estimating electrical life of stator bar of high-voltage motor

ActiveCN111812473AShort breakdown timeHigh test voltageTesting dielectric strengthElectric machineControl theory

The invention discloses a method for quickly estimating the electrical life of a stator bar of a high-voltage motor. Based on an electrical aging test of a group of stator bars and an instantaneous breakdown test of a group of stator bars, the Weibull distribution states and breakdown time of the other stator bars for electrical aging tests and instantaneous breakdown tests can be quickly estimated by drawing on a Weibull distribution failure probability graph according to the relationship of Weibull parameters under different tests. The method has the advantages of being simple, clear in process, rapid in analysis and wide in applicability; and under the condition that the electrical service life of the stator bar is rapidly and accurately estimated, the estimation cost of the service life of the stator bar can be greatly reduced, the insulation design of the stator bar is effectively improved, and the insulation performance of the stator bar is improved.

Owner:HARBIN ELECTRIC MASCH CO LTD

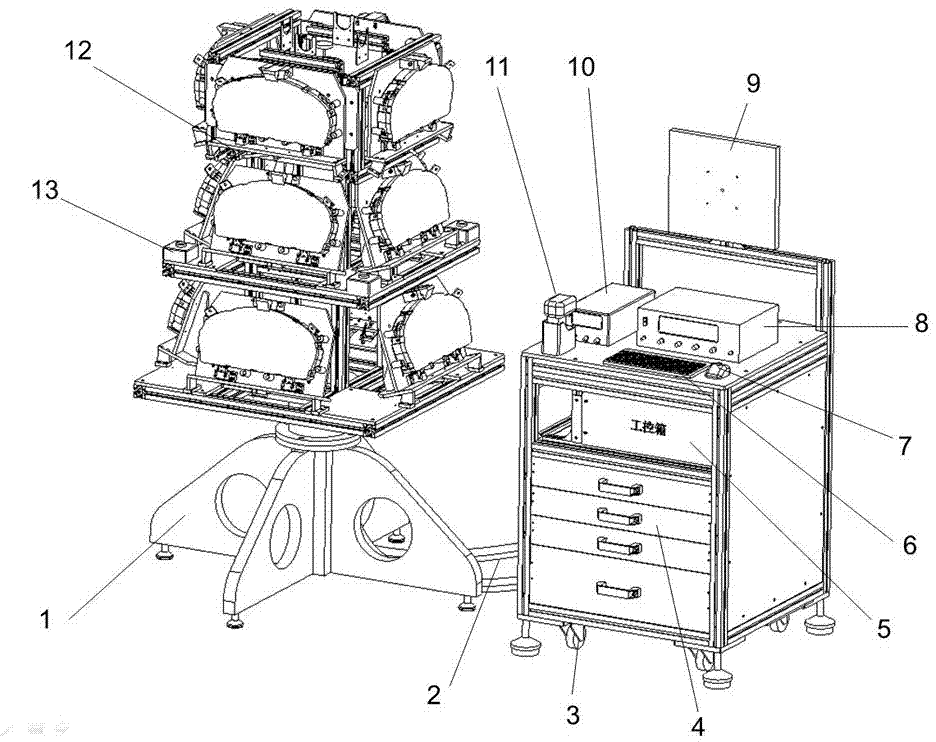

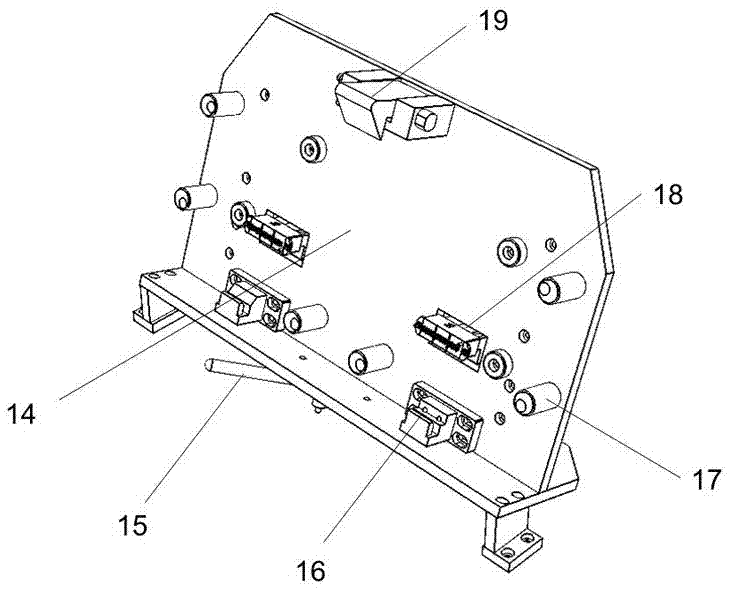

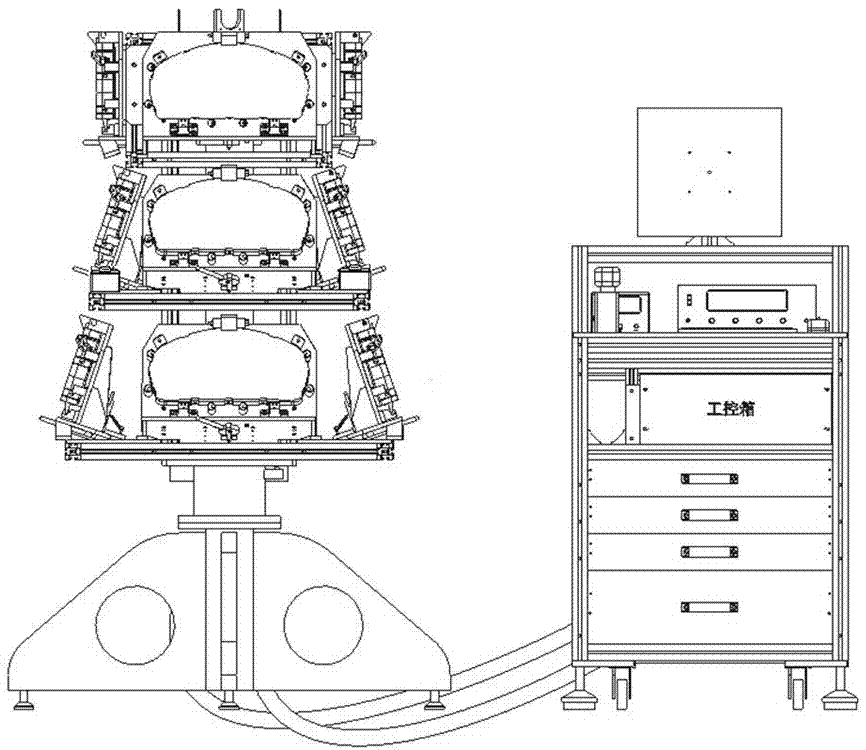

Commercial vehicle combination instrument electrical aging device

The invention discloses a commercial vehicle combination instrument electrical aging device belonging to the vehicle instrument detection technology field. The commercial vehicle combination instrument electrical aging device can be used to solve the problems of the conventional hand-operated detection devices such as large occupied area, low efficiency, and manual determination. The commercial vehicle combination instrument electrical aging device is characterized in that a device main body control part comprises a control cabinet; a keyboard, a mouse, a signal generator, a liquid crystal display screen, a voltage-stabilizing power supply, a wireless scanning spear, an industrial control computer, a circuit control unit, and MISUMI brake universal wheels, which are disposed on the control cabinet; a working bench surface part is constituted by a rotating rack, an electrical aging control bench surface, clamps, and alarming indication lamps; the electrical aging control bench surface is provided with three layers of clamps; the industrial control computer is connected with the circuit control unit, the signal generator, the liquid crystal display screen, and a wireless scanning spear. The commercial vehicle combination instrument electrical aging device is mainly used for the function detection of the D760 commercial vehicle model combination instrument, and is advantageous in that the testing number is large, the automatic degree of the device is high, and the batch production can be facilitated.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

