Patents

Literature

53results about How to "Reasonable action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

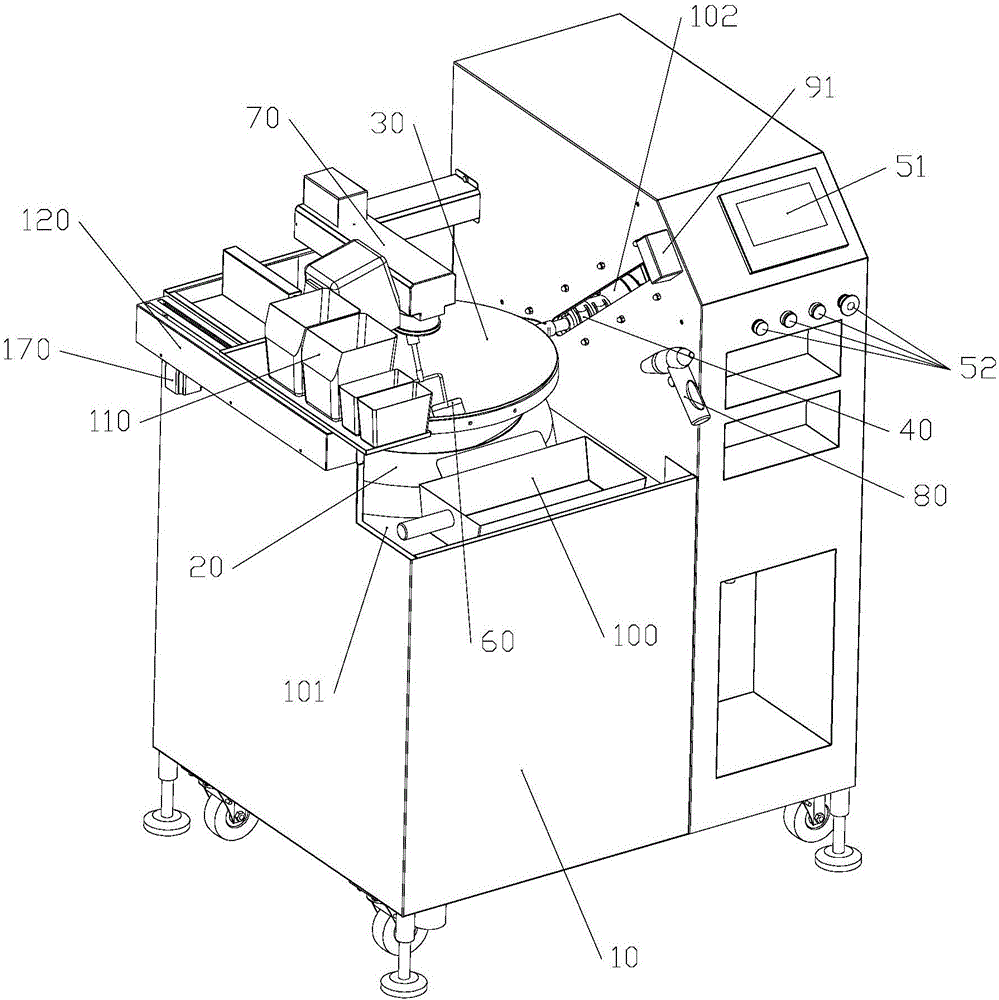

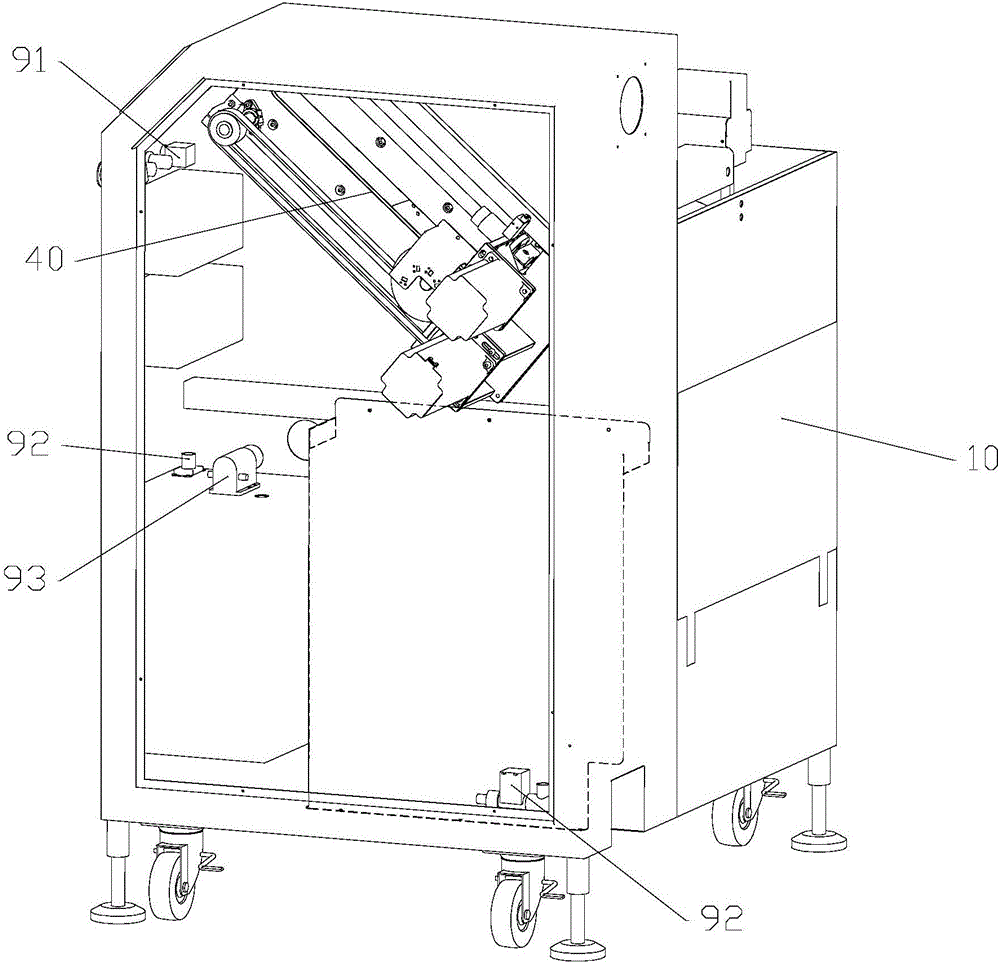

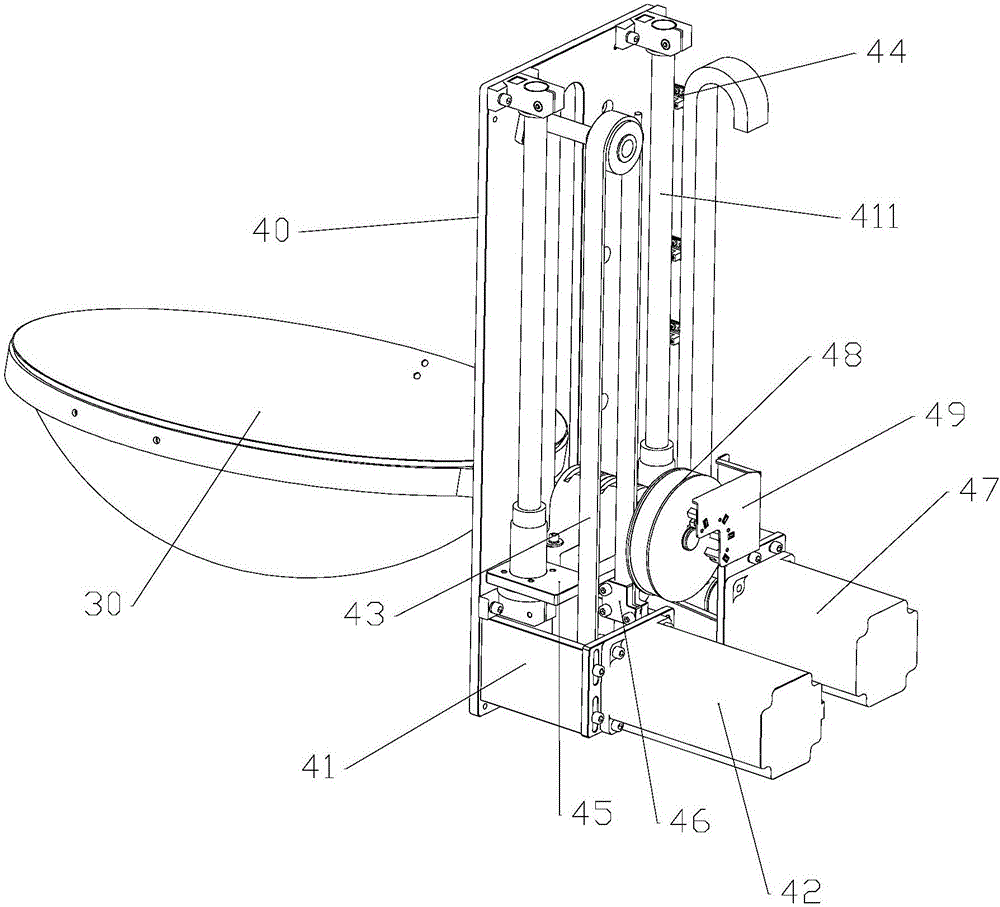

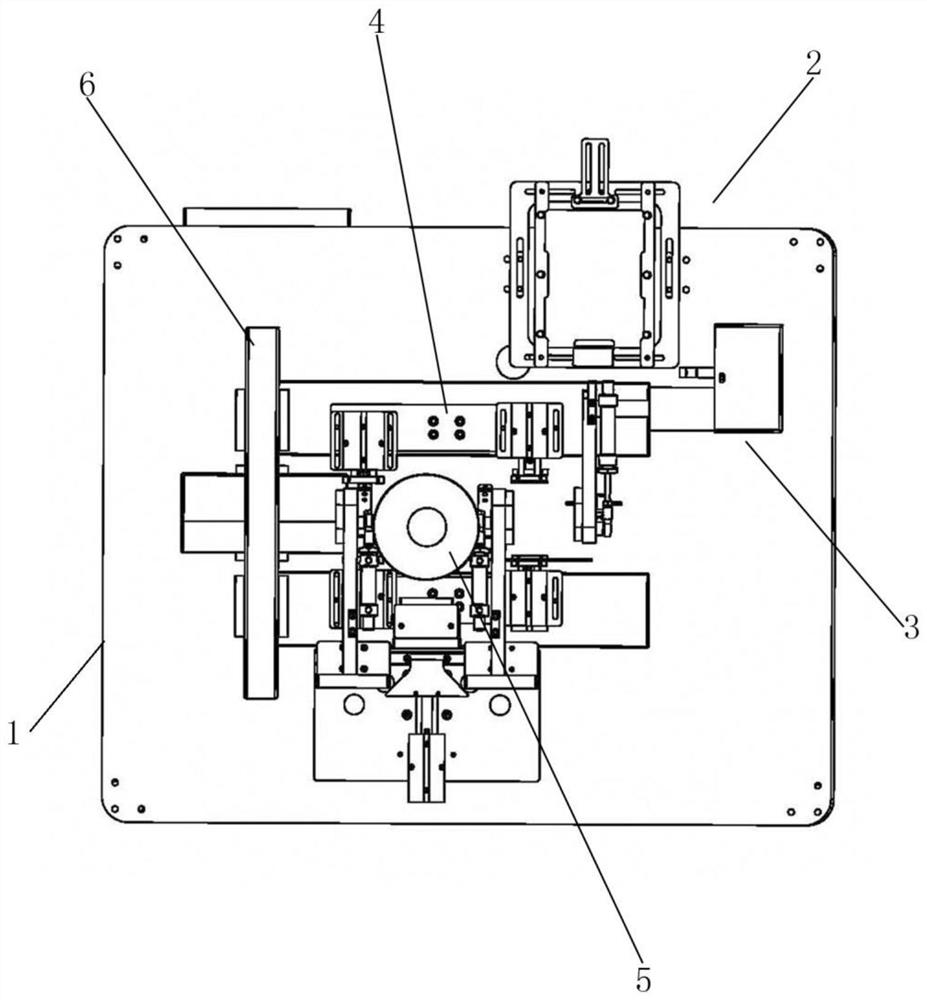

Automatic cooker

ActiveCN106037462AEvenly heatedImprove Stir-Fry QualityCooking insertsControl systemProcess engineering

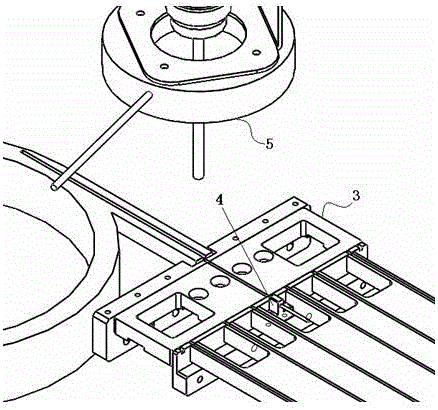

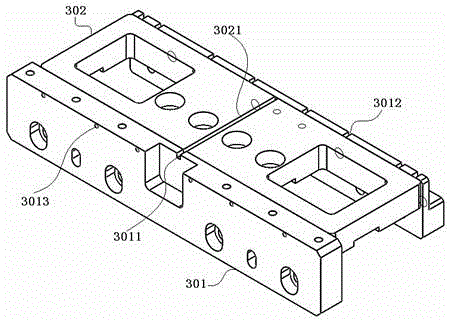

The invention discloses an automatic cooker. The automatic cooker comprises a machine body, a turning cooking mechanism, a stirring cooking mechanism, a water and oil injection device and a control system, wherein an operation table is arranged on the machine body, and a heating device stretching out of the operation table is arranged in the machine body; the turning cooking mechanism comprises a wok and a first drive module, the wok is located above the heating device, the first drive module is located in the machine body, the machine body is provided with a chute, and the wok penetrates through the chute and then is connected with the first drive module; the stirring cooking mechanism comprises a stirring spatula and a second drive module, the stirring spatula is located above the wok, the second drive module is located in the machine body and partly stretches out of the machine body, and the stirring spatula and the second drive module are connected; the water and oil injection device is arranged on the outer wall of the machine body; the control system is arranged in the machine body, and the heating device, the first drive module, the second drive module and the water and oil injection device are all connected with the control system. The automatic cooker enables food to make full contact with air to guarantee that the food is heated uniformly, the turning cooking quality of the food is improved, and turning cooking efficiency is high.

Owner:湖南唐米力科技有限公司

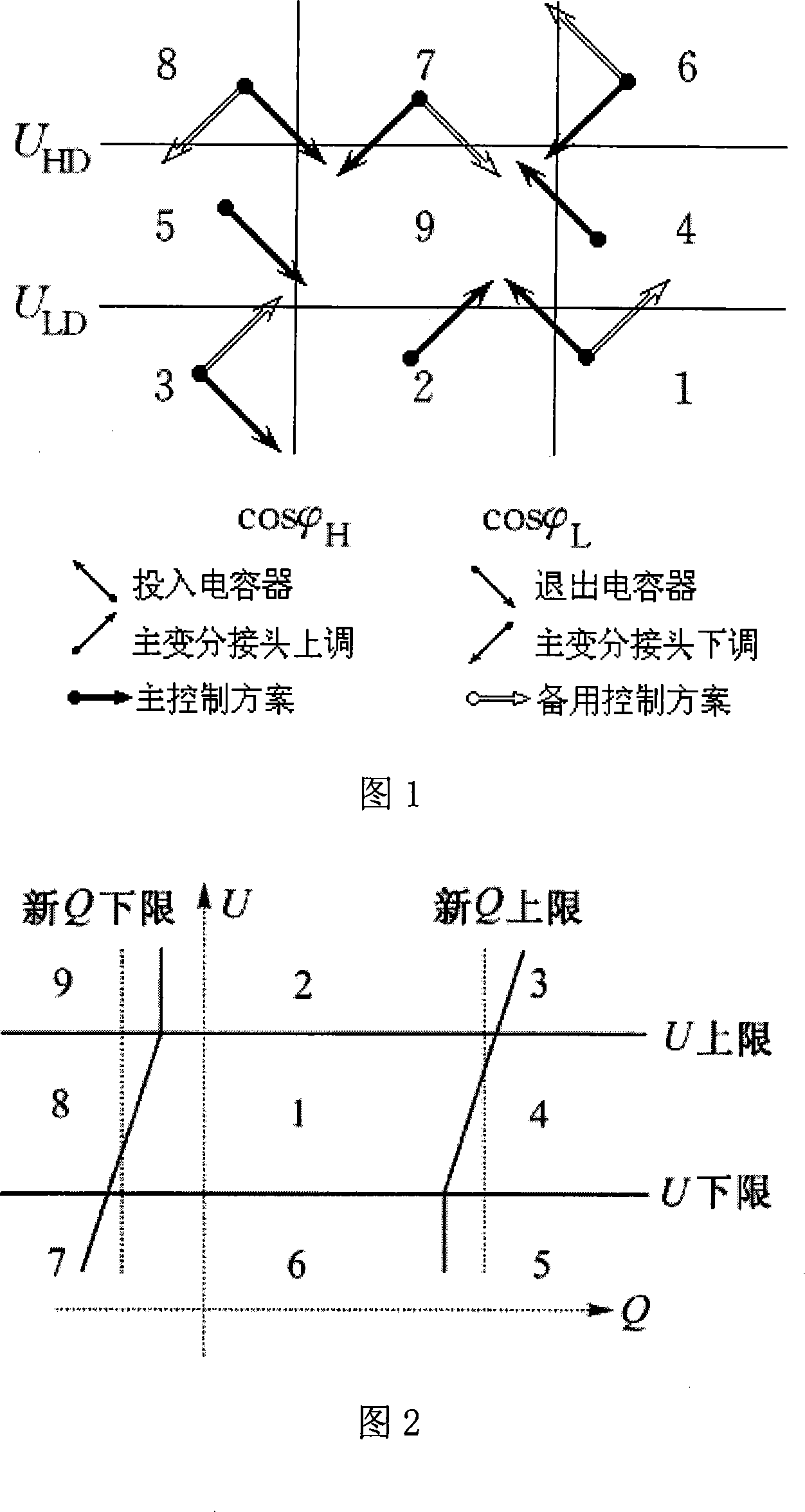

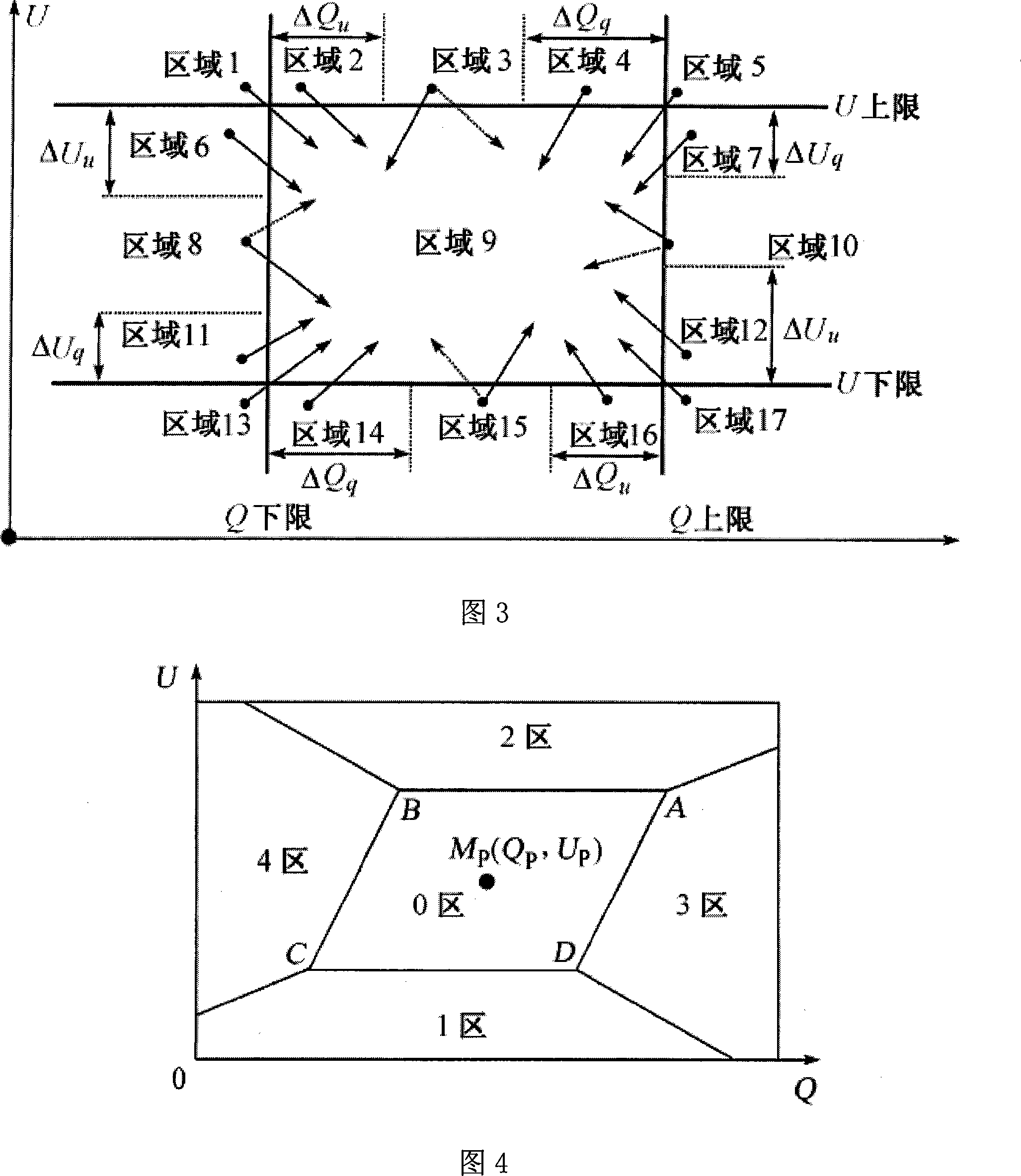

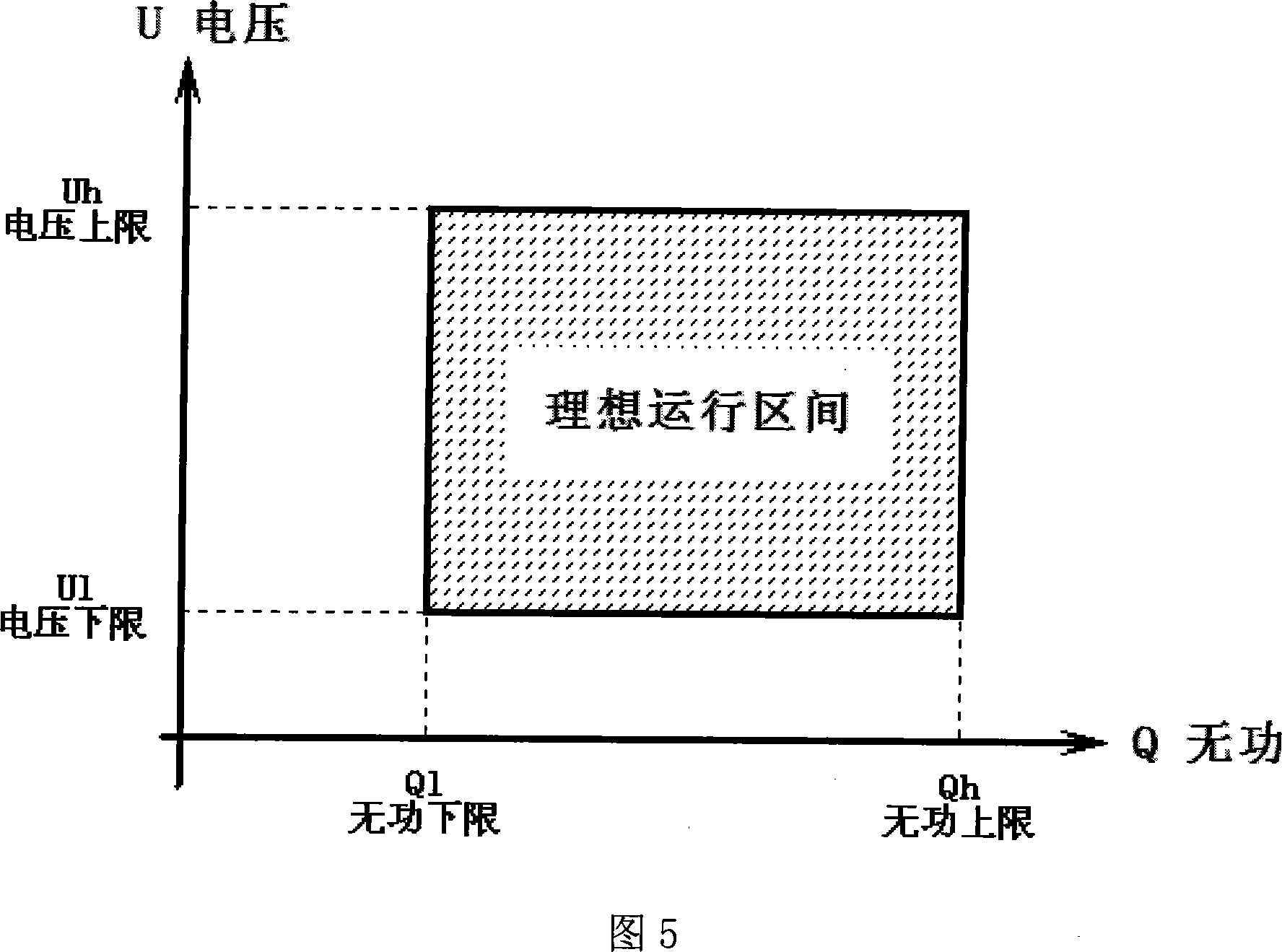

Transforming plant voltage reactive integrated control system acting equipment selection technology

ActiveCN101159381AOverall clarityEasy programmingReactive power adjustment/elimination/compensationAc network voltage adjustmentCapacitanceTransformer

The invention relates to a technique for selecting action equipment for a substation voltage reactive power comprehensive control system. The invention is characterized in that in accordance with the operation requirement, voltage and reactive operation ranges are determined and an ideal operation interval is divided in a system operation region; inside the ideal operation interval, the voltage and reactive are qualified without controlling; when the system operates outer the ideal interval, the voltage and reactive exceed the limit; a serve value supplied by the reactive equipment to the system is calculated, the serve value and the action delay are weighed and a controllable equipment is initially selected; combined with the equipment ordering method, the action equipment and the control direction thereof are finally selected. The invention solves the equipment selection problem between the main transformer and capacitor / reactor, solves the equipment selection problem of unequal capacity capacitor / reactor, and solves the equipment selection problem under the multi-device unequal delay; the action of invention is reasonable; the invention abandons the regional diagram control mode and avoids the problem of trans-region and regional boundary division. The invention changes the weights and properties of the voltage and the reactive power and is capable of suitable for different control modes.

