Farci food forming machine

A molding machine and food technology, applied in food science, baking, dough processing, etc., can solve the problems of easy opening of the dough and low tightness of the pasting part of the dough, and achieve the effect of enhancing and avoiding displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

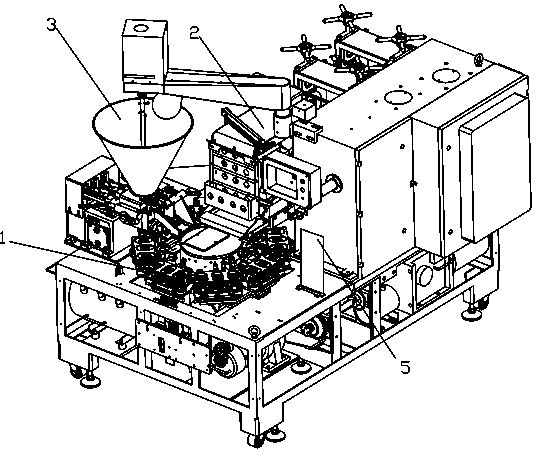

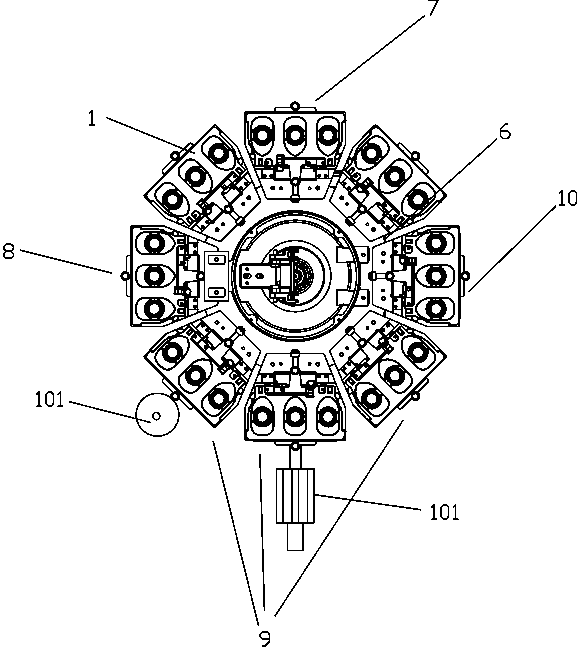

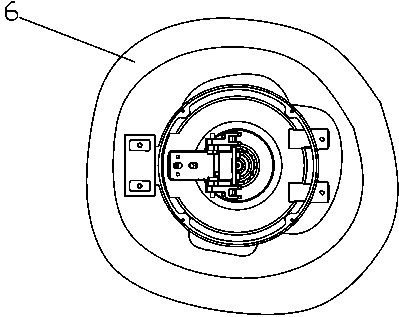

[0067] A stuffed food forming machine comprises a frame and a dough conveying device 3 arranged on the frame, a filling device 4, a skin receiving plate 1, a take-out device 5 and an annular track 6, the dough conveying device 3, the filling The device 4 and the take-out device 5 are respectively fixedly installed on the skin grafting station 7, the stuffing station 8 and the take-out station 10 of the circular track 6. Skin plate 1, a mold clamping device 2 is arranged below the skin joint plate 1, and the mold clamping device 2 includes at least one pair of closing modules that are arranged oppositely, and the mold clamping device 2 passes through the skin joint simultaneously with the skin joint plate 1 Station 7, stuffing station 8, mold clamping station 9 and take-out station 10, the described clamping module starts from mold clamping station 9 and ends at take-out station 10, and is always in a pressing state. The mold clamping device can push the guide wheel 25 through ...

Embodiment 2

[0070] A stuffed food forming machine comprises a frame and a dough conveying device 3 arranged on the frame, a filling device 4, a skin receiving plate 1, a take-out device 5 and an annular track 6, the dough conveying device 3, the filling The device 4 and the take-out device 5 are respectively fixedly installed on the skin grafting station 7, the stuffing station 8 and the take-out station 10 of the circular track 6. Skin plate 1, a mold clamping device 2 is arranged below the skin joint plate 1, and the mold clamping device 2 includes at least one pair of closing modules that are arranged oppositely, and the mold clamping device 2 passes through the skin joint simultaneously with the skin joint plate 1 Station 7, stuffing station 8, mold clamping station 9 and take-out station 10, the described clamping module starts from mold clamping station 9 and ends at take-out station 10, and is always in a pressing state. Between the mold clamping station 9 and the take-out station ...

Embodiment 3

[0073] The upper surface of the skin receiving plate of the stuffed food forming machine is provided with at least one concave skin receiving groove 11, the center of the skin receiving groove 11 is provided with a filling hole 12, and auxiliary filling holes 12 are arranged around the filling hole 12. An uneven notch 13 formed by stuffing food, the surrounding of the filling hole 12 is the inner side and / or upper surface of the filling hole 12 . The filling hole 12 of the skin receiving plate is provided with an uneven notch 13 for assisting in the formation of the stuffing food. The notch 13 has the effect of forming wrinkles on the dough for the first time. When the stuffed food is mold-closed, the mold-clamping device will squeeze the dough, and the notch 13 will contact the dough at the same time, and form wrinkles again, so that the outer surface of the dough of the stuffed food is formed to be consistent with the wrinkles formed when kneading by hand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com