Model coil of interturn insulation test of oil-immersed power transformer and manufacturing method of model coil

A technology of power transformers and transformer coils, which is applied in the directions of transformers/inductor coils/windings/connections, measurement of electrical variables, instruments, etc. It can solve the problems of transformer coil differences and few research results on transformer turn-to-turn insulation, and achieve simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

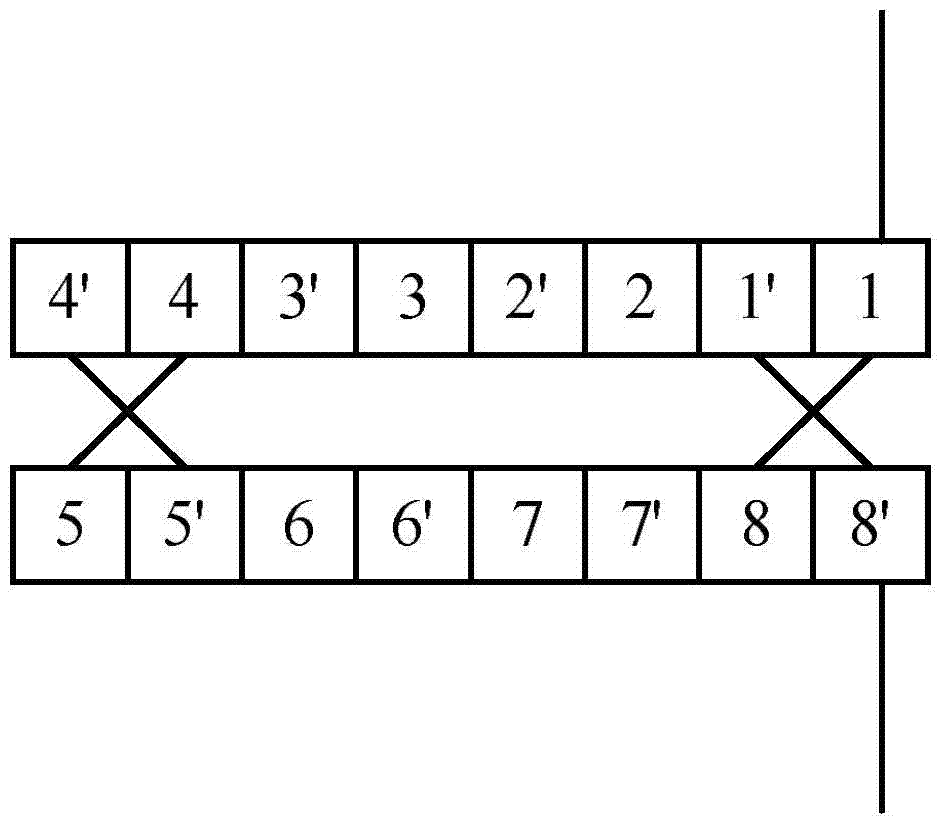

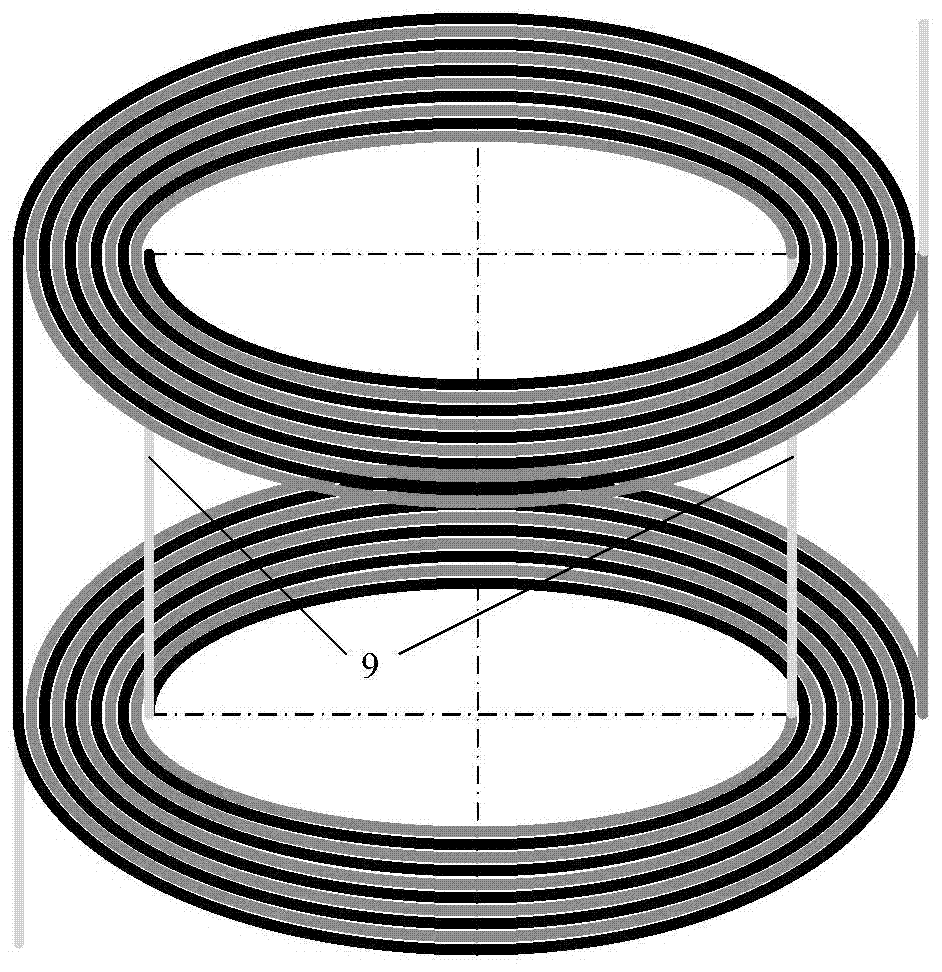

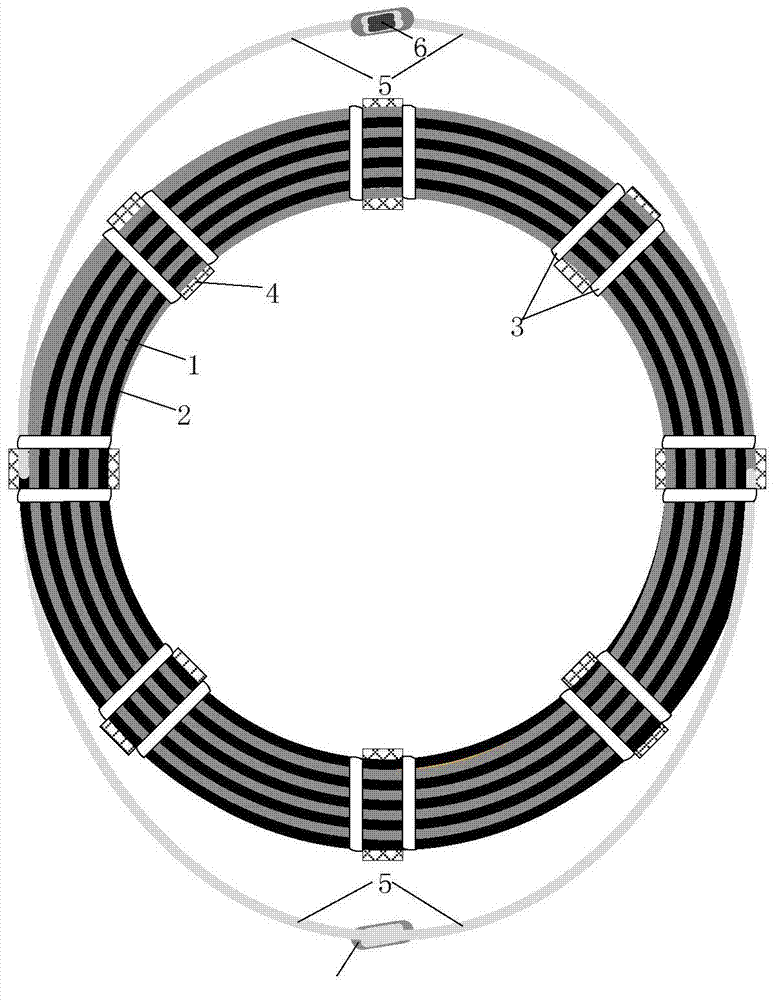

[0039] Combined with a specific 500kV power transformer model coil, such as figure 1 , 2 , 3 shows the embodiment of the model coil for the inter-turn insulation test of the oil-immersed power transformer of the present invention. The specification parameters of the model coil and the type of insulating paper are the same as those of the transformer coil. Pie coil, the two first entangled positions of the transitional part of the two pie coils are wrapped with at least six layers of insulating paper, the two first entangled positions are located in the inner circle of the model coil and the distance is the diameter of the inner circle of the model coil; the beginning and end of each paper-wrapped wire The two ends are connected together and used as high and low voltage lead-out lines respectively; the four lead-out ends of the two paper-wrapped wires are enclosed to form an ellipse, and the two ends of the long axis of the ellipse are the high and low-voltage lead-out lines of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com