Acrylic organosilicone water-emulsion coating as well as preparation method and application for same

An acrylic polysiloxane, acrylic technology, applied in the direction of coating, can solve problems such as affecting the performance of the coating film, and achieve the effects of easy painting, improving water resistance and strength, and high silicone content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Example 1: Preparation of hydrogen-containing polymethylsiloxane emulsion

[0047] (1) Direct preparation

[0048] After mixing the emulsifier 6g sorbitan oleate S-80 (ie Span-80), 14g polyoxyethylene sorbitan oleate T-80 (ie Tween-80) and 200g water, Slowly add 100g of 202 high hydrogen-containing methyl silicone oil (containing 1.5wt% active hydrogen) dropwise under high-speed stirring (1500 rpm) at room temperature, continue stirring for 10 minutes after the addition is completed, and then change to low-speed stirring for 10 minutes, Stirring was stopped, and 320 g of hydrogen-containing polymethylsiloxane emulsion S1 (active hydrogen 1.5 wt %) was prepared.

[0049] Mix 2gS-80, 3gT-80, 1gT-85 and 200g water evenly, raise the temperature to 40°C, and slowly add hydrogen-containing methyl silicone oil (containing 0.75wt% active hydrogen) dropwise under high-speed stirring (1500 rpm) 100g, continue to stir for 10 minutes after the dropwise addition, then change to lo...

example 2

[0054] Example 2: Preparation of Acrylic Polymer

[0055] (1) Preparation of acrylic copolymer emulsion

[0056] After mixing 30g of methacrylic acid and 70g of ethyl acrylate, slowly drop them into 190g of aqueous solution containing 2g of nonylphenol polyoxyethylene ether (NP-10) and 1g of sodium dodecylbenzenesulfonate under rapid stirring After half an hour, the dropwise addition was completed, and then 0.3 g of ammonium persulfate was added to prepare a pre-emulsion. Then take 50g of it, add it to 10g of aqueous solution containing 0.2g of ammonium persulfate, stir, and heat up the water bath to 70°C for reaction. hour, then heated up to 85°C for half an hour, cooled, added water to 303g, and prepared an emulsion P1.

[0057] After mixing 10g of acrylic acid, 70g of ethyl acrylate, 10g of methyl acrylate and 10g of butyl methacrylate, slowly add it dropwise under rapid stirring to 190g of aqueous solution containing 2g of NP-10 and 1g of sodium dodecylbenzenesulfonate ...

