Method for determining cross-linked polyethylene insulation voltage tolerance index of alternating-current cable

A technology of cross-linked polyethylene and AC cables, applied in the direction of testing dielectric strength, etc., can solve the problems of small sample size, difficult operation, high equipment requirements, etc., and achieve small sample size, small dispersion and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in more detail below in combination with specific embodiments.

[0031] Utilize the method proposed by the present invention to carry out electric tree branching test to the cross-linked polyethylene insulation of 110kV AC cable, determine its voltage withstand index, comprise the steps:

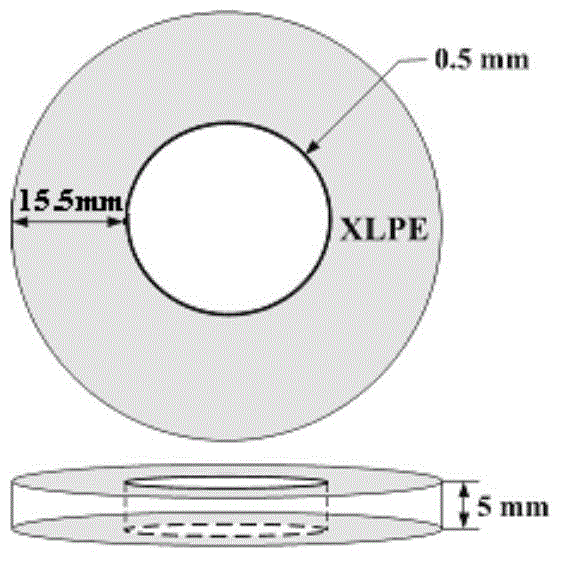

[0032] Step 1: Preparation of test piece. From the insulated core of the 110kV XLPE insulated AC cable, the cable core conductor is pulled out, and the remaining concentric cylinders including the conductor shield, insulation and insulation shield are cut radially with a high-speed lathe to form a thickness of (5 ±0.5)mm hollow disc test piece, or cut a disc into two semicircular test pieces, such as figure 1 shown;

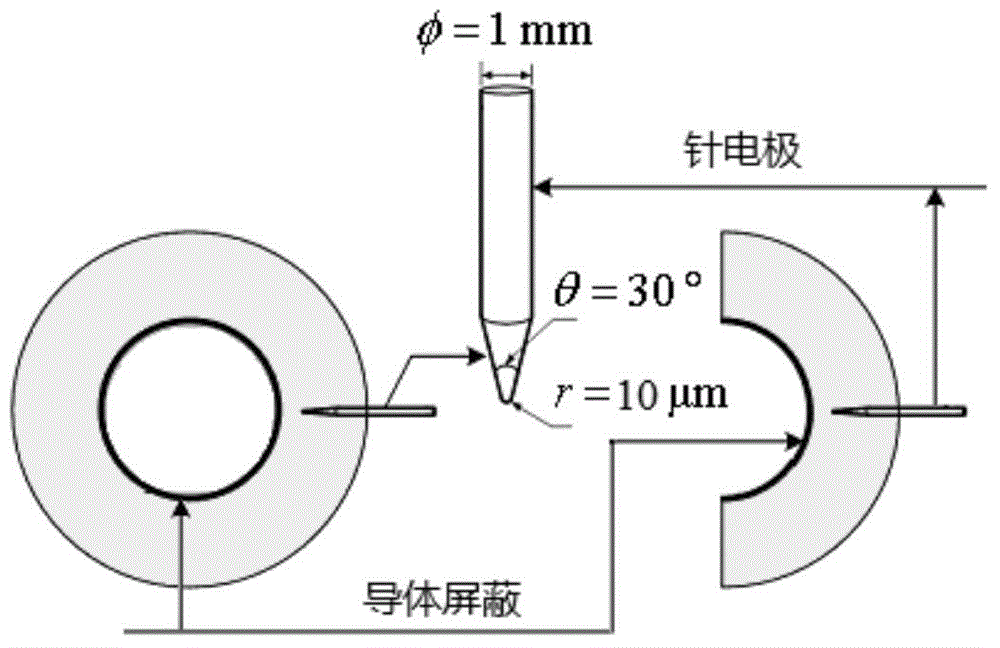

[0033] Step 2: Preparation and pretreatment of needle electrodes. The needle electrode is made of mold steel, with a diameter of (1±0.1) mm, a radius of curvature of the needle tip of (10±1) μm, and a cone angle of 30°. Observe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com