Tool assembly for machining axial flow pump blades, and precision machining method for axial flow pump blades

A technology for machining shafts and tooling is applied in the field of tooling assembly for machining axial flow pump blades and the precision machining field of axial flow pump blades, to achieve the effects of eliminating internal stress, corrosion fatigue performance and improving stress corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further explained below in conjunction with the drawings:

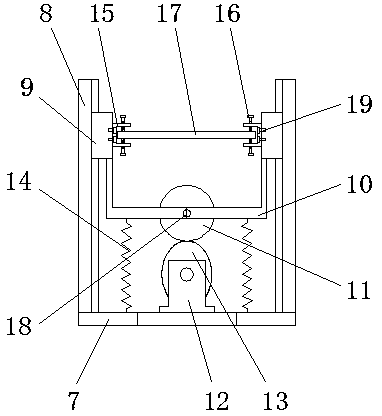

[0056] Such as Figure 1-12 As shown, a tooling combination for machining axial flow pump blades. The axial flow pump blade processing tooling combination consists of rough milling tooling, vibration aging tooling, grinding tooling, semi-finishing tooling, combined pneumatic suction cup tooling and shot blasting nozzle tooling. .

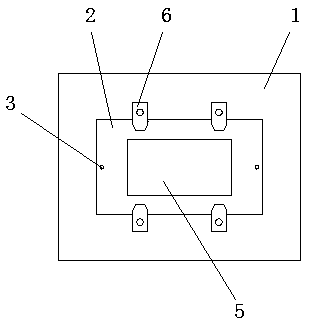

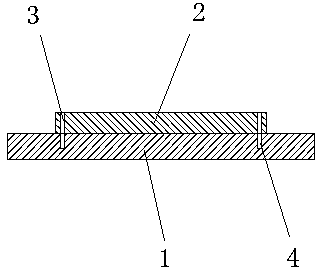

[0057] Such as Figure 1-2 As shown, a tooling combination for machining axial flow pump blades. The rough milling tool is composed of a rough milling base plate 1, a rough milling workpiece 2 and a rough milling press plate 6. The rough milling base plate 1 is fixedly arranged on the worktable of a CNC machine tool. The bottom plate 1 is provided with two rough milling bottom plate positioning pin holes 4, the rough milling workpiece 2 is provided with two rough milling workpiece positioning pin holes 3, and the rough milling workpiece 2 is fixed on the roug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com