Patents

Literature

52results about How to "Safe and secure settings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

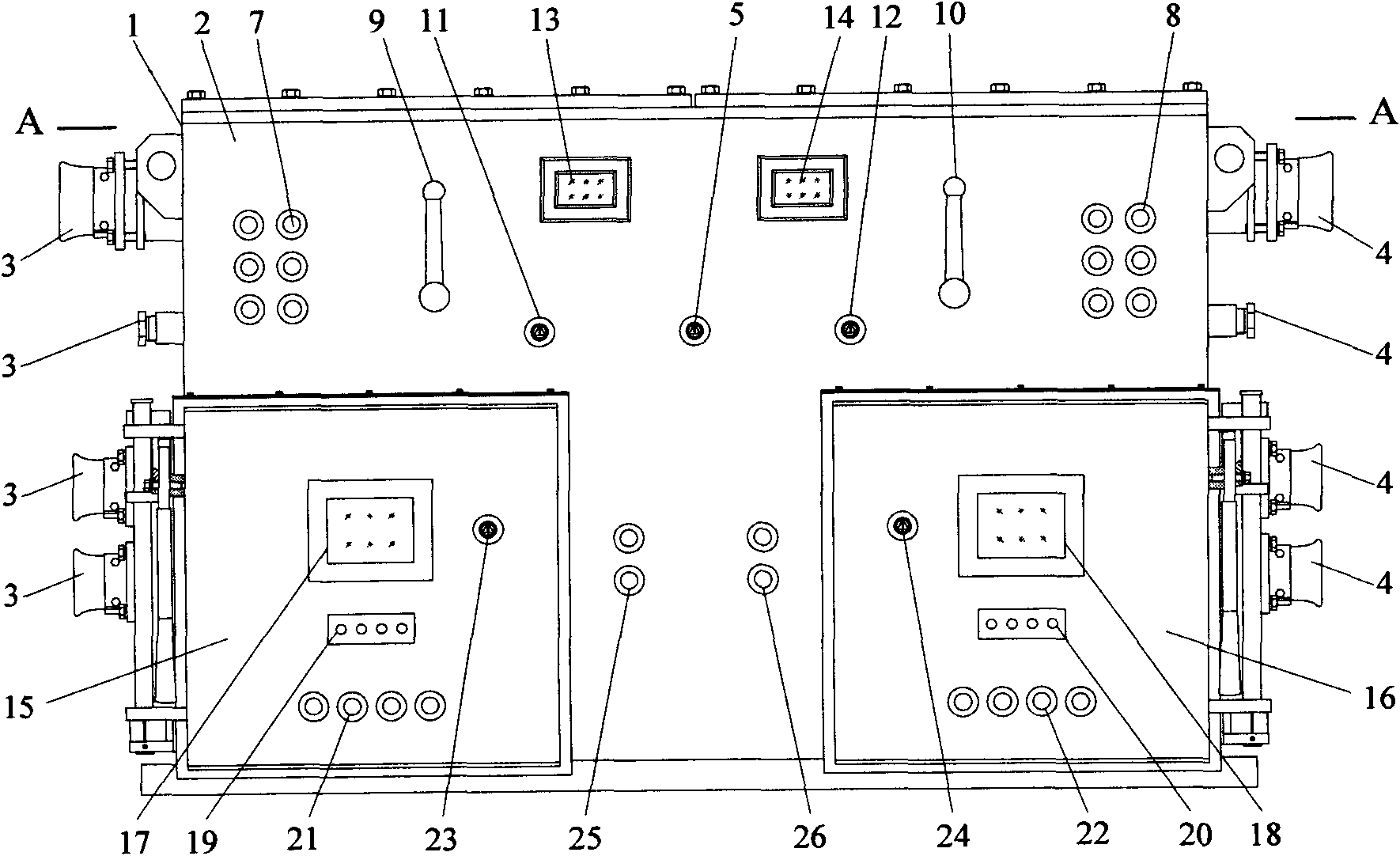

