Adhesive for flexible electronic substrate as well as preparation method and application thereof

A technology for electronic substrates and adhesives, applied in the direction of adhesives, modified epoxy resin adhesives, adhesive types, etc., can solve the problems of adhesive residue and high bonding strength, and achieve less residual adhesive and heat resistance Good, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

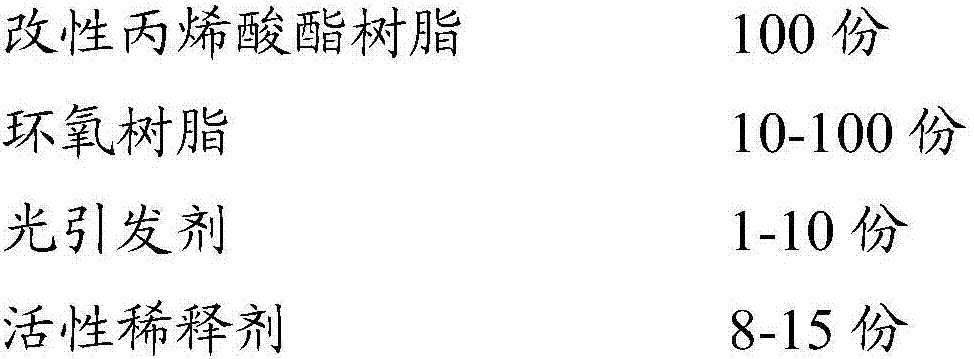

[0073] Mix 100 parts of bisphenol A epoxy-modified acrylate resin (Wenzhou Hengli Printing Materials Co., Ltd., HL-160) with 20 parts of epoxy resin (Bluestar Nantong Xingchen Synthetic Materials Co., Ltd., WSR618), and add 18 1 part of glycidyl methacrylate and 3.6 parts of 1-hydroxycyclohexyl phenyl ketone (Zhejiang Yangfan New Material Co., Ltd., PI008), under dark conditions, use mechanical stirring to mix evenly to obtain component A, and use 2 parts of two Ethylene triamine is component B, which is the two-component BDB adhesive for flexible electronic substrates.