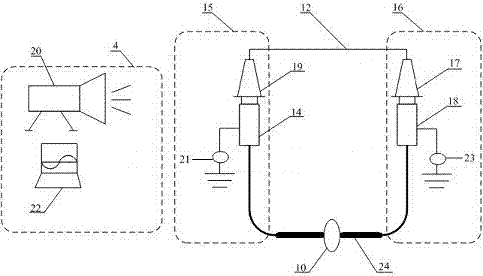

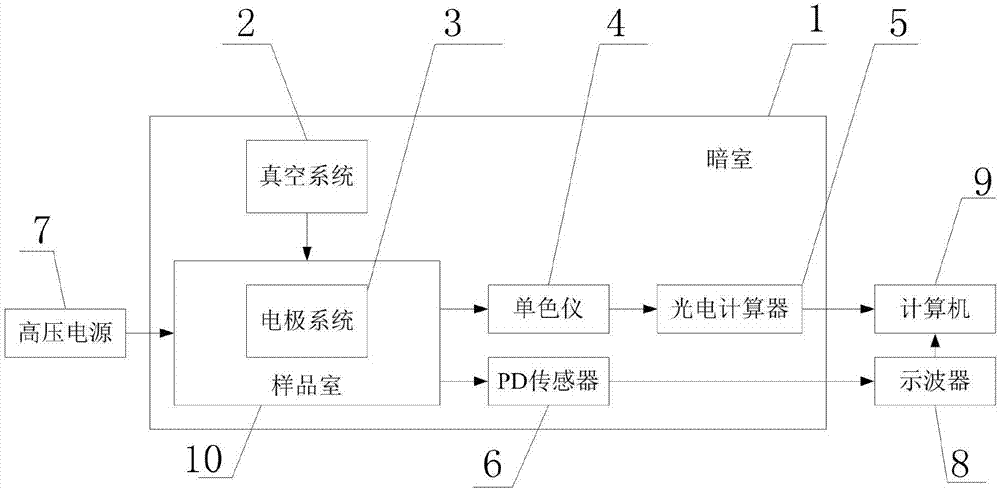

Real-time observation and evaluation equipment for charge behaviors based on electroluminescence

PendingCN107367501AHelps to reveal the mechanism of electrical agingAnalysis by electrical excitationEngineeringElectrical aging

The embodiment of the invention discloses real-time observation and evaluation equipment for charge behaviors based on electroluminescence. The equipment comprises a darkroom, a vacuum system, an electrode system, a monochrometer, a photoelectric calculator, a PD sensor, a high-voltage power supply, an oscilloscope, a computer, a sample room and a silica glass observation window. By externally applying alternating and direct current voltages, a material is stimulated to generate electroluminescence, the processes of injection, extraction, compounding and the like of charge carriers on the surface or in the material can be researched by collecting electroluminescence signal strength and spectral information, and the researches help disclose an electrical aging mechanism of a dielectric material, and an important measure can be provided for the anti-aging research of novel materials.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

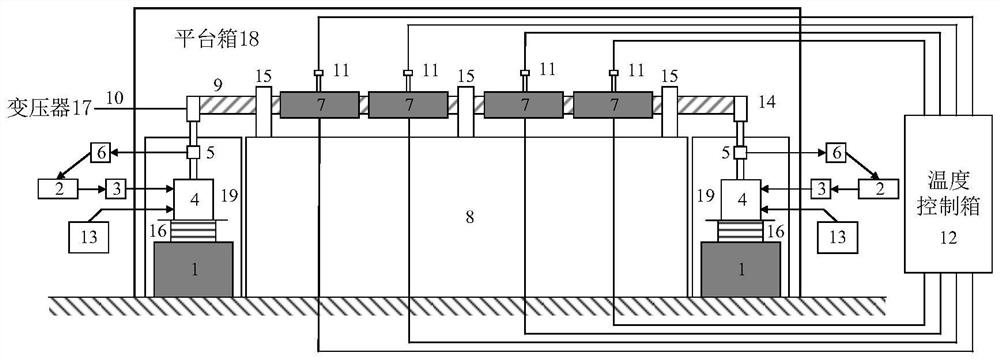

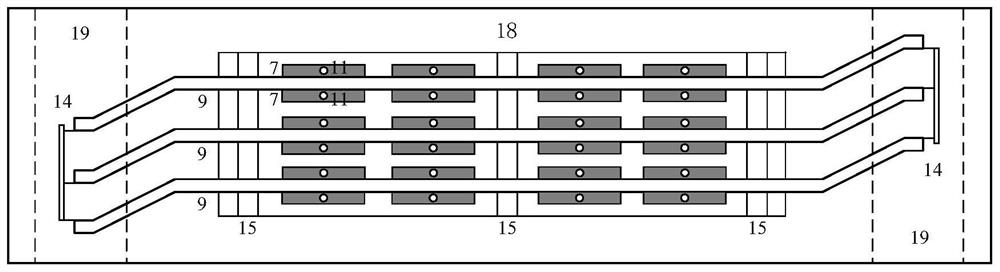

Multi-factor aging stress control platform and method for stator bar of large hydro-generator

