A kind of preparation method of silicone resin microemulsion

A technology of microemulsion and silicone, applied in the field of silicone resin, to achieve the effect of convenient operation, high content of silicone resin and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

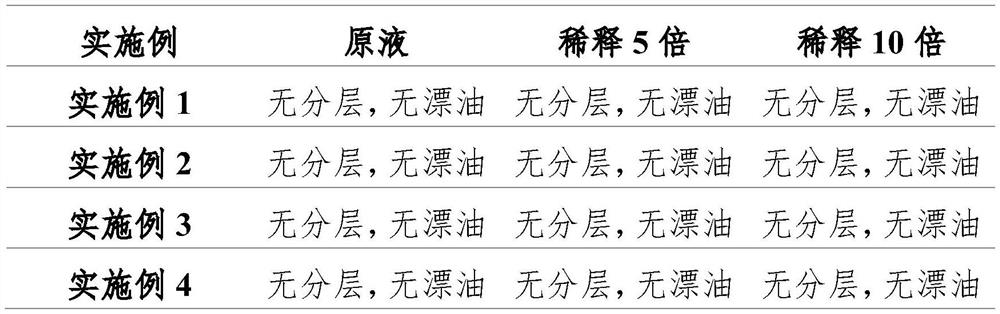

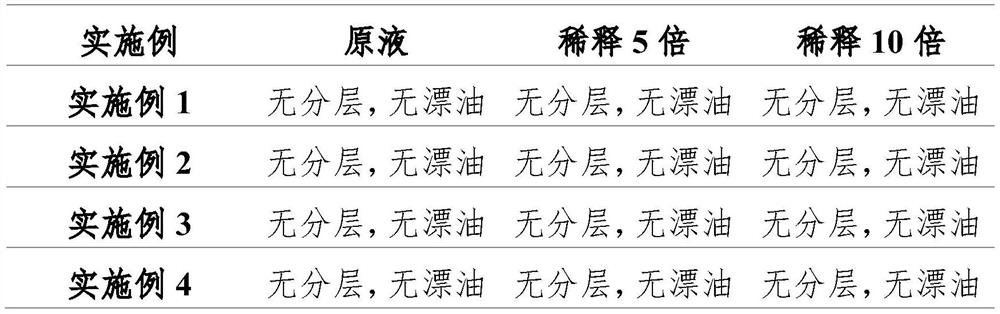

Examples

Embodiment 1

[0026] In terms of parts by mass, add 100 parts of vinyl MQ silicone resin with a viscosity of 2000mPa.s and a vinyl content of 10wt%, 35.4 parts of 3-mercaptopropionic acid and 2.7 parts of benzoin bimethacin in a container equipped with a thermometer and a stirring rod Ether, at room temperature, irradiated with ultraviolet light with a main wavelength of 365nm and an intensity of 120W / cm for 8 minutes, raised the temperature to 70°C, added 140 parts of triethanolamine solution with a concentration of 36wt% under vigorous stirring, and continued to stir vigorously for half an hour to obtain a solid containing About 50 wt% of the translucent silicone resin microemulsion has a pH value of 7.2 as measured by a pH meter.

Embodiment 2

[0028] In terms of parts by mass, add 100 parts of vinyl phenyl silicone resin with a viscosity of 100mPa.s and a vinyl content of 1wt%, 4.45 parts of 4-mercaptobutyric acid and 5.2 parts of benzoin bis Methyl ether is irradiated with ultraviolet light with a main wavelength of 365nm and an intensity of 120W / cm for 5 minutes, and the temperature is raised to 80°C, and 105 parts of triethanolamine solution with a concentration of 5.5wt% is added under vigorous stirring, and the vigorous stirring is continued for half an hour to obtain a solid content of about The pH value of the 50 wt% translucent silicone resin microemulsion is 7.1 as measured by a pH meter.

Embodiment 3

[0030] In terms of parts by mass, add 100 parts of vinyl fluorine-containing silicone resin with a viscosity of 500mPa.s and a vinyl content of 4wt%, 20.9 parts of 6-mercaptocaproic acid and 3.6 parts of benzoin cloves in a container equipped with a thermometer and a stirring rod Ether, irradiated with ultraviolet light with a main wavelength of 365nm and an intensity of 80W / cm for 3 minutes, raised the temperature to 80°C, added 120 parts of diethanolamine solution with a concentration of 12.5wt% under vigorous stirring, and continued to stir vigorously for half an hour to obtain a solid content of about 50wt % translucent silicone resin microemulsion, the pH value measured by a pH meter is 7.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com