Preparation method of a honeycomb ceramic regenerator with ultra-thick outer wall

A technology of honeycomb ceramics and regenerators, applied in the field of porous ceramics processing, can solve the problems of insufficient strength of the outer wall of the honeycomb ceramic regenerator, failure to form a whole, and a pass rate of less than 50%, so as to reduce deformation defects and damage rates , The effect of improving the firing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

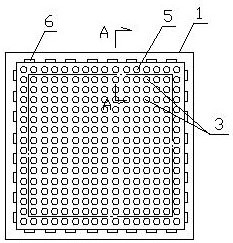

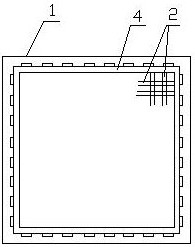

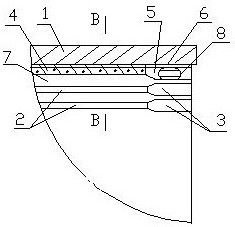

[0039](1) The extrusion die of the honeycomb ceramic regenerator is cut with 45# steel or die steel. The extrusion die includes an outer mold cover 1 and an inner mold core 7, and several outer walls formed around one end of the outer mold cover Mud entry holes 5, a number of inner wall mud entry holes 3 are formed on one end of the inner mold core, an outer wall 4 is formed at one end of the outer wall mud entry holes, and several criss-cross inner walls 2 are formed at one end of the inner wall mud entry holes. The surface of the extrusion area of the outer wall (the surface of the extrusion area of the outer wall refers to the surface of the outer mold sleeve forming the outer surface of the outer wall) is processed to a roughness requirement of Ra3.2, and groove cutting is performed at the same time, and the parallel interval on the surface of the outer mold sleeve is 10 mm , process a groove 6 with a width of 5 mm and a depth of 1 mm, and adjust the ratio of the cross-...

Embodiment 2

[0044] (1) The extrusion die of the honeycomb ceramic regenerator is cut with 45# steel or die steel. The surface roughness of the extrusion area of the outer wall of the outer die sleeve is required to be Ra3.2. At the same time, groove cutting is performed. Every parallel interval of 10 mm on the surface, process a groove 6 with a width of 5.5 mm and a depth of 0.8 mm, and adjust the ratio of the cross-sectional area of the mud entry hole of the mold to the cross-sectional area of the extrusion outer wall to be 1.5; The internal fixation is provided with a pin 8, and the pin is a paper clip (fixed in the mud entry hole by the elasticity of the paper clip).

[0045] (2) Choose 325-mesh spherical and nearly spherical ceramic powder. The ceramic powder is composed of 30 parts of cordierite, 28 parts of alumina, 10 parts of clay, 17 parts of talcum powder and 15 parts of deionized water. 5% of the weight of the base material is added to the base material as an organosilane...

Embodiment 3

[0049] (1) The extrusion die of the honeycomb ceramic regenerator is cut with 45# steel or die steel. The surface roughness of the extrusion area of the outer wall of the outer die sleeve is required to be Ra3.6. At the same time, groove cutting is performed. Every parallel interval of 10 mm on the surface, process a groove 6 with a width of 4.5 mm and a depth of 0.7 mm, and adjust the ratio of the cross-sectional area of the mud entry hole of the mold to the cross-sectional area of the extrusion outer wall to be 2.0; The internal fixation is provided with a pin 8, and the pin is a paper clip (fixed in the mud entry hole by the elasticity of the paper clip).

[0050] (2) Select 300-mesh spherical and nearly spherical ceramic powder. The ceramic powder is composed of 26 parts of cordierite, 30 parts of alumina, 15 parts of clay, 11 parts of talcum powder and 18 parts of deionized water. Add 3% titanate coupling agent of the weight of the base material as a surfactant, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com