InactiveCN112269081ARealistic reproduction of multi-factor aging processTesting dielectric strengthEnvironmental/reliability testsLoop controlTransformer

The invention discloses a multi-factor aging stress control platform and method for a stator bar of a large hydro-generator. The multi-factor aging stress control platform and method can be used for truly reproducing a stator bar real-machine aging process in a laboratory. The platform can realize multi-factor aging stress control for simultaneously applying three aging factors of electricity, heat and machinery to the whole stator bar of the large hydro-generator. The stator bar is heated by the heating plate and is subjected to closed-loop control by the temperature control box. The electrical aging factor is provided by the transformer, and closed-loop control can be carried out on the electrical aging factor through the transformer. Mechanical aging factors are provided by the vibration exciter and can be subjected to closed-loop control by the intelligent signal generator. The three aging factors of electricity, heat and machinery can be controlled by the platform in a closed-loopmanner, the platform can meet the aging test requirements of different stator bars of a large hydro-generator, and a foundation is laid for researching the insulation aging rule and service life prediction of the stator bars.

Owner:XI AN JIAOTONG UNIV +1

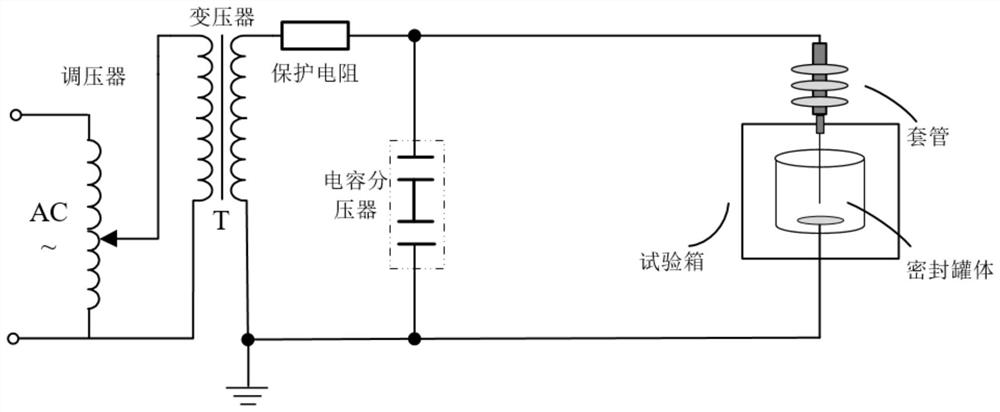

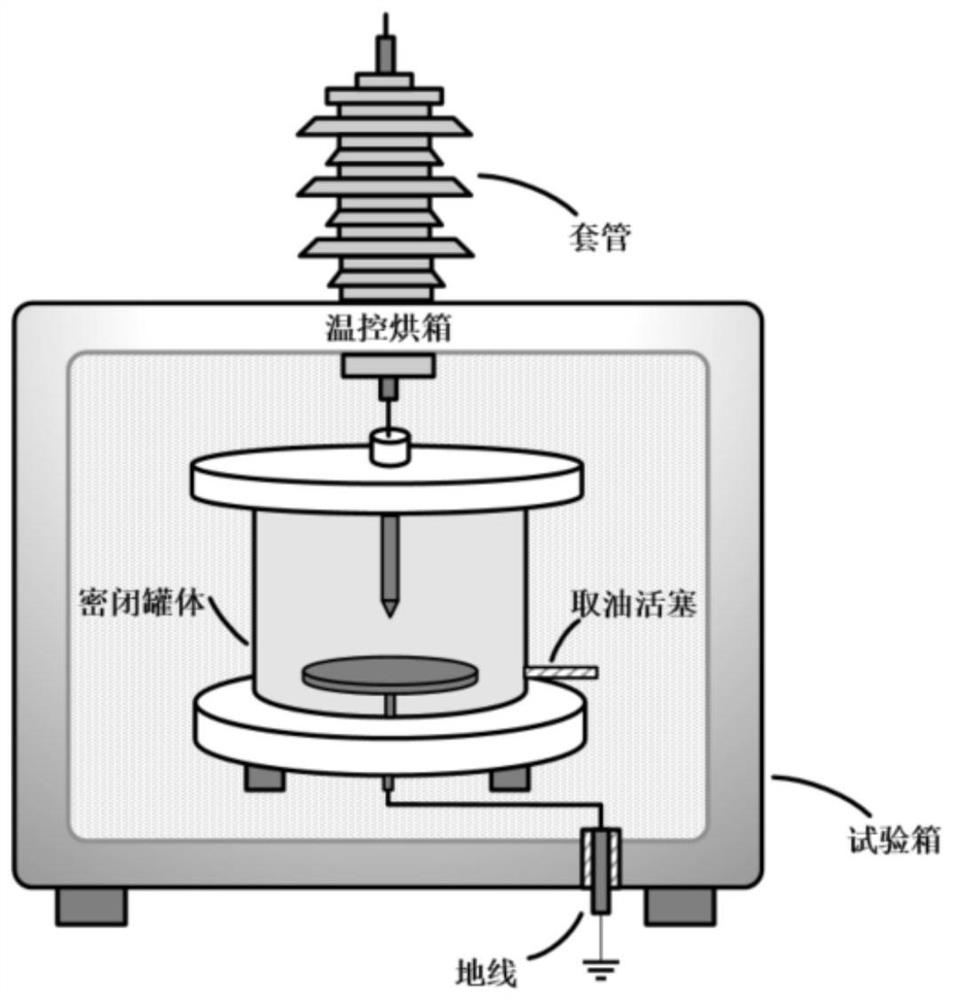

Cable terminal silicone oil electric heating and moisture combined aging test platform

