Straight-through drying oven with air curtain system

A drying furnace, straight-through technology, applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems that cannot meet the requirements of the working environment in the workshop, the smoke is easy to overflow, and the temperature is channeled, so as to prevent channeling temperature problem, reduce energy consumption, and ensure the effect of drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

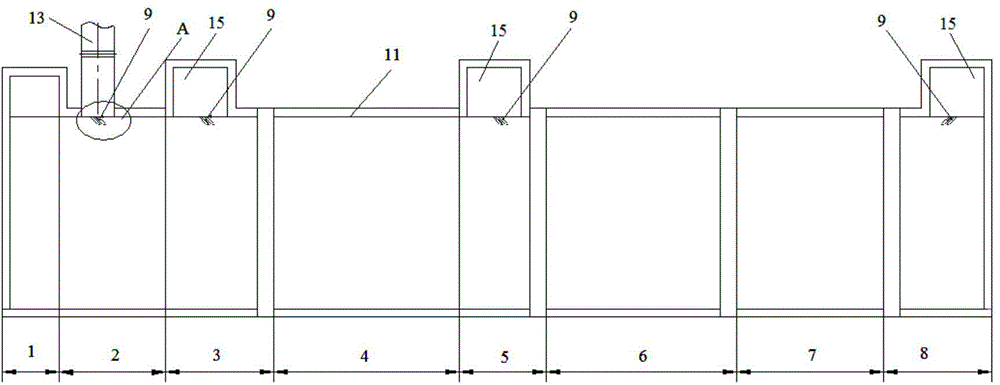

[0025] Such as figure 1 The straight-through drying furnace with air curtain system shown includes entrance hood area 1, fresh air air curtain area 2, entrance air curtain area 3, preheating area 4, and internal air curtain area 5, which are sequentially connected from front to back , heating zone 6, heat preservation zone 7, outlet air curtain zone 8 and outlet smoke hood zone; The top wall plate 11 of the drying furnace in the inlet air curtain area 3 , the inner air curtain area 5 and the outlet air curtain area 8 is respectively provided with a circulating air inlet 15 connecting each air curtain area.

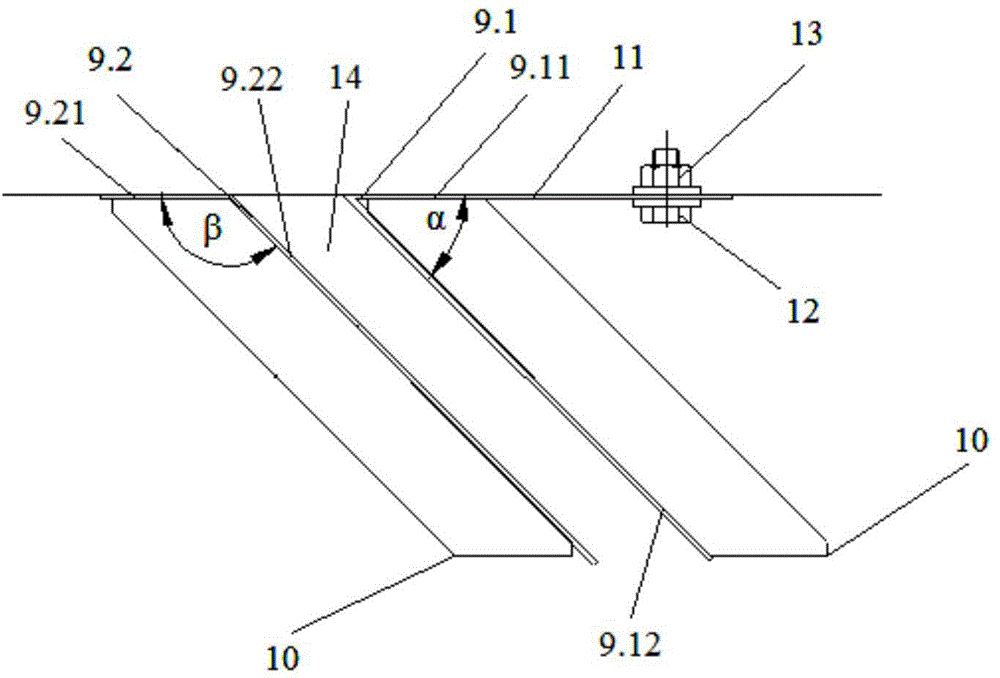

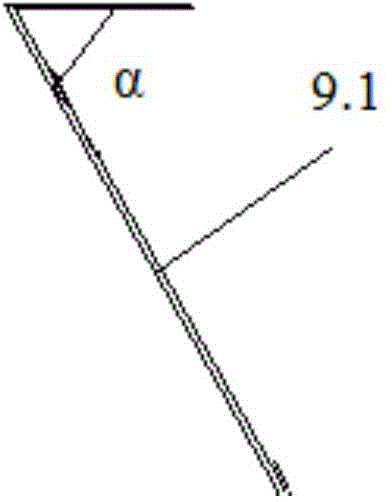

[0026] Several air curtain guide plates 9 are respectively arranged in the fresh air air curtain area 2, the inlet air curtain area 3, the internal air curtain area 5 and the outlet air curtain area 8, such as figure 2 shown, combined with image 3 , 4 As shown, the air curtain guide plate 9 includes a first corner plate 9.1 and a second corner plate 9.2, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com