Motor

A technology of stator iron core and inclined part, which is applied in the shape/style/structure of winding insulation, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of winding area, insulation thickness, surface limitation, etc. , to achieve the effect of saving material cost and reducing insulation thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific structure of the motor of the present invention will be described in detail below with reference to the accompanying drawings.

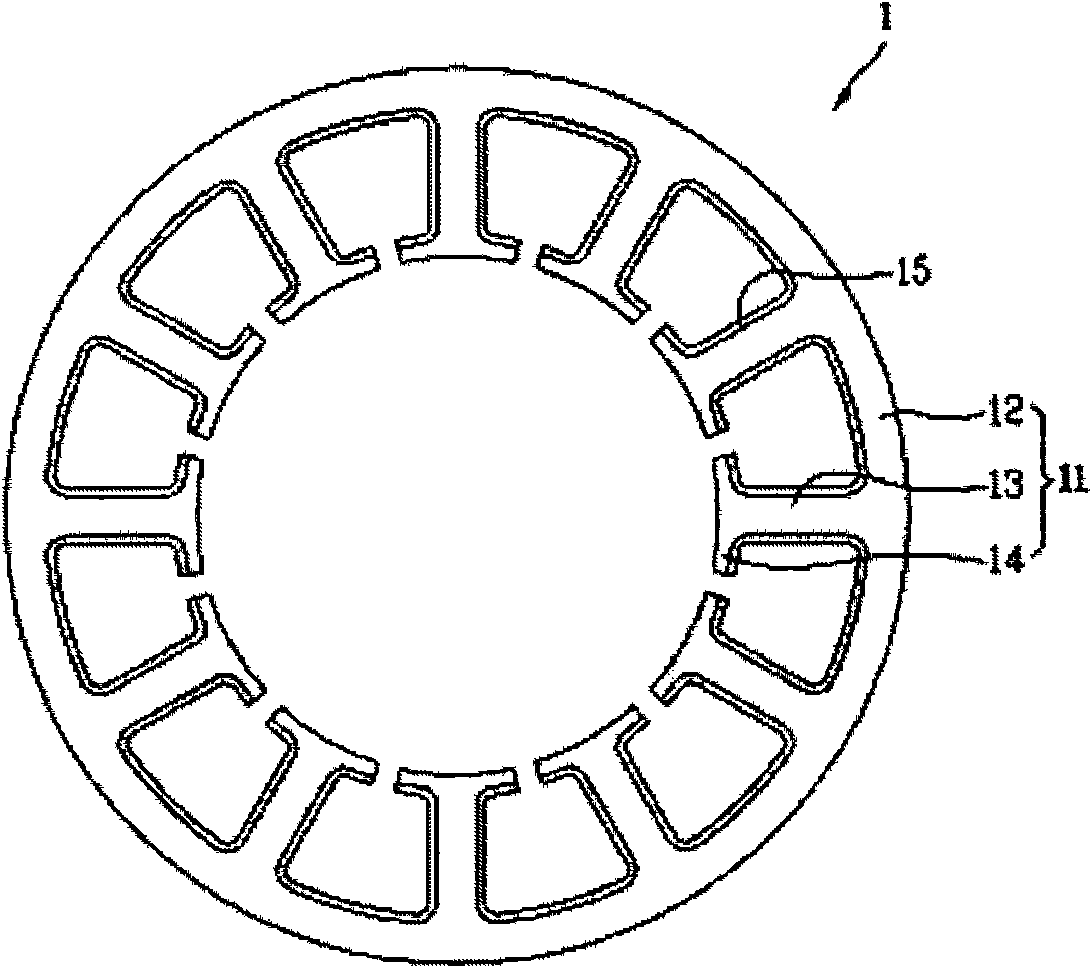

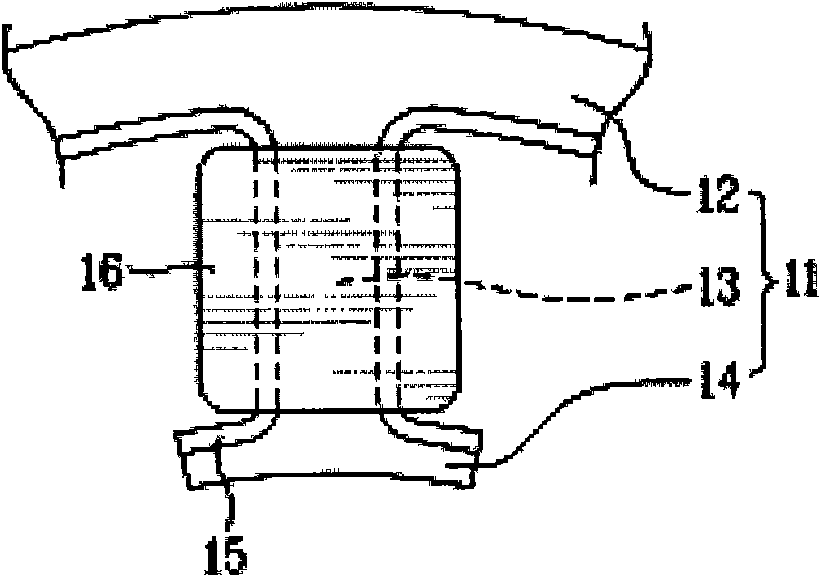

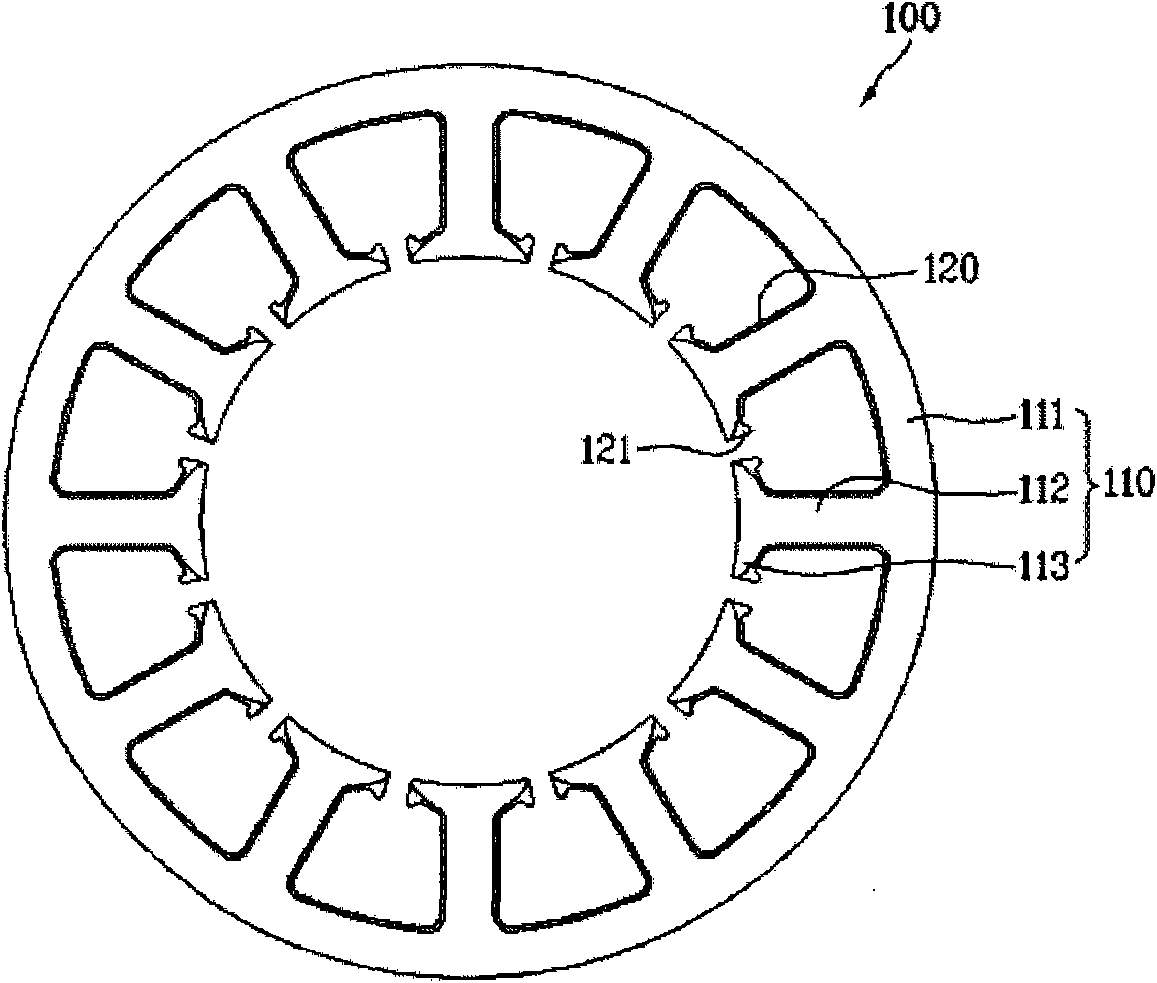

[0036] image 3 It is a schematic cross-sectional view of the stator core and the insulator structure of the present invention, Figure 4 It is a sectional view of the motor structure of the present invention.

[0037] like image 3 , Figure 4 As shown, the motor 100 of the present invention includes: a stator core 110 fixedly arranged on the casing (not shown in the figure), an insulator 120 that makes the stator core 110 in an insulated state, and when the power is turned on Stator windings 130 forming a rotating magnetic field.

[0038] The stator core 110 is composed of a plurality of silicon steel sheets composed of a plurality of T-shaped pieces 112 protruding in the radial direction of the stator core 110 in the radial direction of the stator core 110, and a plurality of T-shaped pieces 112 formed in the circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com