Insulating material electrical aging performance evaluation device and detection method

A technology of insulating materials and evaluation devices, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems that the performance of the material itself cannot be effectively evaluated, and achieve improved reliability, strong practicability, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

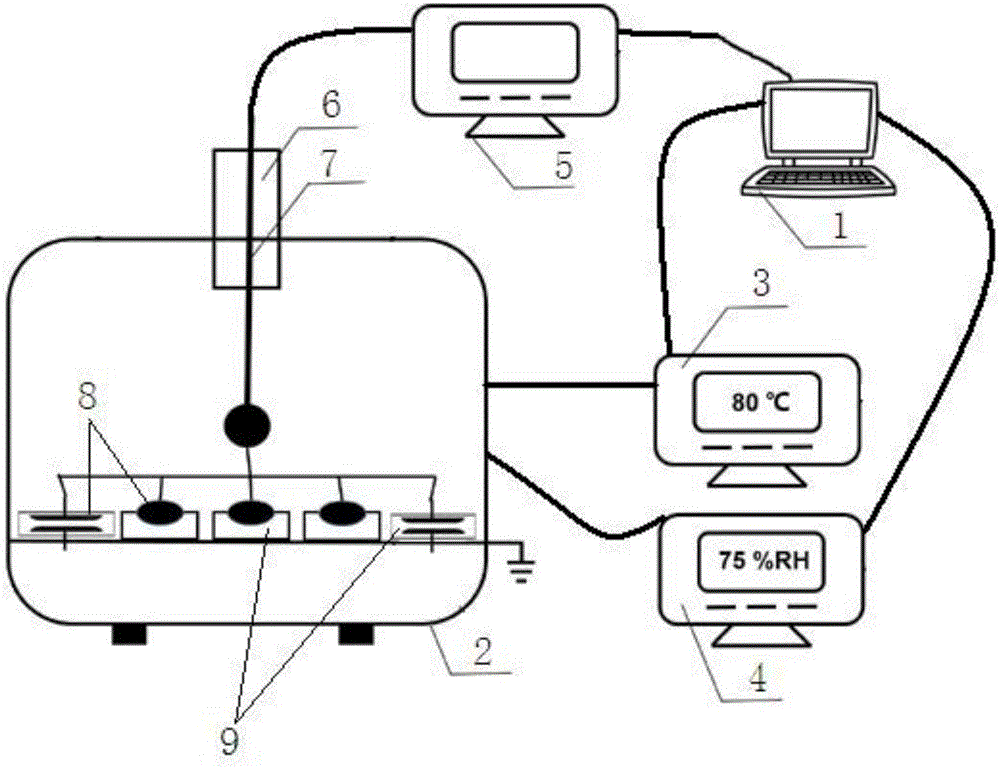

Method used

Image

Examples

Embodiment 1

[0051] Aging tests of HPN, PA, and PBT materials at different temperatures and voltages for 1 month.

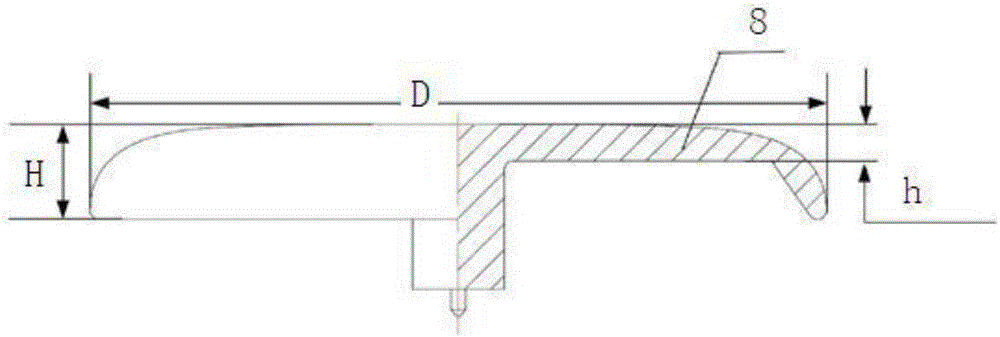

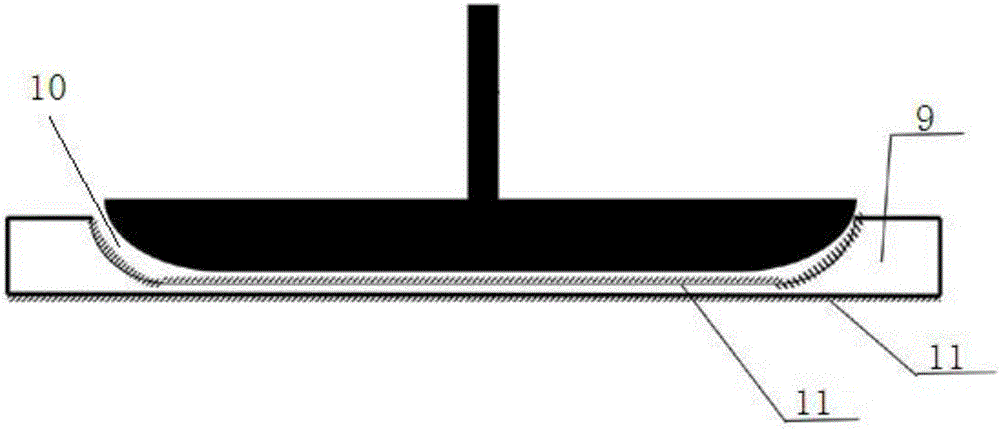

[0052] The nylon material to be tested is injection-molded into a sample tooling 9I type by an injection molding machine, and the distance between the bottom of the groove 10 and the bottom surface of the sample tooling 9 is 1mm.

[0053] The groove 10 and the bottom surface of the sample tooling 9 are plated with silver 11, the electrodes 8 connected to the high-voltage lead wire 7 are put into the groove 10 and pressed tightly, and immersed in insulating oil, and the bottom surface of the sample tooling 9 is grounded.

[0054] The diameter D of the electrode 8 used is 40 mm, the thickness h is 2 mm, and the surface roughness is less than 1.6 um.

[0055] Repeat the above steps to put all other groups of samples into the sample chamber 2, apply a power frequency voltage of 5kV / 10kV / 15kV to the samples through the high-voltage introduction device, control the ambient humidity...

Embodiment 2

[0059] Aging test of epoxy materials at different temperatures and voltages for 1 month.

[0060] The epoxy material to be tested is formed into a sample tooling 9II by APG process, and the distance between the parallel electrodes 8 is 1mm. The electrode 8 at the high voltage end of the sample tooling 9 is connected to the high voltage lead 7, and the electrode 8 at the low voltage end is grounded.

[0061] Repeat the above steps to put all other groups of samples into the sample chamber 2, apply a power frequency voltage of 5kV / 10kV / 15kV to the samples through the high-voltage introduction device, control the ambient humidity to 50%RH, and control the ambient temperature to 80°C, 100 ℃ and 120 ℃ were tested for 1 month. After 1 month, the breakdown strength of the material was tested.

[0062] The test results of breakdown strength (kV / mm) are shown in Table 2:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com