Owner:NARI TECH CO LTD +1

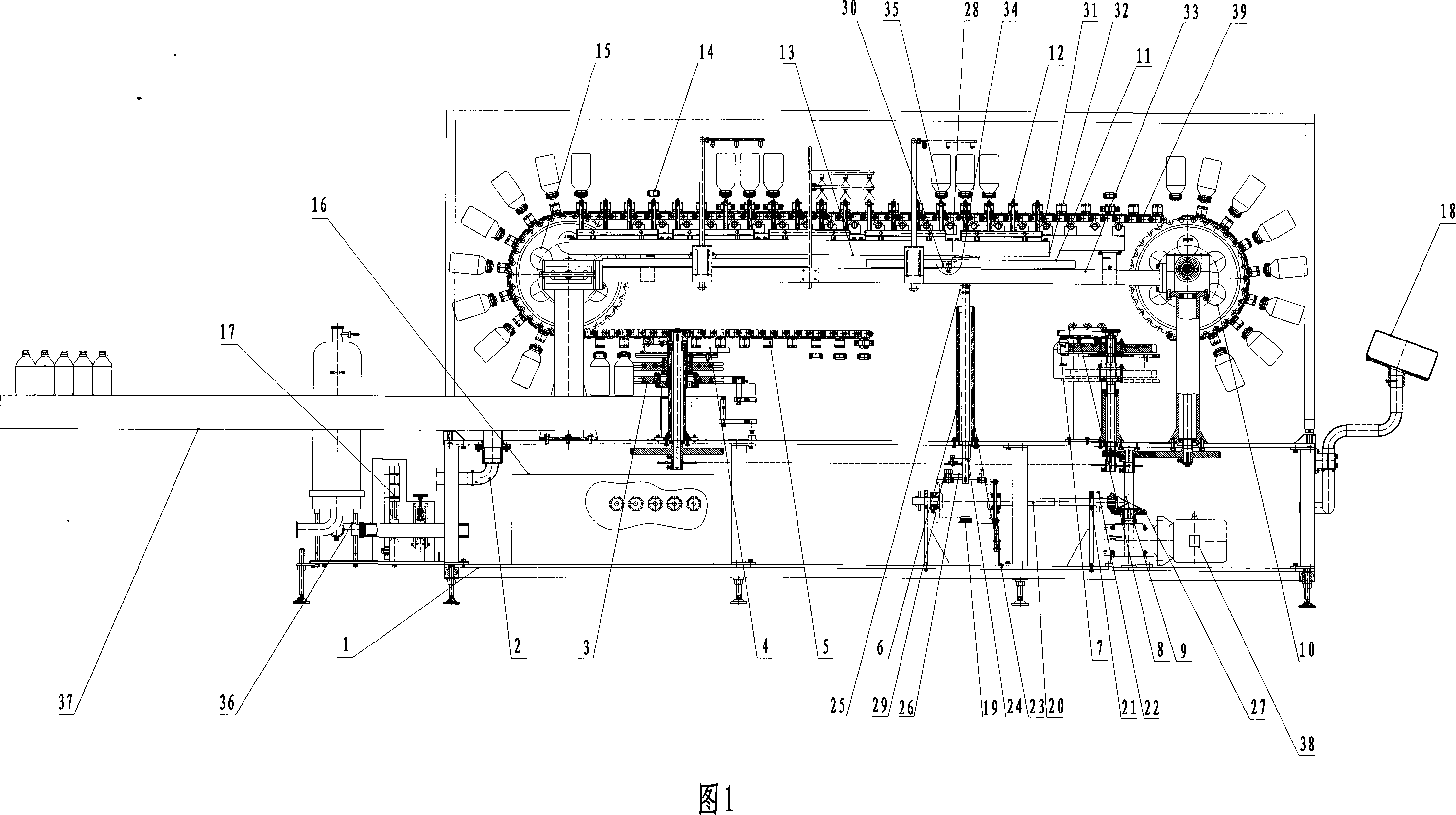

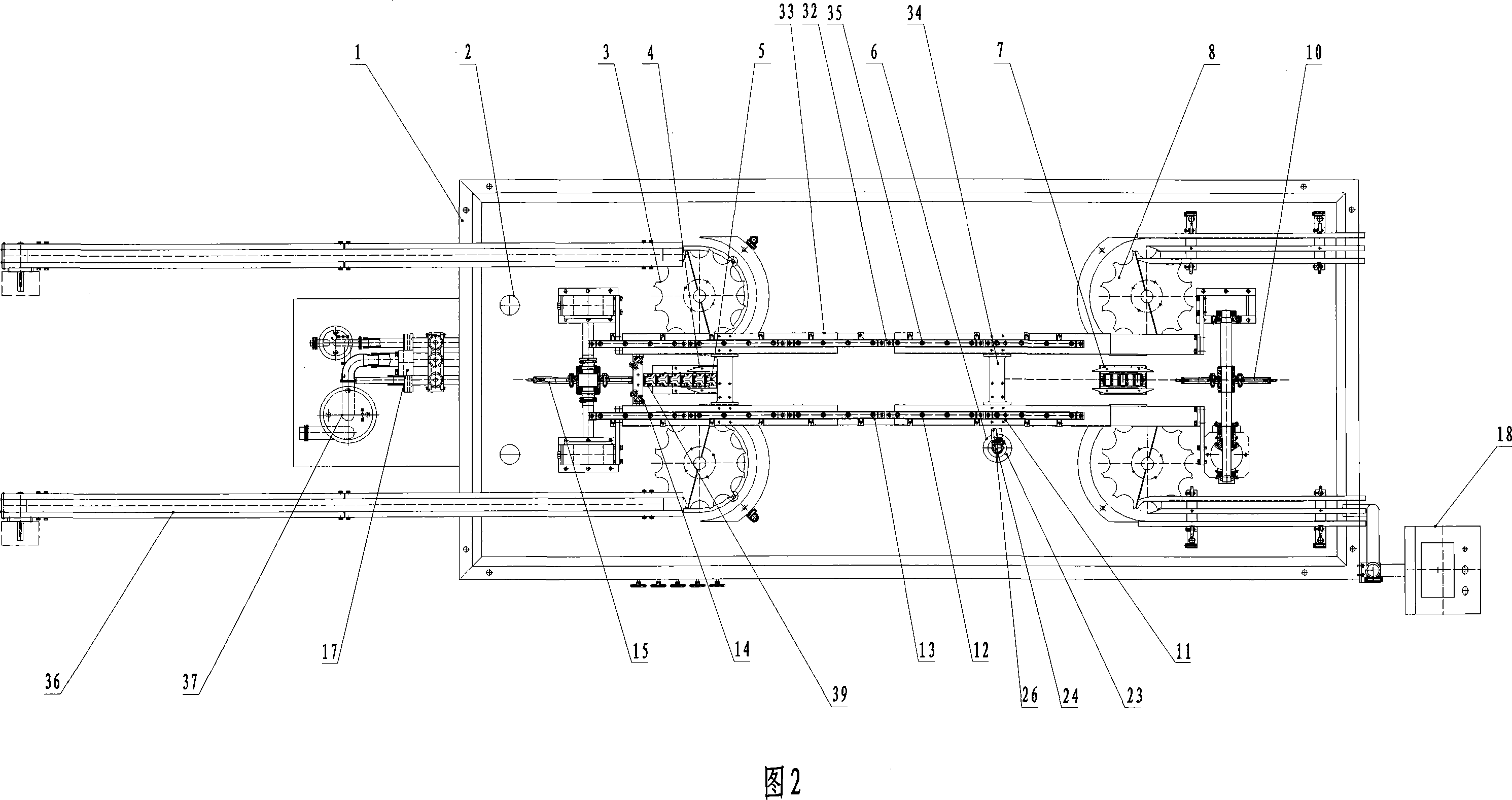

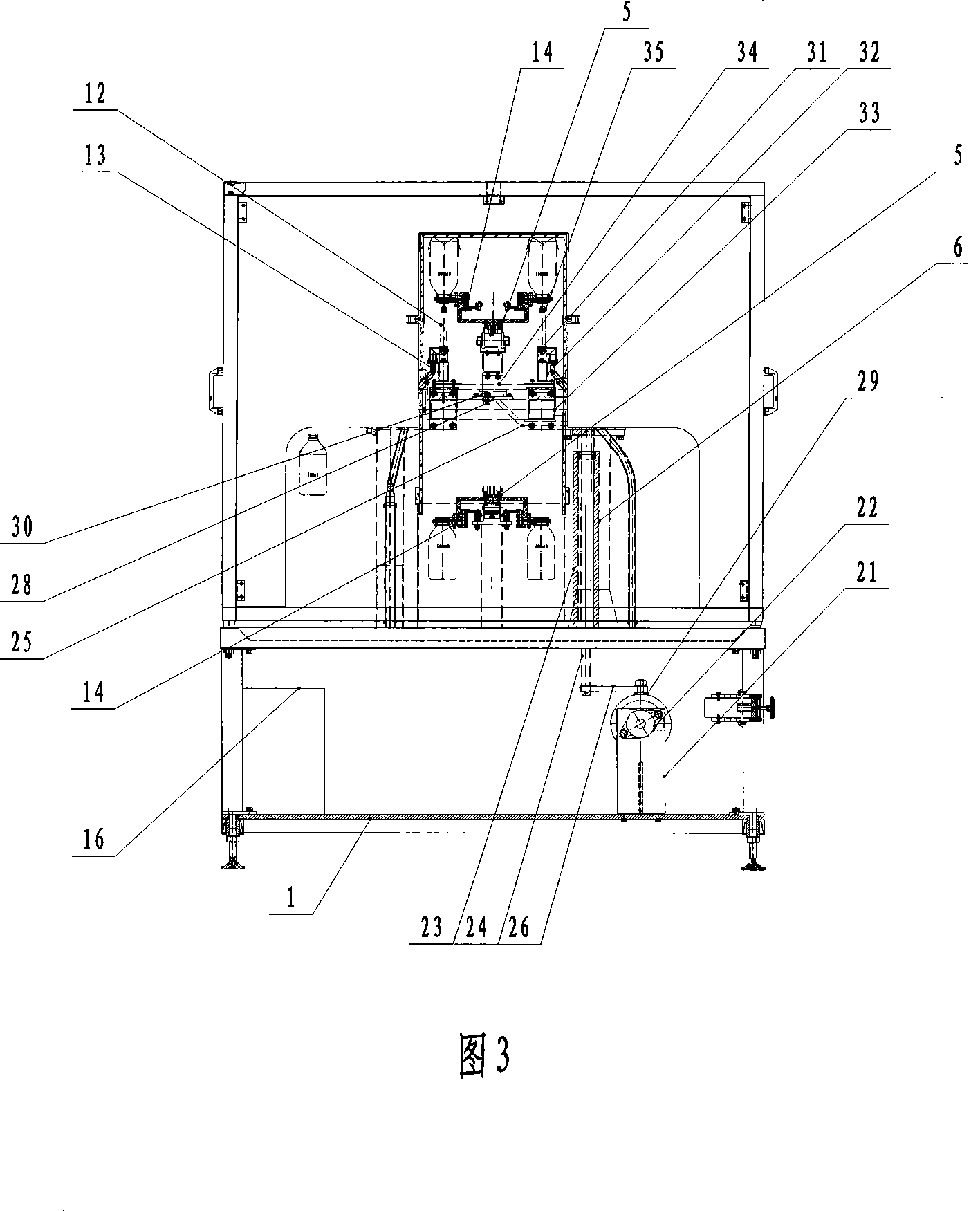

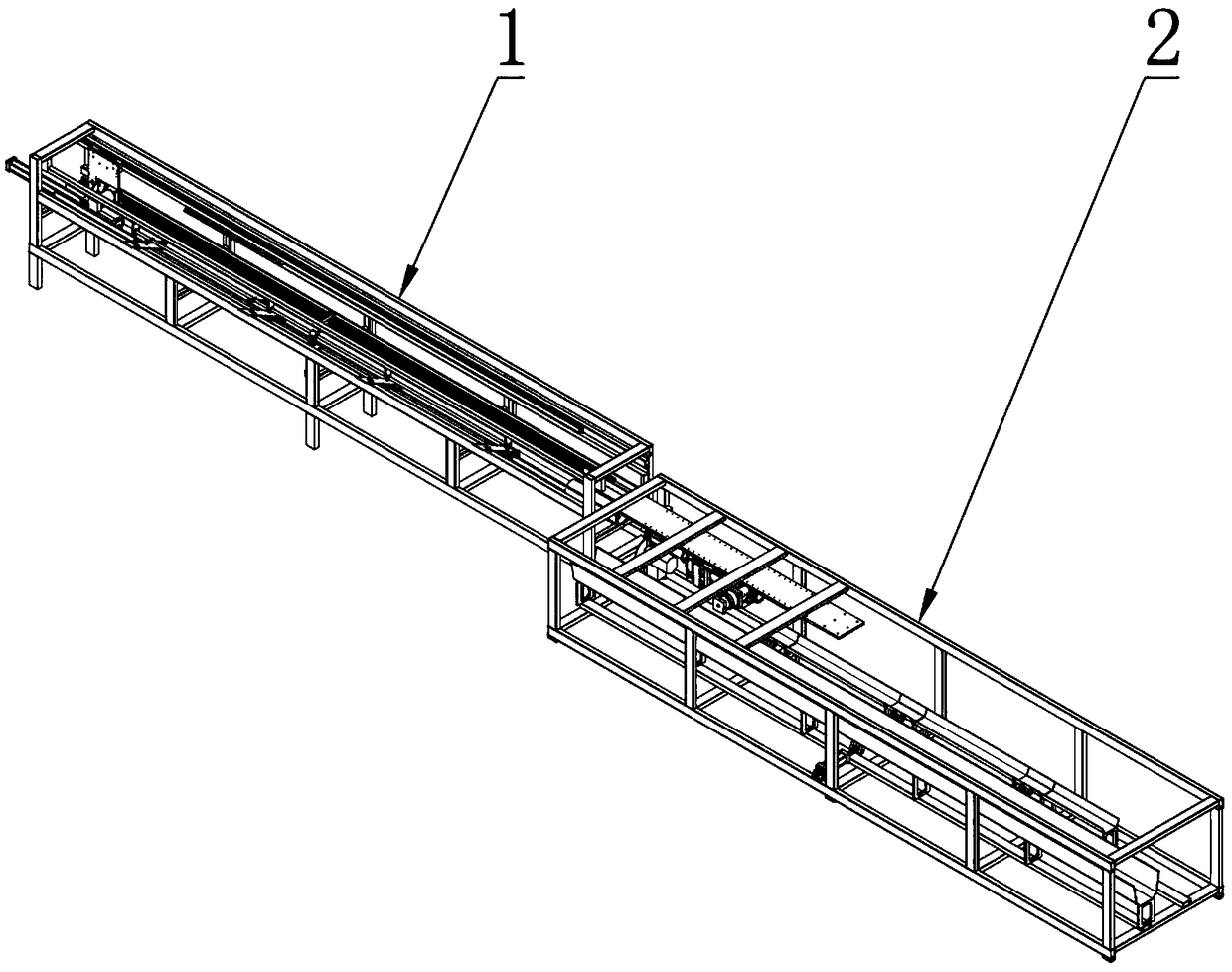

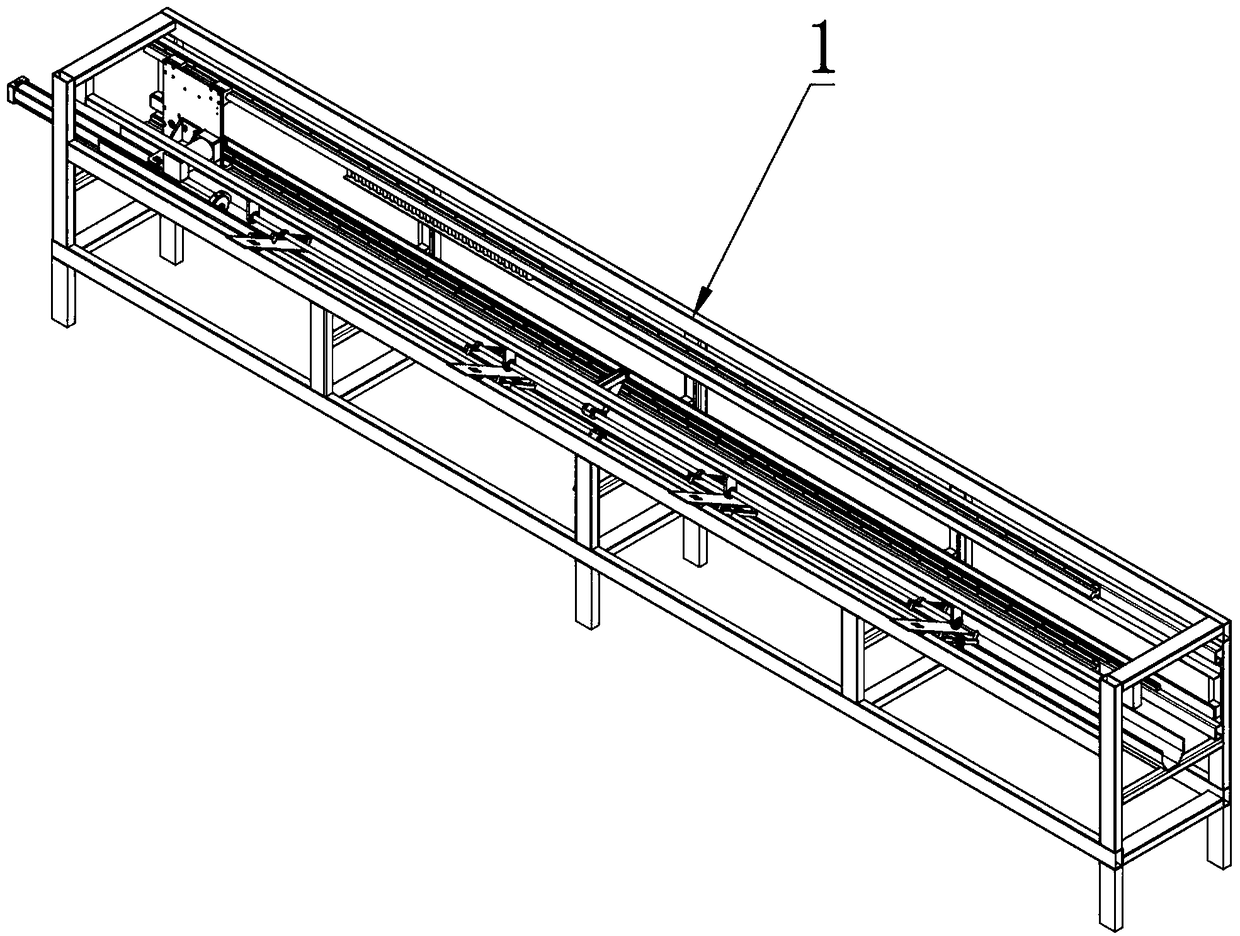

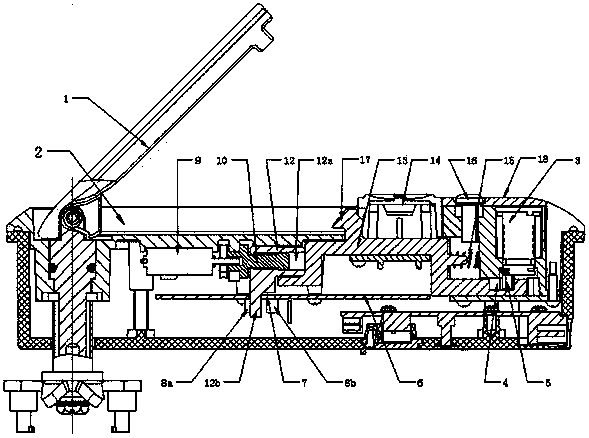

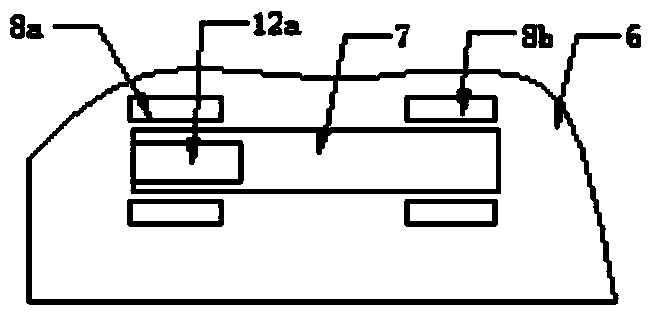

Straight line type bottle washing machine

InactiveCN101195120ACompact structureSmall footprintHollow article cleaningLow noiseElectrical control

The invention discloses a liner-type bottle cleaning machine, which comprises a frame, a water and air supplying device, a bottle input mechanism, a bottle input dial wheel mechanism, a circulating transmitting mechanism, a reciprocal tracking mechanism, a bottle output dial wheel mechanism, a tracking cleaning mechanism, an electrical control box and a power device, wherein the bottle input mechanism, the bottle input dial wheel mechanism, the circulating transmitting mechanism, the reciprocal tracking mechanism, the bottle output dial wheel mechanism, the tracking cleaning mechanism, the electrical control box and the power device are arranged on the frame, the bottle input mechanism is connected with the bottle input dial wheel mechanism, one portion of an upper bottle sending rail which is on the circulating transmitting mechanism is matched and connected with the bottle input dial wheel mechanism, the other portion of the upper bottle sending rail is matched and connected with the bottle output dial wheel mechanism, the tracking cleaning mechanism which is connected with the reciprocal tracking mechanism is located between the upper bottle sending rail and a lower bottle sending rail of the circulating transmitting mechanism, a water and air controlling device is arranged on a pipe line of the water and air supplying device which is connected with the reciprocal tracking mechanism and the bottle input dial wheel mechanism, the circulating transmitting mechanism, the reciprocal tracking mechanism, the bottle output dial wheel mechanism and the tracking cleaning mechanism are connected with the power device through an actuating mechanism. The invention is the linear-type bottle cleaning machine with simple and compact structure, small occupying space, wide applying range, low noise, high automation level and working efficiency and good operational quality.

