Heat exchange unit

a heat exchange unit and heat exchange resin technology, applied in the direction of lighting and heating apparatus, machine operation mode, etc., can solve the problems of small cracks and fractures in the insulating resin layer, drawbacks recur, etc., to improve the adhesion, prevent cracks and fractures, and optimize the surface roughness of the heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

1. First Embodiment

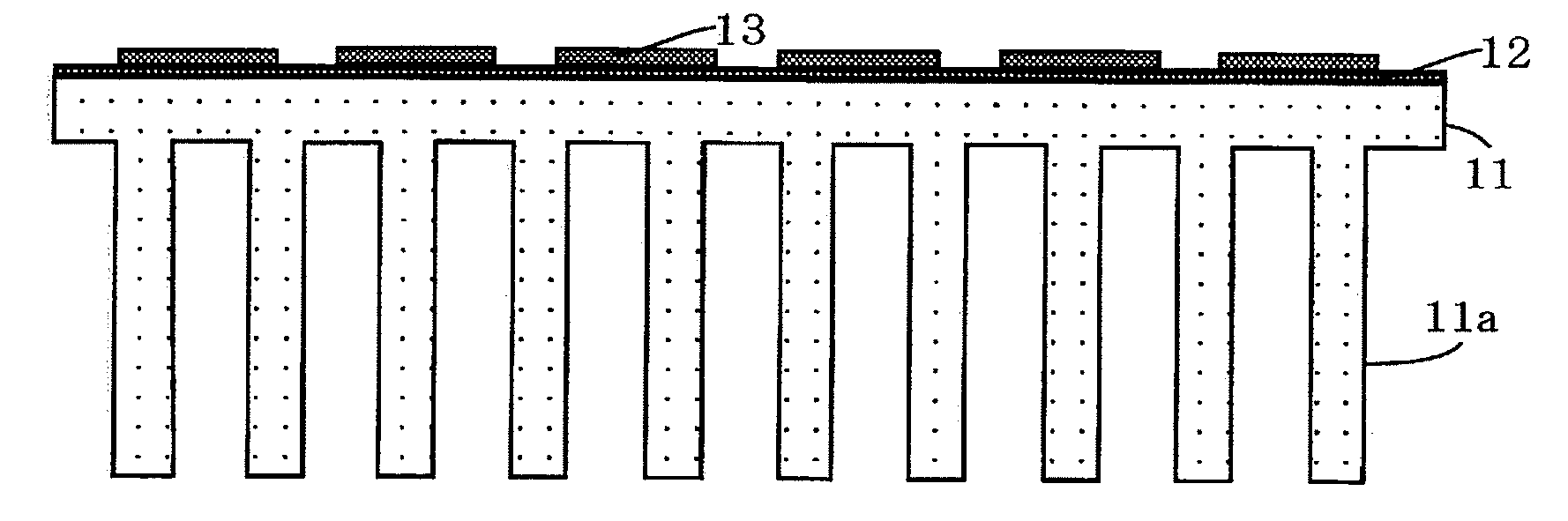

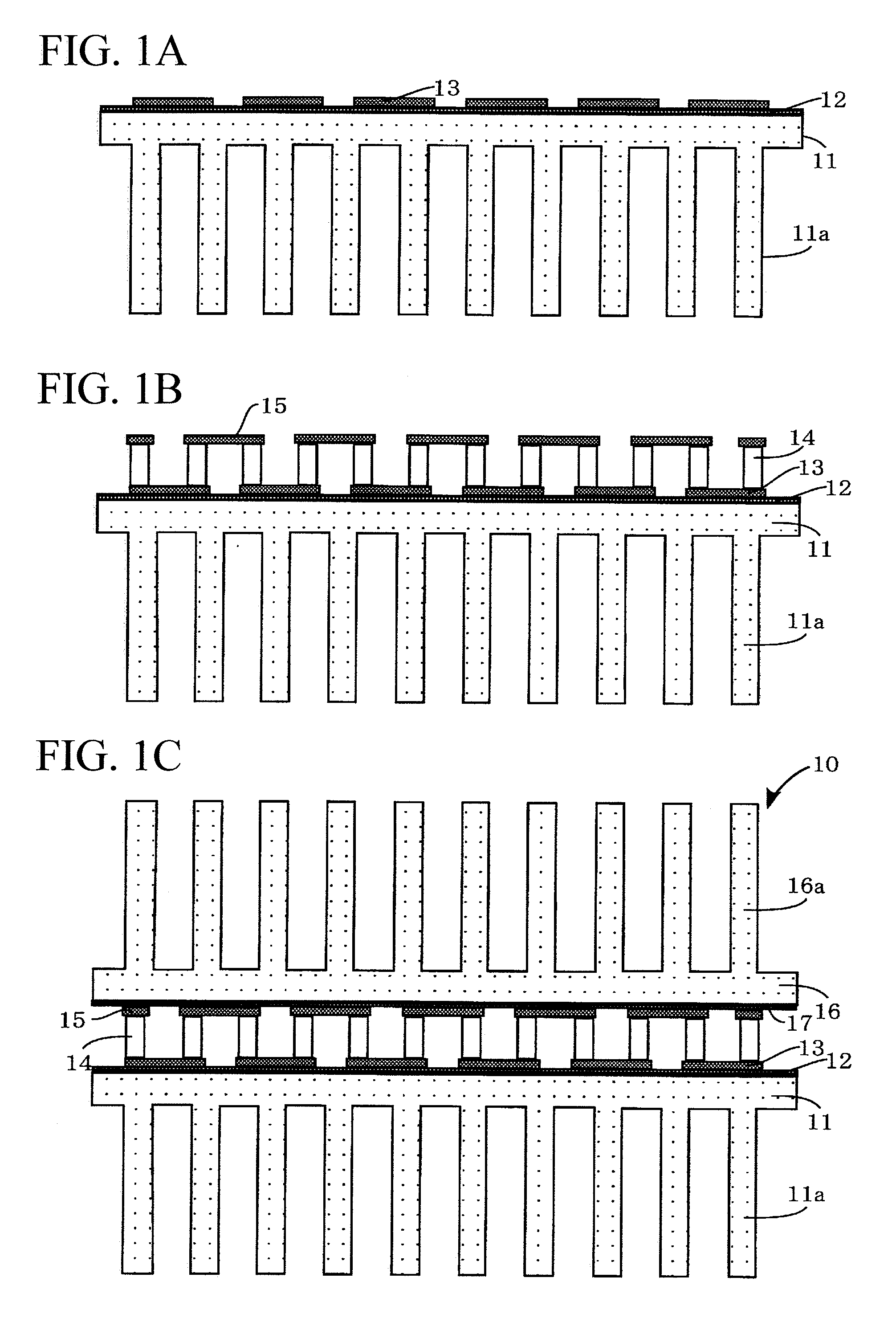

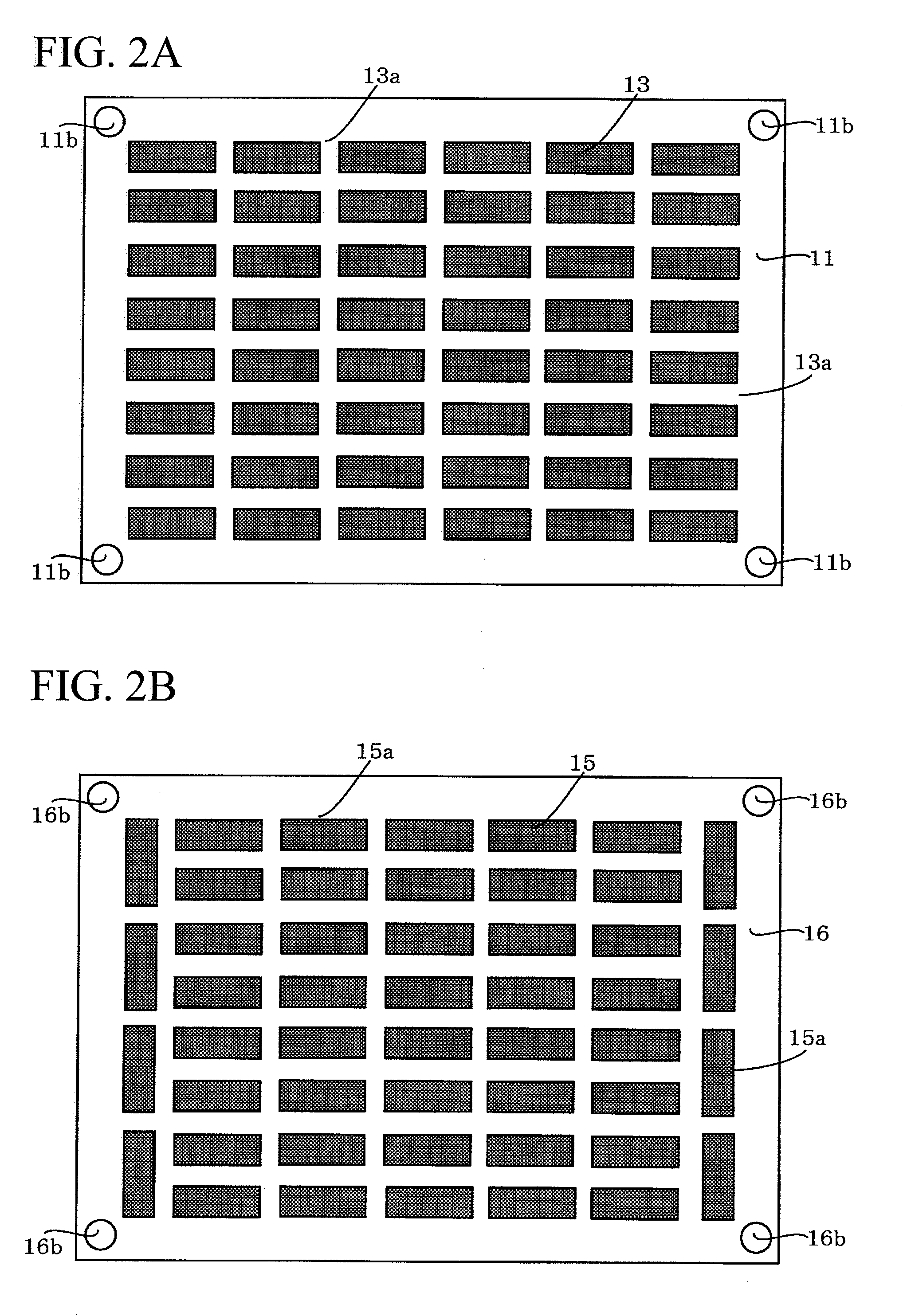

[0043]A heat exchange unit 10 according to a first embodiment of the present invention will be described with reference to FIGS. 1A to 1C. As shown in FIG. 1C, the heat exchange unit 10 is constituted of a first heat exchanger (serving as a heat-dissipation or heat-absorption air-cooled heatsink) 11, an insulating layer 12 formed on the surface of the first heat exchanger 11, a lower electrode (serving as a heat-dissipation or heat-absorption electrode) 13 disposed on the insulating layer 12, a plurality of thermoelectric elements 14 bonded onto the lower electrode 13, an upper electrode (serving as a heat-dissipation or heat-absorption