Method for using safe frame type hydraulic press

A frame-type, hydraulic press technology, applied in the field of hydraulic presses, can solve problems such as potential safety hazards and threats to the lives of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

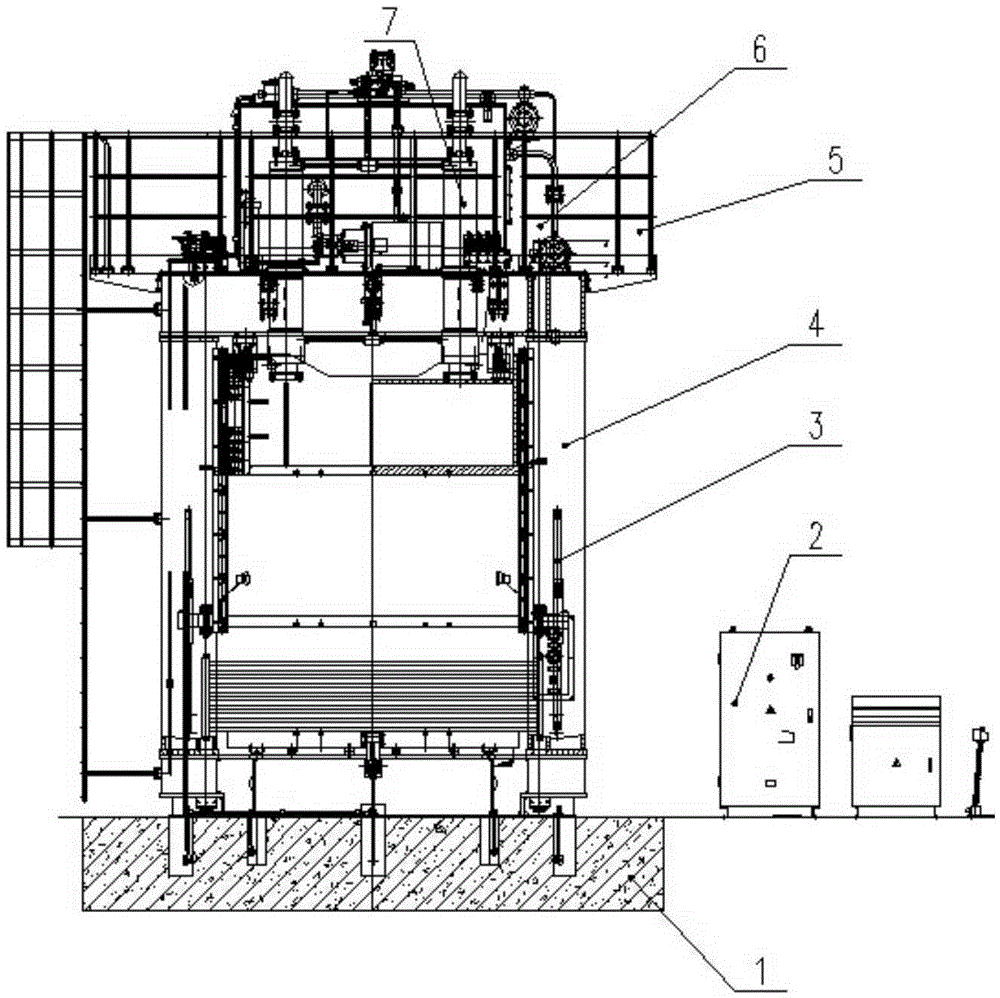

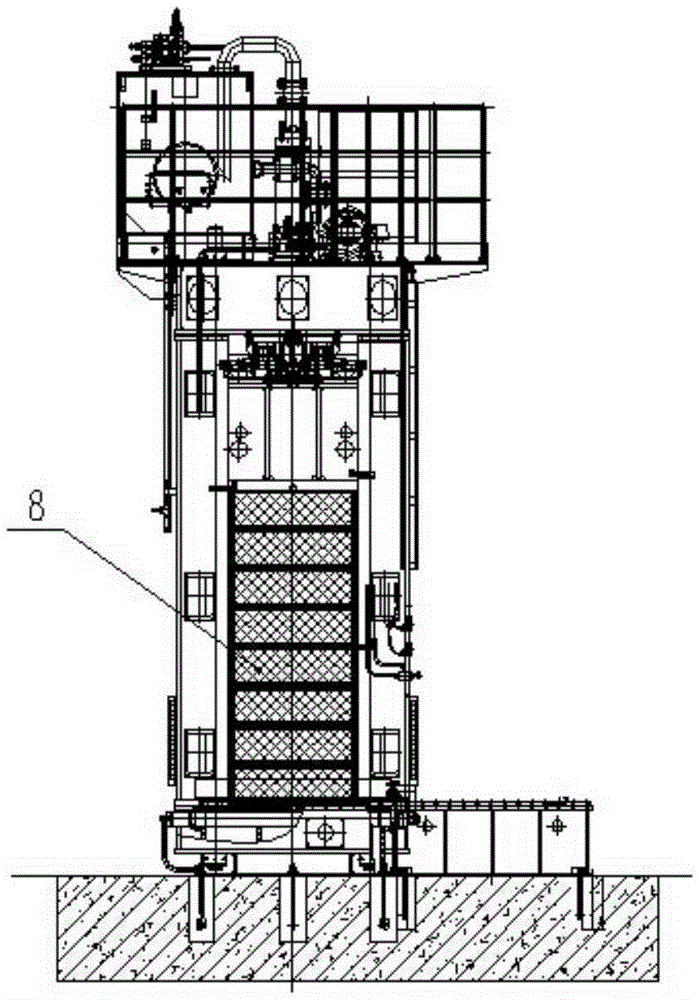

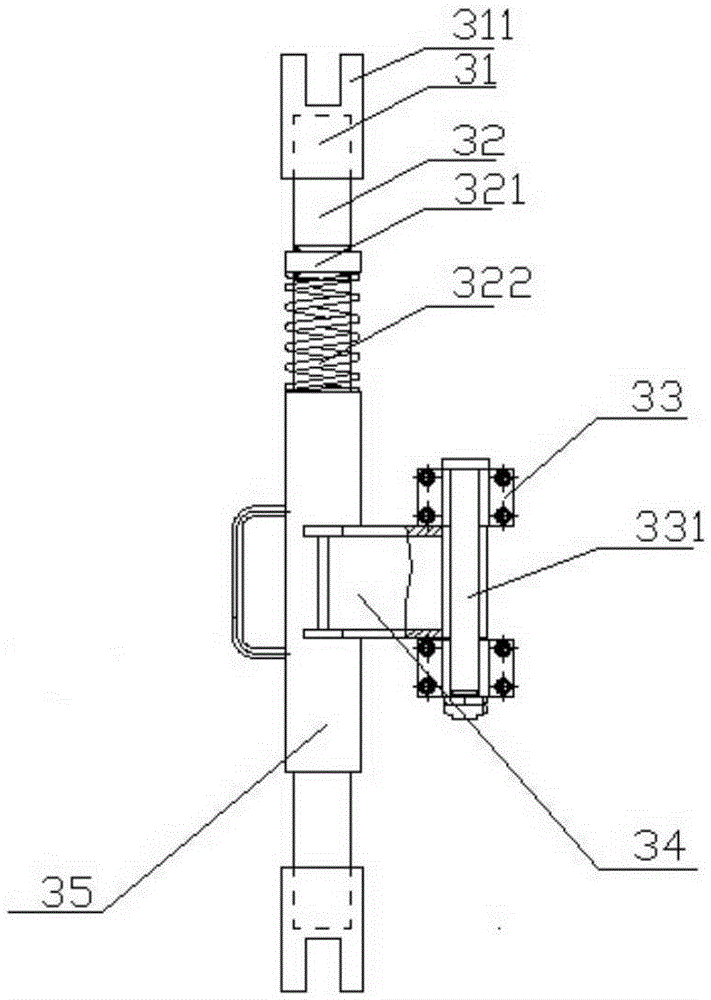

[0056] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a safe frame hydraulic machine includes a foundation 1, an electrical system 2, a safety block 3, a fuselage 4, an inspection platform 5, a hydraulic system 6 and a protective net 8; the foundation 1 is installed on the ground, and the foundation 1 The surface is parallel to the ground, the depth of the foundation 1 is 800mm, and there are anchor bolt holes on the foundation 1; the depth of the anchor bolt holes is 600mm of the depth of the foundation 1; the fuselage 4 is installed on the foundation 1, and the fuselage 4 is a frame type structure, the side wall of the fuselage 4 is provided with a safety block 3, and the top is provided with an inspection platform 5; the inspection platform 5 is provided with a hydraulic system 6; an oil cylinder 7 is provided between the hydraulic system 6 and the fuselage 4;

[0057] The electrical system 2 includes a safety light curtain and a travel limit device; the...

Embodiment 2

[0082] A method for preparing the top cap 31 of a safe frame-type hydraulic press in this embodiment, the steps are:

[0083] 1) Raw material preparation: the components and weight percentages of the materials used in the top cap 31 are: C: 0.31%, Cr: 2.30%, Si: 0.65%, Mn: 2.3%, S≤0.045%, P≤0.045%, and the rest is Fe;

