Aluminum-based composite material multi-direction double-level deformation restraining device and application method thereof

A technology of aluminum-based composite materials and deformation devices, which is applied in the field of multi-directional double-stage restraint deformation devices for aluminum-based composite materials, can solve the problems of increasing the size of the material in the diameter direction, and achieve the prevention of significant reduction, controllable deformation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

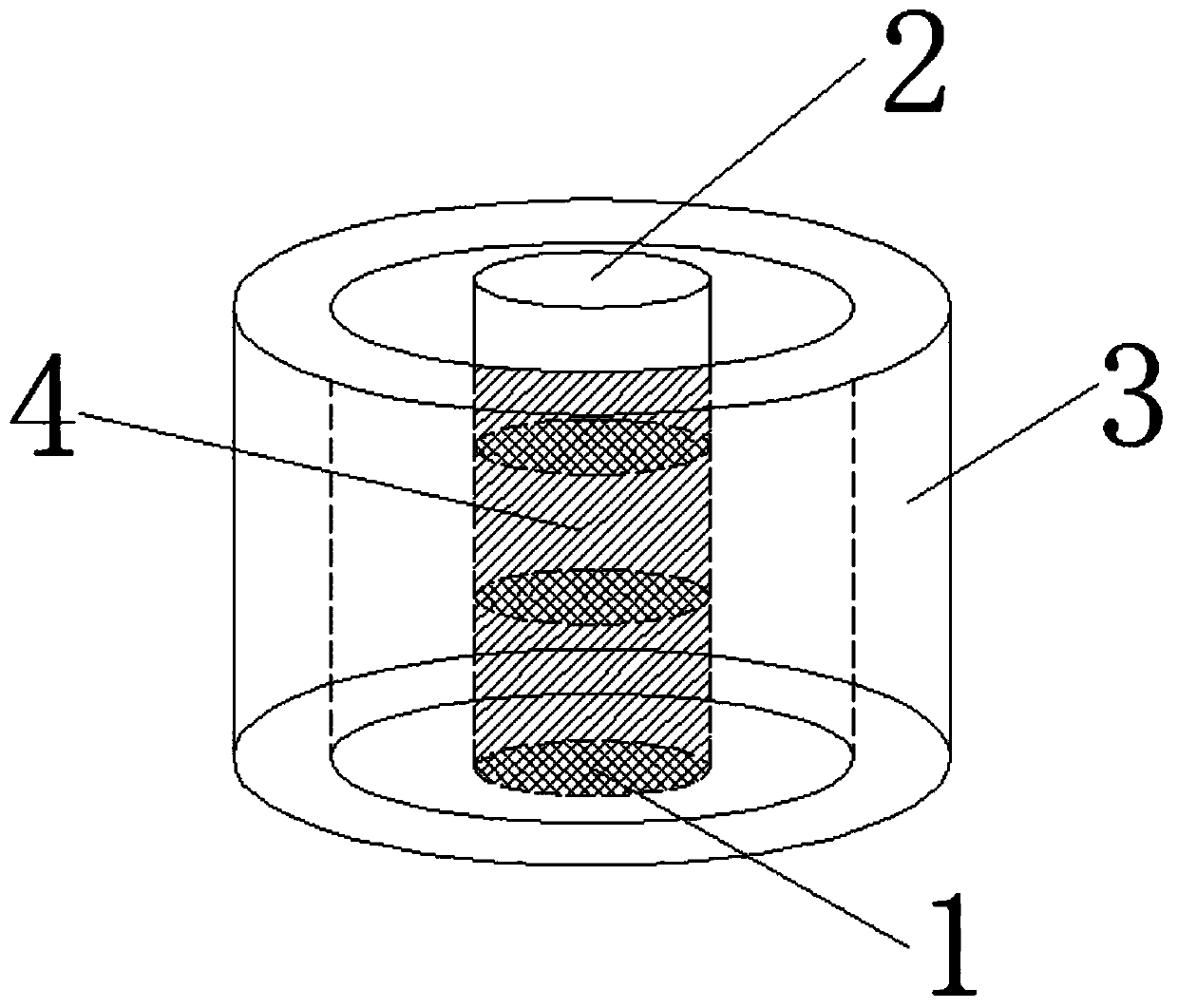

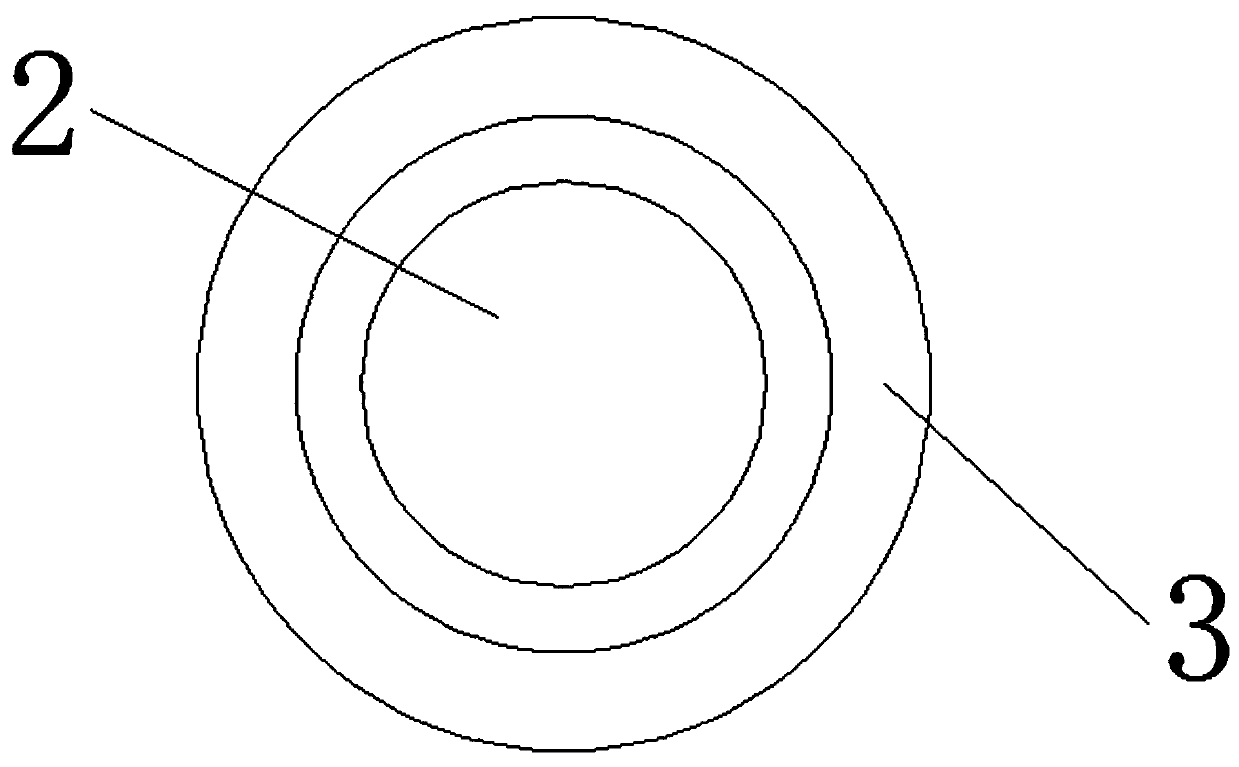

[0019] Specific Embodiment 1: In this embodiment, a multi-directional two-stage constrained deformation device for aluminum-based composite materials is composed of a lower indenter 1, an upper indenter 2, and an annular restraint mold 3; the lower indenter 1 and the upper indenter 2 Relatively set, the blank 4 is arranged between the lower ram 1 and the upper ram 2, and the annular constraining mold 3 is sleeved around the periphery of the lower ram 1 and the upper ram 2, and the lower ram 1, the upper ram 2 It is on the same straight line as the central axis of the annular constraint mold 3 and is perpendicular to the platform of the press.

[0020] In this embodiment, the covering is one of the important factors to ensure the deformation strengthening effect of the composite material. The traditional deformation strengthening process of composite materials is very easy to cause cracks in the composite material, resulting in deformation failure; and after adding the sheath, ...

specific Embodiment approach 2

[0022] Specific implementation mode 2: In this implementation mode, the method of using the multi-directional dual-stage restraint deformation device for aluminum-based composite materials is carried out according to the following steps:

[0023] 1. Multi-directional and double-stage restraint blank preparation, processing the sheath into a circular cylinder, and then wrapping it on the cylindrical aluminum matrix composite material to be deformed; the height of the aluminum matrix composite material to be deformed is the same as that of the sheath, and to be deformed The aluminum-based composite material is interference-fitted with the sheath to obtain a blank 4;

[0024] 2. Preheating: Preheat the lower pressing head 1, the upper pressing head 2, the annular restraint mold 3, the blank 4 and the heat preservation board respectively;

[0025] 3. Device combination, place the insulation board on the press platform, place the lower indenter 1, the blank 4 and the upper indenter...

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 2 in that: the sheath in step 1 is processed from aluminum alloy, and the type of the aluminum alloy is the same as that of the aluminum-based composite material matrix. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com