PendingCN111693836AAvoiding the Practical Problem of Difficult Oil ExtractionAccurate test methodDielectric property measurementsMaterial resistanceTest powerEngineering

The invention relates to a cable terminal silicone oil electric heating and moisture combined aging test platform. The test platform comprises a test power supply, a test oven, a sealed test tank bodyand a wall bushing,. A silicone oil sample to be tested is placed in the sealing test tank body, the sealing test tank body is placed in the sample drying oven. The silicone oil electrical aging testcan be effectively carried out under the cooperation of the overall structure of the tank body. It can be guaranteed that researchers can smoothly carry out the insulation silicone oil electric heating and humidity combined aging test, and various change factors including the temperature, the electrode spacing, the external voltage, the environment humidity and the like can be adjusted. A more accurate test means is provided for researching the aging characteristics of the silicone oil of the power cable terminal, and the platform is helpful for scientific research personnel to comprehensively research the change mechanism of different aging processes caused by different aging factors of the silicone oil.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +3

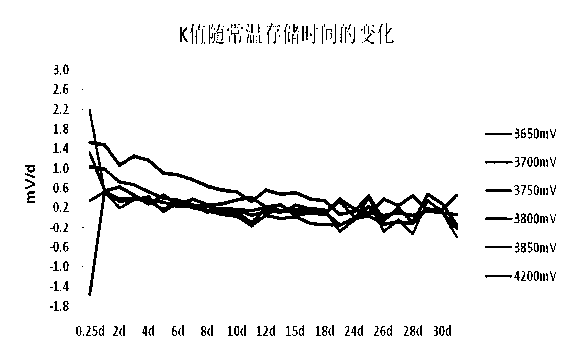

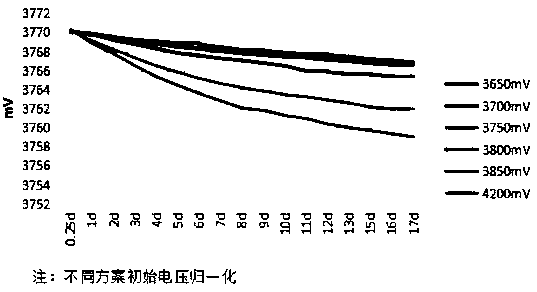

Method for designing lithium ion battery aging scheme and predicting effectiveness of scheme