Owner:TRUKING TECH LTD

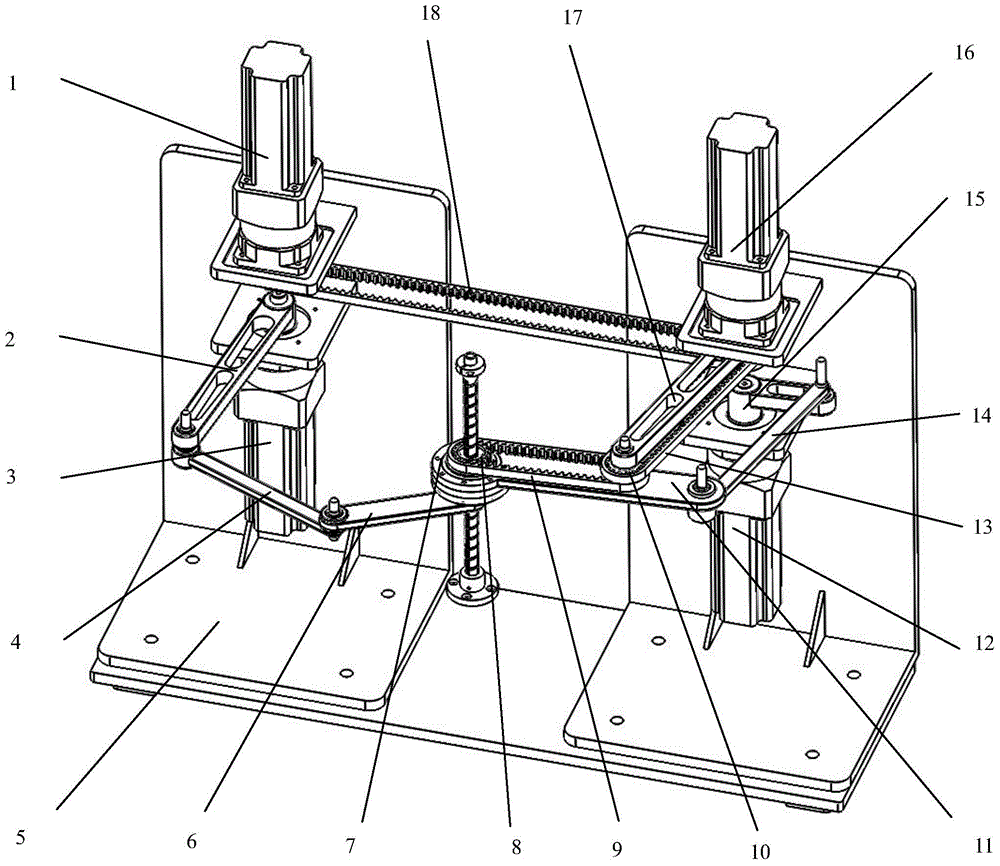

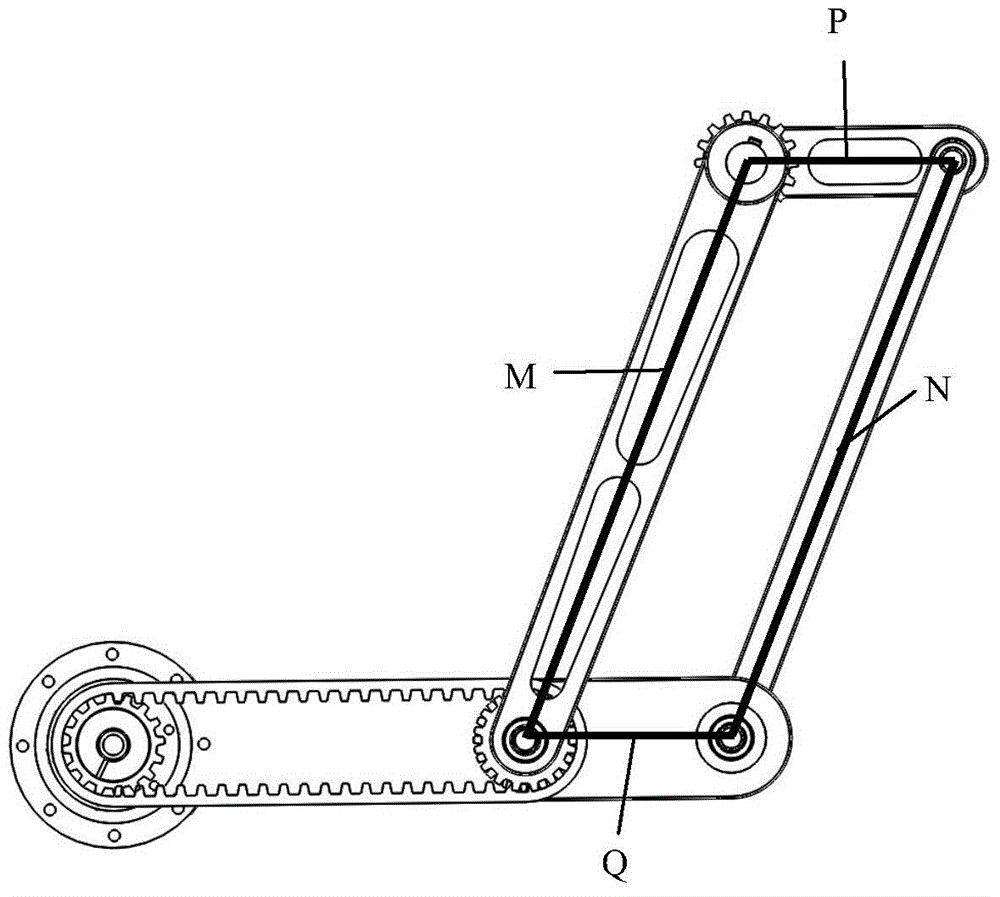

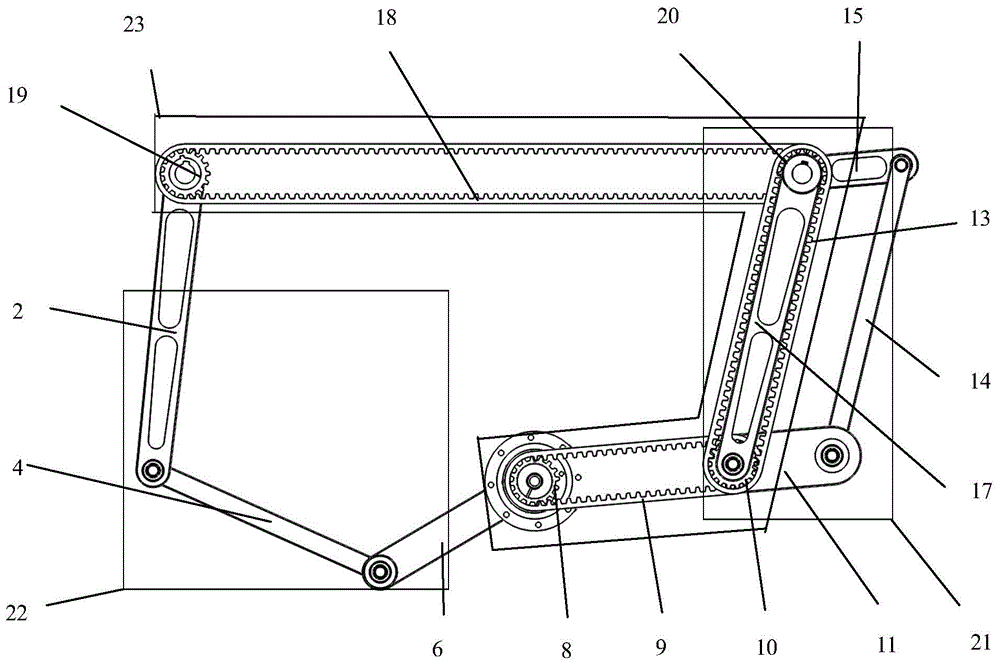

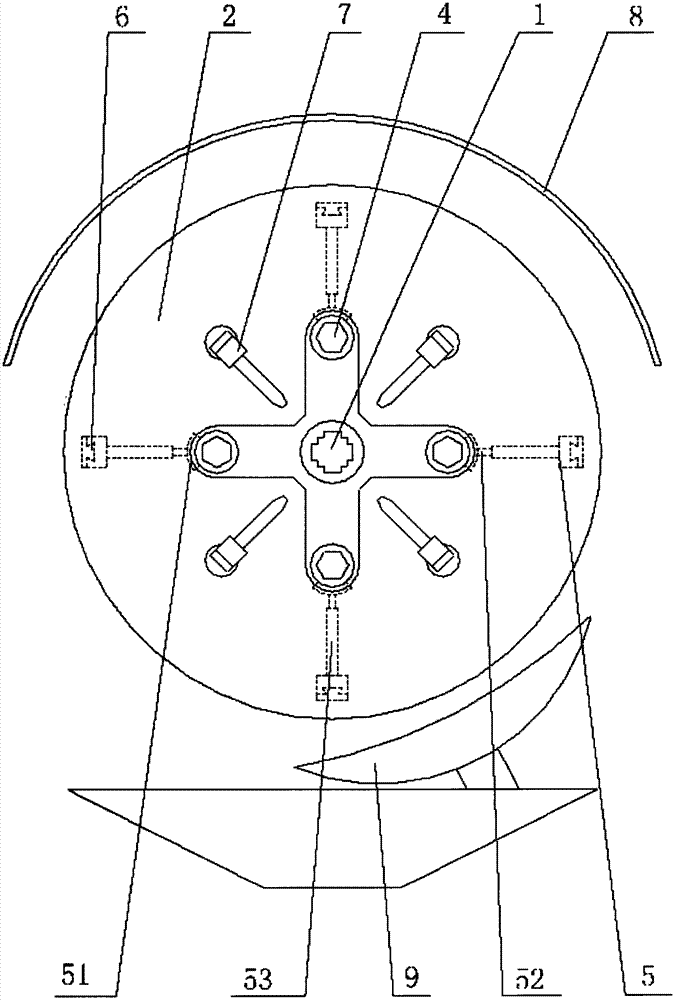

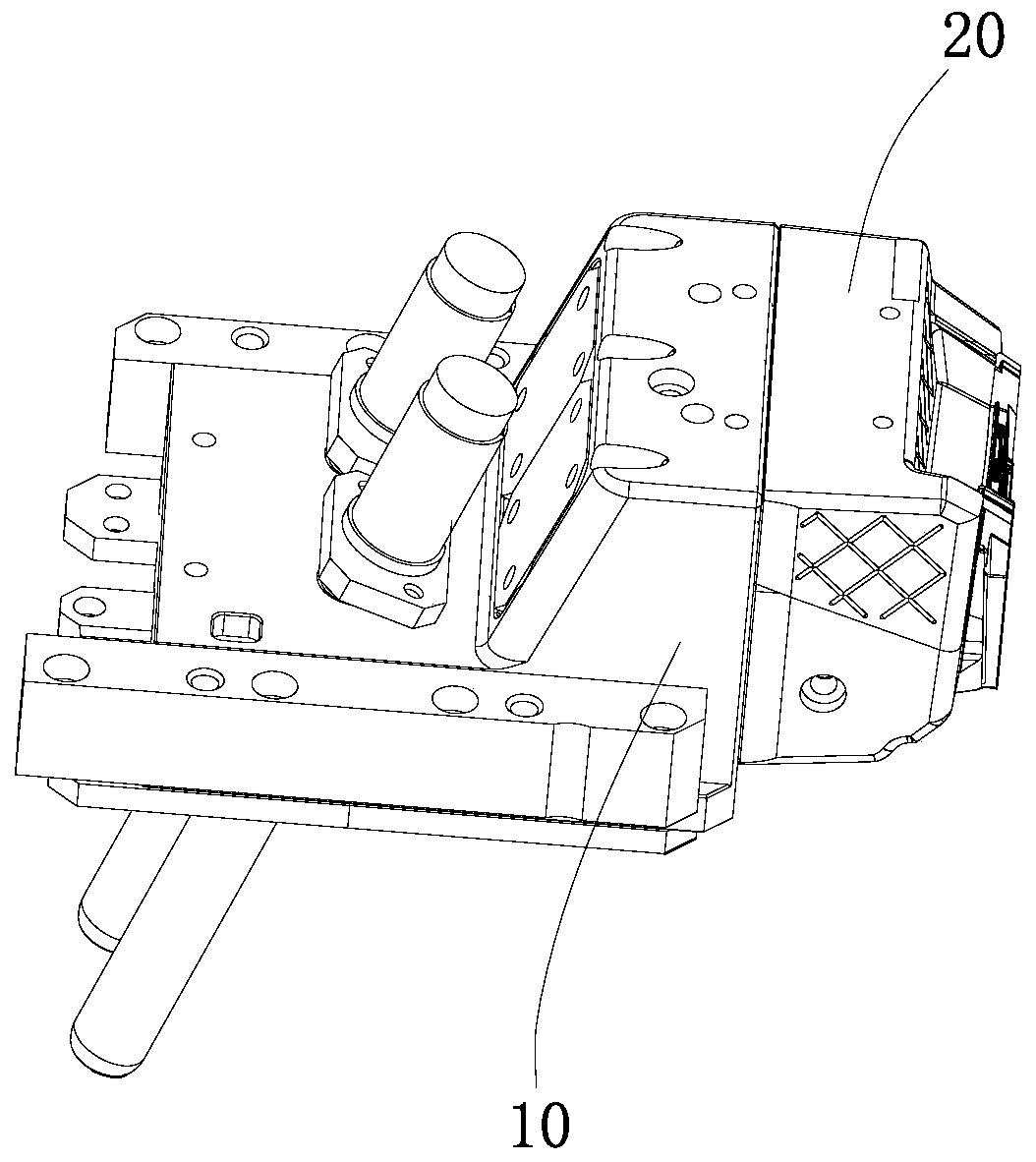

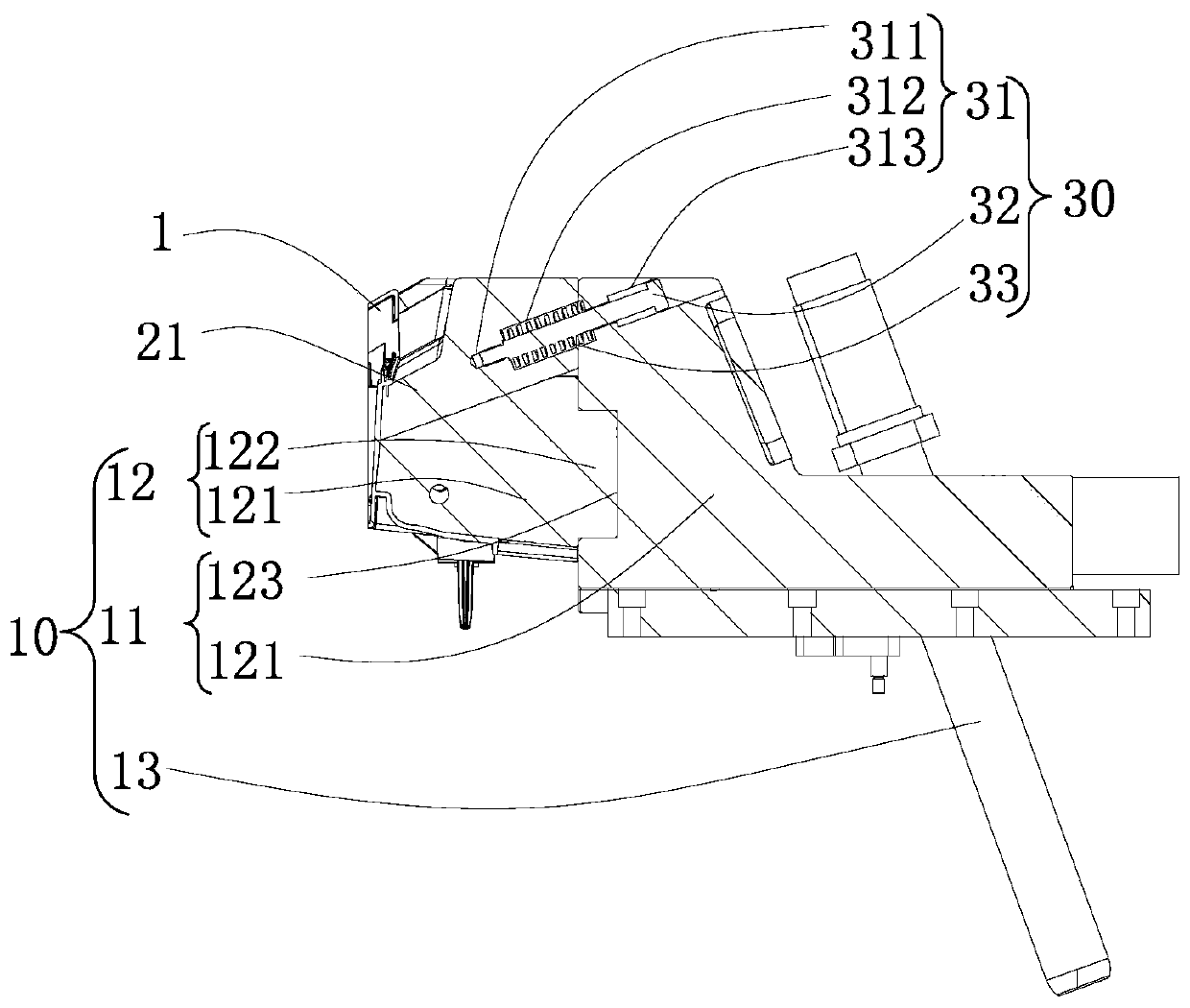

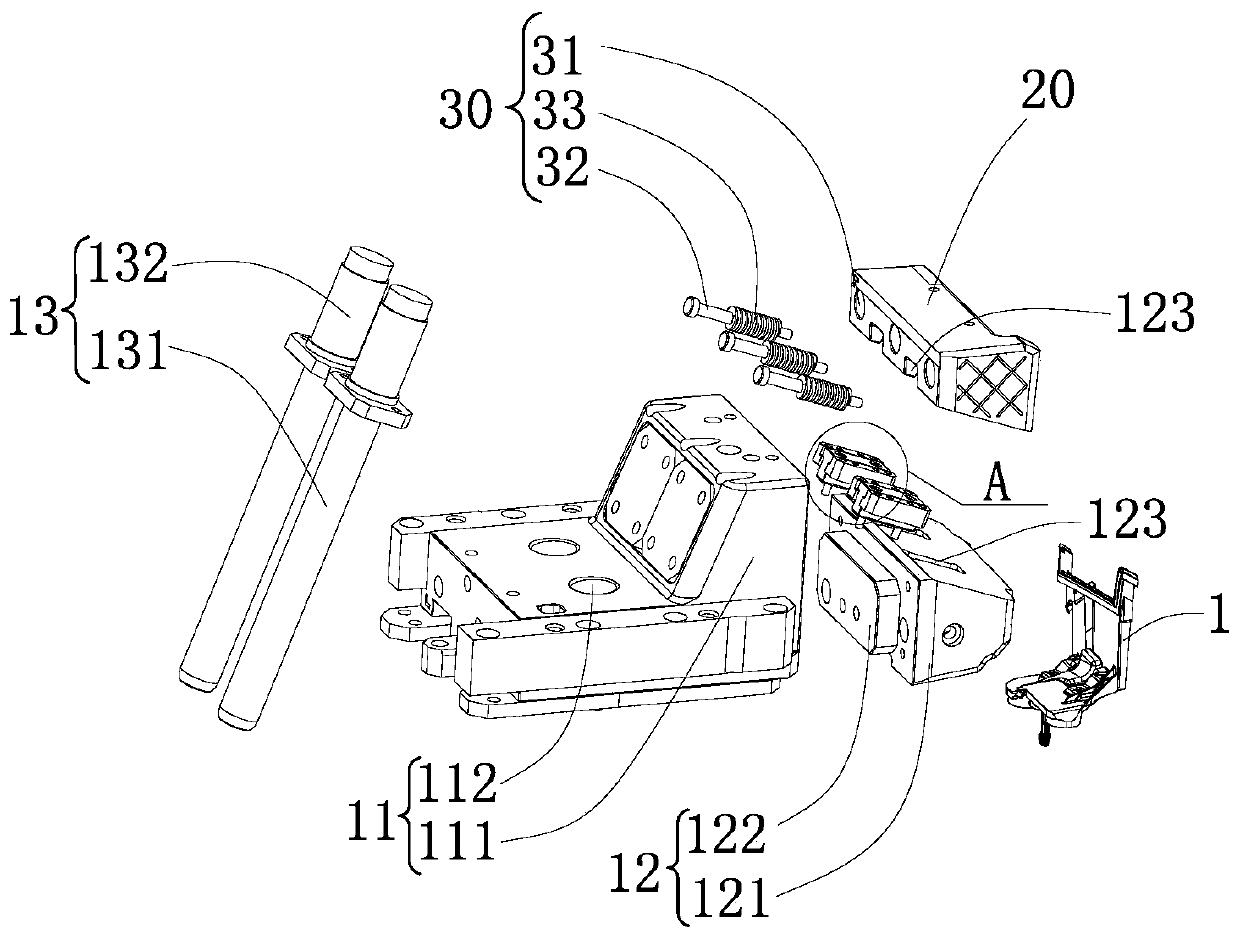

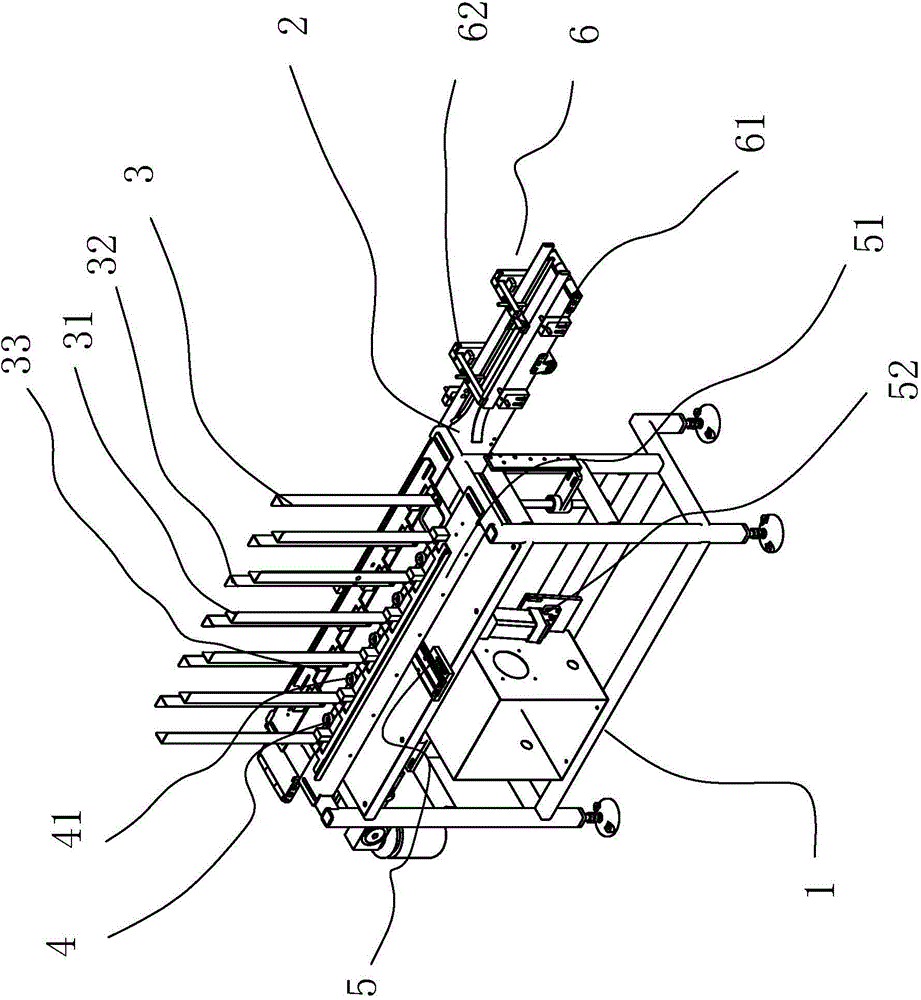

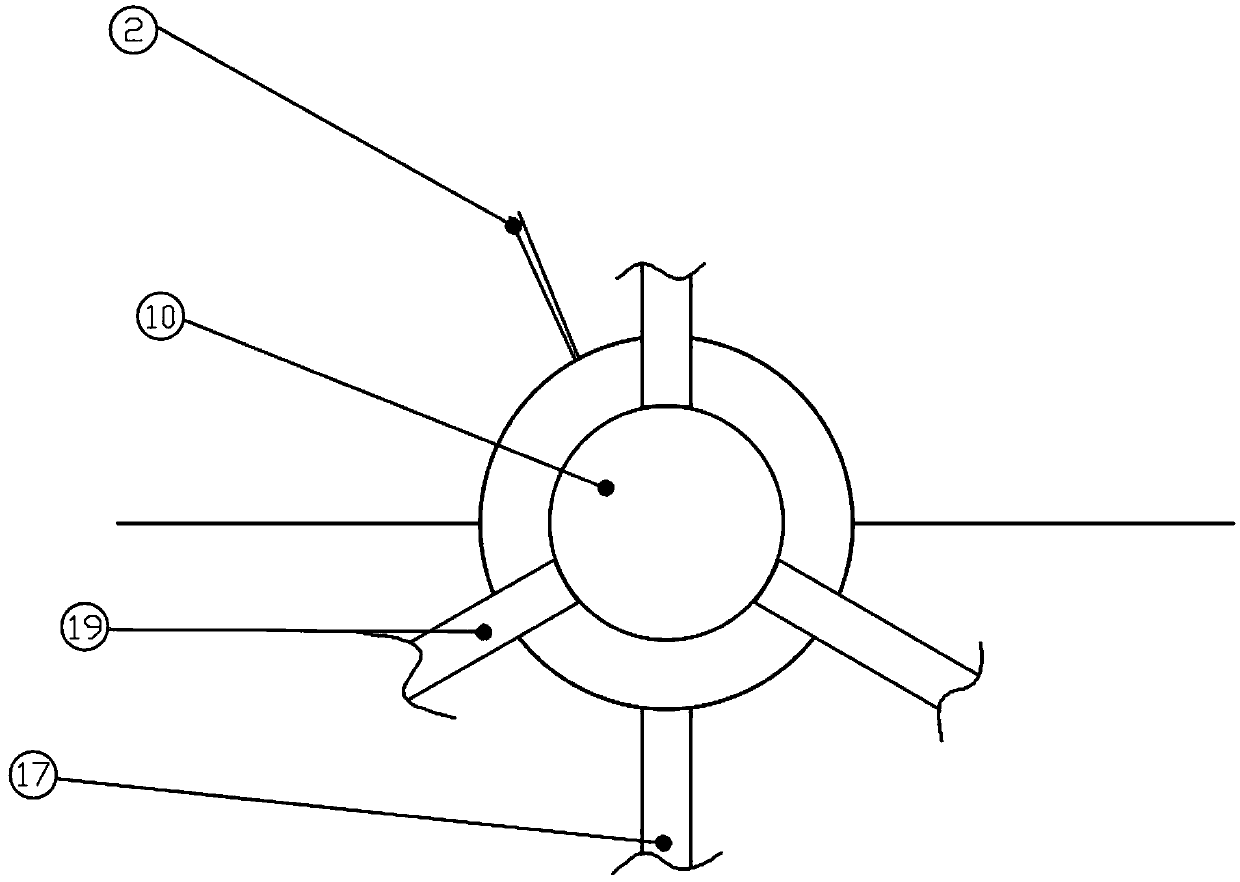

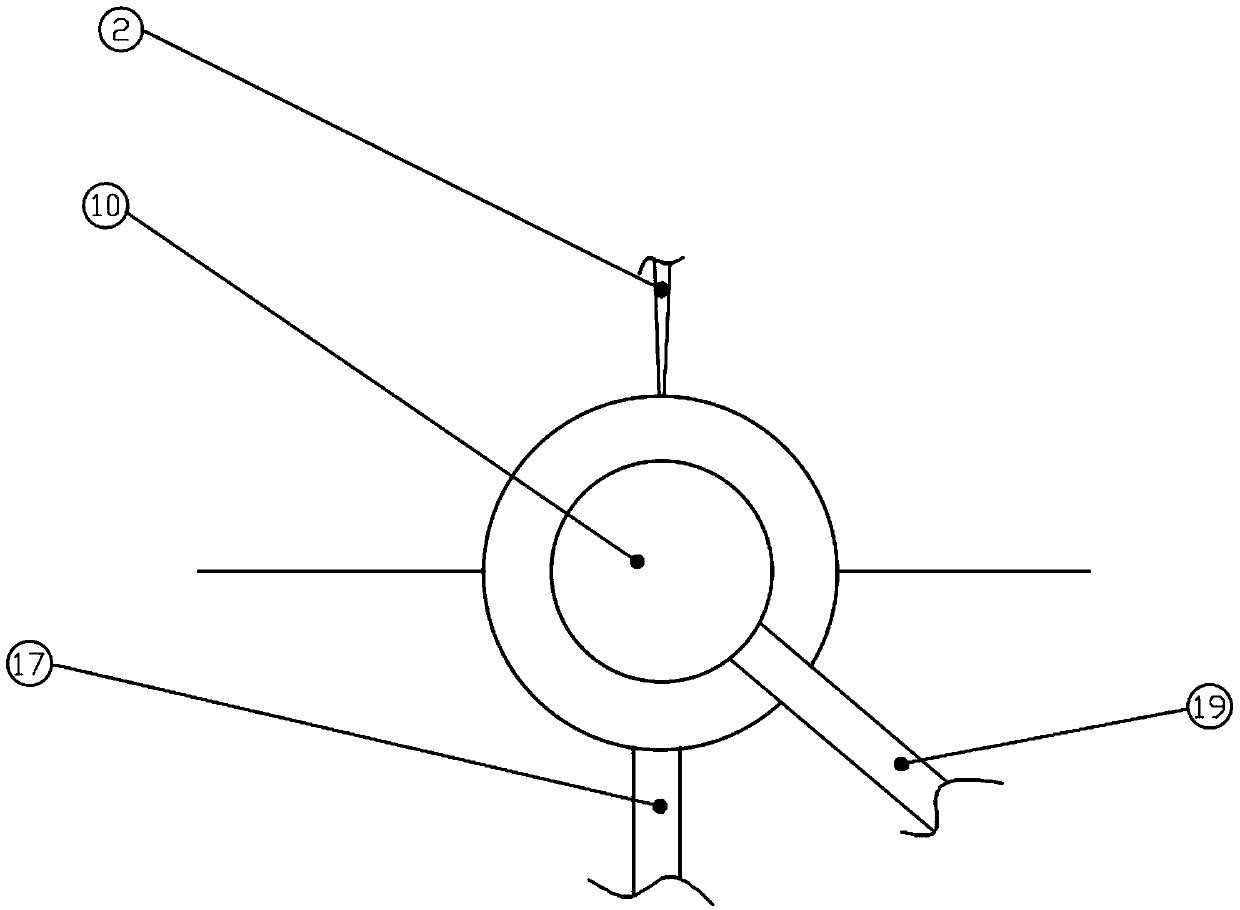

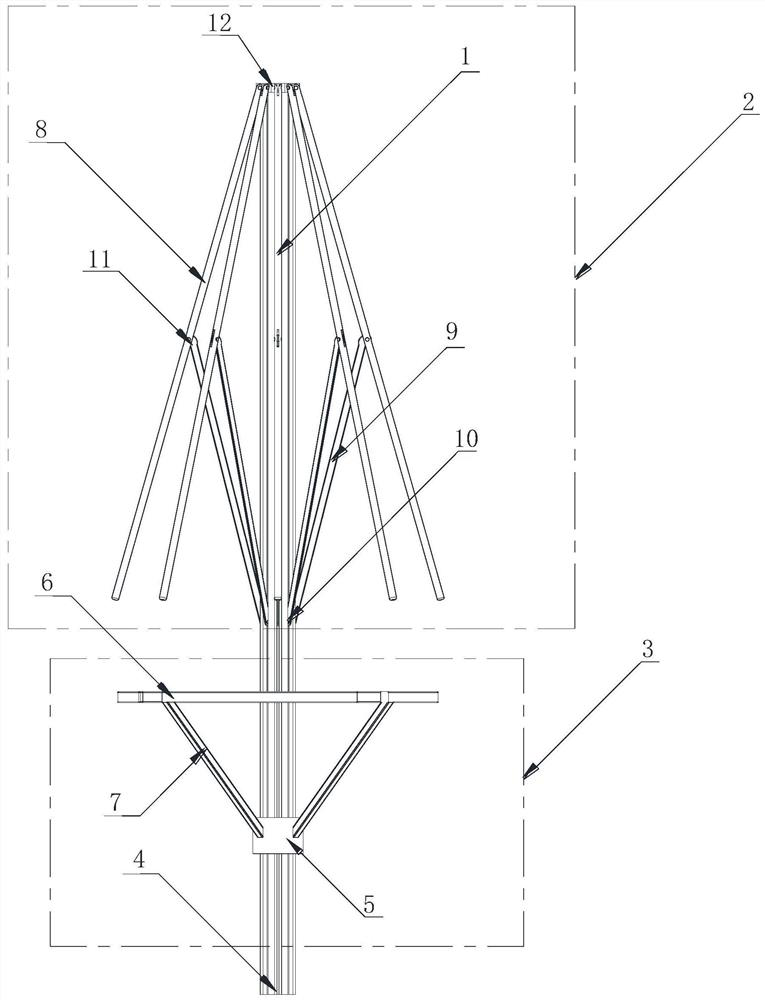

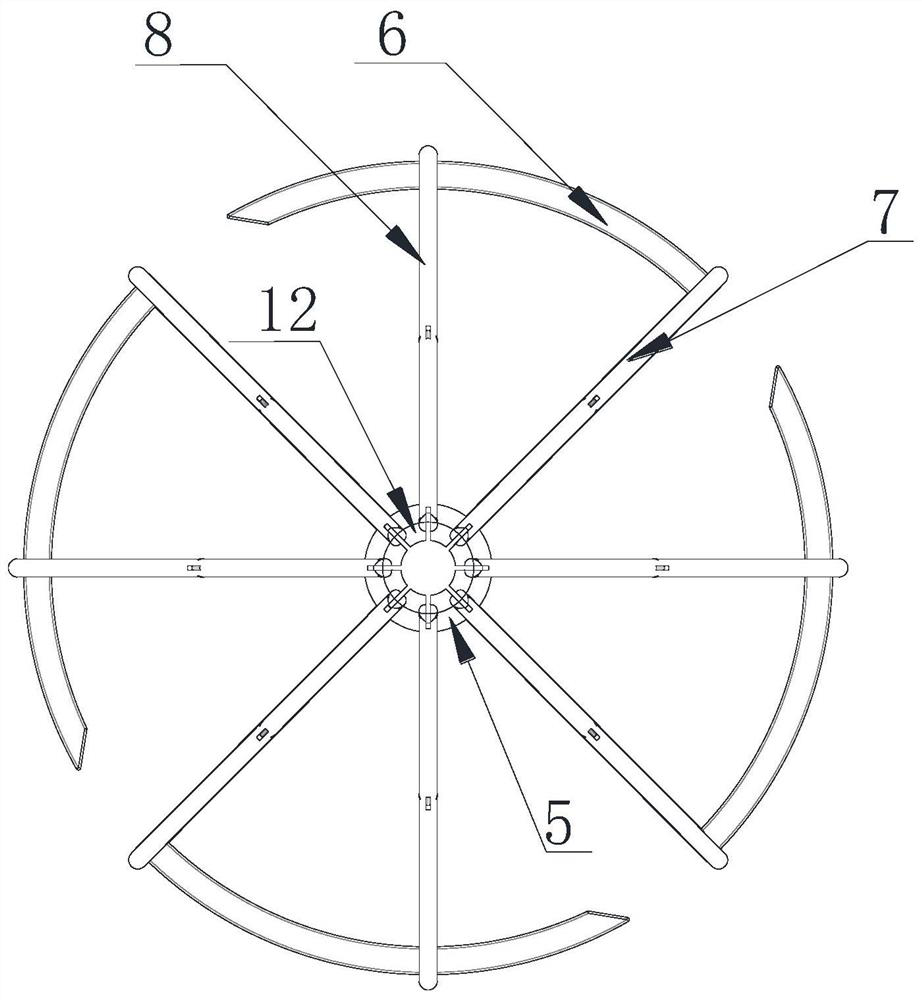

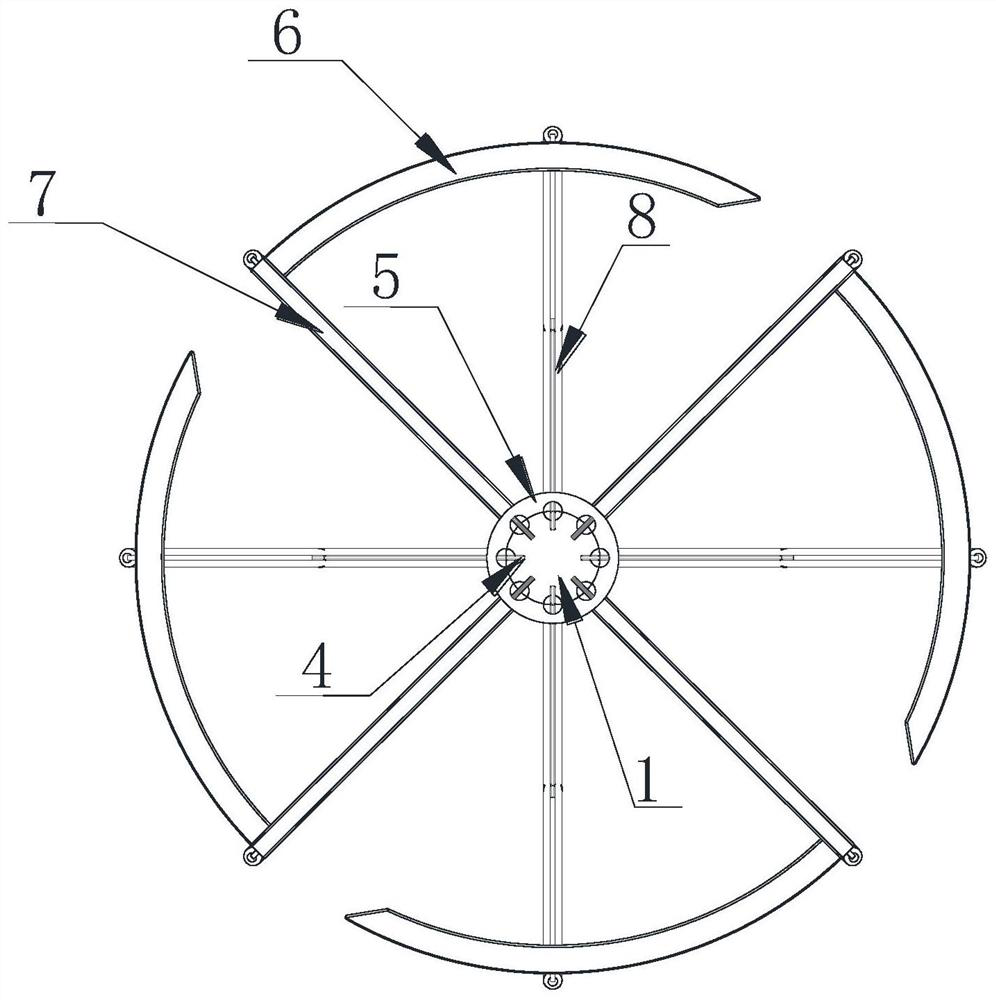

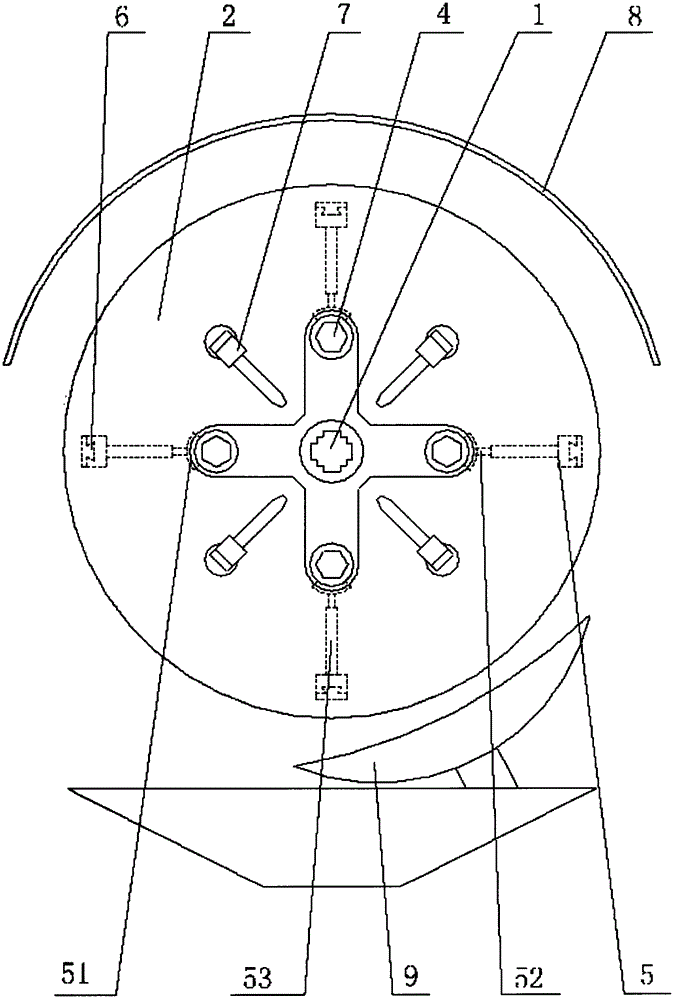

Four-DOF (degree of freedom) parallel sorting robot

ActiveCN104690713AClear division of laborReasonable actionProgramme-controlled manipulatorParallel sortingEngineering

The invention discloses a four-DOF (degree of freedom) parallel sorting robot and belongs to the technical field of industrial robots. The robot comprises a rack, an end effector, a first branched chain, a second branched chain and a synchronous belt branched chain, wherein the first branched chain comprises a first driving arm, a first driven arm, a second driving arm and a connecting rod; the second branched chain comprises a third driving arm, a third driven arm and a third secondary driven arm; the synchronous belt branched chain comprises belt pulleys and synchronous belts; the first branched chain and the second branched chain are connected with driving devices through the driving arms respectively; the synchronous belt branched chain is connected with a fourth driving device through a first belt pulley; the first branched chain, the second branched chain and the synchronous belt branched chain are connected with the end effector. The robot has the characteristics of simplicity in manufacturing, convenience in mounting and debugging, lower manufacturing cost and the like.

Owner:ANHUI HISEED ROBOT CO LTD

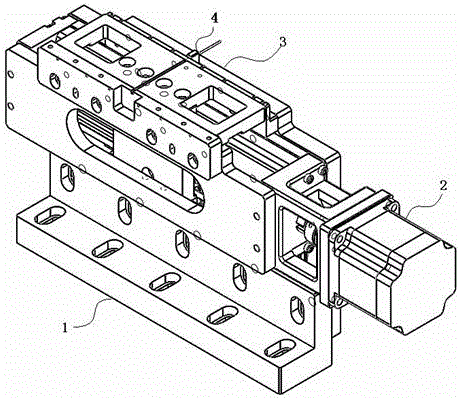

Numerical control machine tool

ActiveCN105436963ASafe and secure settingsReasonable settingPositioning apparatusMaintainance and safety accessoriesNumerical controlEngineering

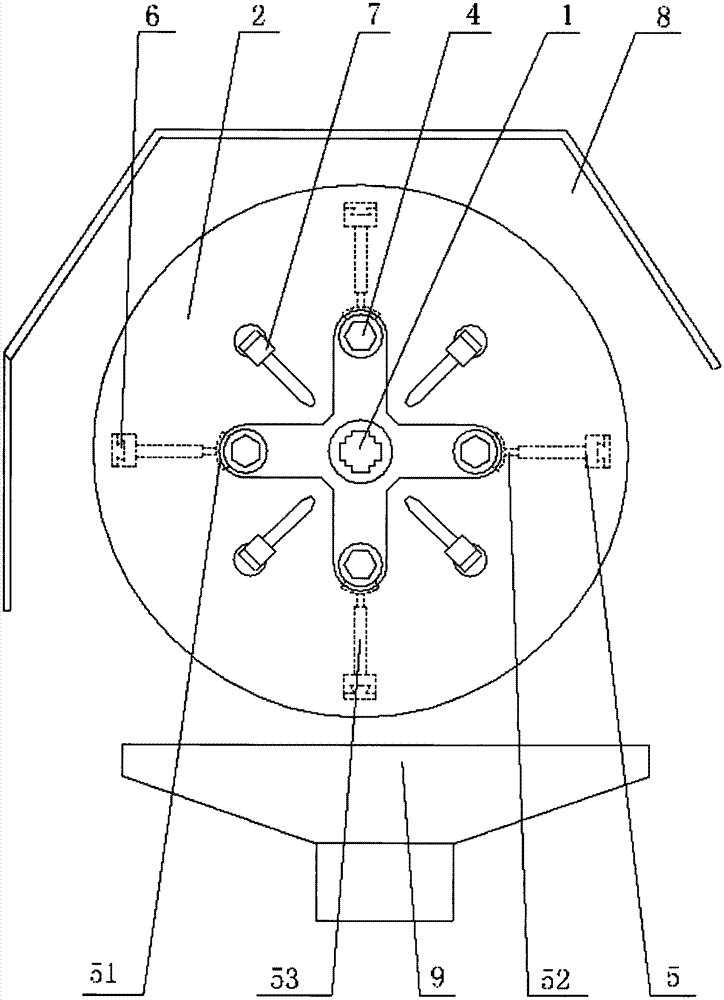

The invention provides a numerical control machine tool. The numerical control machine tool comprises a workpiece clamping mechanism and a cutter clamping mechanism, wherein the cutter clamping mechanism comprises a positioning shaft, the positioning shaft is sleeved with a cutter disc, at least two cutter movement grooves are formed in the cutter disc, and cutters are arranged in the cutter movement grooves in a penetrating mode in the axial direction of the cutter disc; the positioning shaft is located at the center of the cutter disc, a cuter pushing mechanism used for pushing the cutters to the positioning shaft from the direction away from the positioning shaft is arranged in the cutter movement grooves, the cutter pushing mechanism is provided with a cutter locking / automatic unlocking mechanism, a cutter restoration mechanism used for pulling the cutters to be close to the outer edge of the cutter disc along the cutter movement grooves is arranged in the cutter movement grooves, and the cutter pushing mechanism is provided with a sliding guide rail mechanism and a pushing and sliding driving mechanism; a cutter capturing mechanism is arranged on the positioning shaft. The numerical control machine tool has the advantages that multiple groups of cutters are arranged in the cutter disc in a hidden mode, using is safe, actuating units used for cutter change are reasonably arranged, and cutter change is stable and smooth.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

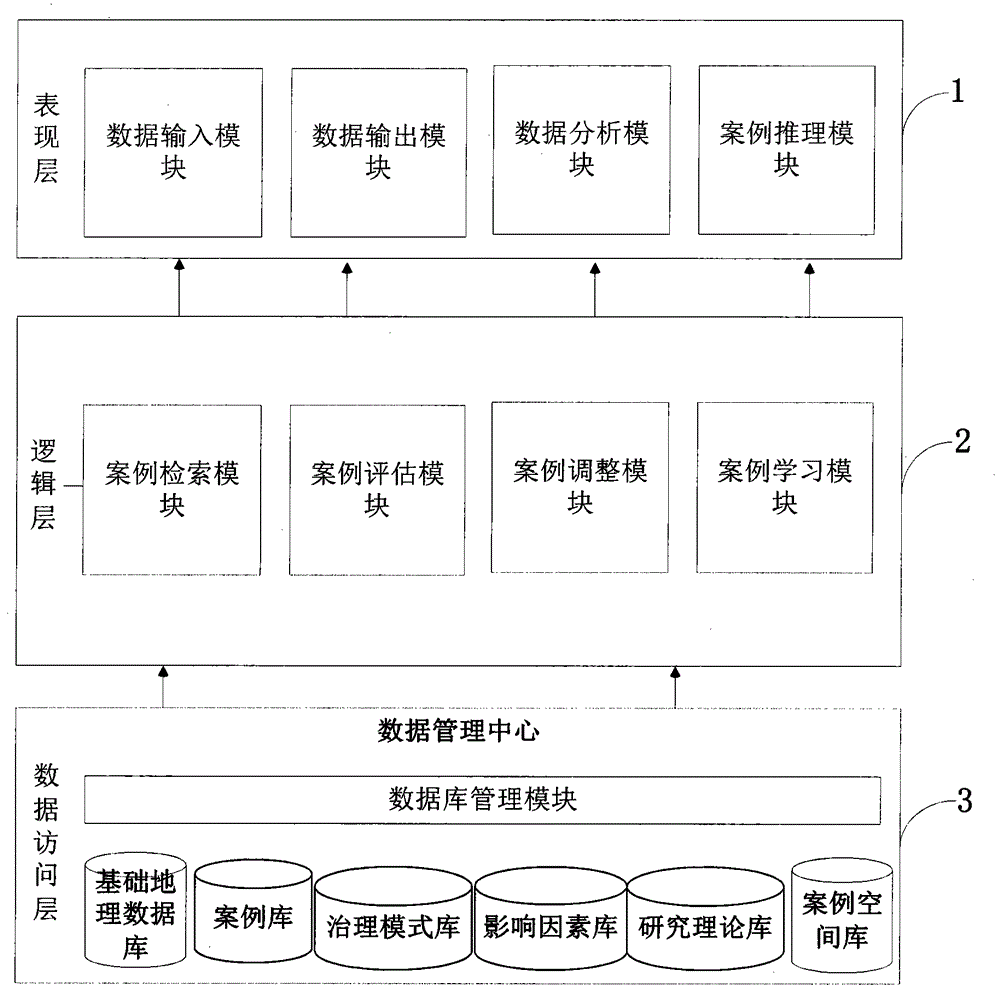

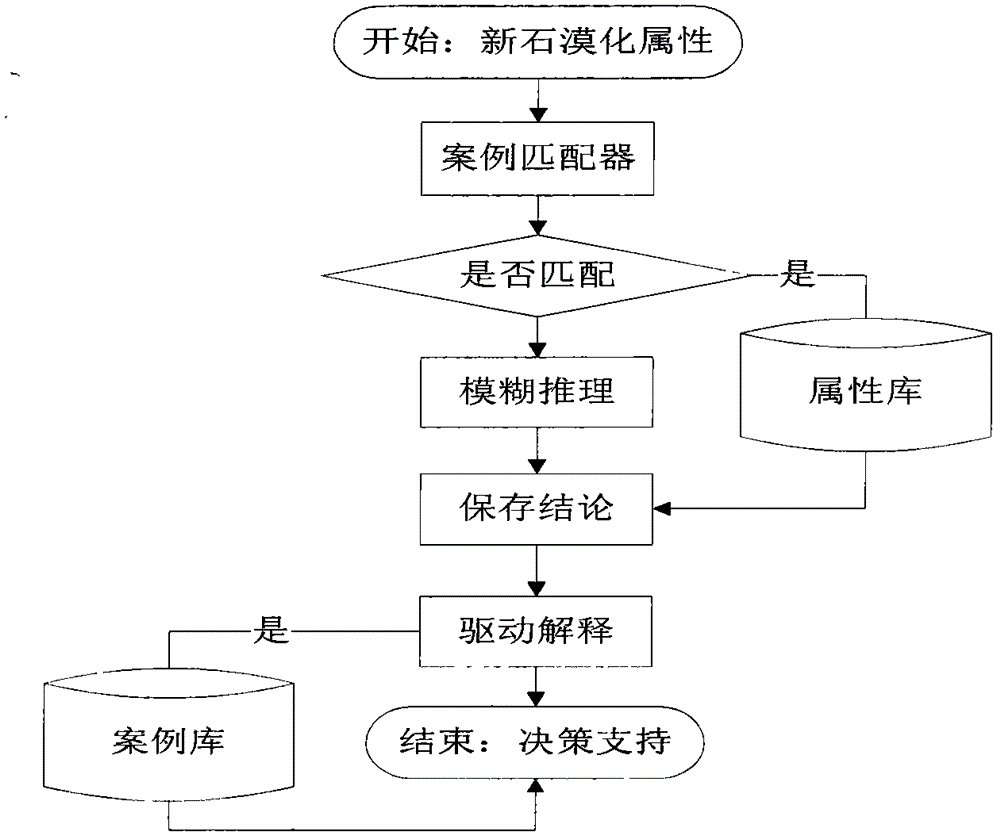

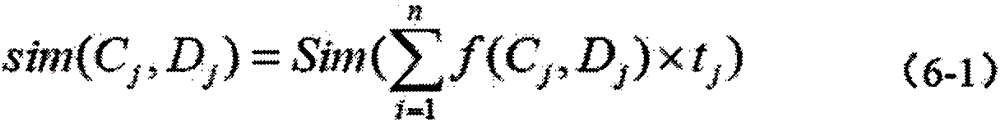

Rocky desertification governance model case library management system and rocky desertification governance model case library management method

InactiveCN104794528ARocky desertification control measures are reasonableReasonable actionInference methodsSpecial data processing applicationsSystem requirementsDecision taking

