Fully automatic carton molding machine

A fully automatic, forming machine technology, applied to paper/cardboard containers, container manufacturing machinery, containers, etc., can solve the problems of long transmission distance, low production efficiency, inflexibility, etc., and achieve reasonable action, production efficiency and product qualification rate Improvement, the effect that work is flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

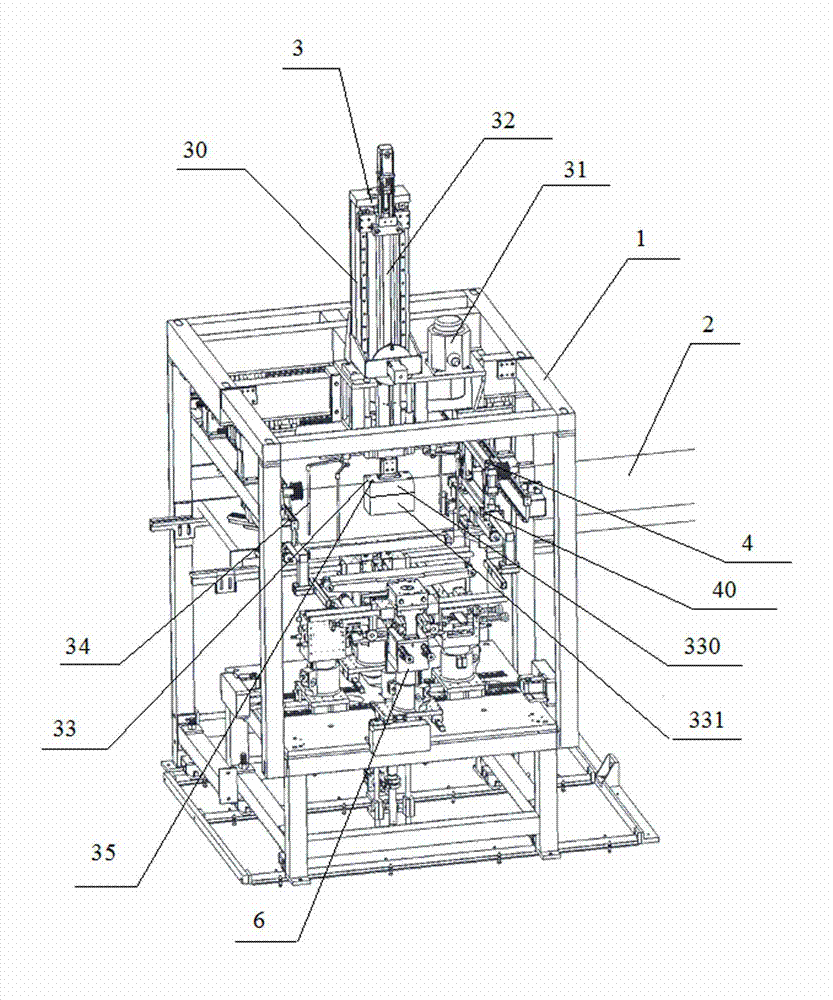

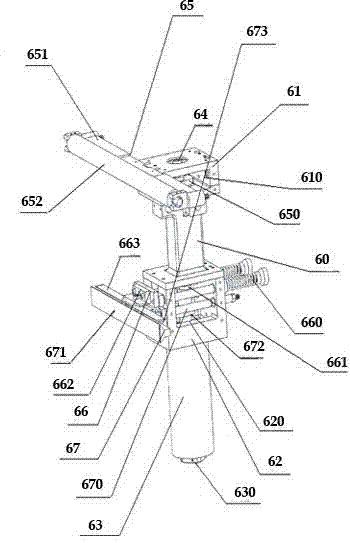

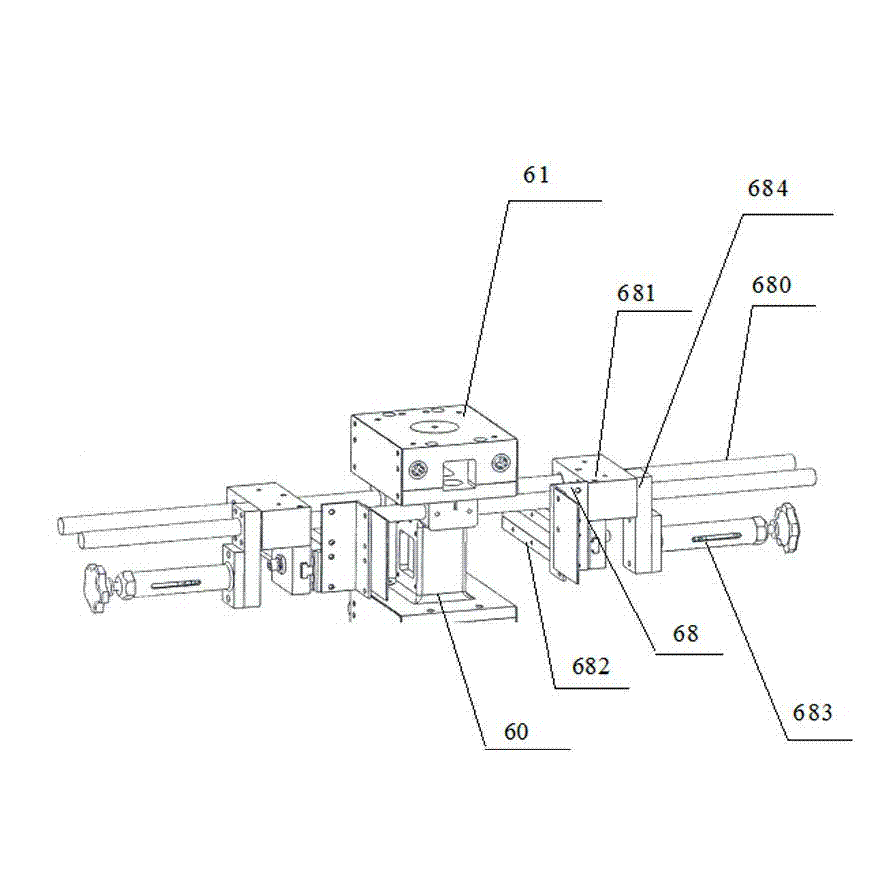

[0016] In this example, refer to Figure 1 to Figure 3 As shown, the fully automatic carton forming machine includes a frame 1, a conveyor belt 2 arranged in the frame 1 and extending outward, a box pressing device 3 arranged above the conveyor belt 2, and a box pressing device arranged on the top of the box pressing device. 3 The box holding device 4 on both sides, and the forming head device 5 arranged under the conveyor belt 2; another automatic carton forming machine is also provided with a conveyor belt 2, a box pressing device 3, a box holding device 4 and a forming machine. The PLC control system (not shown) of the head device 5; the box pressing device 3 includes a box pressing main body 30, a thimble 34 arranged below the box pressing main body 30, and a box pressing servo on the side of the box pressing main body 30 Motor 31, and be arranged on the pressing box main body 30 and the pressing box screw rod 32 that extends downwards, and be arranged on the mold 33 of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com