Active organic light-emitting diode (OLED) display device and manufacturing method thereof

A display device and active technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of light extraction rate and process, low contact resistance of cathode and cathode power line, etc. The effect of extraction rate, reduction of contact resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

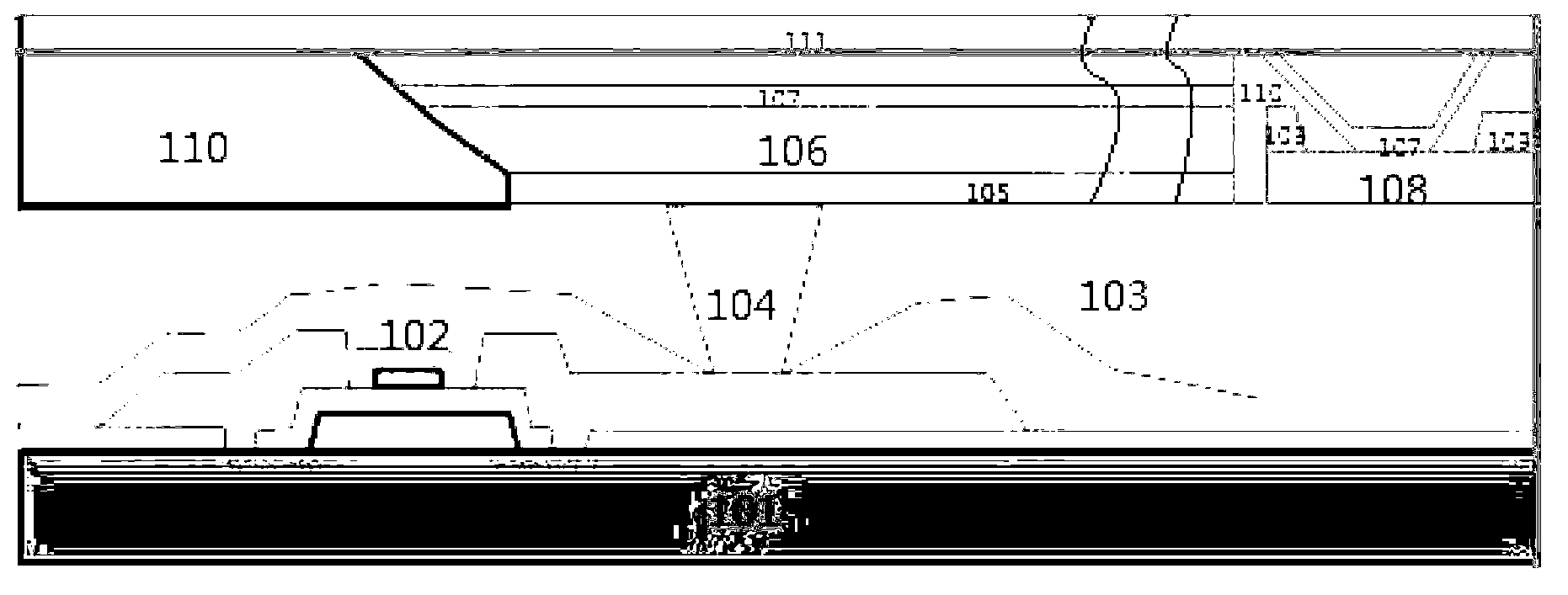

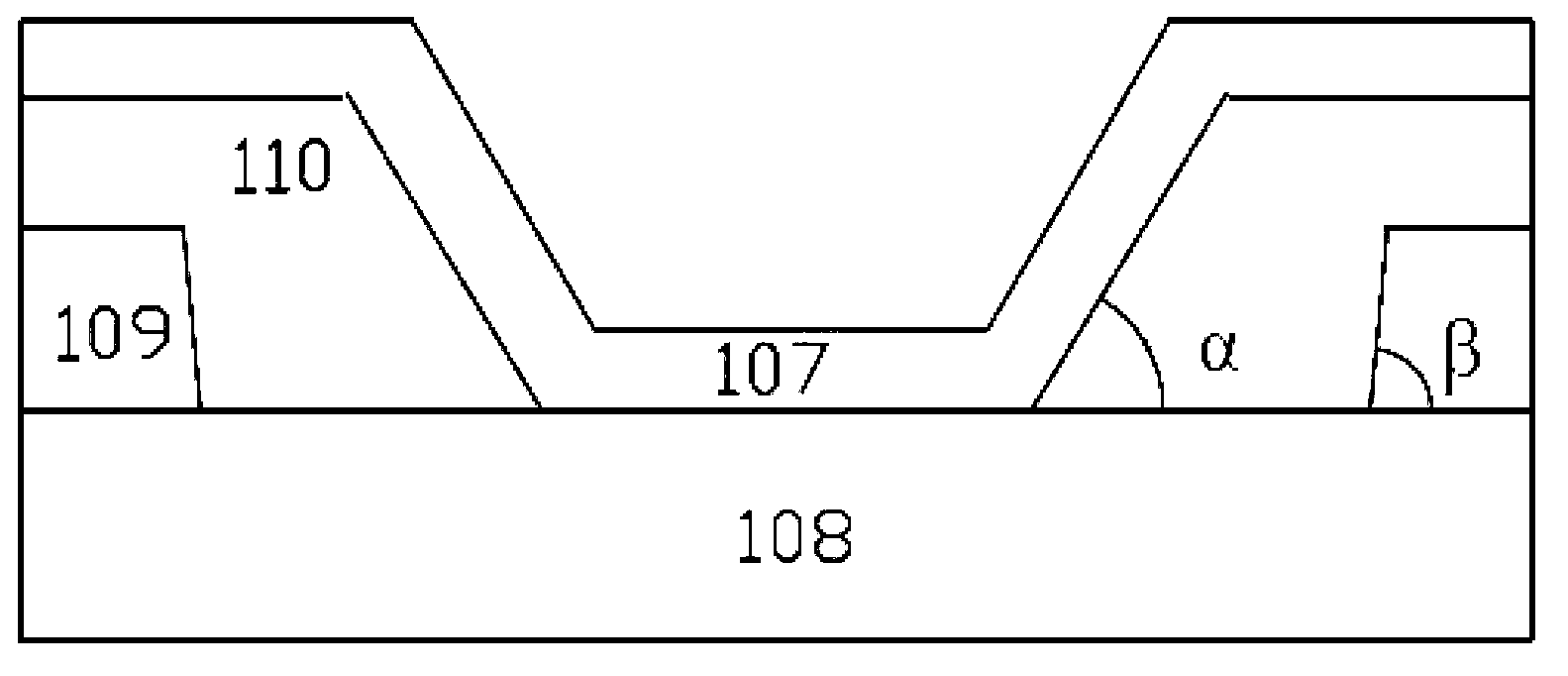

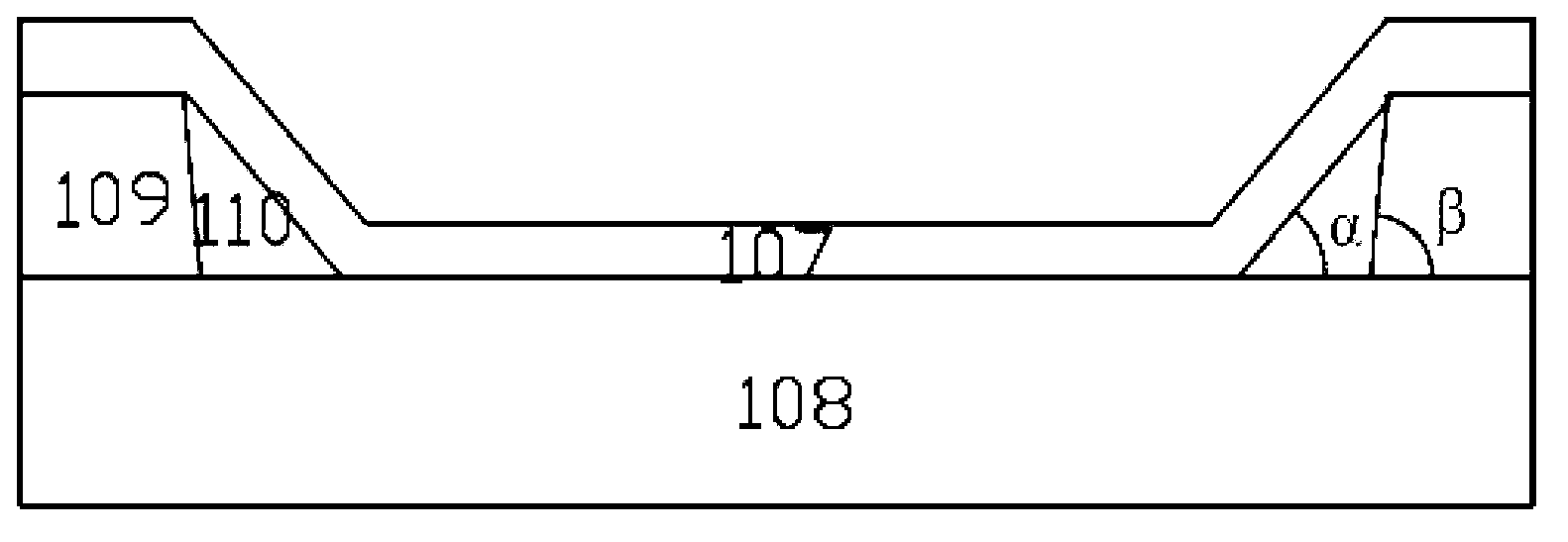

[0044] This embodiment provides an active OLED display device, as attached figure 1 and Figure 2a As shown, it includes a display area and a non-display area. The display area includes an anode, an organic functional layer and a cathode. The non-display area includes a cathode power line 108. An insulating layer 109 is arranged on the cathode power line 108. The cathode 107 covers the insulating layer 109. The insulating layer 109 is provided with a contact hole for connecting the cathode 107 and the cathode power supply line 108, and the insulating layer 109 is also covered with a planarization layer 110, and the planarization layer 110 extends to cover the cathode power supply line 108, and leaves a cathode The contact hole between 107 and the cathode power supply line 108, the slope angle α formed by the contact surface of the planarization layer 110 and the cathode power supply line 108 is 60°. A planarization layer 110 is covered on the insulating layer 109 partially d...

Embodiment 2

[0061] This embodiment provides an active OLED display device, as attached figure 1 and 2b As shown, the structure and manufacturing method of the active OLED display device are the same as those in Embodiment 1, the only difference is that the slope angle formed by the planarization layer 110 covering the insulating layer is α is 45 degrees.

Embodiment 3

[0063] This embodiment provides an active OLED display device. The structure and manufacturing method of the active OLED display device are the same as those in Embodiment 1, the only difference being that the slope angle α formed by the planarization layer and the contact surface of the cathode power line is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com