electrode) 15 bonded onto the thermoelectric elements 14, a second heat exchanger (serving as a heat-dissipation or heat-absorption air-cooled heatsink) 16, and an insulating layer 17 formed on the surface of the second heat exchanger 16. A pair of terminals connected to a pair of leads (both not shown) is formed on one end of the ...

second embodiment

2. Second Embodiment

[0084]The first embodiment is directed to the heat exchange unit 10 constituted of the first heat exchanger 11 and the second heat exchanger 16 each serving as air-cooled heatsinks, which is not a restriction; hence, it is possible to employ a water-cooled heatsink. A second embodiment is designed to use water-cooled heatsinks as first and second heat exchangers.

[0085]A heat exchange unit 20 according to a second embodiment of the present invention will be described with reference to FIGS. 6A to 6C. As shown in FIG. 6C, the heat exchange unit 20 is constituted of a first heat exchanger (serving as a heat-dissipation or heat-absorption water-cooled heatsink) 21, an insulating layer 22 formed on the surface of the first heat exchanger 21, a lower electrode (serving as a heat-dissipation or heat-absorption electrode) 23 disposed on the insulating layer 22, a plurality of thermoelectric elements 24 bonded onto the lower electrode 23, an upper electrode (serving as a ...

third embodiment

3. Third Embodiment

[0116]The heat exchange unit 10 of the first embodiment and the heat exchange unit 20 of the second embodiment are designed such that the electrodes 13, 15, 23, and 25 are uniformly formed on the surfaces of the heat exchangers 11, 16, 21, and 26; but when prescribed areas on the surfaces of the heat exchangers do not allow for the uniform alignment of the electrodes thereon, it is possible to align the electrodes so as to be kept out of the prescribed areas on the surfaces of the heat exchangers. A third embodiment of the present invention is designed based on this concept.

[0117]A heat exchange unit 30 according to the third embodiment of the present invention will be described with reference to FIGS. 10A to 10C. As shown in FIG. 10C, the heat exchange unit 30 is constituted of a first heat exchanger (serving as a heat-dissipation or heat-absorption water-cooled heatsink) 31, insulating layers 32a and 32b formed on the surface and the backside of the first heat e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com