Oil paper insulation electric heating combined aging sealing system

A technology of sealing system and oil-paper insulation, applied in the direction of testing dielectric strength, etc., can solve the problems of product dissipation, inconsistent operation status of transformer sealing, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

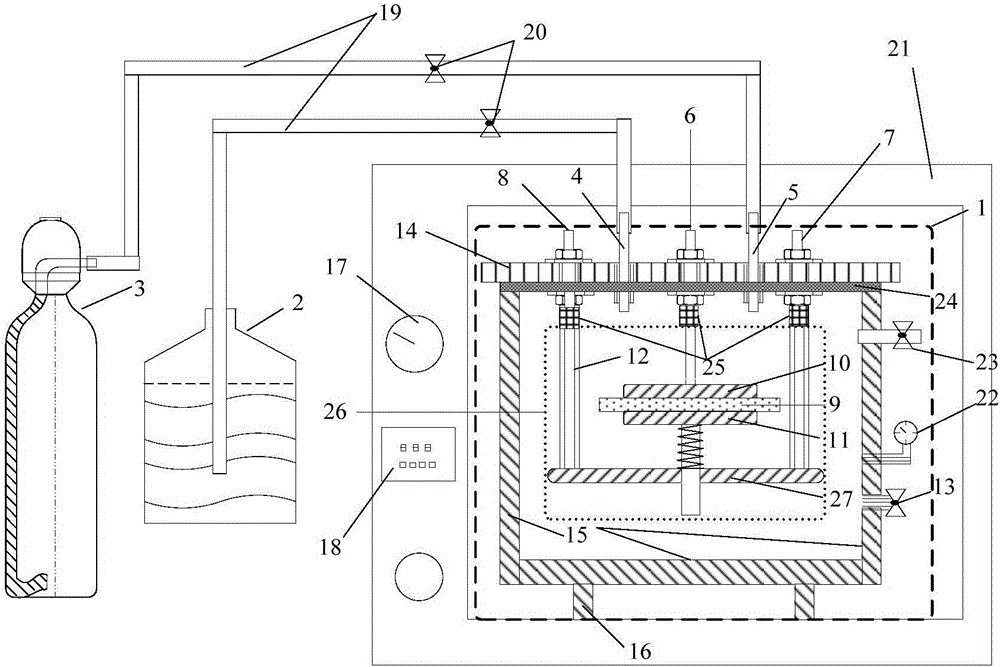

[0026] like figure 1 As shown, the oil-paper-insulated electric-heating combined aging sealing system of the present invention includes an electrical aging sealing system 1 , a thermal aging sealing system 21 , an oil storage tank 2 and a nitrogen cylinder 3 .

[0027] Wherein the thermal aging sealing system 21 comprises an openable sealed cavity, the side wall of the sealed cavity is provided with a thermal aging system pressure gauge 17 and a temperature controller 18;

[0028] The electrical aging sealing system 1 is arranged in the sealing cavity of the heat aging sealing system 21, comprising a cavity with an upward opening, the top of the cavity is sealed by an epoxy sealing plate 14, and the gap between the epoxy sealing plate 14 and the top of the cavity is A sealing ring 24 for sealing is provided, and an oil filling port 4 and an air filling port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com