The invention discloses a rocky desertification governance model case library management system and a rocky desertification governance model case library management method. A three-layer (a data access layer, a service logic layer and a presentation layer) system structure based on a client and a server is adopted. The method comprises the following steps: a large number of cases related to the small-watershed rocky desertification governance model in Guangxi and even the southwestern region are collected widely, and the basic condition of an existing successful small-watershed rocky desertification governance model is stored in a case library as a case basis of reasoning in the future; a user inputs the basic information of a case to be retrieved according to the system requirements during governance; and retrieving is carried out according to indicator data input by the user, the similarity is calculated, a case with the highest similarity is selected for matching, a result is output if the user is satisfied with the result, and the case is adjusted and applied to the decision of a target case if the user is not is satisfied with the result. Decision makers can get inspiration in all aspects of rocky desertification governance so as to create a new method for the small-watershed rocky desertification governance model.

Owner:胡宝清

Demolding mechanism of multi-direction core pulling sliding block

PendingCN110900984AReasonable actionSimple structureDomestic articlesClassical mechanicsStructural engineering

Owner:JIAXING YAOU PHOTOELECTRIC TECH CO LTD

Multi-cutter-location numerical control lathe

ActiveCN105436521AReasonable settingReasonable actionAutomatic/semiautomatic turning machinesTurret lathesCutter locationEngineering

The invention provides a multi-cutter-location numerical control lathe which comprises a workpiece clamping mechanism and a cutter clamping mechanism. The cuter clamping mechanism comprises a positioning shaft, the positioning shaft is sleeved with a cutter disc, the cutter disc is provided with two or more cutter movable grooves, cutters are transversely arranged in the cutter movable grooves in a penetrating mode in the axial direction, each cutter comprises two or more sets of turning tools in different cutter head shapes, and one or more sets of turning tools are provided with two or more cutter heads; the cutter movable grooves are internally provided with cutter pushing and lifting mechanisms, the cutter pushing and lifting mechanisms are provided with cutter locking / automatic unlocking mechanisms, the cutter movable grooves are internally provided with cutter reset mechanisms, and the cutter reset mechanisms are provided with slippage guide rail mechanisms and a pushing and lifting and slippage drive mechanism; the positioning shaft is provided with a cutter capturing mechanism. The multi-cutter-location numerical control lathe has the advantages that multiple sets of cutter heads conduct combined machining, all sets of cutters are hidden in the cutter disc, the multi-cutter-location numerical control lathe is safe to use, all action mechanisms for replacing cutters are reasonable in arrangement, and cutter replacing action is stable and smooth.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

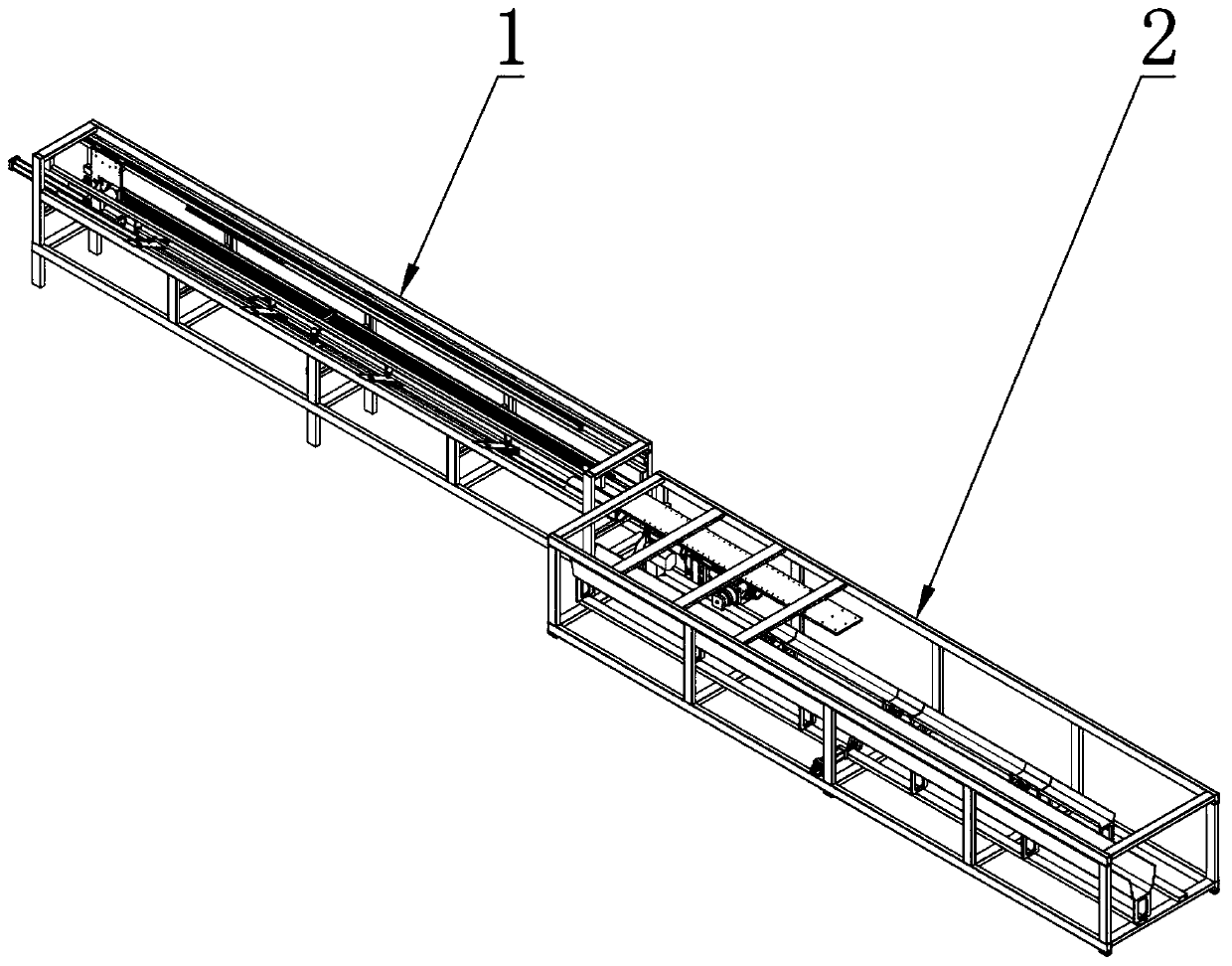

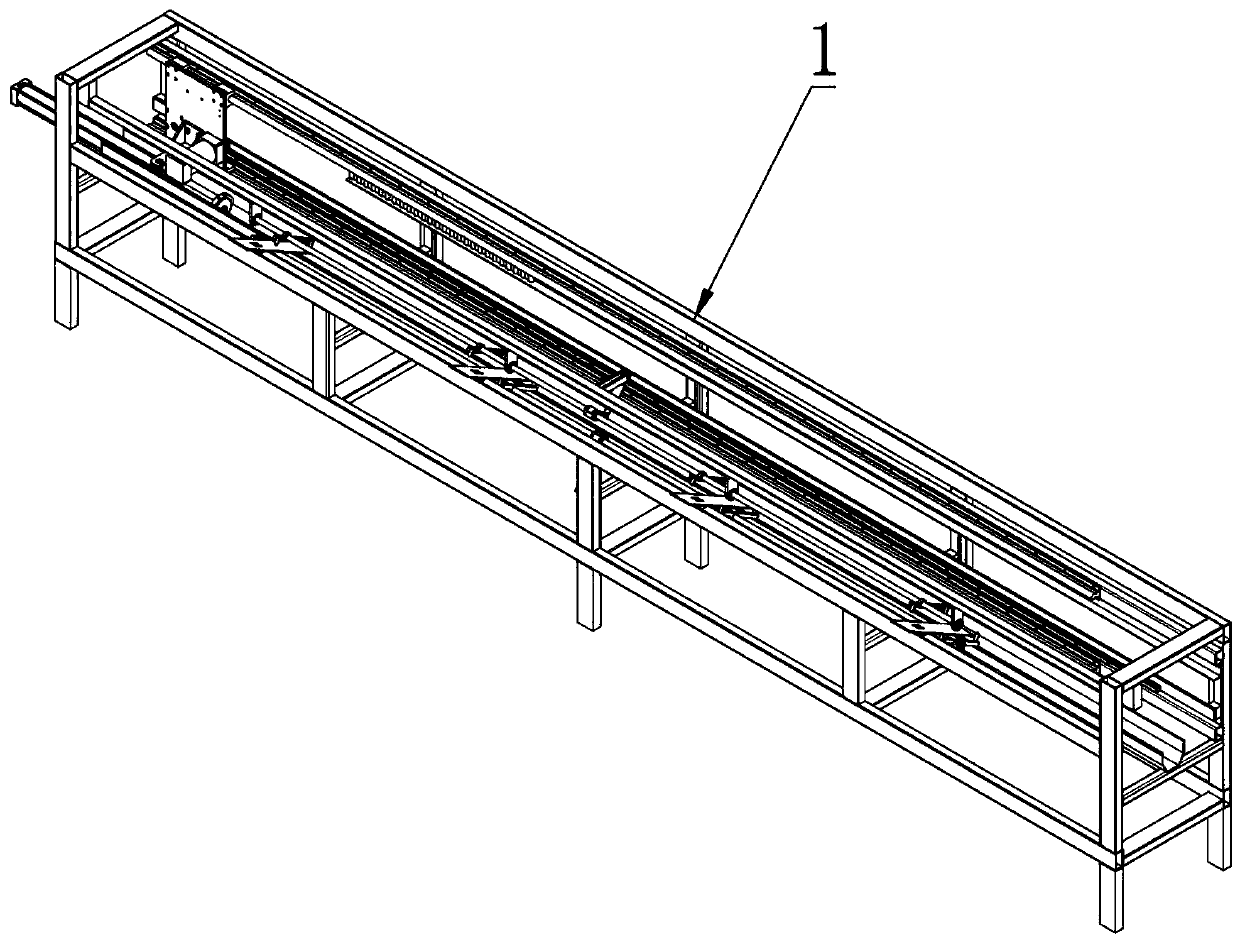

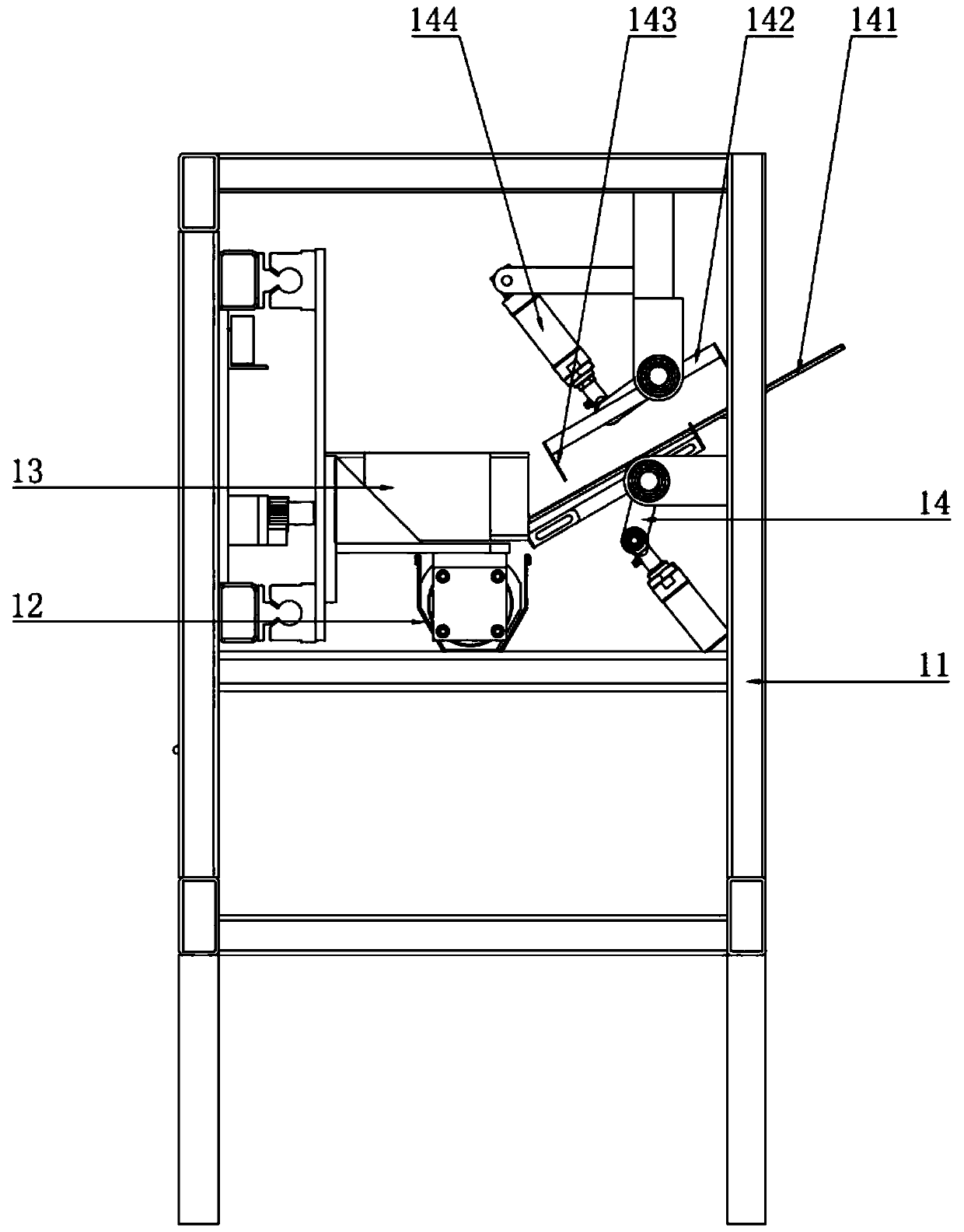

Mechanical equipment for automatically cutting steel bars

The invention discloses mechanical equipment for automatically cutting steel bars. The mechanical equipment for automatically cutting steel bars comprises a feeding device, a cutting device and a clamp set. A feeding frame of the feeding device is provided with a feeding groove, a pushing mechanism and a feeding mechanism, and the pushing mechanism can reciprocate in a groove body of the feeding groove movably and can push the steel bars in the feeding groove to the cutting device. A cutting frame of the cutting device is provided with a cutting machine, an unloading mechanism and a storage groove, and the cutting device is correspondingly connected with the feeding device. The clamp set comprises a first clamp and a second clamp arranged on two sides of the cutting mechanism respectively.The first clamp is fixed to the feeding tail end of the feeding groove. The second clamp is arranged above the unloading mechanism in the mode of corresponding to the first clamp. The cutting frame is provided with a horizontal moving mechanism in driving connection with the second clamp so that the second clamp can reciprocate on the unloading mechanism. The mechanical equipment is high in automation degree, does not need manual intervention in the cutting process, and is efficient and reliable.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