PendingCN108417915AImprove securityShort aging cycleSecondary cells testingSecondary cells charging/dischargingElectricityCyclic test

The invention provides a method for designing a lithium ion battery aging scheme and predicting the effectiveness of the scheme. The method includes the steps of firstly, determining the precharge cut-off voltage of a battery before aging; secondly, manufacturing a seed cell to perform aging, selecting self-discharge, and verifying the aging scheme; thirdly, performing EIS and SEM tests to predictthe advantages and disadvantages of the aging scheme. The method has the advantages that semi-electrical aging is adopted, and high safety and short aging cycle are achieved; the method for predicting and verifying the effectiveness of the aging scheme is highly targeted, simple, effective, capable of verifying the effectiveness without using a large number of cells and capable of simplifying thework flow; the defect that a method using circulating testing results to show the advantages and disadvantages of the aging scheme is high in time consumption is improved, and work efficiency is increased.

Owner:ZHENGZHOU BAK BATTERY CO LTD

High current-carrying capacity overhead insulation cable and manufacturing technology

PendingCN107871556AImprove delivery capacityLess investmentPlastic/resin/waxes insulatorsPower cables with screens/conductive layersLow-density polyethylenePhosphorous acid

The invention discloses a high current-carrying capacity overhead insulation cable. A semi-conductive shielding layer and a crosslinking polyethylene insulating layer successively wrap an outer conductive layer. The crosslinking polyethylene insulating layer is formed by the following constituents low density polyethylene, high density polyethylene, phosphite ester, bisphenol A, dicumyl peroxide,di-tert-butyl peroxide, trimethylolpropane triacrylate, methacrylate, carbon black,stearic acid, stearin, stearin, ethylene thiourea and texanol. Carbon black is P type and has a particle size of 12-22nm. A sulfur content is 100-500PPM and an ash content is 100-500PPM. The high current-carrying capacity overhead insulation cable meets the demand for a high load, improves a capacity of transmittingcurrent by the overhead cable, can meet demands for tolerable temperature of long time working and a highest operation temperature, guarantee reliability of safe operation, does not cause thermal aging and electric aging insulation faults and thus can realize dynamic capacity increase according to the real time environment for the operation of the cable.