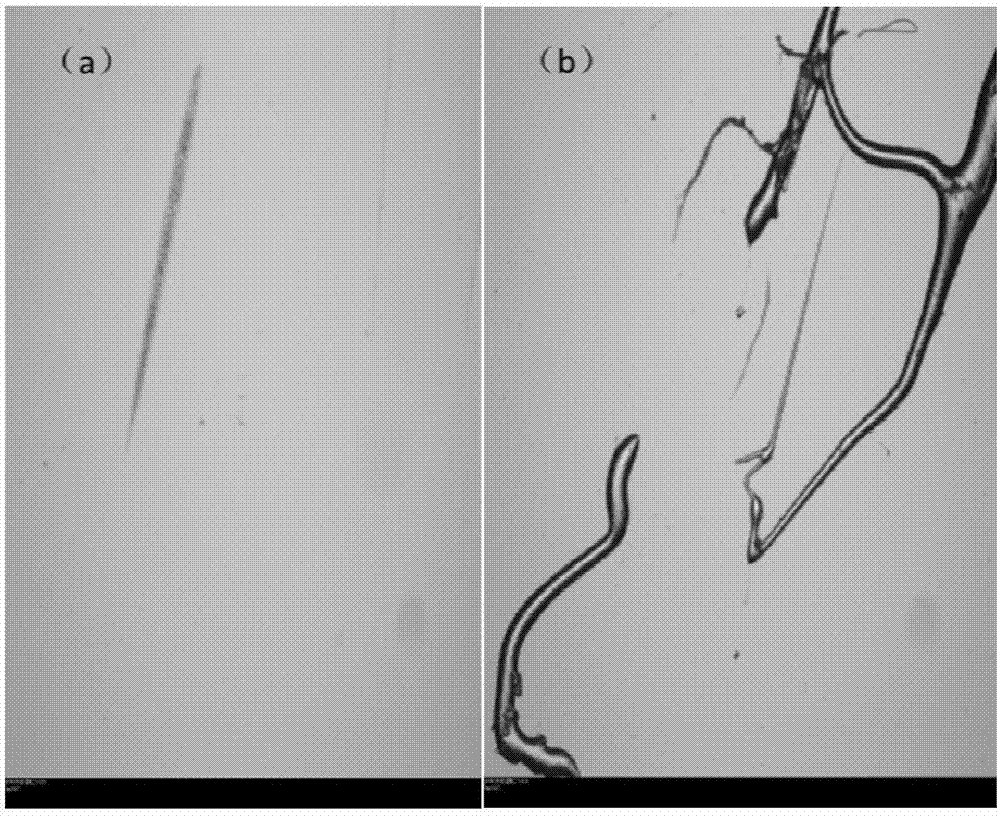

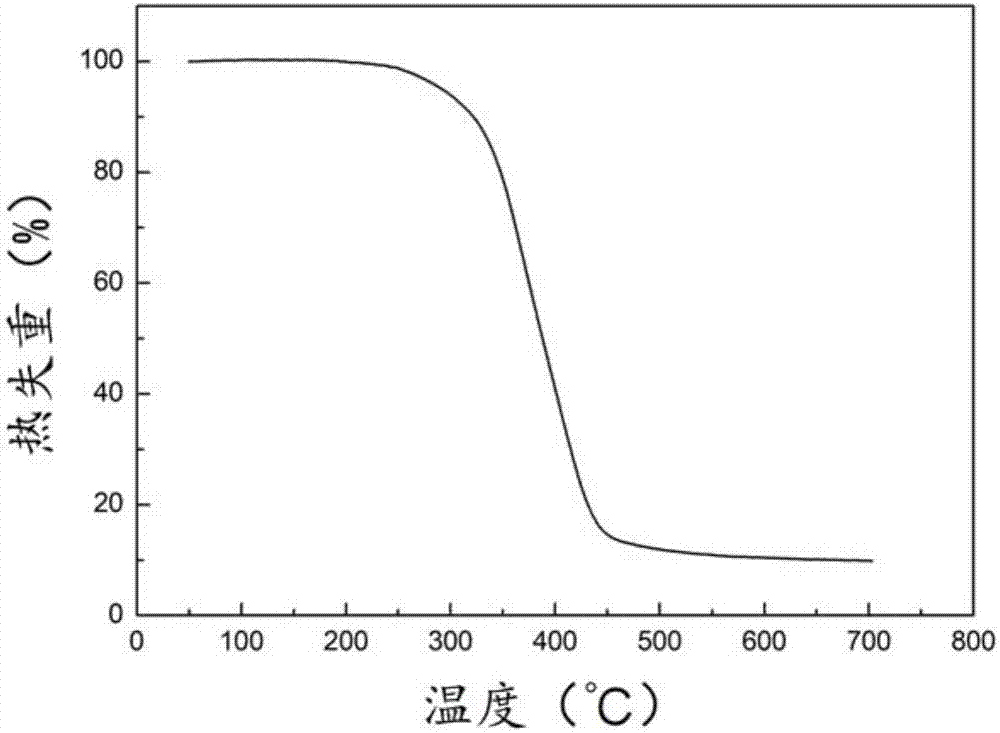

[0074] Add component B to component A and stir evenly, place in a vacuum oven to remove air bubbles, and use an applicator to evenly coat the adhesive on the cleaned hard glass substrate (the thickness of the adhesive layer is 0.1mm). Then the polyimide film (Shanghai Synthetic Resin Research Institute, H film) is pasted on the hard glass substrate coated with adhesive, cured at room temperature for 30min, an...

Embodiment 2~4

[0077] The method of Example 1 is adopted to prepare the adhesive for two-component BDB flexible electronic substrates, the difference is only in changing the amount of diethylenetriamine, its adhesive strength, peel strength and T onset See Table 1 for the values.

[0078] Table 1

[0079]

Embodiment 5~7

[0081] The method of Example 1 was used to prepare the adhesive for two-component BDB flexible electronic substrates. onset See Table 2 for the values.

[0082] Table 2

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com