[0084] 2) Heat treatment: the forging blank in step 1) is annealed, that is, heated to 790 ° C, kept for 2 hours, and air-cooled;

[0085] 3) Machining: process the forging blank after preheating in step 2) into the overall shape of the top cap 31 with a lathe, and process threads;

[0086] 4) Secondary heat treatment: heating the top cap 31 processed in step 3) to a temperature of 810° C., keeping it warm for 2 hours, and quenching with the quenching liquid; the composition and weight percentage of the quenching liquid are: ammonium molybdate: 3%, hard Sodium fatty lactylate: 2.7%, maleimide: 1.5%, sodium benzoate: 1.5%, the balance is water;

[0087] 5) Te...

Embodiment 3

[0090] A method for preparing the top cap 31 of a safe frame-type hydraulic press in this embodiment, the steps are:

[0091] 1) Raw material preparation: the components and weight percentages of the materials used in the top cap 31 are: C: 0.31%, Cr: 2.30%; Si: 0.65%, Mn: 2.3%, S≤0.045%, P≤0.045%, and the rest is Fe;

[0092] 2) Heat treatment: the forging blank in step 1) is annealed, that is, heated to 730° C., kept for 1.5 hours, and air-cooled;

[0093] 3) Machining: process the forging blank after preheating in step 2) into the overall shape of the top cap 31 with a lathe, and process threads;

[0094] 4) Secondary heat treatment: heating the top cap 31 processed by step 3) to a temperature of 755° C., keeping it warm for 1.5 hours, and quenching with a quenching liquid; the composition and weight percentage of the quenching liquid are: ammonium molybdate: 5%, hard Sodium fatty lactylate: 2.1%, maleimide: 2.1%, sodium benzoate: 0.8%, the balance is water;

[0095] 5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com