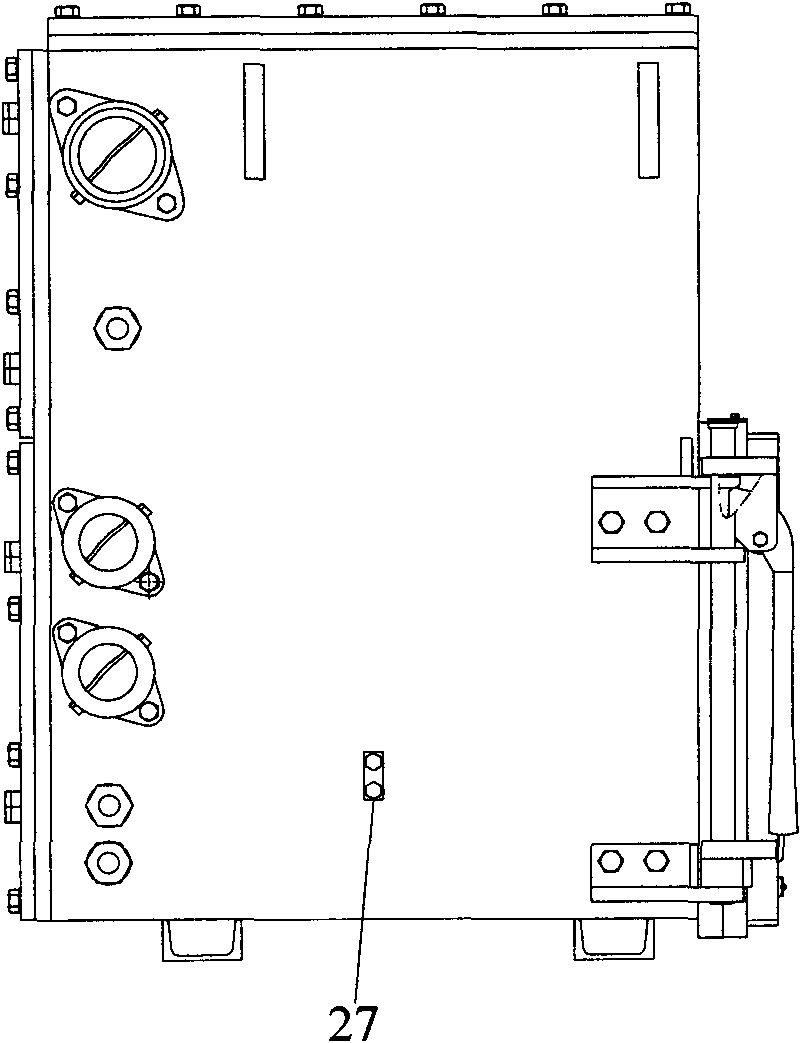

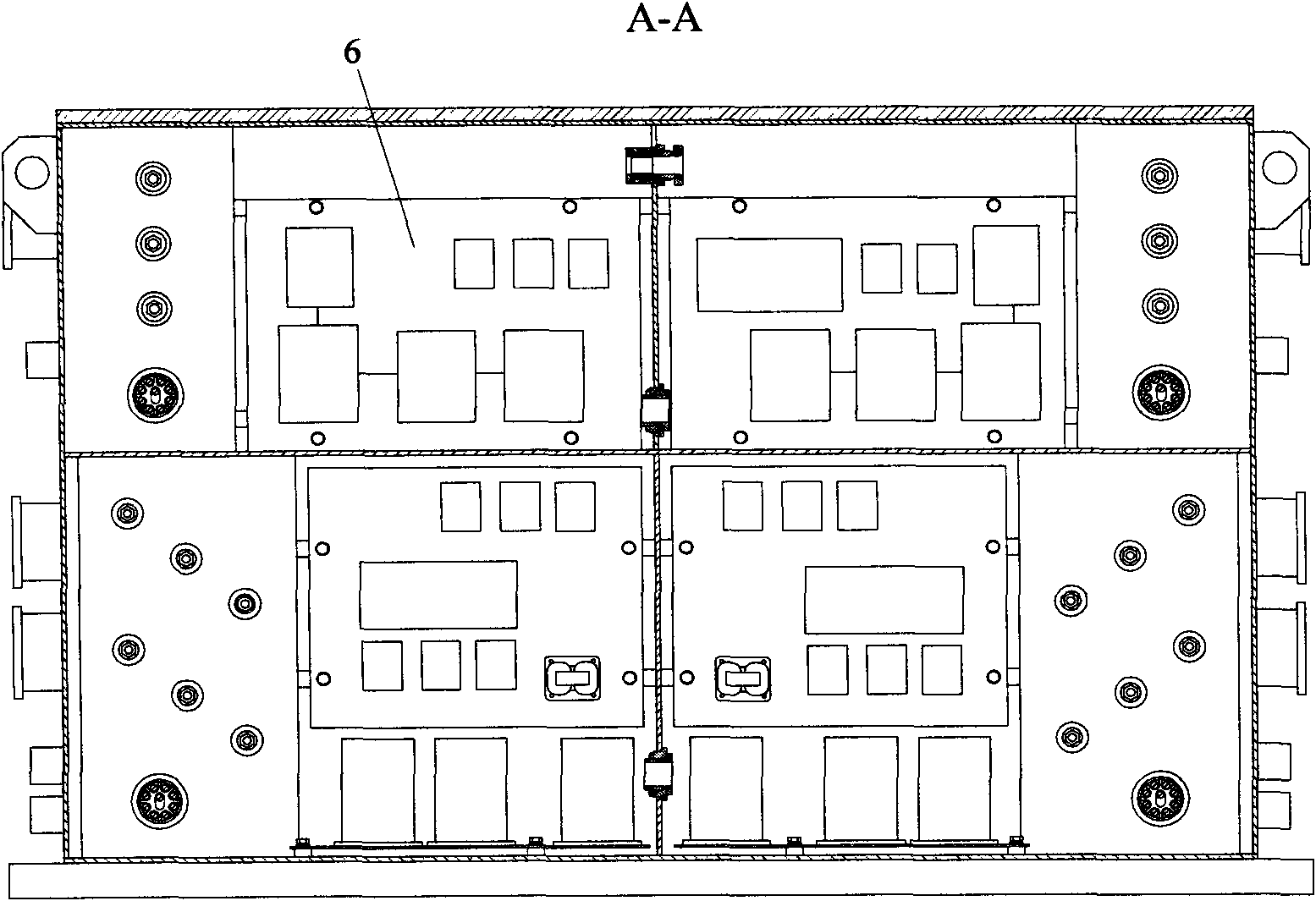

Dual-power dual-fan integrated switch with preferred main power

InactiveCN102102535AIdeal Automatic Control Switching DeviceAdvancedMining devicesElectric switchesMicrocomputerAutomatic control