Owner:JIANGSU HENGTONG POWER CABLE

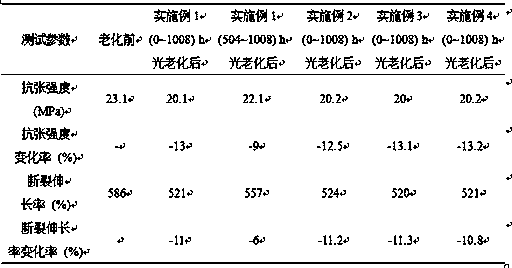

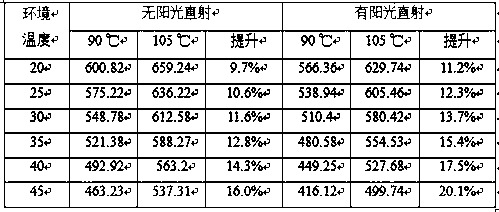

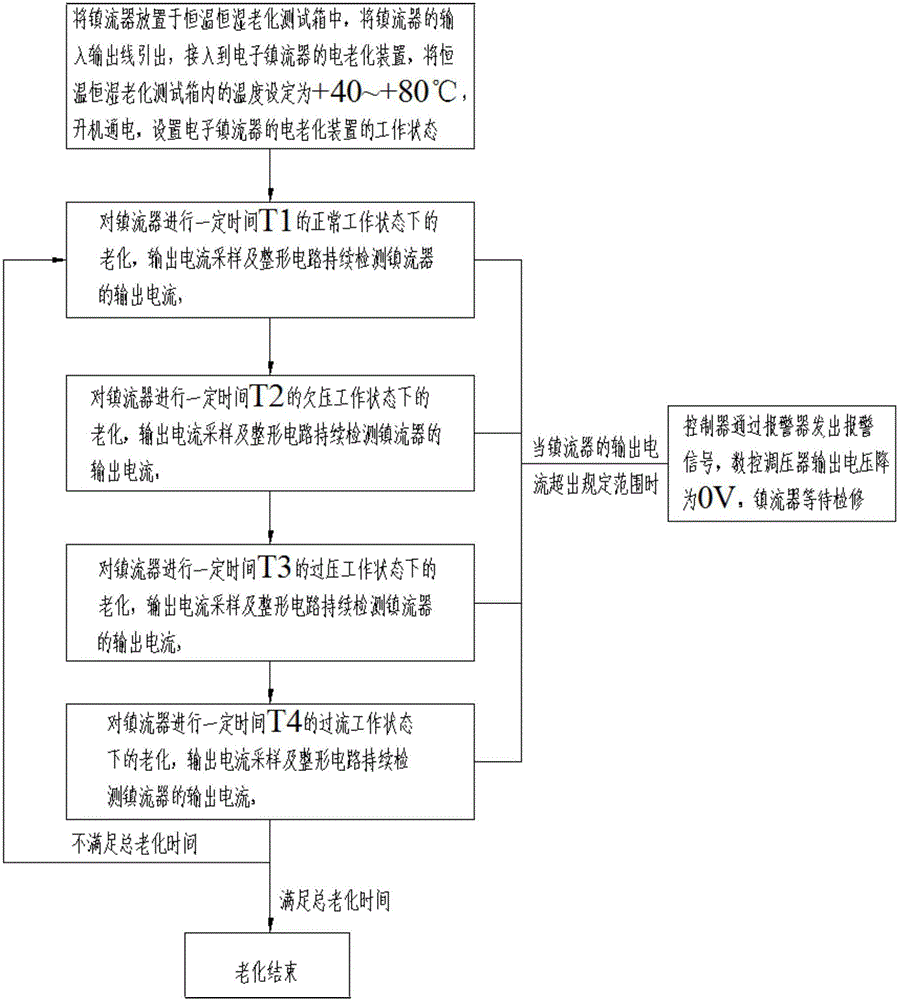

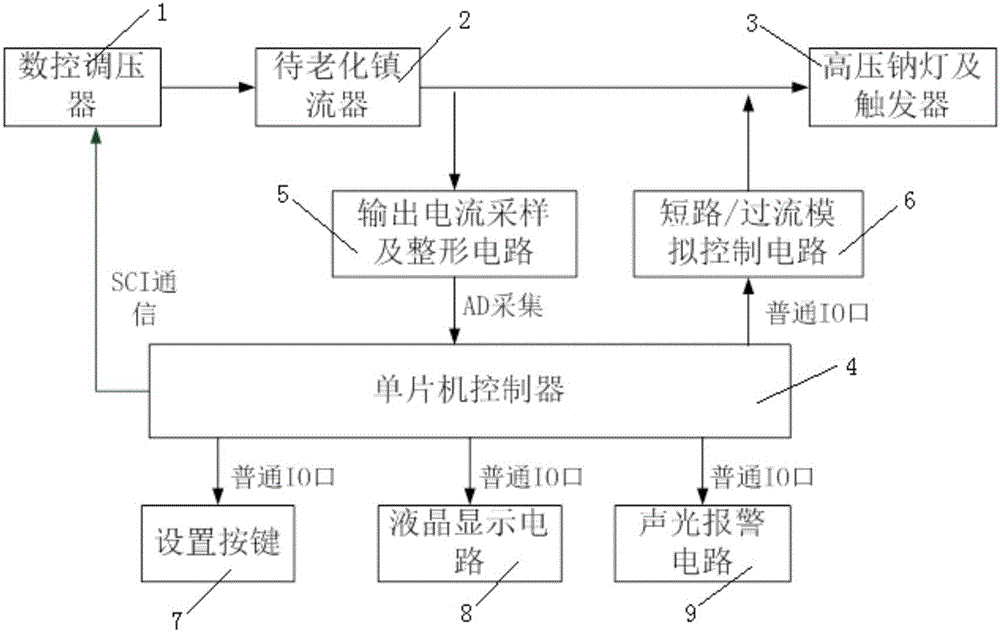

Electrical aging device and method for electronic ballast

InactiveCN105929265AImprove performance and stabilityEnvironmental/reliability testsOvervoltageNumerical control

Owner:XIAYGAN ZHICHENG TECH SERVICES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com