Embodiment 3~17

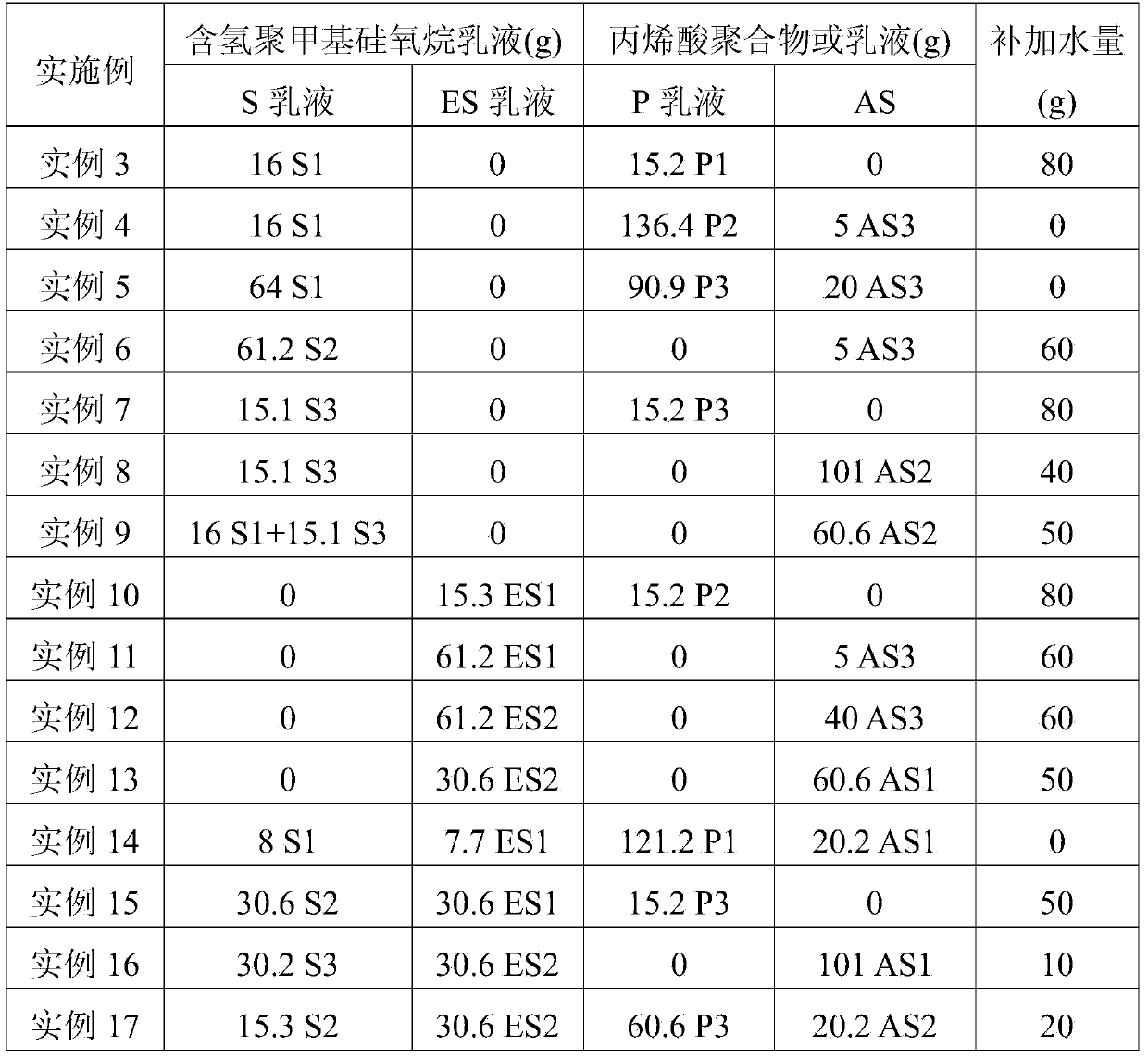

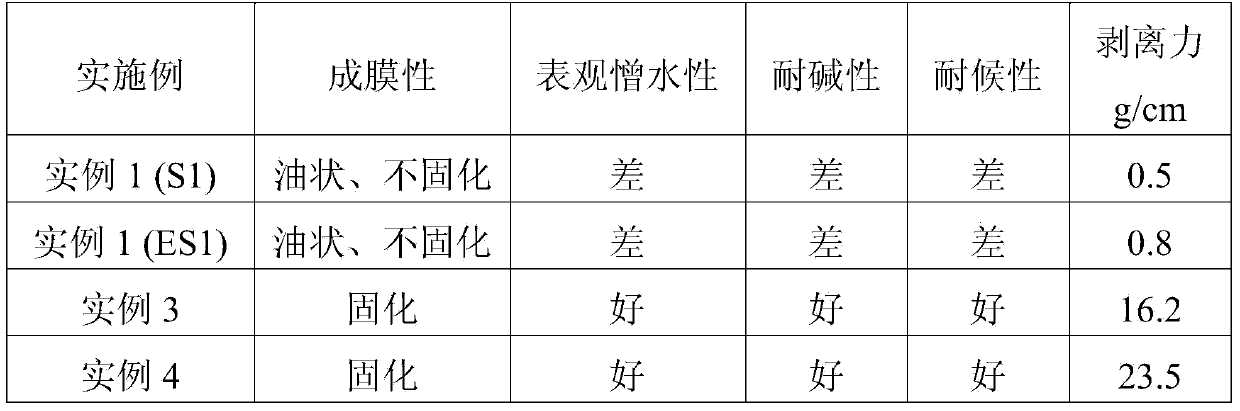

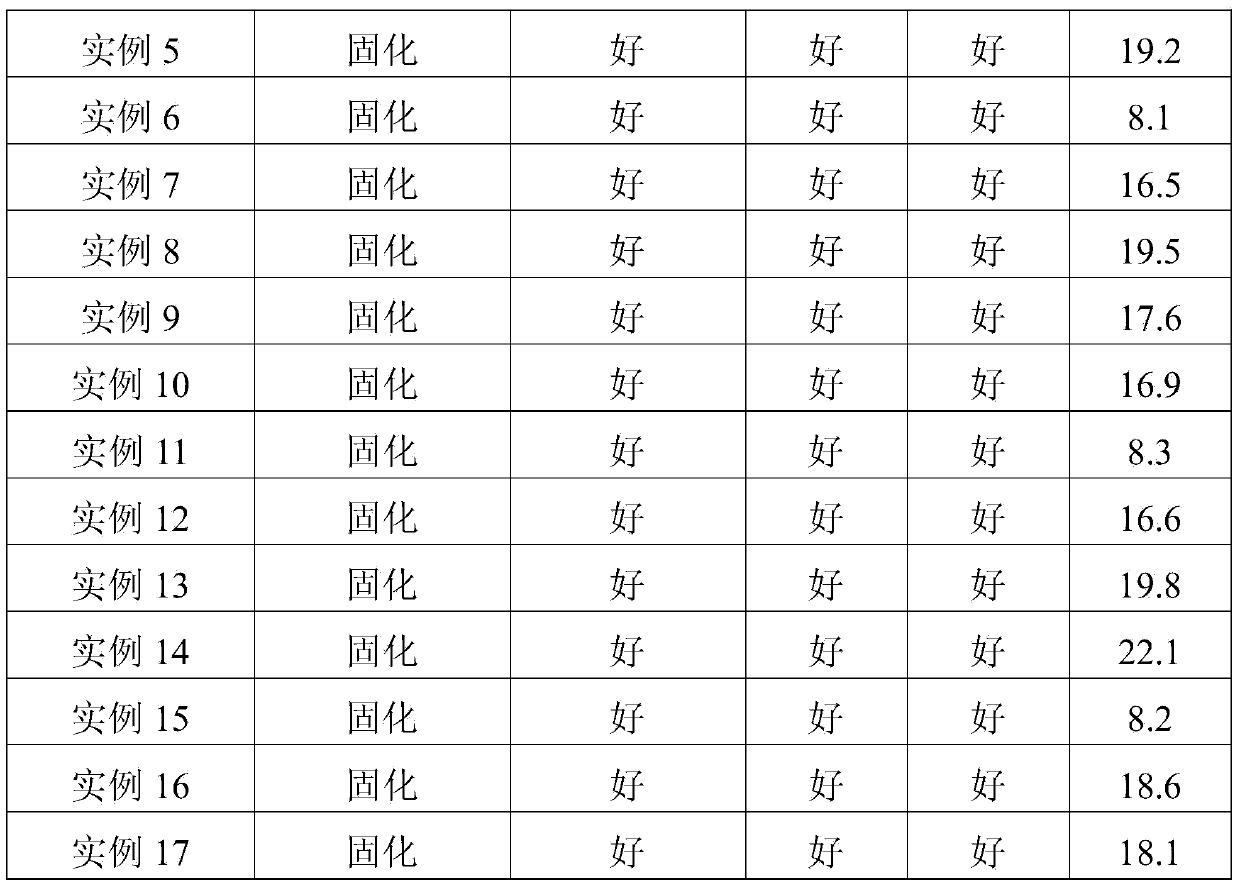

[0063] Embodiment 3~17: the preparation of acrylic silicone water-emulsion coating

[0064] According to the hydrogen-containing polymethylsiloxane emulsion and the acrylic acid polymer obtained in the above examples 1-2, prepare the acrylic silicone water-emulsion paint according to the formula in Table 1, and the specific operation is as follows: the hydrogen-containing polymethylsiloxane The emulsion is compounded with the acrylic polymer or its emulsion at room temperature, and the corresponding water is added, and the corresponding acrylic silicone water-emulsion paint is respectively obtained after stirring evenly. The contents of each component are shown in Table 2.

[0065] Experiments have proved that at room temperature, hydrogen-containing polymethylsiloxane emulsions S1, S2, S3, ES1, ES2 and acrylic polysiloxane emulsions AS1, AS2, AS3 are still stable after one year of storage, without floating oil, separation, etc. Layer, precipitation, agglomeration, gel phenome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com