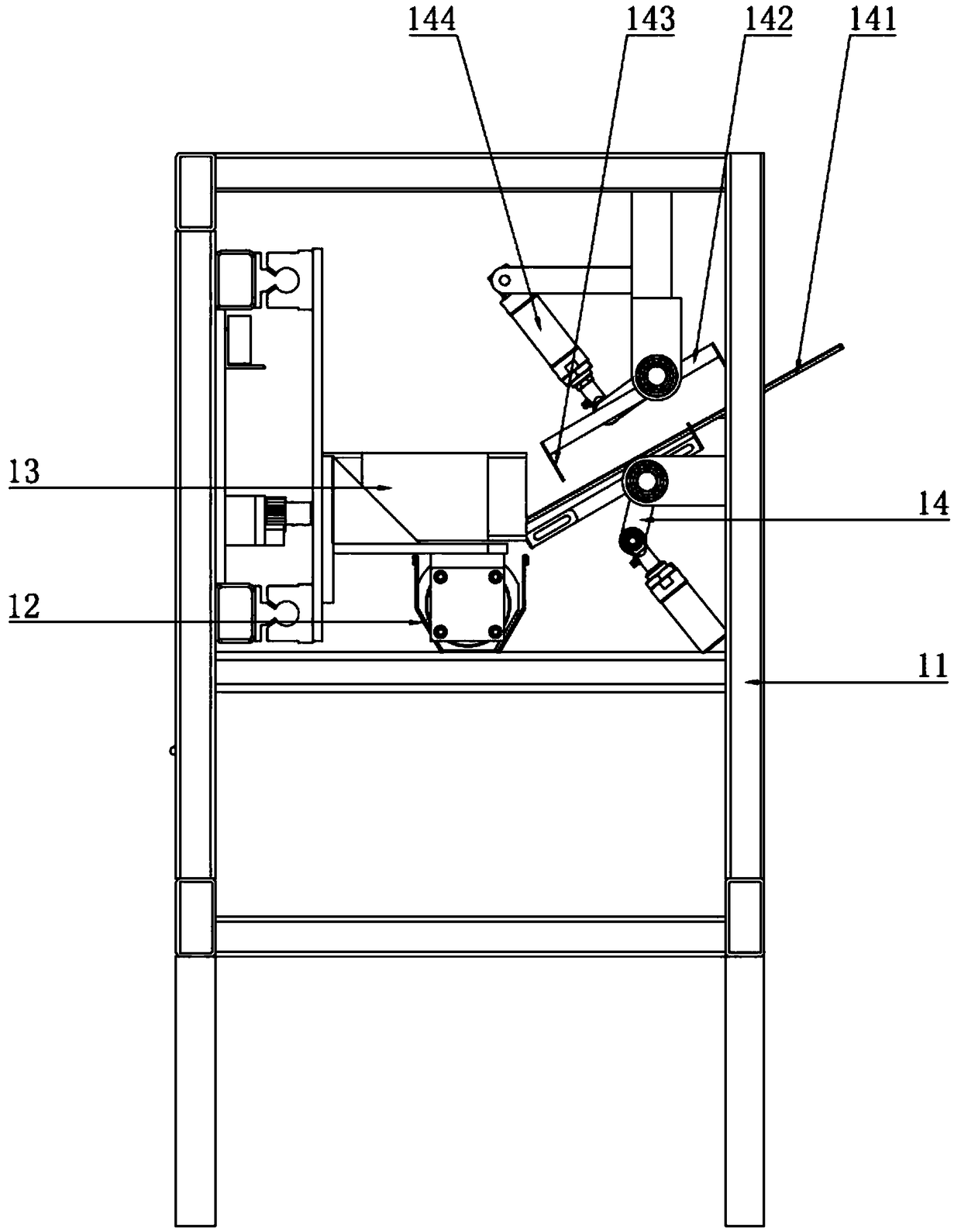

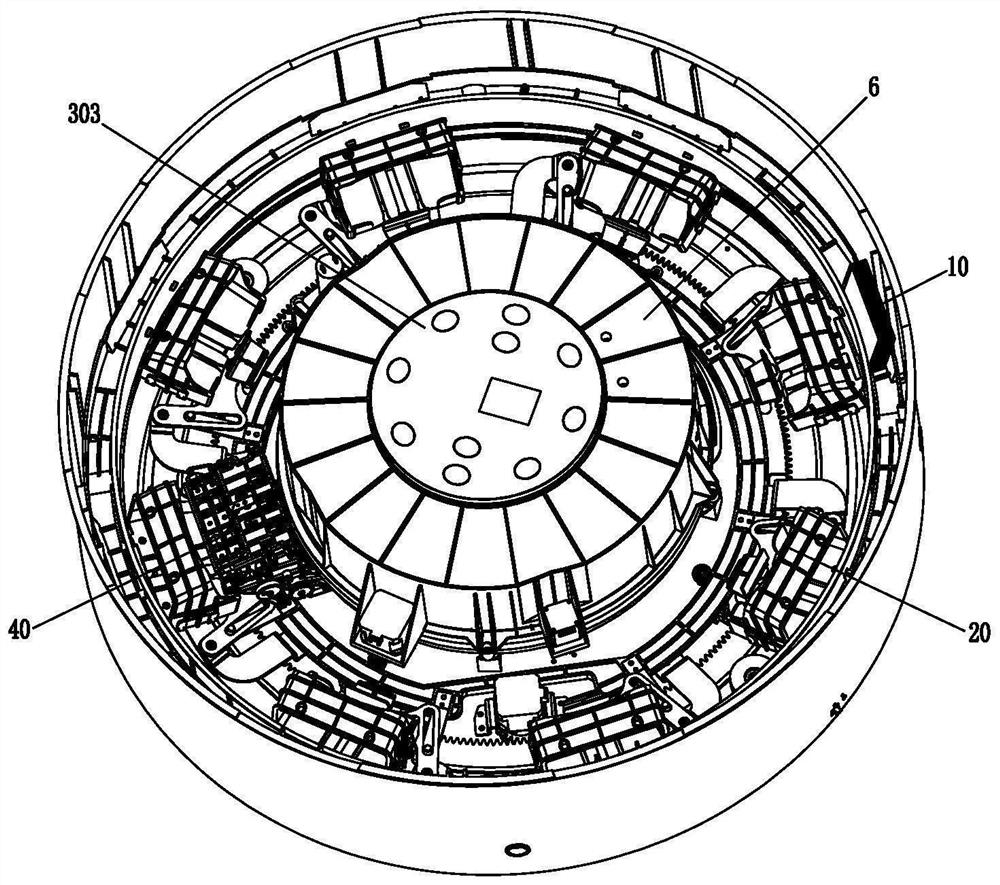

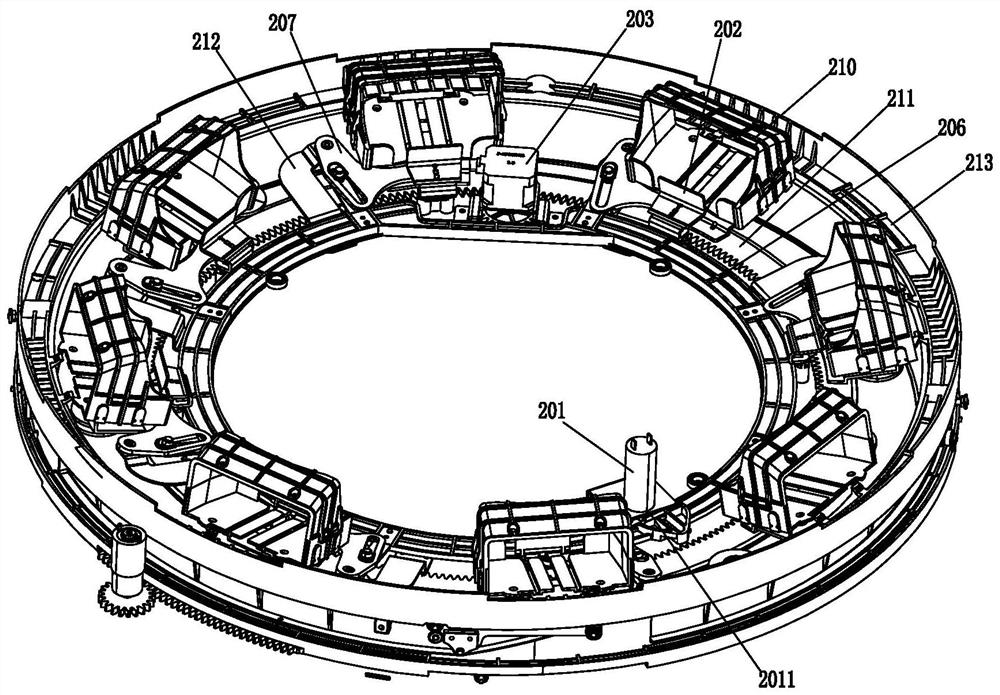

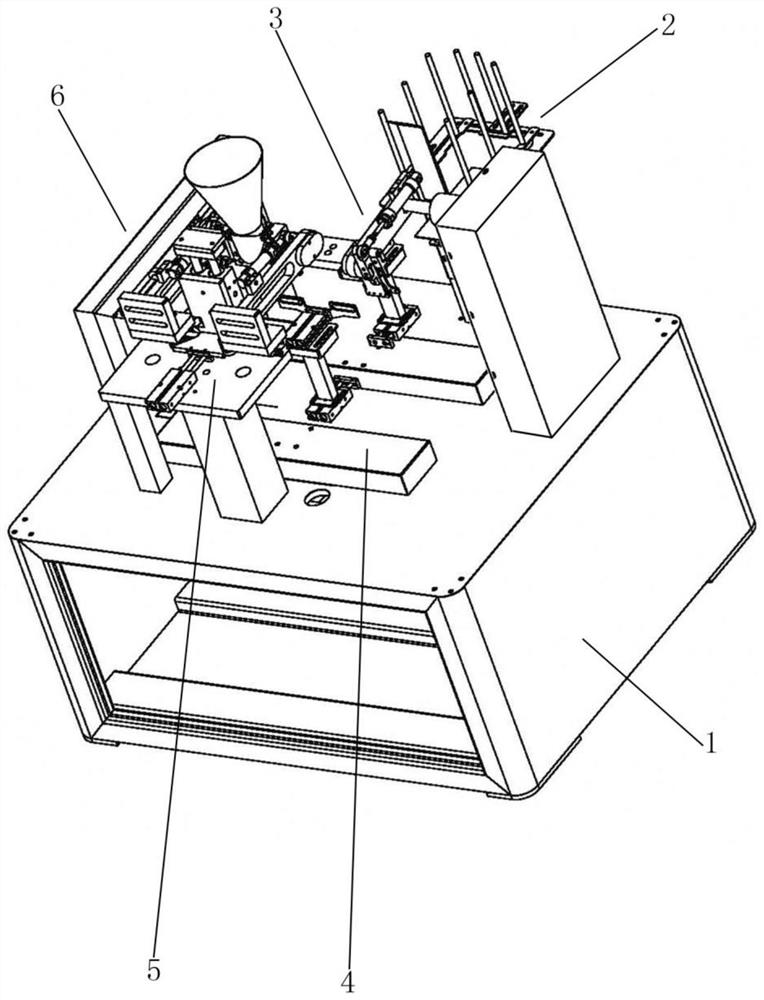

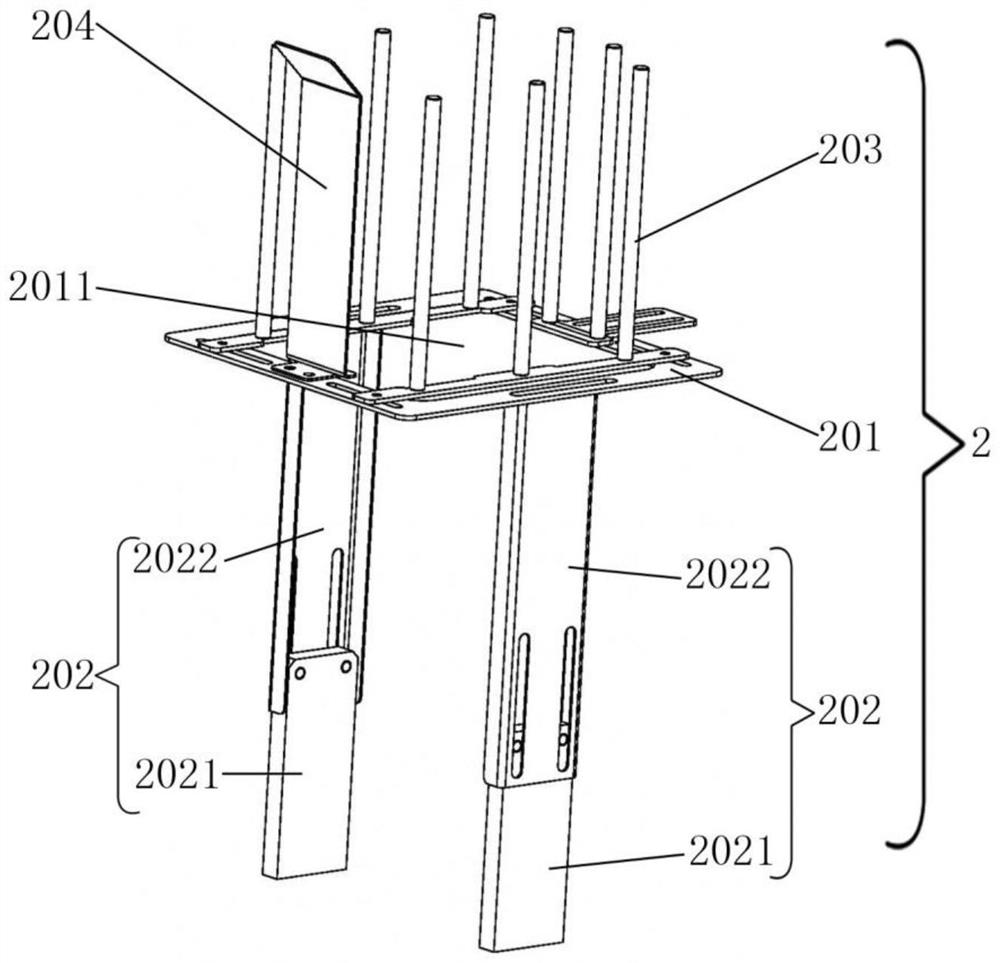

Poker machine, poker card lifting device of poker machine and poker card arrangement method

PendingCN113304462ASimple structureReasonable actionCard gamesMechanical engineeringSoftware engineering

The invention discloses a poker machine, a poker card lifting device of the poker machine and a poker card arrangement method. The poker card lifting device comprises a poker card bearing arm used for bearing poker cards and a poker card lifting driving mechanism used for driving the poker card bearing arm to go up and down. The poker card lifting device of the poker machine is installed on a base of the poker machine and corresponds to poker card receiving boxes one by one, and is used for lifting poker cards in the poker card receiving boxes to the table top of the poker machine. The poker card lifting device is simple in structure, reasonable in action, reliable in operation, low in manufacturing cost and convenient to install and debug.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

Automatic tray-sucking machine

InactiveCN104859896AReduce investmentRealize fully automated operationPackagingDe-stacking articlesEngineeringMechanical engineering

The invention discloses an automatic tray-sucking machine. The automatic tray-sucking machine comprises a frame, a conveying device arranged on the frame, a storage rack located besides the conveying device, and a sucking device located below the storage rack and further comprises a transverse conveying device and a tidying device. The transverse conveying device is located below the storage rack. The tidying device is arranged behind the conveying device. The automatic tray-sucking machine has following beneficial effects: by optimizing the overall structure, food supports can orderly enter a conveyer belt after trays are sucked up and then subjected to food-loading operation in sequence in order to realize fully-automated operation, thereby reducing input in labor; meanwhile, the automatic tray-sucking machine is capable of optimizing mechanisms of all devices such that motion is performed reasonably and mechanical movement is carried out smoothly; and the automatic tray-sucking machine is used for support-separating equipment in the field of food production.

Owner:FOSHAN RUIPUHUA PACKING MACHINERY CO LTD

Magnet set vertical tungsten steel sheet distributing mechanism

ActiveCN106002169AImprove the efficiency of material distribution and dischargeStrong reliabilityMetal working apparatusDischarge efficiencyEngineering

The invention discloses a magnet set vertical tungsten steel sheet distributing mechanism. The distributing mechanism comprises a base and a distributing driving motor arranged on the base; a distributing disc mechanism is further arranged on the base and comprises a fixed pedestal fixed to the base and a distributing disc, and the distributing disc is movably arranged in the fixed pedestal; a feed port used for being communicated with tungsten steel sheet vibrating disc rails is formed in one side of the fixed pedestal, multiple discharge ports used for being communicated with multiple discharging rails are formed in the other side, and multiple air blowing channels are formed in the side opposite to the multiple discharge ports; a guide groove is formed in the distributing disc, and the guide groove can be sequentially communicated with the air blowing channel, the feed port and the discharge ports in the moving process of the distributing disc in the fixed pedestal. By using the distributing mechanism, intelligent distributing can be achieved on the basis of an original single vibrating disc, and the distributing and discharging efficiency is effectively improved.