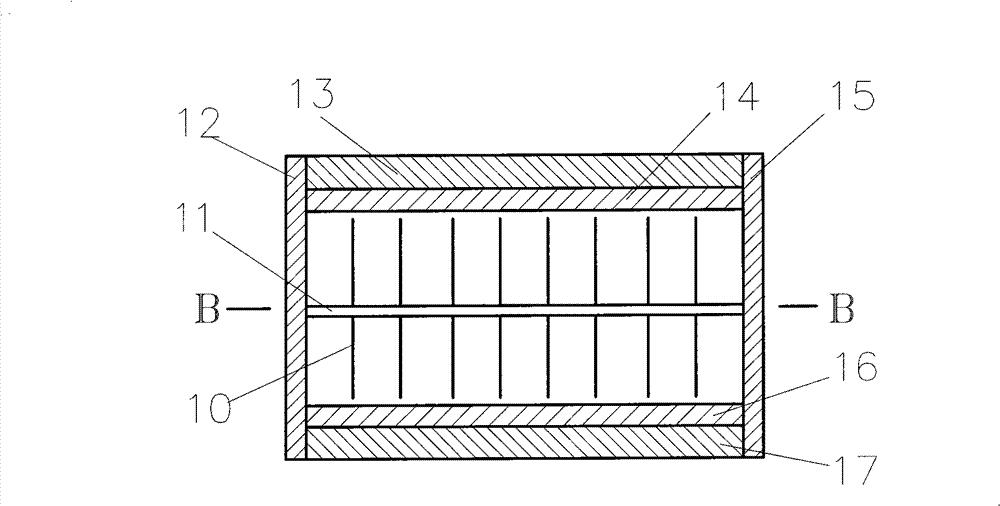

The invention relates to a dual-power dual-fan integrated switch with a preferred main power. The dual-power dual-fan integrated switch mainly comprises a switch box, a front panel, an indicator light, a power layer button, a disconnecting switch, a power switch, a selective switch, a control box, a display screen, a setting button, a fan switch, a function selection button, a main switch, a junction box, a circuit board, and a wire; the dual-power dual-fan integrated switch is provided with two fans, two control box panels and two control circuits; the control circuits are controlled by a main circuit, a stand-by circuit and a microcomputer program, automatic conversion can be performed between the fans, the main power supply is automatically prioritized, and quick conversion and instantaneous automation are realized. The dual-power dual-fan integrated switch has an advanced design, is reasonable in setting, safe, stable and reliable and is a very ideal automatic control switching device for a coal mine underground fan.

