Decorative sheet structure and manufacturing method

A manufacturing method and technology of decorative boards, which are applied in the direction of manufacturing tools, joining of wooden veneers, wood processing appliances, etc., can solve the problems of low wood utilization rate, low strength of decorative boards, poor stability, etc., and achieve high production efficiency, Simple production process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

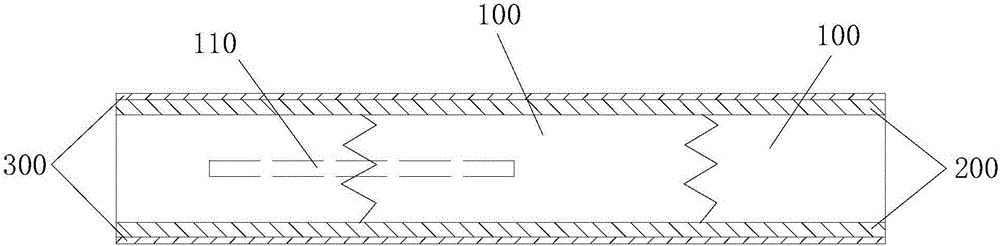

[0061] The decorative board described in this embodiment adopts eucalyptus small-diameter log as the raw material of the finger-jointed board base material, and directly selects the log for slotting and drying, and refers to image 3 Saw and cut the material in the same way, by finger-joining the end and side splicing of the obtained cuboid wood chips 100 of equal thickness, the substrate finger-jointed board is prepared, and then press a layer on the substrate with the same grain direction as the substrate. The vertical veneer is finally pasted with a veneer paper 300 on the outermost layer to make a decorative board.

[0062] The specific preparation steps of the decorative board are:

[0063] 1) Material selection: Select fast-growing small-diameter eucalyptus round wood for the preparation of decorative board substrates according to requirements.

[0064] 2) Cutting and rounding: the diameter of the log is 6.5 cm to 8.5 cm, the cut length is 600 mm to 800 mm, and the diam...

Embodiment 2

[0076] The specific preparation steps of the decorative board are:

[0077] 1) Material selection: Select fast-growing small diameter eucalyptus round wood for the preparation of decorative board substrates according to requirements

[0078] 2) Cutting and rounding: the diameter of the log is 8.5 cm to 10.5 cm, the length of the cutoff is 800 mm to 1000 mm, and the diameter of the rounded wood is 8 cm to 10 cm.

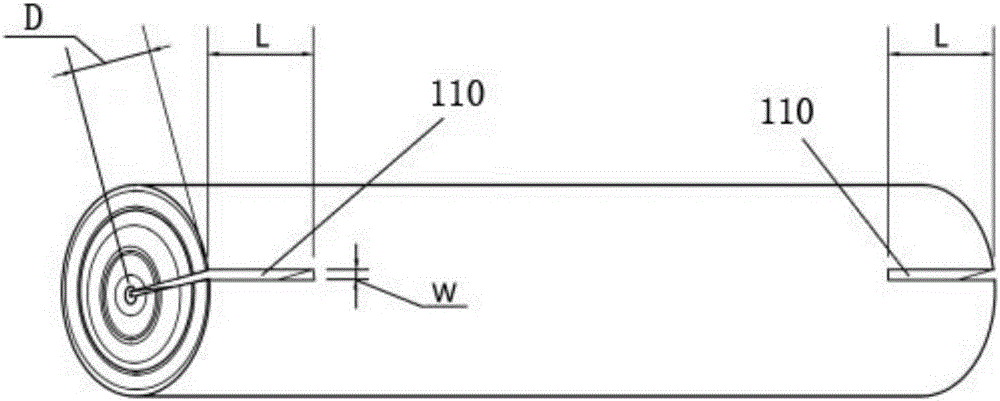

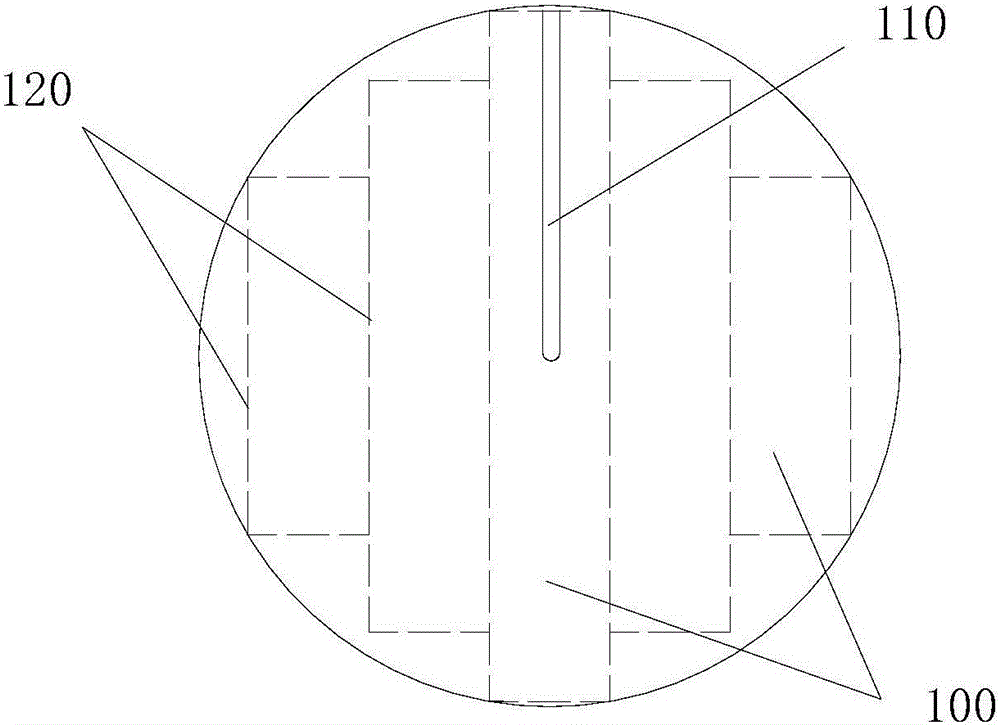

[0079] 3) Stress release grooves 110 are formed: draw stress release grooves 110 at both ends of the base material small-diameter round material with a length of 8% of the length of the round material, the longest of which is no more than 20 cm, and the stress release grooves 110 are perpendicular to the core of the pith , with a depth equal to the radius of the log and a width of 3 mm.

[0080] 4) Drying: Choose a place with good ventilation and no sunlight exposure to dry the logs naturally to a moisture content of 35% to 55%; then stack the logs into a drying kiln...

Embodiment 3

[0090] The specific preparation steps of the decorative board are:

[0091] 1) Material selection: Select fast-growing small-diameter eucalyptus round wood for the preparation of decorative board substrates according to requirements.

[0092] 2) Cutting and rounding: the diameter of the log is 10.5 cm to 12.5 cm, the cut length is 1000 mm to 1200 mm, and the diameter of the rounded wood is 10 cm to 12 cm.

[0093] 3) Stress release grooves 110 are formed: draw stress release grooves 110 at both ends of the base material small-diameter round material with a length of 10% of the length of the round material, the longest of which is not more than 20 cm, and the stress release grooves 110 are perpendicular to the marrow , with a depth equal to the radius of the log and a width of 4 mm.

[0094] 4) Drying: Choose a place with good ventilation and no sunlight exposure to dry the logs naturally to a moisture content of 35% to 55%; then stack the logs into a drying kiln at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com