Owner:苏州茂特斯自动化设备有限公司

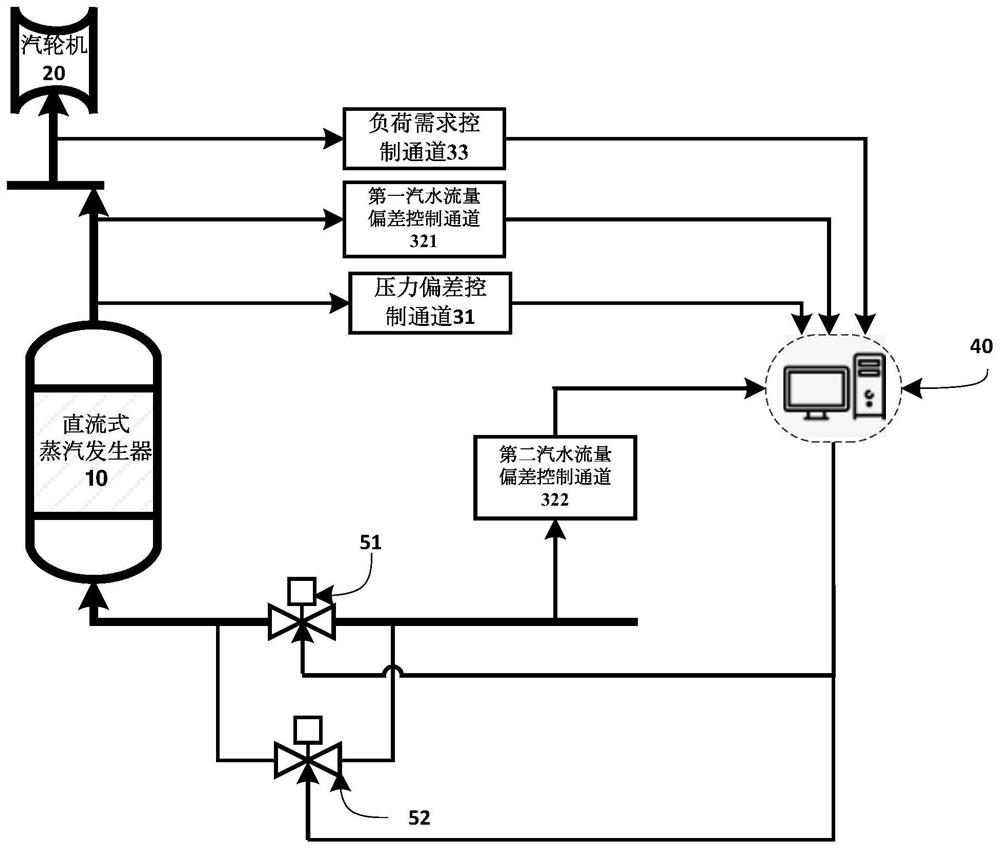

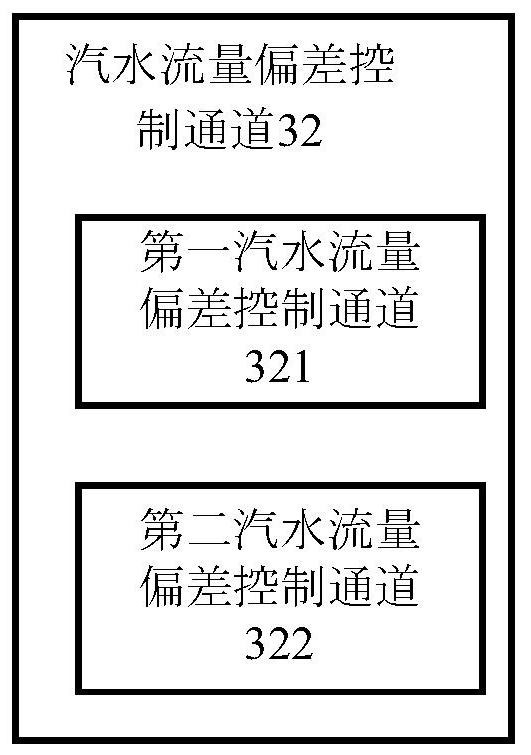

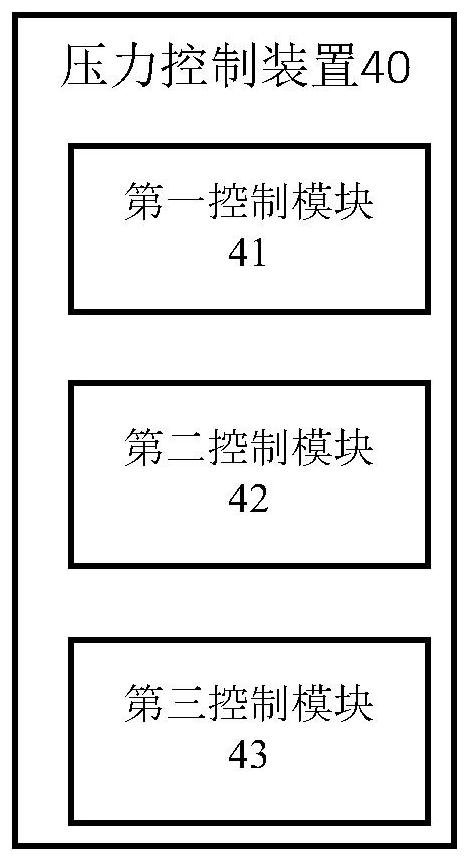

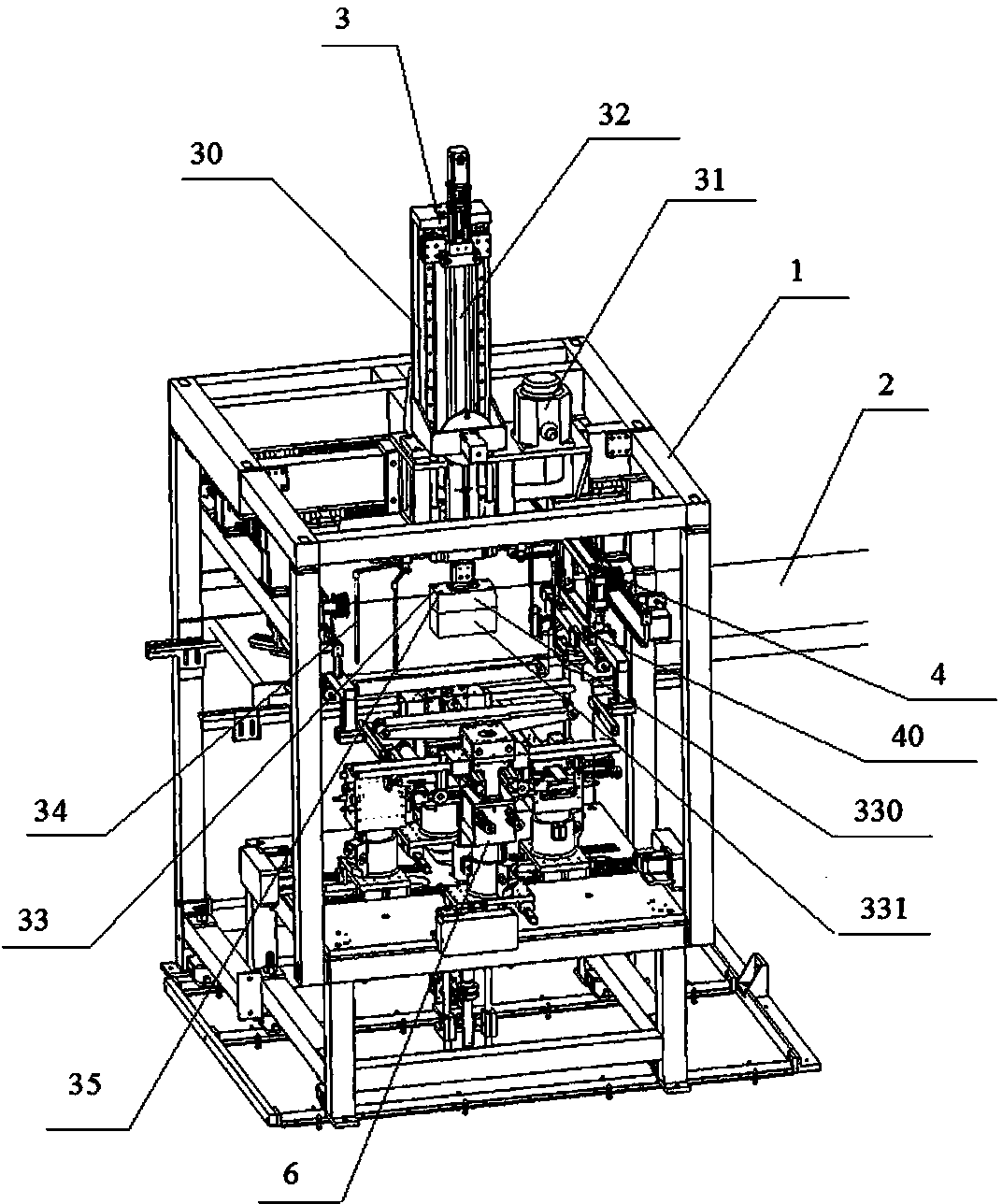

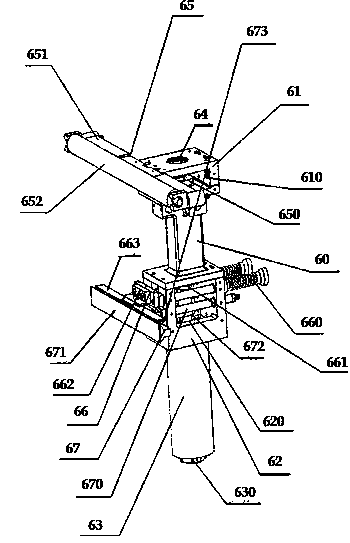

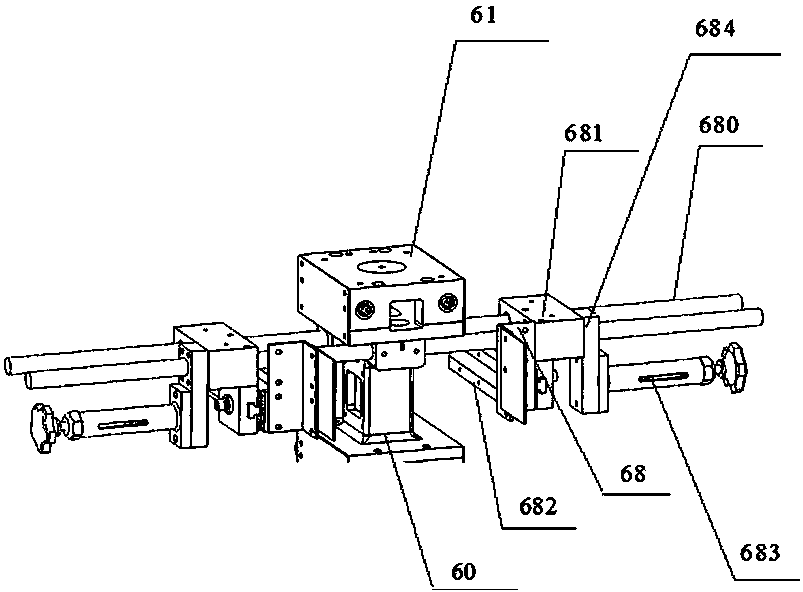

Straight-flow steam generator pressure control method and system

The invention discloses a straight-flow steam generator pressure control method and system. The system comprises a straight-flow steam generator, a steam turbine, a water supply adjusting valve set, a pressure deviation control channel, a first control module, a steam-water flow deviation control channel, a second control module and a load demand control channel used for measuring a steam inlet pressure value of the steam turbine; and a third control module which is used for comparing the steam inlet pressure value with a switching threshold value and selectively outputting high and low load signals. The water supply adjusting valve set comprises a first valve and a second valve, the first valve is selectively opened or closed according to high and low load signals, and the second valve is selectively opened or closed according to the high and low load signals. According to the straight-flow steam generator pressure control method and system, the requirements for coarse adjustment and fine adjustment are distinguished through the third control module, so that opening and closing of the first valve and the second valve are controlled correspondingly, and the requirements for coarse adjustment and fine adjustment are met at the same time.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Fully automatic carton molding machine

InactiveCN103085316BStable jobWork flexiblyContainer making machineryMolding machineProgrammable logic controller

Owner:广东力顺源智能自动化有限公司

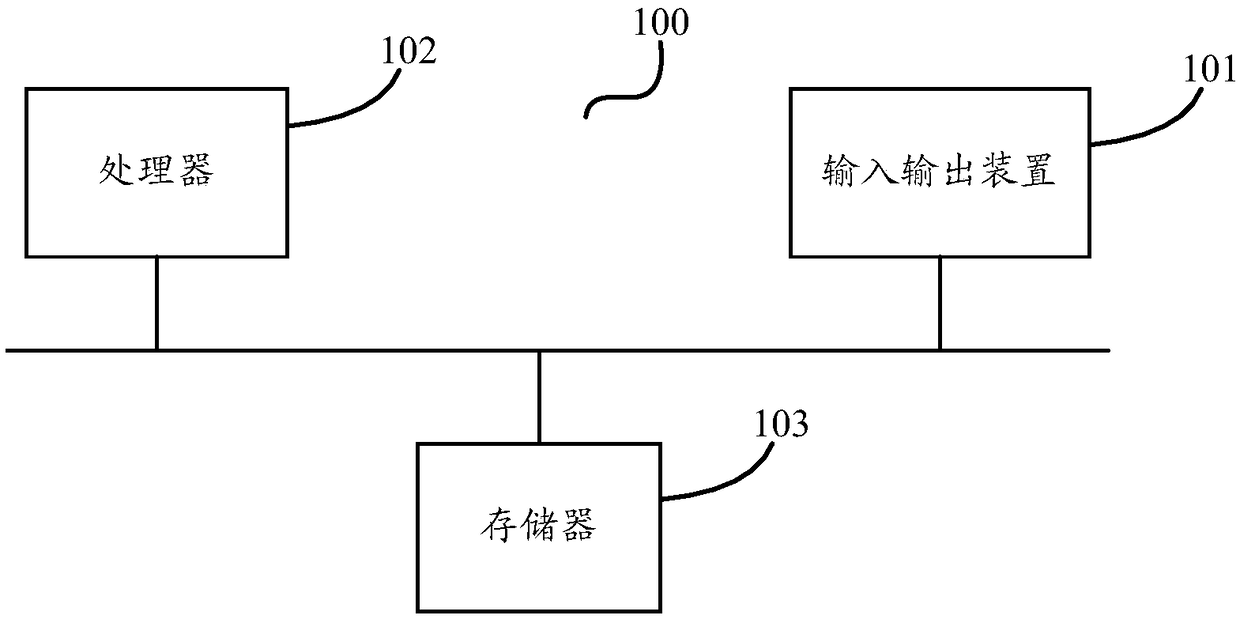

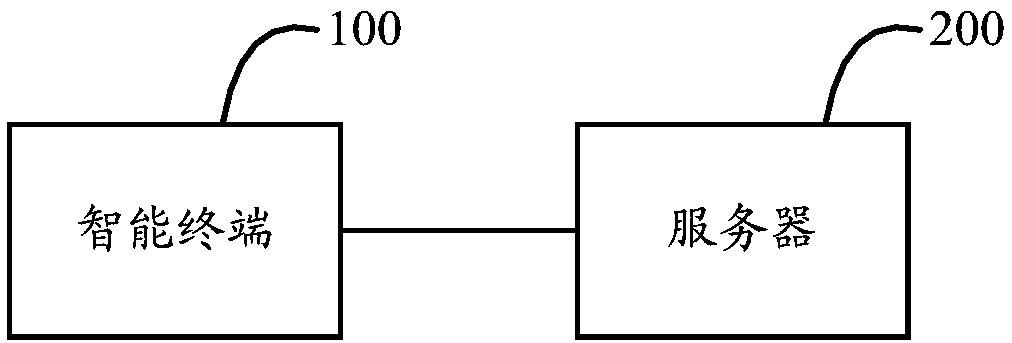

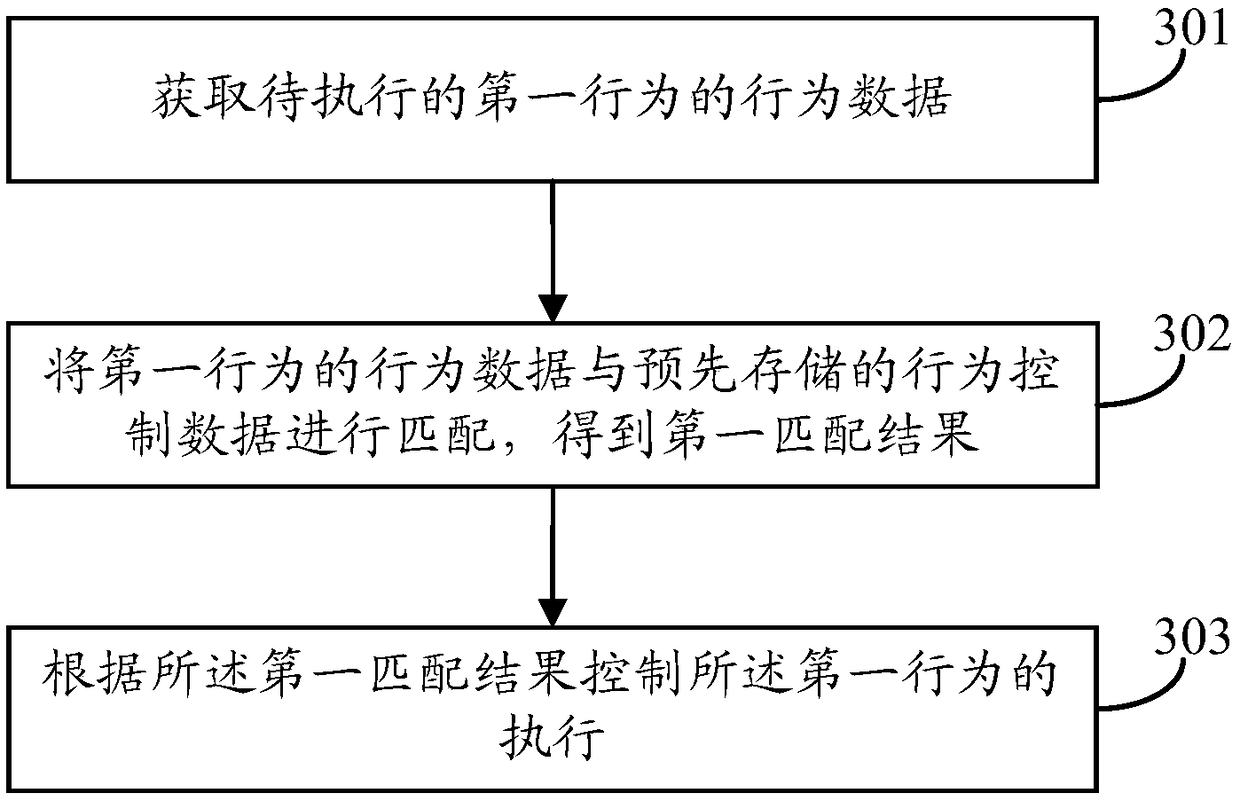

Artificial intelligence terminal system, server and behavior control method thereof

ActiveCN109313645AReasonable actionFulfil requirementsProgramme-controlled manipulatorDatabase management systemsBehavior controlControl data

The present invention relates to the technical field of computers. Disclosed are an artificial intelligence terminal system, a server and a behavior control method thereof. The method comprises: receiving data of a first behavior to be executed, the data of the first behavior being uploaded by an artificial intelligence terminal; performing matching on the basis of the data of the first behavior to be executed and behavior control data in a pre-established behavior control database to obtain a first feasibility; and transmitting the first feasibility to the artificial intelligence terminal, such that the artificial intelligence terminal can determine, according to the first feasibility, whether to execute the first behavior or not. In the embodiment of the present invention, the behavior control data can be used to regulate the behavior of the artificial intelligence terminal.

Owner:深圳市大富智慧健康科技有限公司

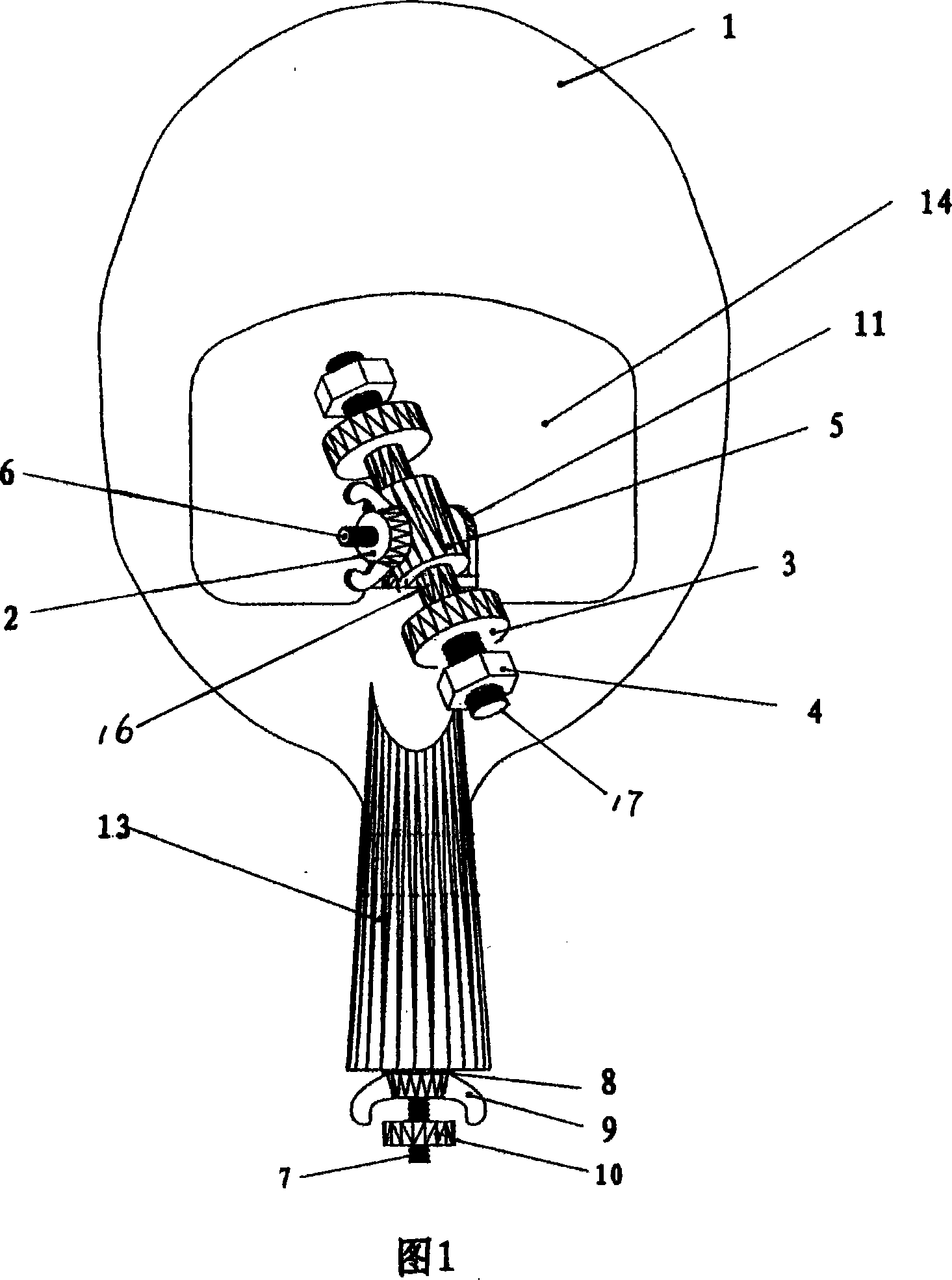

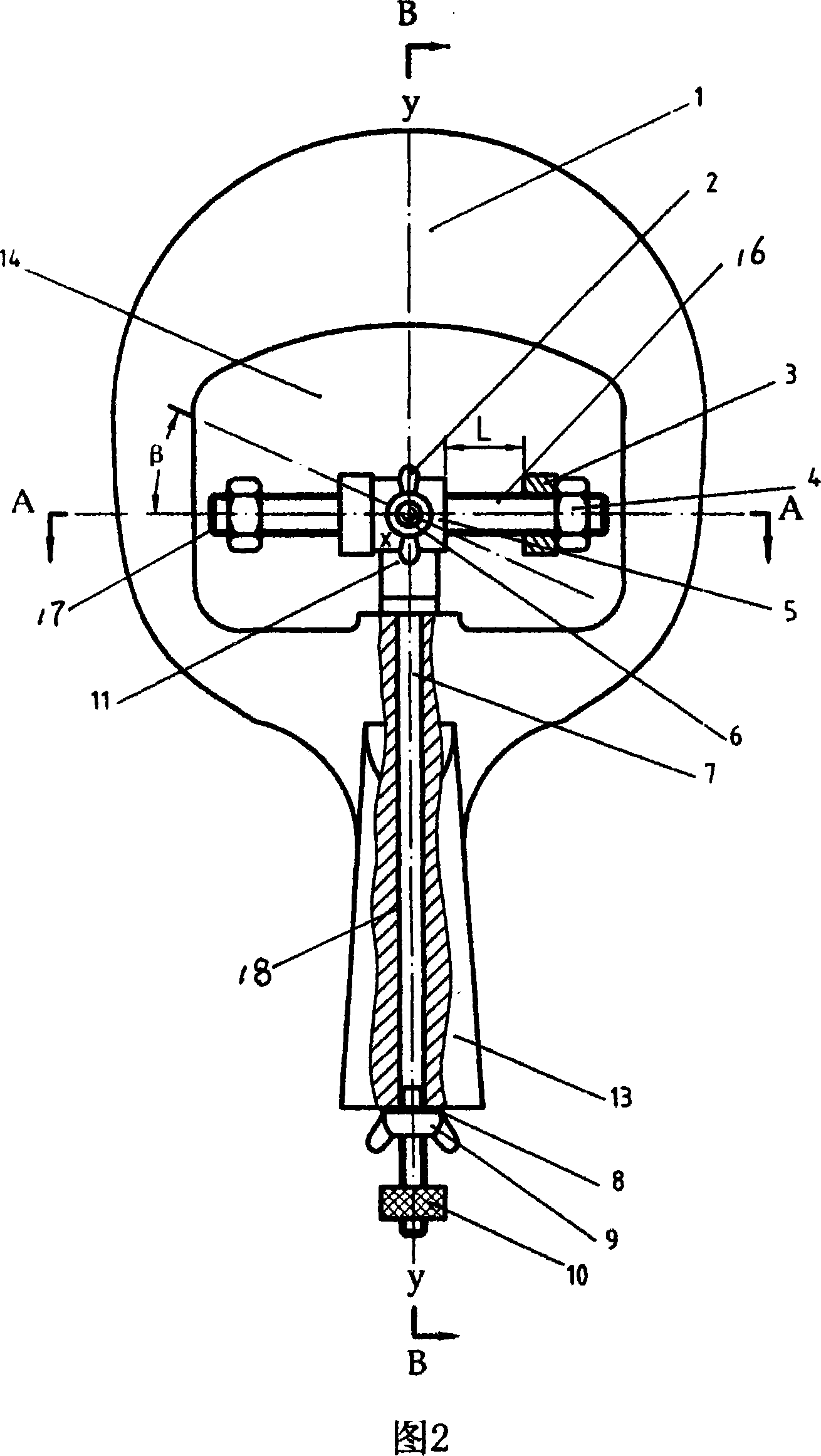

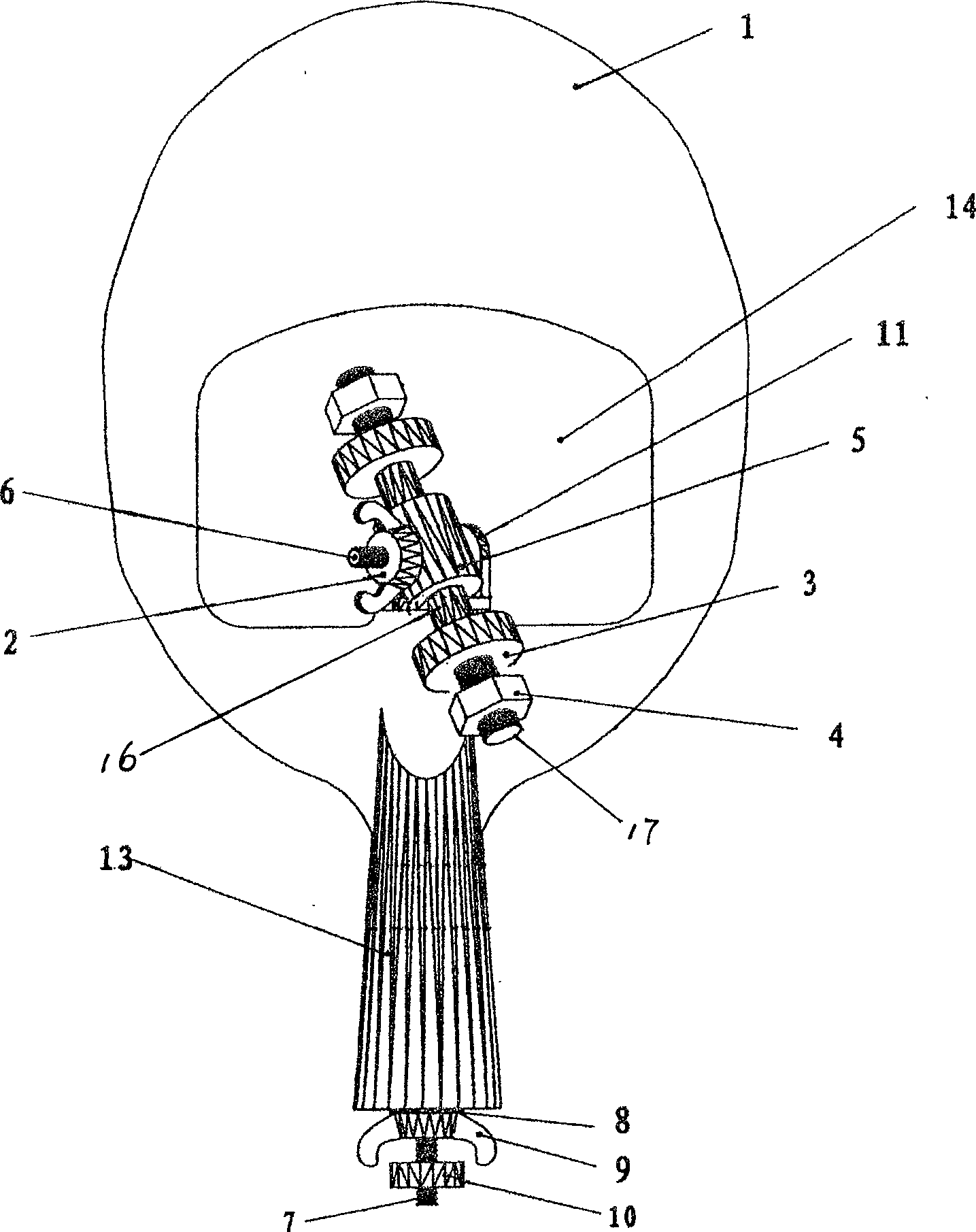

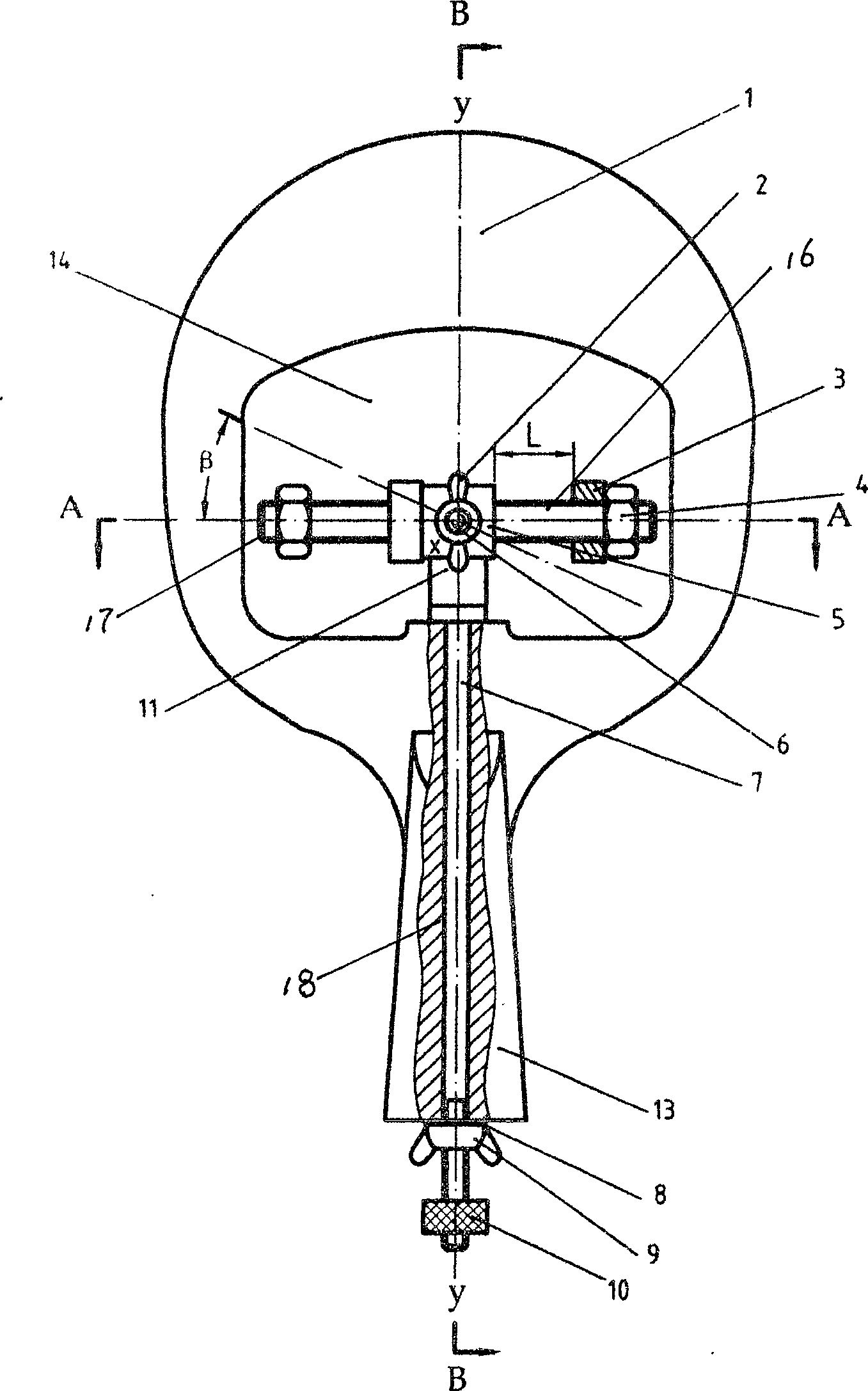

Special racket for table tennis auxiliary training

The invention relates to a special racket for booster training of Ping-Pong, which comprises a veneer and a racket handle. The veneer has a gap in the middle. A central bracket is fixed in the gap near the center line of the racket handle. A slider frictional damping and a knocking gear are fixed in the central bracket through a sliding framework bearing bolt and sliding framework jam nut. The special racket is convenient to adjust weight, barycentre, slipper frictional resistance and slipper travel. Users can act racket swing motion without ball and has the sense of approximate true batting and friction ball. Through repeated training with the invention, practicer can enhance strength, harmonize movement, and set skilled movement, which can help speed up the study, master, consolidation and development of multinomial operative technology.