Owner:山西潞安石圪节煤业有限责任公司 +1

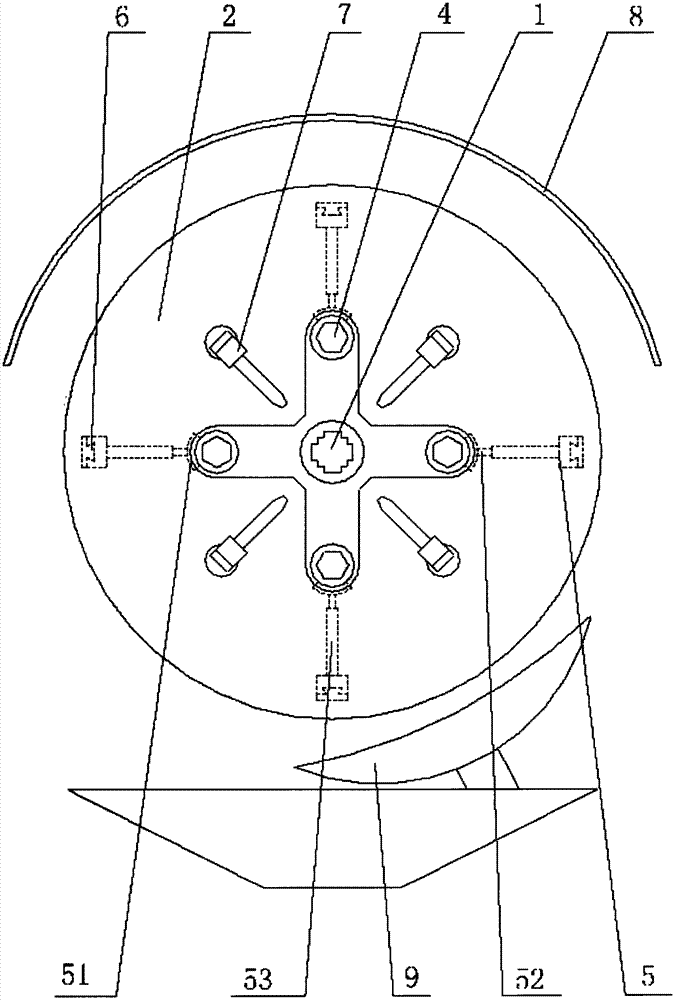

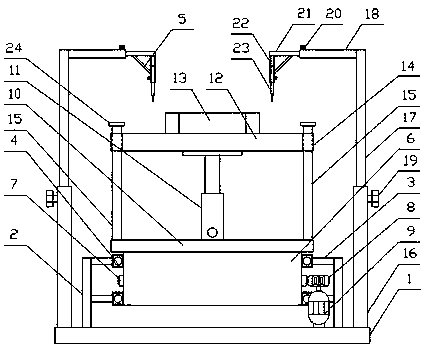

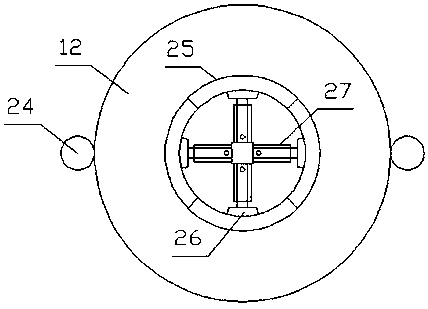

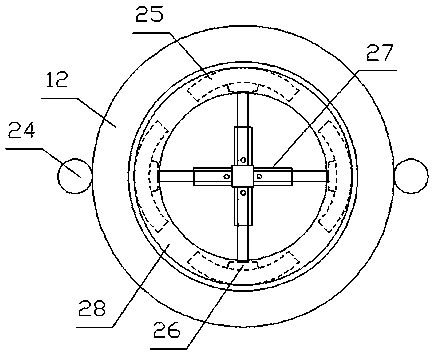

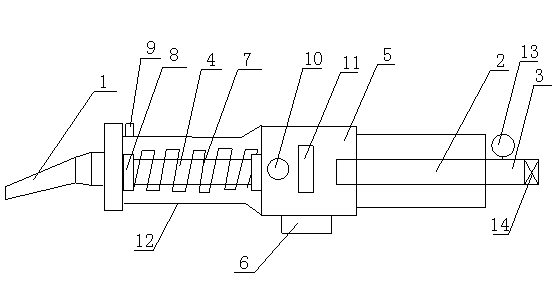

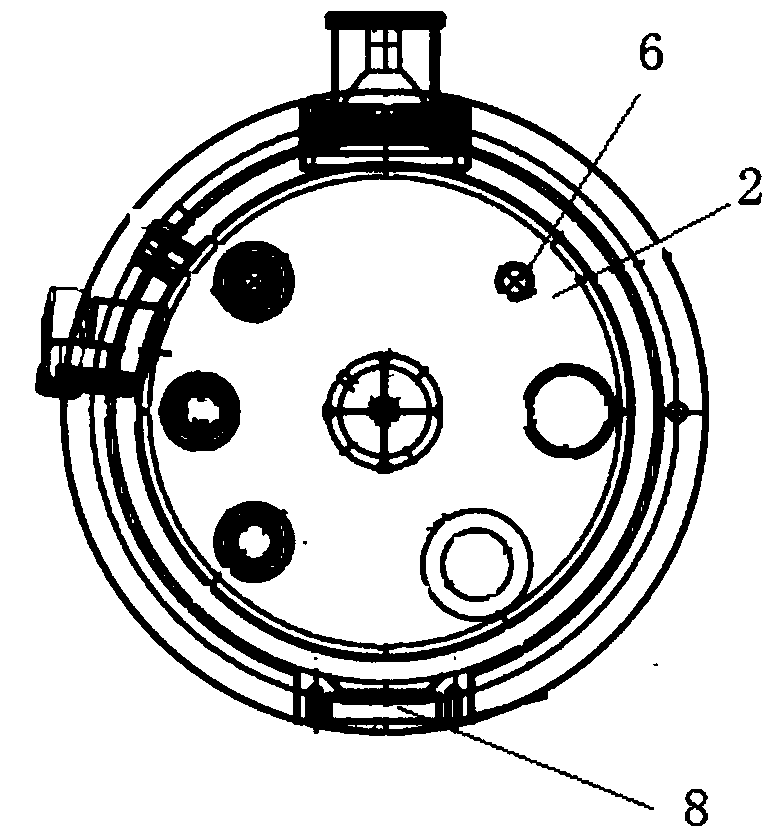

Numerical control machine tool

ActiveCN105436963ASafe and secure settingsReasonable settingPositioning apparatusMaintainance and safety accessoriesNumerical controlEngineering

The invention provides a numerical control machine tool. The numerical control machine tool comprises a workpiece clamping mechanism and a cutter clamping mechanism, wherein the cutter clamping mechanism comprises a positioning shaft, the positioning shaft is sleeved with a cutter disc, at least two cutter movement grooves are formed in the cutter disc, and cutters are arranged in the cutter movement grooves in a penetrating mode in the axial direction of the cutter disc; the positioning shaft is located at the center of the cutter disc, a cuter pushing mechanism used for pushing the cutters to the positioning shaft from the direction away from the positioning shaft is arranged in the cutter movement grooves, the cutter pushing mechanism is provided with a cutter locking / automatic unlocking mechanism, a cutter restoration mechanism used for pulling the cutters to be close to the outer edge of the cutter disc along the cutter movement grooves is arranged in the cutter movement grooves, and the cutter pushing mechanism is provided with a sliding guide rail mechanism and a pushing and sliding driving mechanism; a cutter capturing mechanism is arranged on the positioning shaft. The numerical control machine tool has the advantages that multiple groups of cutters are arranged in the cutter disc in a hidden mode, using is safe, actuating units used for cutter change are reasonably arranged, and cutter change is stable and smooth.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

