Technology for compatibilizing middle-minihydraulic turbine generator

A hydroelectric generator, capacity expansion and transformation technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems affecting the economic and safe operation of power stations, performance index deterioration, obsolete and aging equipment, etc., and achieve mechanical strength Higher, thinner insulation thickness, reduced space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

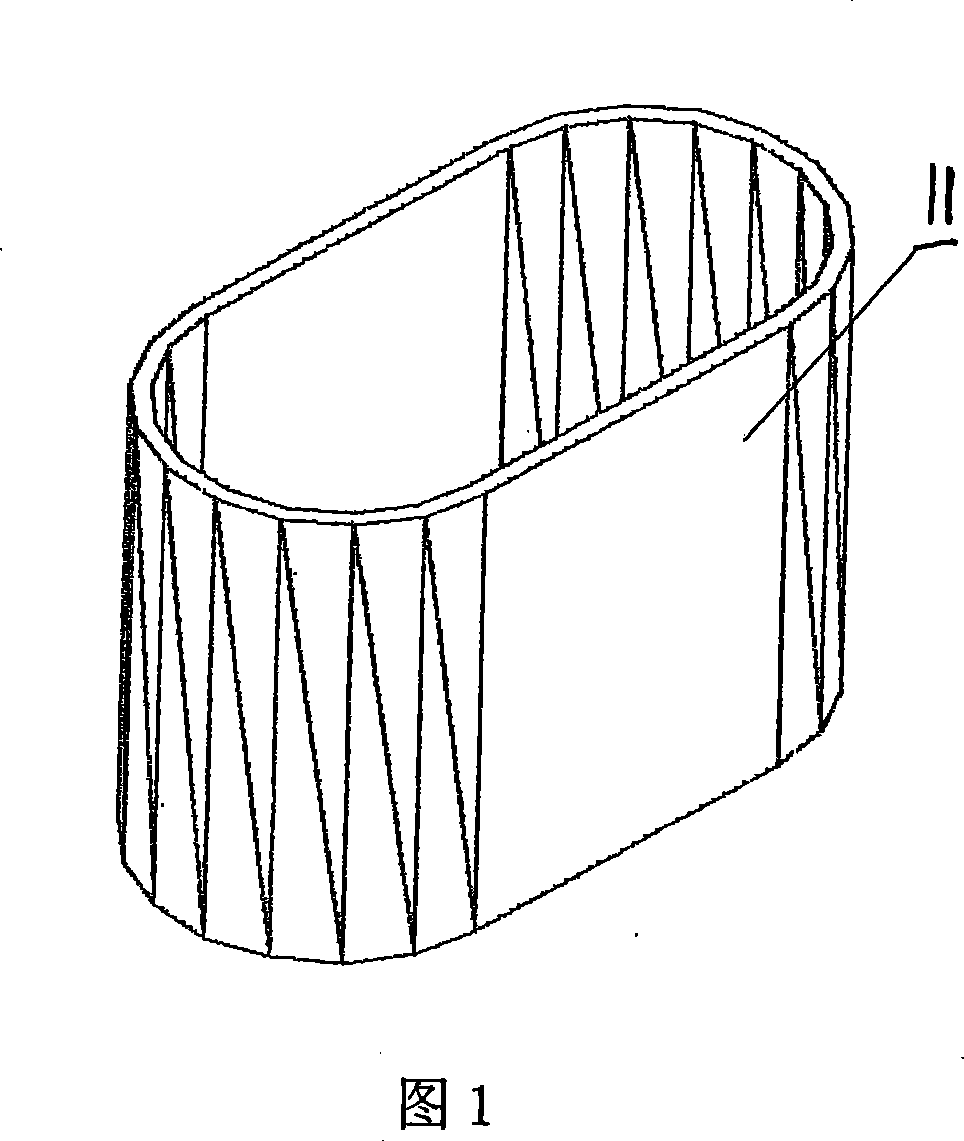

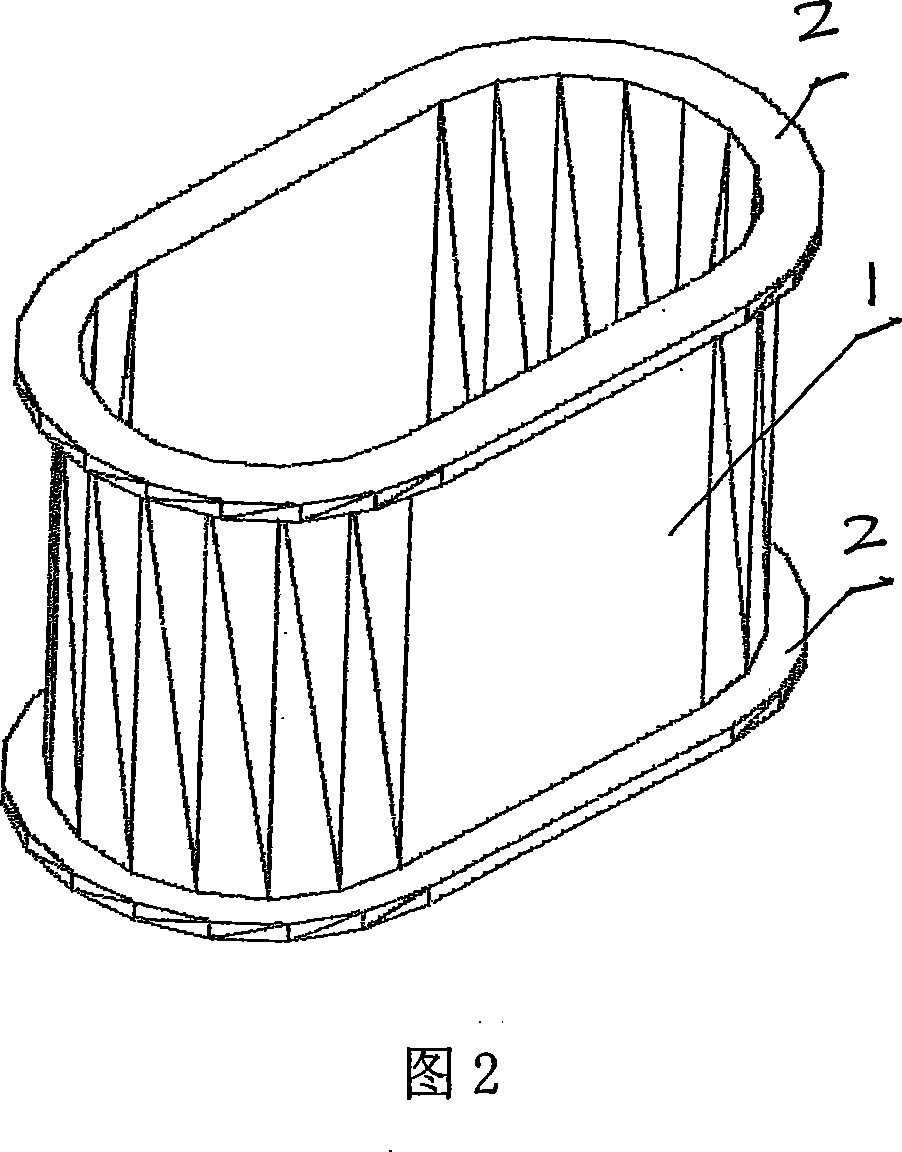

[0018] Embodiment 1: The capacity-enhancing transformation technology of the small and medium-sized hydroelectric generators of this embodiment, under the condition that the groove shape of the original stator core and the height dimension of the magnetic pole core cannot be changed, focuses on the following aspects:

[0019] ●Reduce the insulation thickness of the insulated flat copper wire in the stator coil.

[0020] Thin the insulation thickness of the main insulating powder mica tape of the stator coil.

[0021] ●Develop a new F-class stator coil insulation structure to reduce the unnecessary space occupied by the coil in the slot.

[0022] ●Thin the insulation thickness between turns of the rotor coil.

[0023] ●Develop a new F-class rotor coil insulation structure, improve the insulation form of the pole body, and reduce the thickness of the upper and lower insulation pads to reduce unnecessary space for the coil in the slot.

[0024] 1. Structural design features o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com