A kind of silicone acrylic emulsion and preparation method thereof

A silicone-acrylic emulsion and emulsifier technology, applied in the coating and other directions, can solve the problems of high film-forming temperature and low organic silicon content, and achieve the effects of strong hydrophobicity, lower film-forming temperature and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

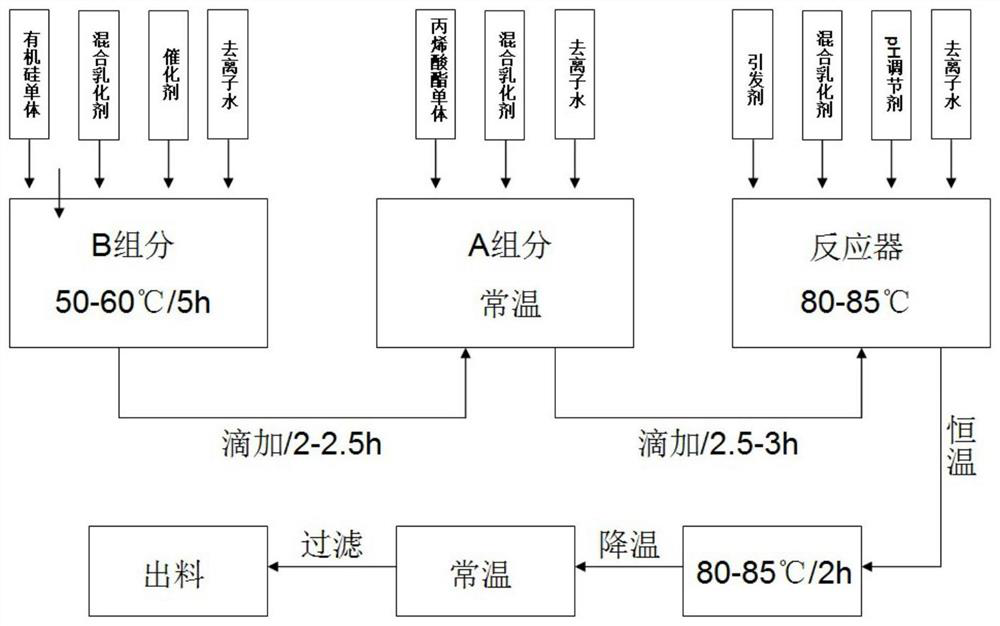

Method used

Image

Examples

Embodiment 1

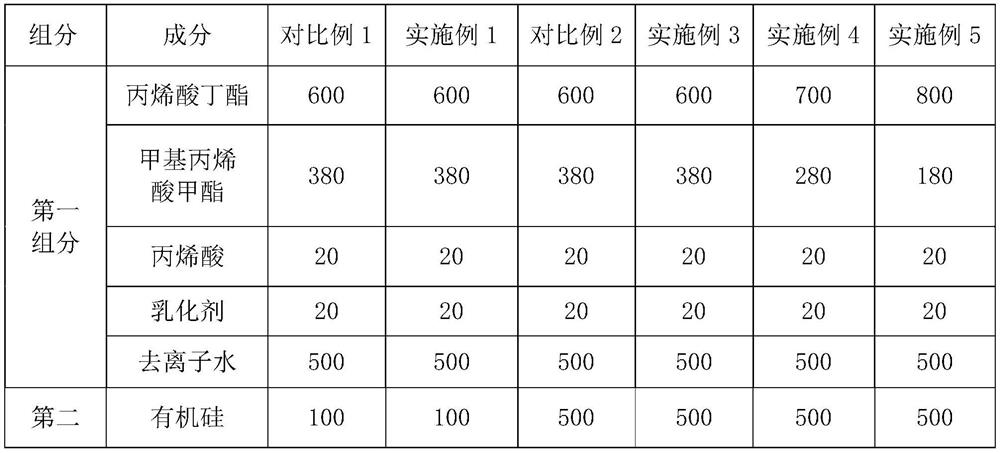

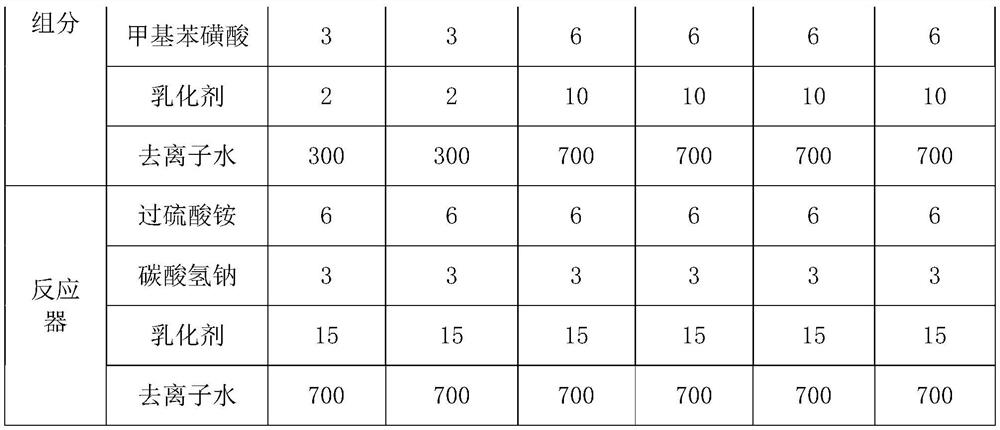

[0036] Prepare the raw materials according to the formula shown in Table 1. The emulsifier is a mixture of sodium lauryl sulfate and alkylphenol polyoxyethylene ether, the mass ratio of the two is 2:1; the organic silicon monomer is octamethylcyclotetrasiloxane The mixture of oxygen and vinyl triethoxy siloxane, the mass ratio of the two is 3:1;

[0037] Mix methyl methacrylate, butyl acrylate, acrylic acid, emulsifier and deionized water, and stir at room temperature for 30 minutes to form the first component after pre-emulsification; combine the silicone monomer, dodecylbenzene sulfonic acid, emulsifier and Mix deionized water, stir at room temperature for 30 minutes to pre-emulsify, then heat to about 55°C and keep at constant temperature for 5 hours to form the second component; add deionized water, emulsifier and sodium bicarbonate into the reactor to mix, stir and heat to 80°C At around -85°C, nitrogen gas is introduced into the reactor, and ammonium persulfate is added aft...

Embodiment 2

[0040] The difference between Example 2 and Example 1 lies in the ratio of raw materials.

Embodiment 3

[0042] The difference between Example 3 and Example 1 lies in the ratio of raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com