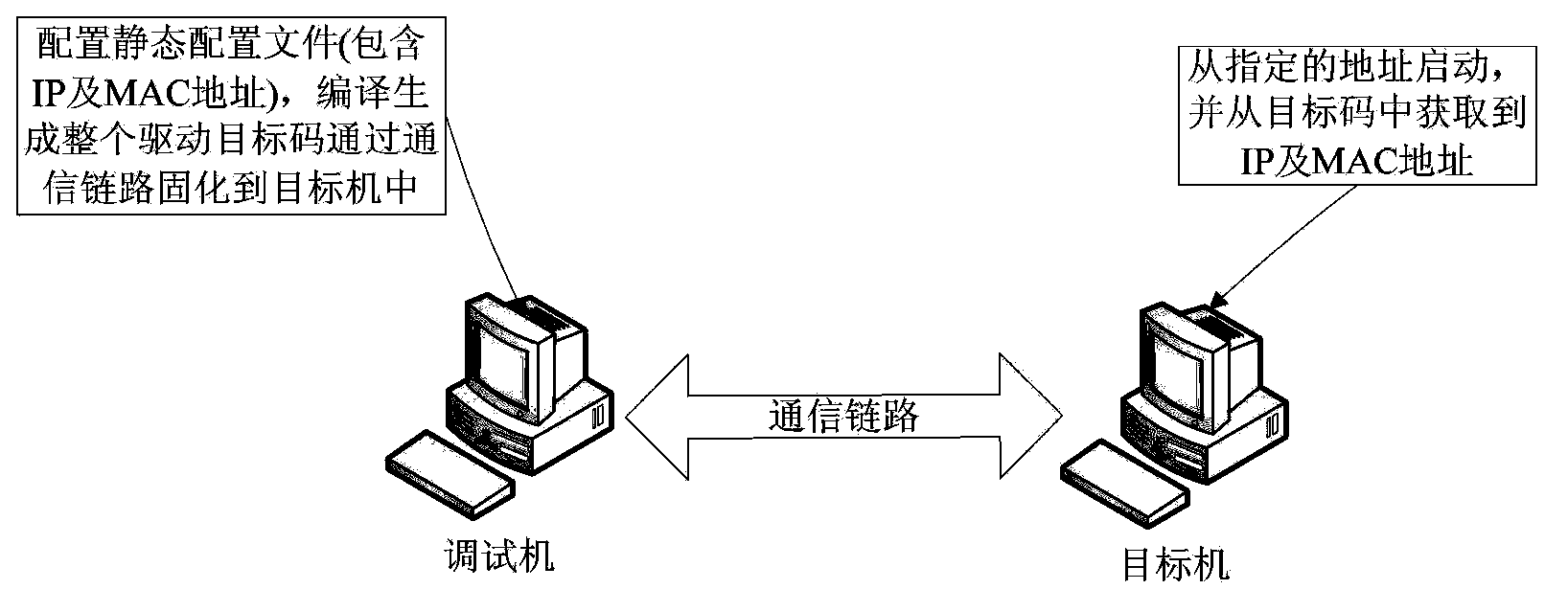

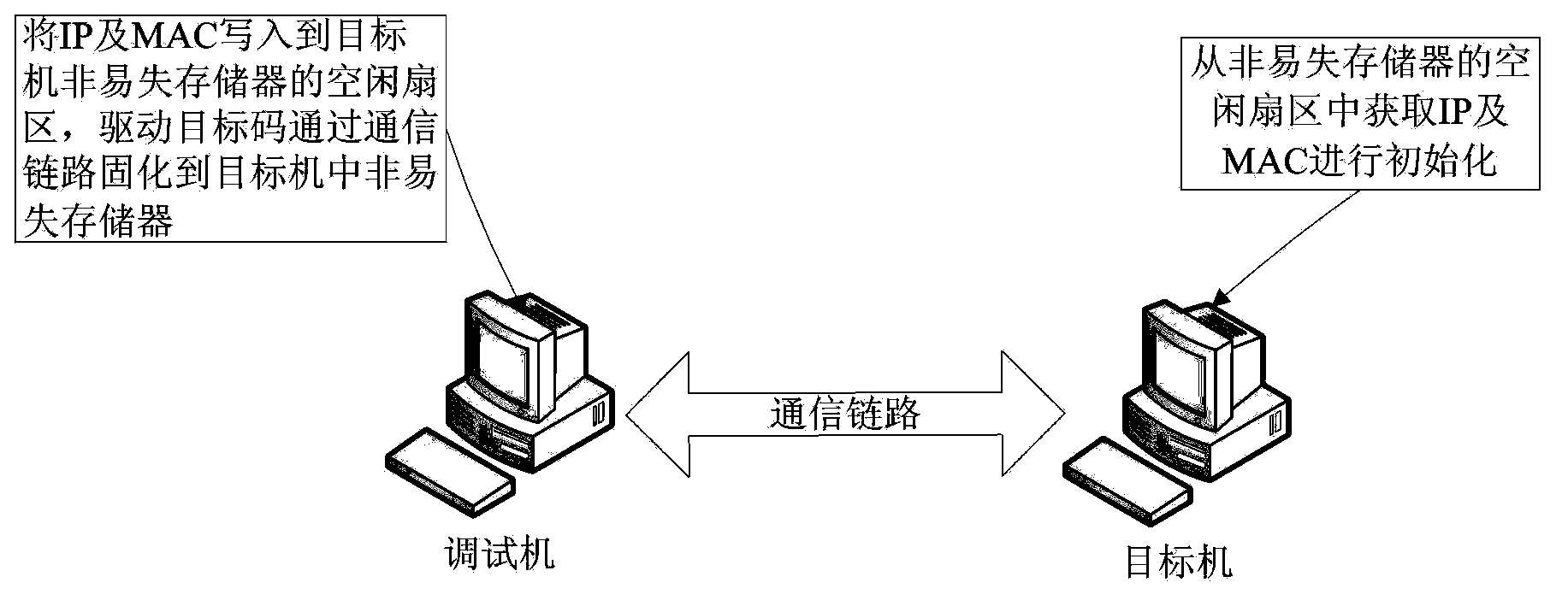

Method for setting IP (Internet Protocol) and MAC (Media Access Control) addresses based on embedded system platform