Owner:钟罗杰

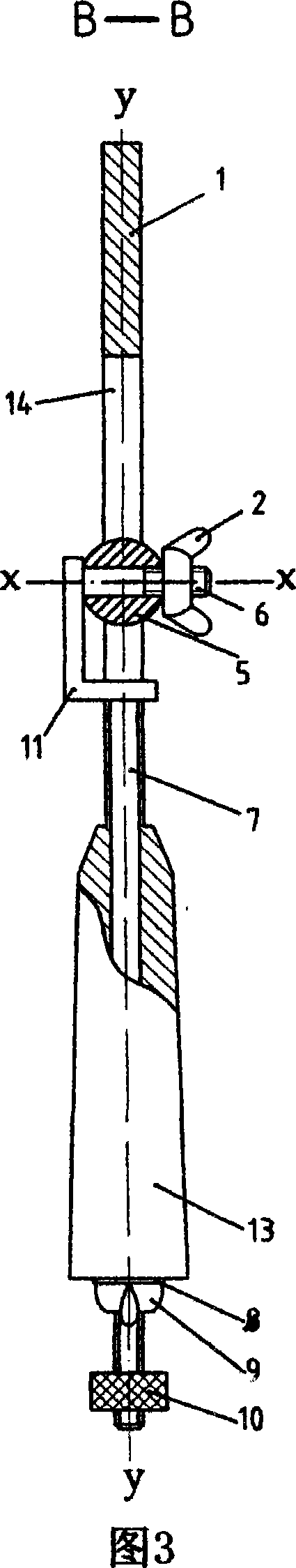

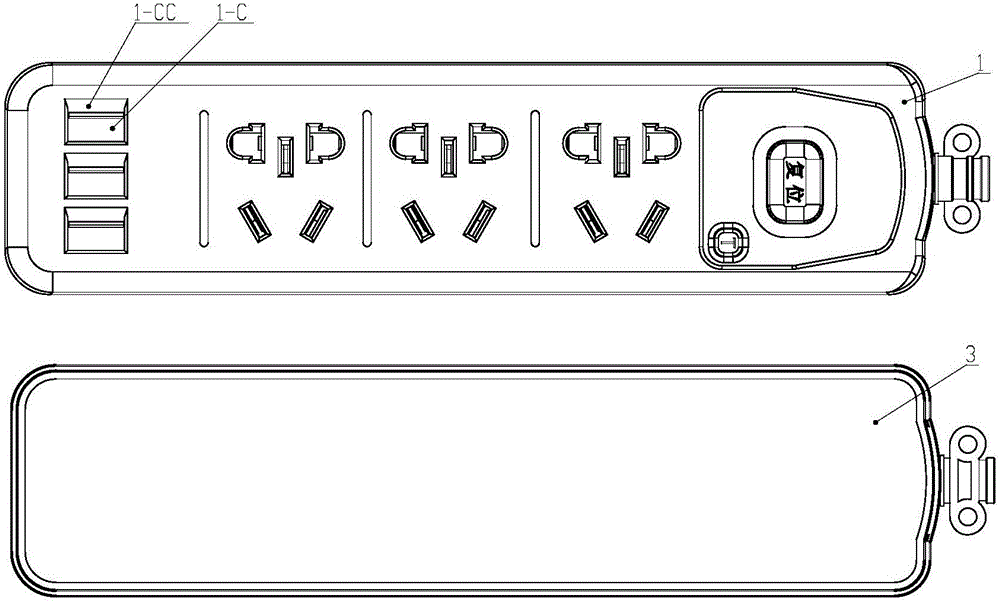

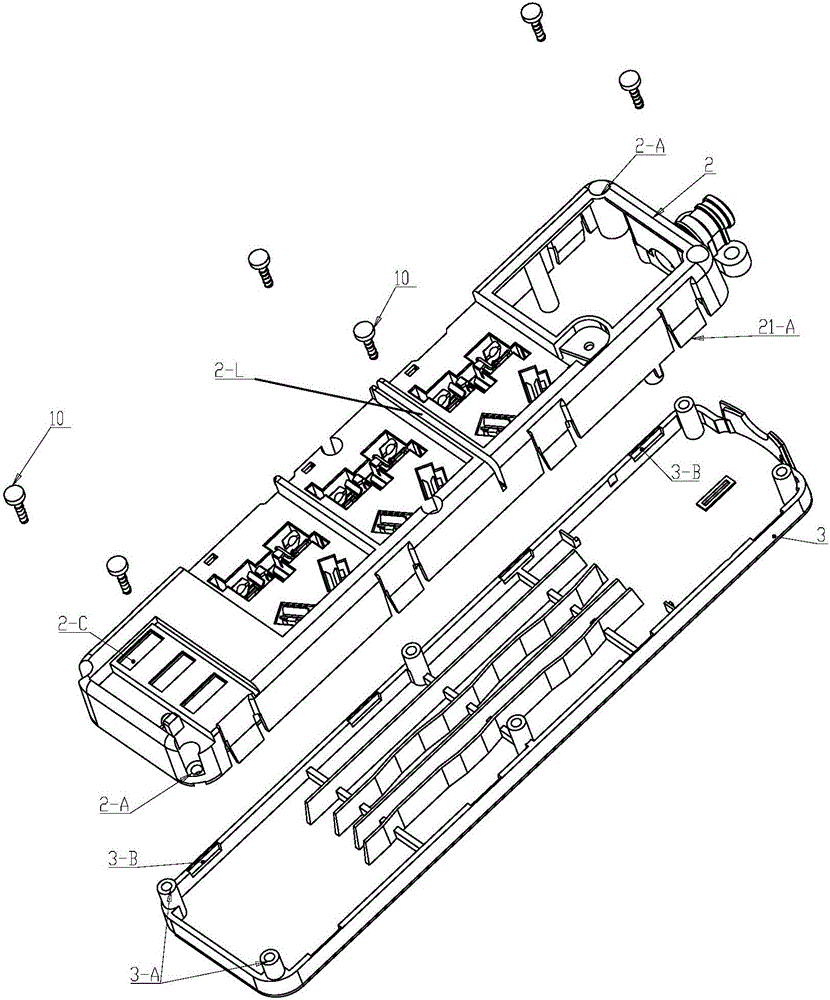

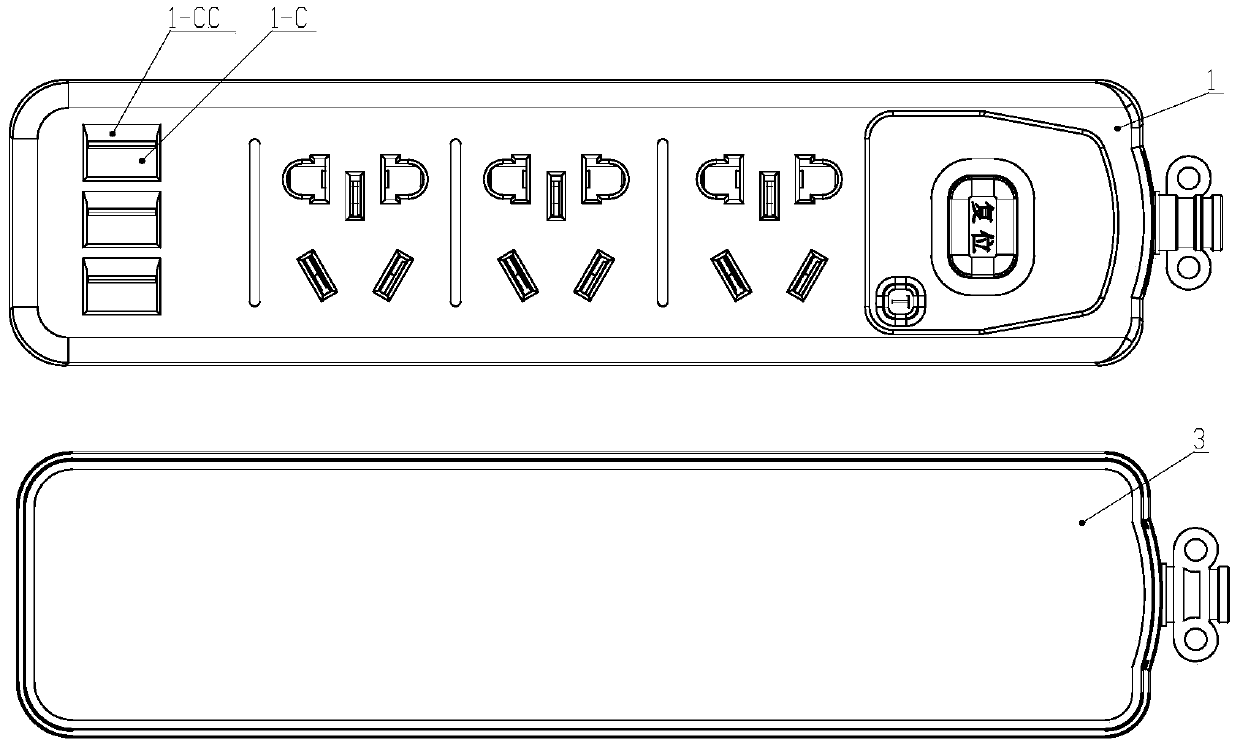

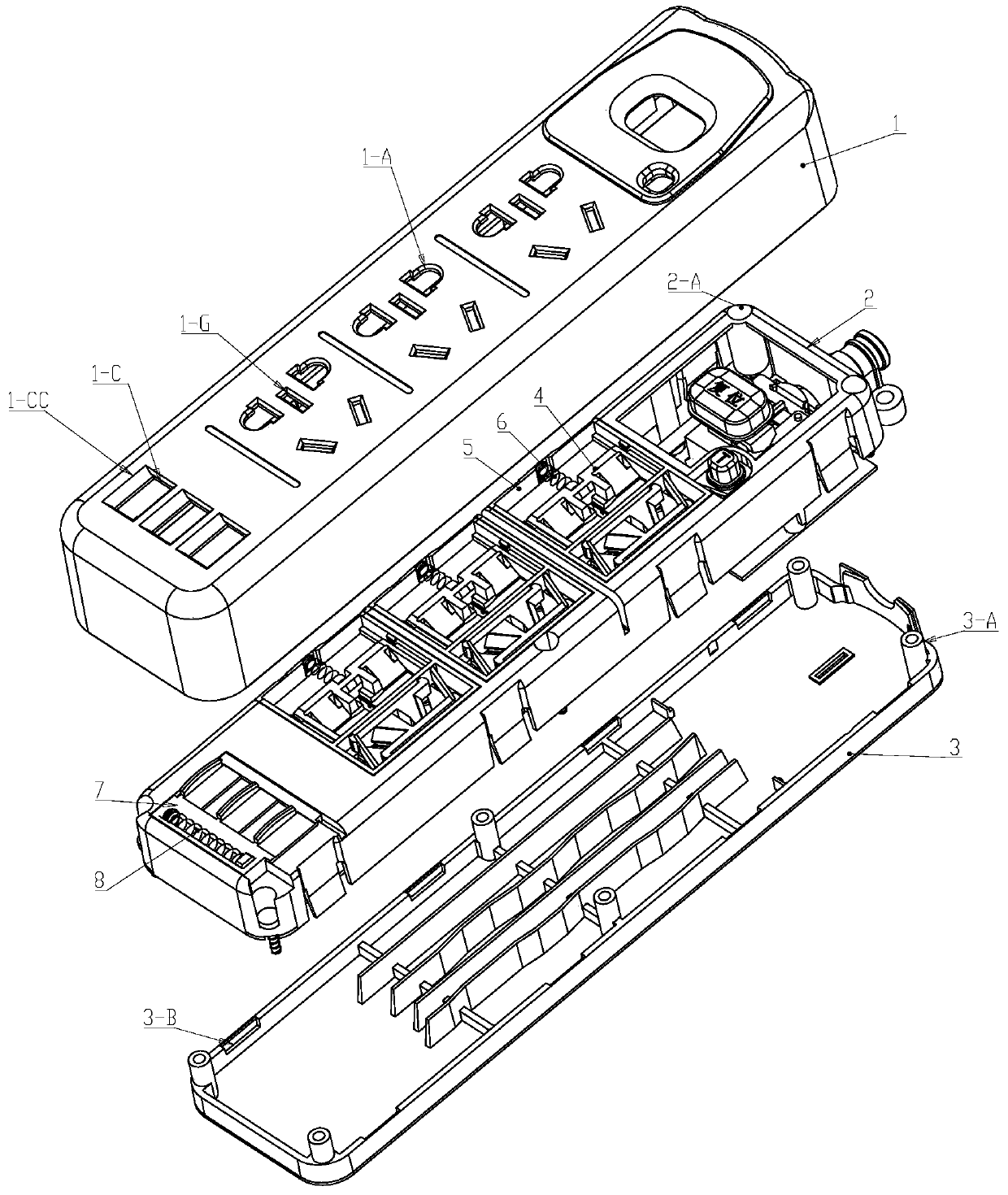

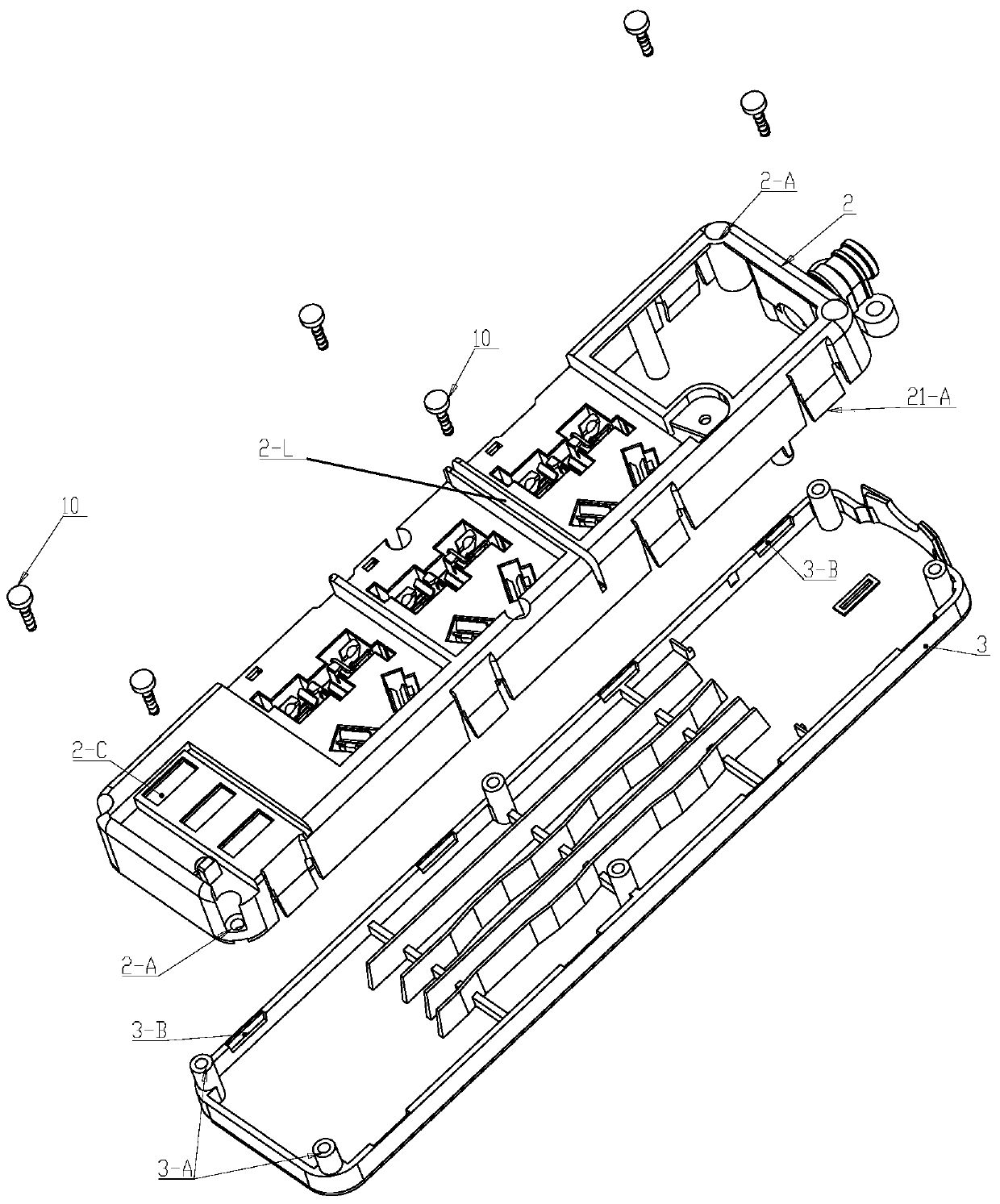

Wiring board

ActiveCN105006679AReduce resistance to movementAvoid stickingCoupling device detailsEngineeringDual purpose

The invention provides a wiring board comprising a top cover, a middle frame, and a bottom casing. The top cover is equipped with dual-purpose jacks and single jack baffle plates equipped with elastic repositioning mechanisms. Each single jack baffle plate is provided with a guiding slope on which a metallic slice is fixed. The top cover is equipped with USB sockets. One inner sidewall of each USB socket on the top cover is provided with a USB guiding slope. Each USB socket on the top cover is correspondingly provided with a USB baffle plate equipped with an elastic repositioning mechanism. Each USB baffle plate comprises a transverse sealing plate and a vertical pushing plate. The bottom casing is provided with a plurality of screw bolts. The middle frame is provided with a screw placing vertical groove. The screw placing vertical groove is provided with a screw nut stopping step. The inner sidewall of the top cover is connected with the outer sidewall of the middle frame through a buckling structure. The wiring board has beneficial effects that one baffle plate seals two jacks so as to simplify structure; each baffle plate is provided with the metallic slice so as to effectively prevent a plug from being jammed; each USB baffle plate is provided with the vertical pushing plate so as to achieve simple structure and stable and reliable operation; the middle frame is in screw connection with the bottom casing and the top cover is in buckled connection with the middle frame such that fast assembly and good firmness are achieved.

Owner:WENZHOU VAN SHEEN ELECTRIC APPLIANCE

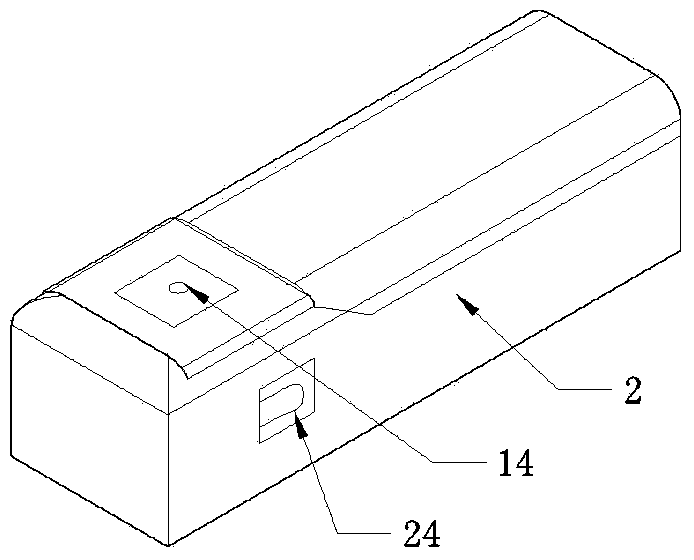

Electromechanical integrated intelligent cabinet lock

ActiveCN103714609AReasonable structureCompact structureBuilding locksIndividual entry/exit registersEngineeringDrive motor

The invention discloses an electromechanical integrated intelligent cabinet lock, which has various intelligent lock control functions, is simple, convenient, safe, reliable and stable to use, integrates multiple functions as a whole, and is simple and reasonable in structure. The electromechanical integrated intelligent cabinet lock comprises a lock body, a lock tongue, an intelligent lock control device and / or an auxiliary lock control device, wherein the lock tongue is arranged on the lock body, the intelligent lock control device is arranged on the lock tongue correspondingly and consists of a control main board, a detector and a corresponding actuator, the detector and the corresponding actuator are respectively connected with the control main board, the actuator comprises a driving motor, and a transmission conversion mechanism which is arranged between the lock tongue and the driving motor.

Owner:益升华恒珠精密零部件有限公司

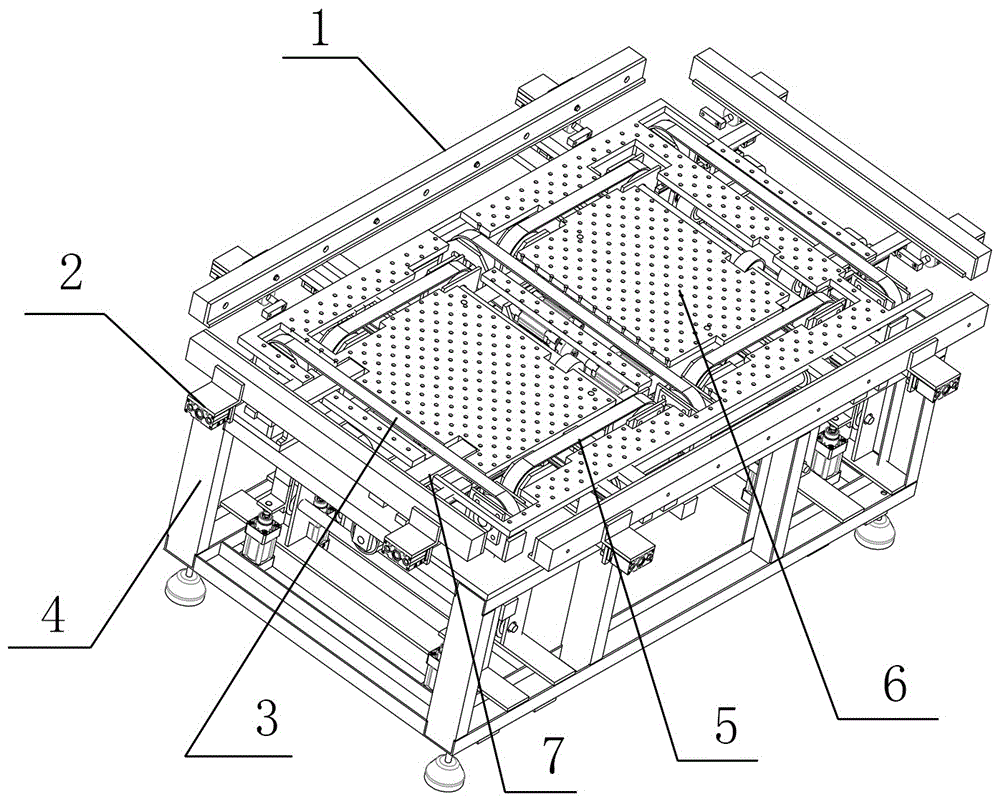

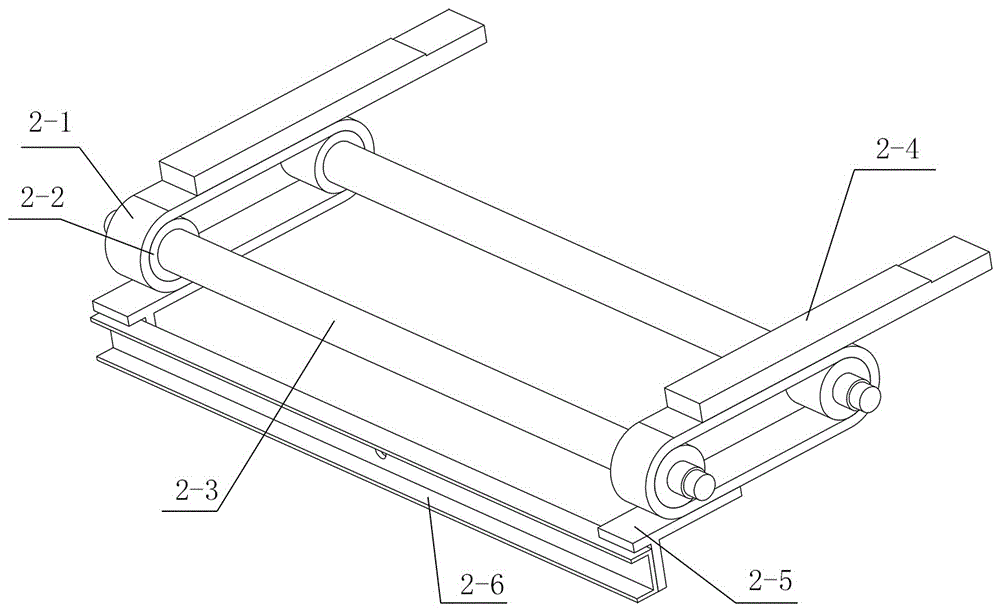

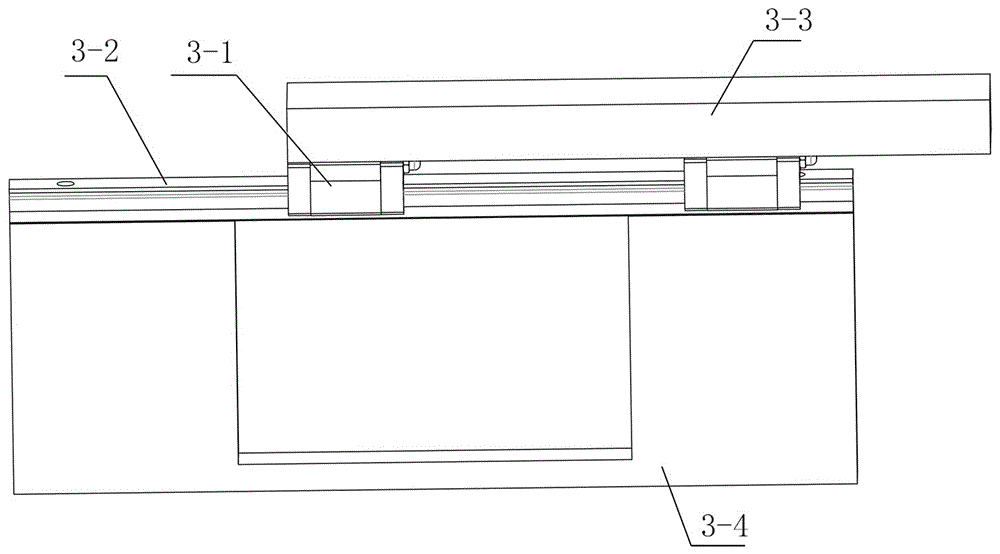

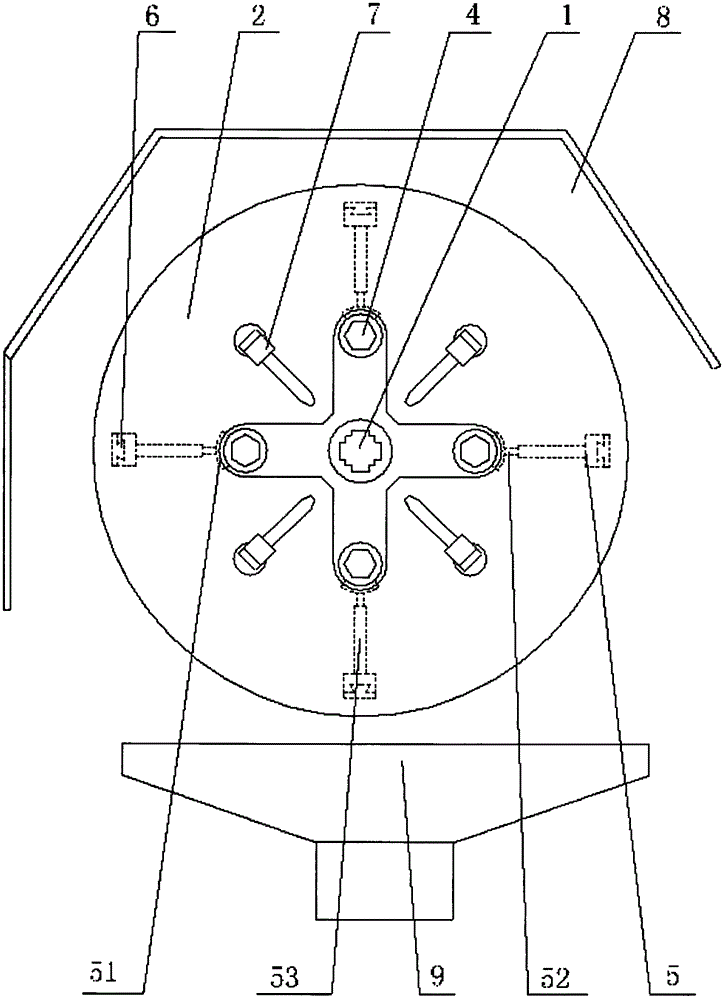

Thermal insulation photovoltaic module air floatation location group frame device

PendingCN106409743AEquipment structure safetyReasonable actionFinal product manufactureSemiconductor/solid-state device manufacturingThermal insulationFloating platform

The present invention relates to a thermal insulation photovoltaic module air floatation location group frame device, belonging to the photovoltaic device manufacturing technology field. The thermal insulation photovoltaic assembly test group frame device for an agriculture glasshouse comprises a long pressing strip, a location mechanism, a short pressing strip, a rack, a cylinder, a pressing strip connecting plate, a silencing chain combination, a sliding blocking guide rail combination, a horizontal transmission system, a longitudinal transmission system and an air-floating platform. The thermal insulation photovoltaic module air floatation location group frame device is safe in structure and reasonable in motion, can flatly perform air floatation and uniform distribution adsorption in the photovoltaic assembly group frame for the agriculture glasshouse and prevent the battery pieces in the assembly from buckling deformation caused by the group frame force so as to reduce the occurrence of the subfissure.

