Precoat metal plate and its manufacturing method

A manufacturing method and technology for metal plates, which can be applied to metal layered products, chemical instruments and methods, metal material coating processes, etc. The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0045] Pre-coated metal plate

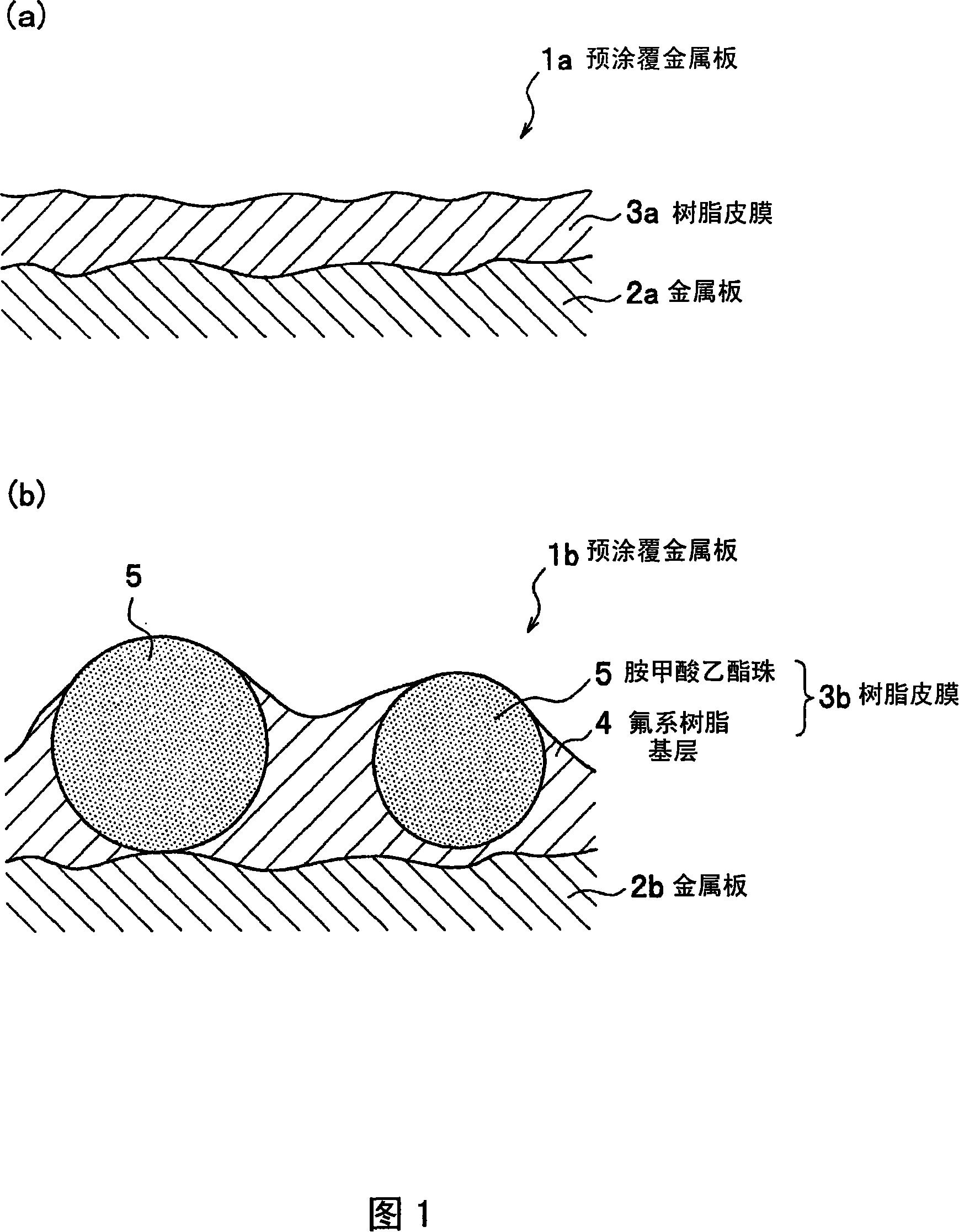

[0046] First, the structure of the pre-coated metal plate according to the first embodiment of the present invention will be described.

[0047] The pre-coated metal plate 1a according to the first embodiment of the present invention includes a metal plate 2a having a base material as shown in FIG. 1A; the surface formed on the metal plate 2a, and is controlled into the outermost surface of the film and the inside of the film. The proportion of fluorine concentrations becomes a resin film 3a of the predetermined value. Here, the surface of the metal plate 2a refers to at least one of the surfaces of the metal plate 2a, preferably two sides. Next, the structures of the pre-coated metal plate 1a will be described.

[0048] (1) Metal plate

[0049] The metal plate 2a used in the first embodiment is not particularly limited, except for the most common cold rolled steel sheet, molten galvanized steel plate, electrozoal steel plate, alloying molten galvan...

Embodiment 1~5

[0079] In Examples 1 to 5, the pre-coated metal plate 1a was produced according to the above-mentioned production method. Each structure of the pre-coated metal plate 1a is as follows.

[0080] (Metal plate)

[0081] An aluminum alloy plate with a thickness of 0.5 mm and based on JIS 5052-H34 is used.

[0082] (Corrosion resistance film)

[0083] Phosphoric chromic acid film is formed on both sides of the aluminum alloy plate, and the adhesion amount of the phosphoric chromic acid film is 20mg / m in terms of Cr conversion. 2 .

[0084] (Fluorine resin film)

[0085] Coat the outermost surface of the phosphoric chromic acid film with a fluorine-based paint, and bake it at the baking temperature (peak temperature of the metal plate 2a) 200, 220, 250, 260, and 280°C to produce a fluorine film with a thickness of 5μm. System resin film. Here, as the fluorine-based paint, a fluorine-based paint in which the following two liquids are mixed is used.

[0086] (Main agent): Fluorine resin w...

Embodiment 6~13

[0107] Next, examples related to the weight average molecular weight and appearance of the fluorine-based resin used as the main agent will be described. As Examples 6-13, the pre-coated metal plate 1a was produced according to the manufacturing method described above. Each structure of the pre-coated metal plate 1a is as follows.

[0108] (Metal plate)

[0109] An aluminum alloy plate with a thickness of 0.5 mm and JIS 5052-H34 standard is used.

[0110] (Corrosion resistance film)

[0111] Phosphoric chromic acid film is formed on both sides of the aluminum alloy plate. The adhesion amount of the phosphoric chromic acid film is 20mg / m in terms of Cr 2 .

[0112] (Resin film)

[0113] A fluorine-based paint was applied to the outermost surface of the phosphoric chromic acid film, and baked at a baking temperature (peak temperature of the metal plate 2a) of 250°C to form a fluorine-based resin film 3a with a film thickness of 5 μm. Here, as the fluorine-based paint, a mixed fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com