Multi-factor phase color tube aging simulation experiment method

A simulation experiment, multi-factor technology, applied in the direction of measuring devices, instruments, measuring electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0021] A multi-factor phase color tube aging simulation experiment method, the steps are:

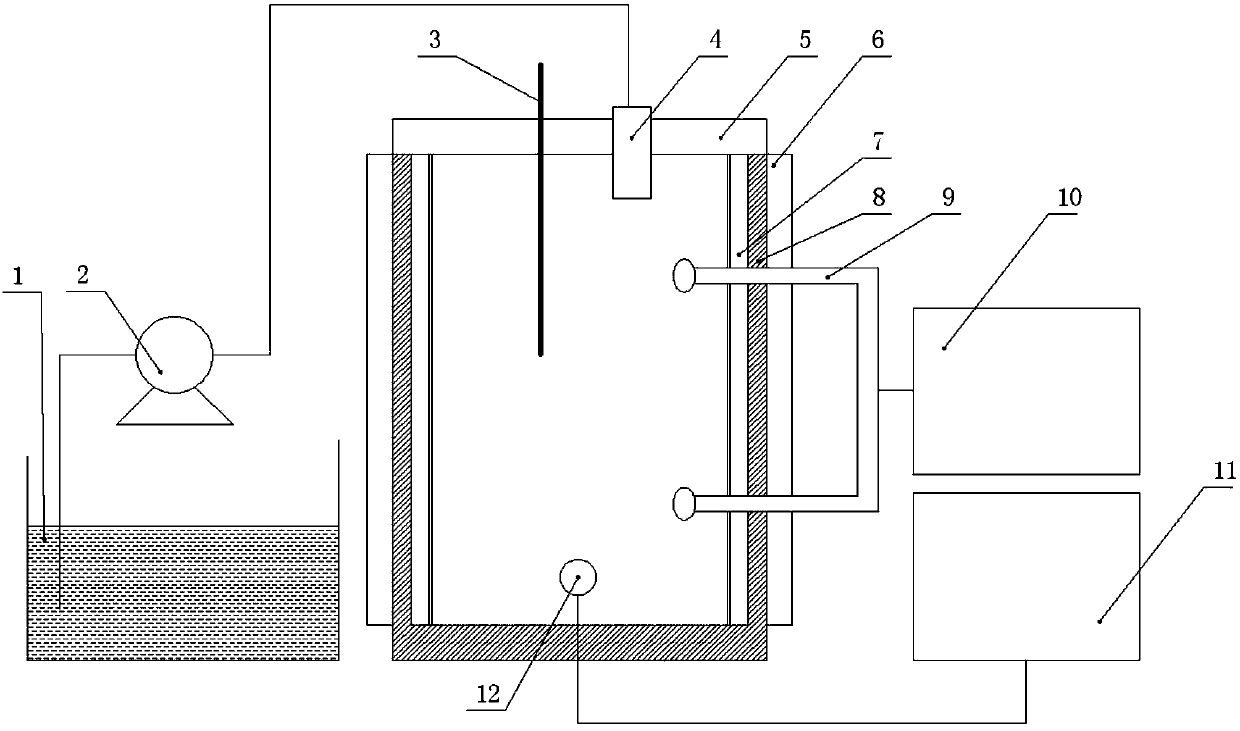

[0022] ⑴ Prepare a test box, which is equipped with heating system, chemical erosion system, radiation system, high voltage electrode and data detection system;

[0023] (2) Place the cylindrical phase-chromatic tube in the inner cavity of the box;

[0024] (3) The temperature range of the inner cavity of the box is 25-2500°C, and the humidity is 0-10%;

[0025] ⑷ Inject chemical corrosion liquid into the inner cavity of the box through the chemical corrosion system;

[0026] (5) The inner cavity of the box is fed with 2-20kV AC voltage through the high-voltage electrode;

[0027] ⑹ The radiation system is opened in the cavity of the box, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com