Owner:河南昊诚光电科技有限公司

Multi-tool CNC lathe

ActiveCN105436521BImprove cooling effectOptimize the tool change processAutomatic/semiautomatic turning machinesTurret lathesTool bitCutter location

The invention provides a multi-cutter-location numerical control lathe which comprises a workpiece clamping mechanism and a cutter clamping mechanism. The cuter clamping mechanism comprises a positioning shaft, the positioning shaft is sleeved with a cutter disc, the cutter disc is provided with two or more cutter movable grooves, cutters are transversely arranged in the cutter movable grooves in a penetrating mode in the axial direction, each cutter comprises two or more sets of turning tools in different cutter head shapes, and one or more sets of turning tools are provided with two or more cutter heads; the cutter movable grooves are internally provided with cutter pushing and lifting mechanisms, the cutter pushing and lifting mechanisms are provided with cutter locking / automatic unlocking mechanisms, the cutter movable grooves are internally provided with cutter reset mechanisms, and the cutter reset mechanisms are provided with slippage guide rail mechanisms and a pushing and lifting and slippage drive mechanism; the positioning shaft is provided with a cutter capturing mechanism. The multi-cutter-location numerical control lathe has the advantages that multiple sets of cutter heads conduct combined machining, all sets of cutters are hidden in the cutter disc, the multi-cutter-location numerical control lathe is safe to use, all action mechanisms for replacing cutters are reasonable in arrangement, and cutter replacing action is stable and smooth.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

power strip

ActiveCN105006679BReduce resistance to movementAvoid stickingCoupling device detailsPatch panelCPU socket

The invention provides a wiring board comprising a top cover, a middle frame, and a bottom casing. The top cover is equipped with dual-purpose jacks and single jack baffle plates equipped with elastic repositioning mechanisms. Each single jack baffle plate is provided with a guiding slope on which a metallic slice is fixed. The top cover is equipped with USB sockets. One inner sidewall of each USB socket on the top cover is provided with a USB guiding slope. Each USB socket on the top cover is correspondingly provided with a USB baffle plate equipped with an elastic repositioning mechanism. Each USB baffle plate comprises a transverse sealing plate and a vertical pushing plate. The bottom casing is provided with a plurality of screw bolts. The middle frame is provided with a screw placing vertical groove. The screw placing vertical groove is provided with a screw nut stopping step. The inner sidewall of the top cover is connected with the outer sidewall of the middle frame through a buckling structure. The wiring board has beneficial effects that one baffle plate seals two jacks so as to simplify structure; each baffle plate is provided with the metallic slice so as to effectively prevent a plug from being jammed; each USB baffle plate is provided with the vertical pushing plate so as to achieve simple structure and stable and reliable operation; the middle frame is in screw connection with the bottom casing and the top cover is in buckled connection with the middle frame such that fast assembly and good firmness are achieved.

Owner:WENZHOU VAN SHEEN ELECTRIC APPLIANCE

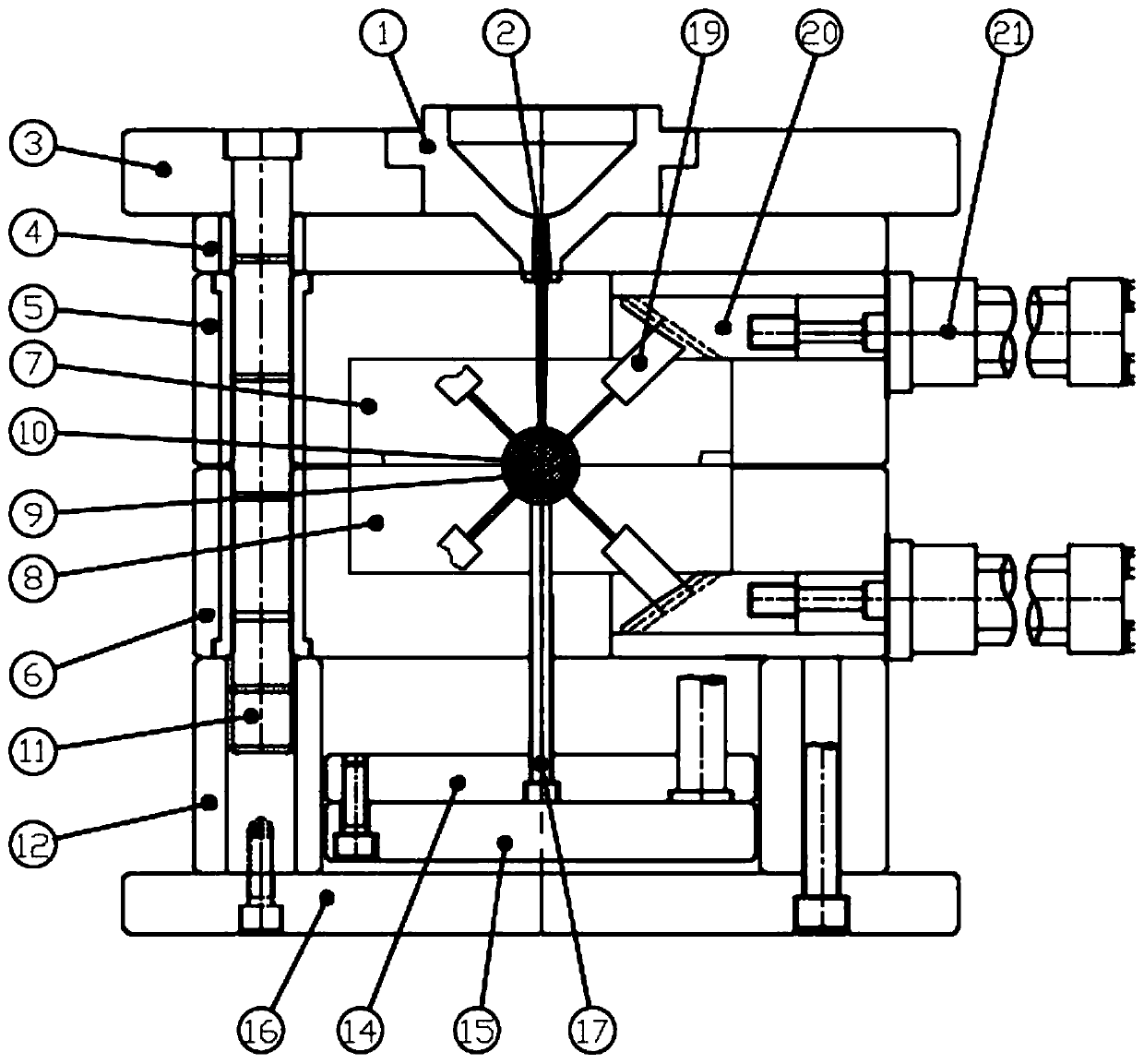

Mould for one-step molding steel ball in center position, and injection molding method

The invention relates to the technical field of built-in steel ball injection molding, in particular to a mould for one-step molding a steel ball in the center position, and an injection molding method. The mould comprises oil cylinders, a slide insert, a slide needle, a front mould panel, a back mould bottom plate, a stripper plate and an injection molding module, wherein the injection molding module comprises a plate A, a plate B, a front mould core and a back mould core; a first semicircular groove is formed in the lower surface of the front mould core; a second semicircular groove is formed in the upper surface of the back mould core; the oil cylinders are arranged on the plate A and the plate B and control, and control the slide needle to stretch out and draw back through the slide insert; the slide insert and the slide needle are embedded into the injection molding module; and the slide needle stretches into an injection molding cavity. According to the mould for one-step moldingthe steel ball in the center position provided by the invention, the slide needle is introduced for positioning the steel ball, so that the steel ball is ensured to be located in the center positionof the injection molding cavity, the injection molding outer surface is smooth, and the smoothness of the product is ensured; and by adopting the structure, the problems that according to an existinginjection molding machine mould, the steel ball cannot be placed in the center of the injection molding center, and the product surface is not smooth are solved successfully.

Owner:SHENZHEN JINCAIHONG PLASTIC

Special racket for table tennis auxiliary training

The invention relates to a special racket for booster training of Ping-Pong, which comprises a veneer and a racket handle. The veneer has a gap in the middle. A central bracket is fixed in the gap near the center line of the racket handle. A slider frictional damping and a knocking gear are fixed in the central bracket through a sliding framework bearing bolt and sliding framework jam nut. The special racket is convenient to adjust weight, barycentre, slipper frictional resistance and slipper travel. Users can act racket swing motion without ball and has the sense of approximate true batting and friction ball. Through repeated training with the invention, practicer can enhance strength, harmonize movement, and set skilled movement, which can help speed up the study, master, consolidation and development of multinomial operative technology.

Owner:钟罗杰

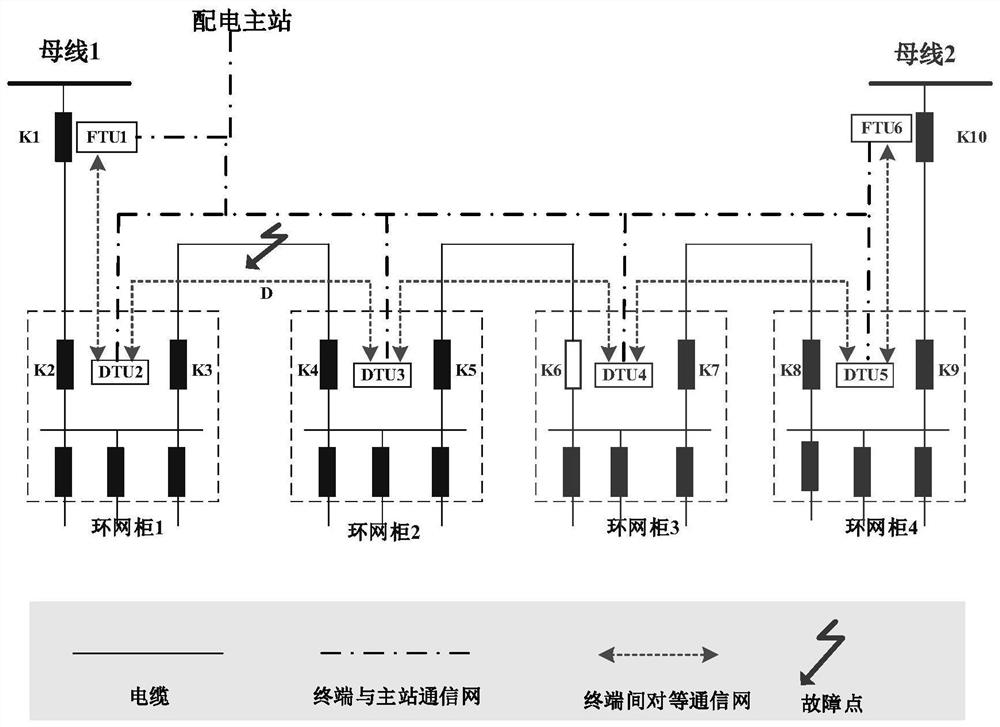

Distributed FA and master station FA cooperative control method for adaptive communication time delay

PendingCN111864901AReasonable designMove quicklyCircuit arrangementsData switching networksControl communicationsPrivate network

The invention discloses a distributed FA and master station FA cooperative control method for an adaptive communication time delay. The method comprises the following steps that an intelligent distributed FA and master station FA interaction model considering the communication time delay is established; the distributed FA considering the communication time delay and the master station FA are cooperatively controlled; and when the communication time delay is unstable, the distributed FA and master station FA cooperative control strategy is adaptively adjusted. The method is reasonable in design, the distributed FA can adapt to various communication modes such as an optical fiber, a wireless private network and a wireless public network, the cooperative control strategy of the distributed FAand the main station FA adapts to the communication time delay, the line fault processing is more reliable, the fault isolation range is more accurate, and the power supply reliability is improved.

Owner:JIANGSU ELECTRIC POWER CO +3

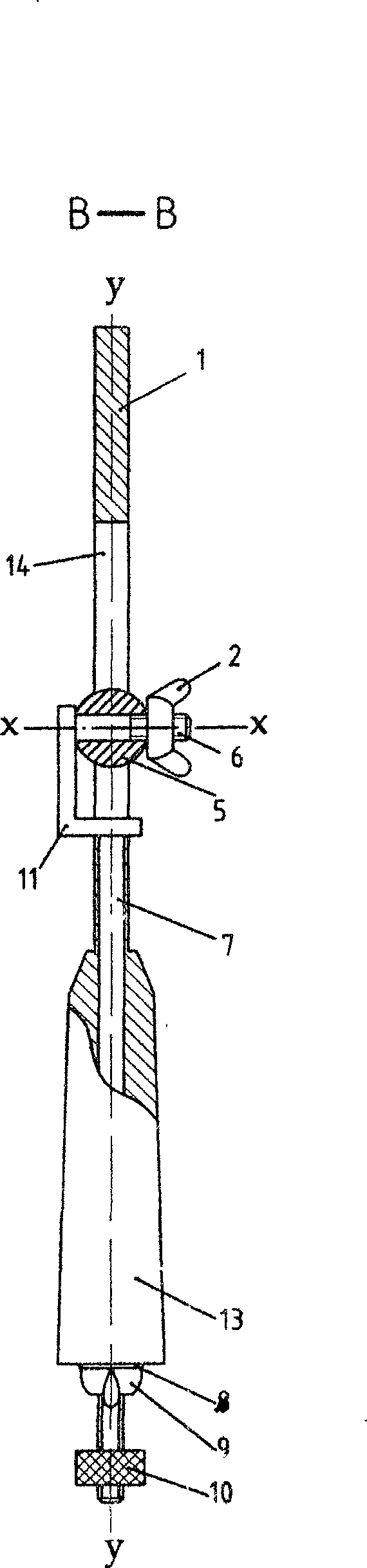

Threading device

The invention provides a threading device. The threading device comprises a supporting column extending in a vertical direction, a warp threading structure arranged on the supporting column and used for pressing warp, and a weft threading structure arranged on the supporting column and used for pressing weft. The threading device is suitable for the complicated three-dimensional distribution of the warp and weft in the three-dimensional textile. As the warp threading structure and the weft threading structure are set in the threading device, both the weft and the warp can be compressed, and the needs of three-dimensional textile can be met.

Owner:CHINESE TEXTILE ACAD

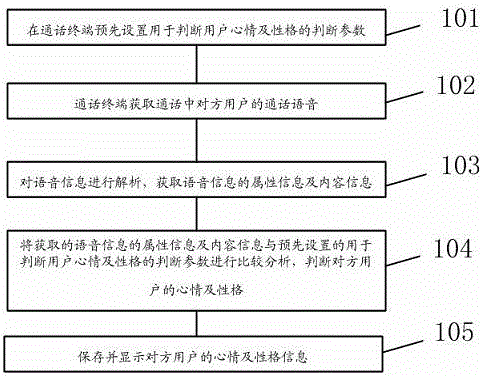

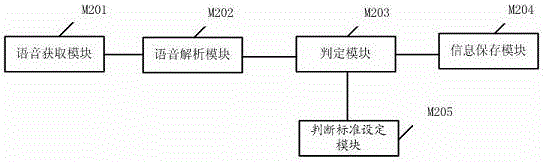

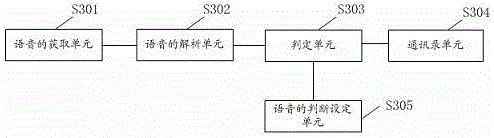

Method, system and mobile phone for judging user's mood and personality based on call voice

ActiveCN103634472BProfessional Statistical AnalysisEasy accessSpeech analysisSubstation equipmentAnalysis dataSpeech sound

Owner:威海高新园区运营管理有限公司

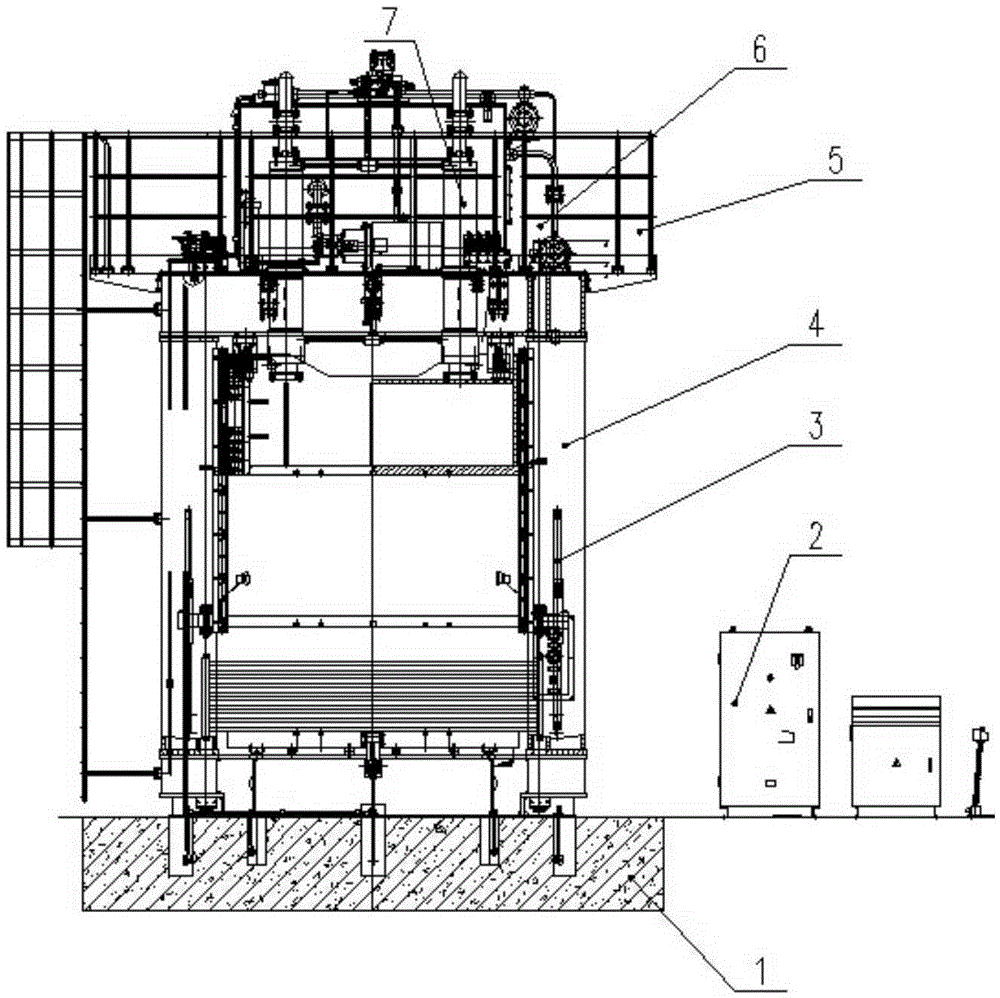

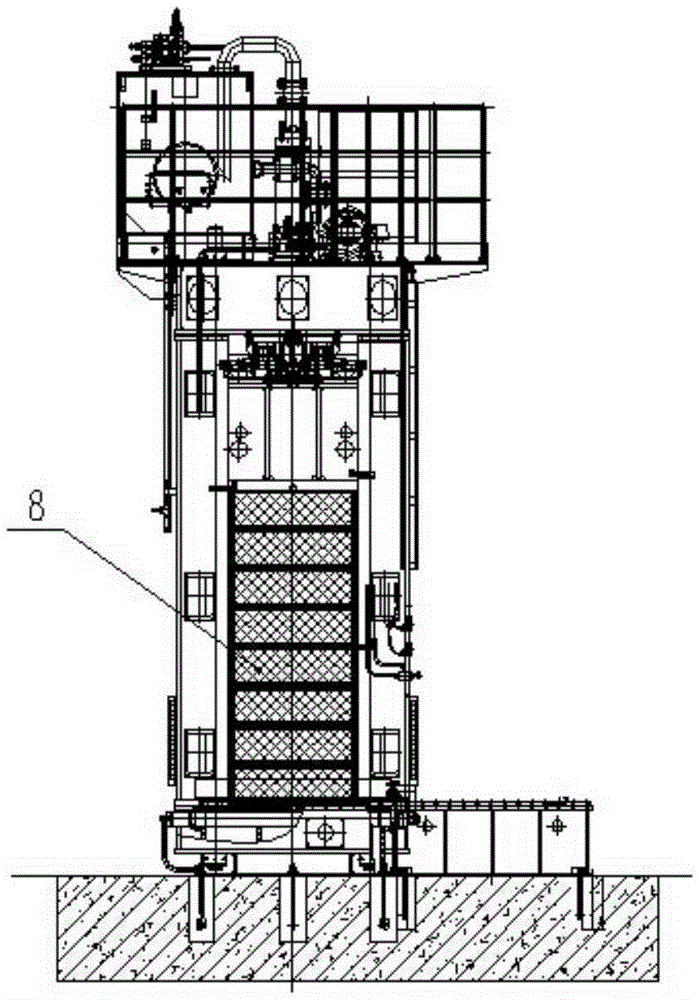

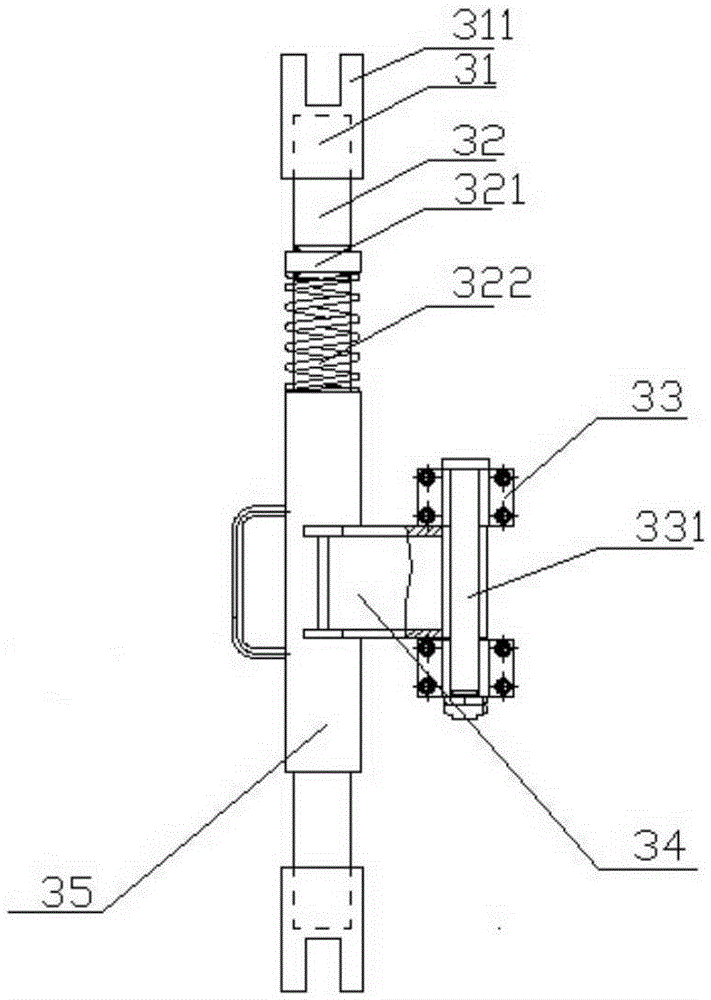

Method for using safe frame type hydraulic press

ActiveCN105252797AImprove reliabilityEnsure safetyEngineering safety devicesQuenching agentsEngineeringCanis lupus familiaris

Owner:TIANSHUI METALFORMING MACHINE TOOL GRP ANHUI PRESS

Horizontal filling packaging machine capable of effectively reducing occupied space

PendingCN112046853ASimple equipment structureReasonable actionWrapper twisting/gatheringSolid materialPackaging machineEngineering

A horizontal filling packaging machine capable of effectively reducing an occupied space comprises a machine table, a packaging bag storage frame, a bag taking mechanism, a packaging bag transferringdevice, a filling mechanism and a sealing mechanism. The horizontal filling packaging machine is characterized in that the packaging bag storage frame is located at the rear end of the right side of the machine table, and the bag taking mechanism is located at the right side of the machine table and in front of the packaging bag storage frame; the packaging bag transferring device is located in the middle of the machine table and moves left and right in the transverse direction of the machine table; the filling mechanism is located in the middle of the machine table and in front of the packaging bag transferring device; and the sealing mechanism is located at the left side of the machine table. Compared with the prior art, the horizontal filling packaging machine has the beneficial effectsthat by simplifying the mechanisms and improving and optimizing the position distribution of all the mechanisms, all the equipment structures can be simpler, and actions are more reasonable; and particularly the packaging bag transferring device is improved, so that the purpose of transferring packaging bags from two adjacent stations to a next adjacent station can be achieved at the same time, the working efficiency is greatly improved, and the occupied space is greatly reduced.

Owner:广东华达胜机械实业有限公司

CNC machine tool

ActiveCN105436963BSafe and secure settingsReasonable settingPositioning apparatusMaintainance and safety accessoriesNumerical controlMachine tool

The invention provides a numerical control machine tool. The numerical control machine tool comprises a workpiece clamping mechanism and a cutter clamping mechanism, wherein the cutter clamping mechanism comprises a positioning shaft, the positioning shaft is sleeved with a cutter disc, at least two cutter movement grooves are formed in the cutter disc, and cutters are arranged in the cutter movement grooves in a penetrating mode in the axial direction of the cutter disc; the positioning shaft is located at the center of the cutter disc, a cuter pushing mechanism used for pushing the cutters to the positioning shaft from the direction away from the positioning shaft is arranged in the cutter movement grooves, the cutter pushing mechanism is provided with a cutter locking / automatic unlocking mechanism, a cutter restoration mechanism used for pulling the cutters to be close to the outer edge of the cutter disc along the cutter movement grooves is arranged in the cutter movement grooves, and the cutter pushing mechanism is provided with a sliding guide rail mechanism and a pushing and sliding driving mechanism; a cutter capturing mechanism is arranged on the positioning shaft. The numerical control machine tool has the advantages that multiple groups of cutters are arranged in the cutter disc in a hidden mode, using is safe, actuating units used for cutter change are reasonably arranged, and cutter change is stable and smooth.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

A mechanical device for automatically cutting steel bars

The invention discloses mechanical equipment for automatically cutting steel bars. The mechanical equipment for automatically cutting steel bars comprises a feeding device, a cutting device and a clamp set. A feeding frame of the feeding device is provided with a feeding groove, a pushing mechanism and a feeding mechanism, and the pushing mechanism can reciprocate in a groove body of the feeding groove movably and can push the steel bars in the feeding groove to the cutting device. A cutting frame of the cutting device is provided with a cutting machine, an unloading mechanism and a storage groove, and the cutting device is correspondingly connected with the feeding device. The clamp set comprises a first clamp and a second clamp arranged on two sides of the cutting mechanism respectively.The first clamp is fixed to the feeding tail end of the feeding groove. The second clamp is arranged above the unloading mechanism in the mode of corresponding to the first clamp. The cutting frame is provided with a horizontal moving mechanism in driving connection with the second clamp so that the second clamp can reciprocate on the unloading mechanism. The mechanical equipment is high in automation degree, does not need manual intervention in the cutting process, and is efficient and reliable.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com