InactiveCN103914309AAvoid damageExtended service lifeProgram loading/initiatingIp addressMedia access control

The invention discloses a method for setting IP (Internet Protocol) and MAC (Media Access Control) addresses based on an embedded system platform. The method comprises the steps of: a) selecting an idle sector from a nonvolatile memory of a target machine; s) writing an IP address and an MAC address from the selected idle sector; 3) modifying an interface function for acquiring the address in the driving layer of the target machine, and the function of the modified interface function is that the CPU (Central Processing Unit) of the target machine reads the IP address and the MAC address from the idle sector; 4) generating a target code by compiling and connecting modified codes and curing the target code in the nonvolatile memory; and 5) electrifying the target machine, initializing a network card and finishing the address set. According to the method, the technical problem that an existing method for setting the IP and MAC addresses can waste time and influence the life of large areas of the nonvolatile memory, the IP and MAC addresses of the network card of the target machine can be quickly modified, a mass of debug time can be saved, and the life of the nonvolatile memory of the target machine can be prolonged.

Owner:AVIC NO 631 RES INST

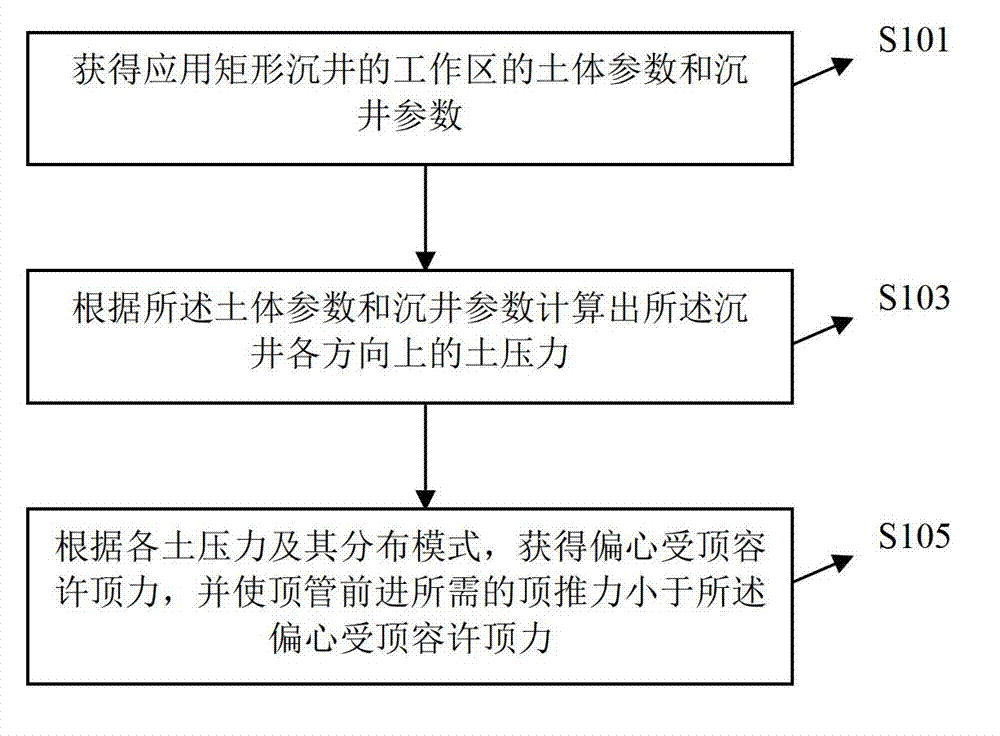

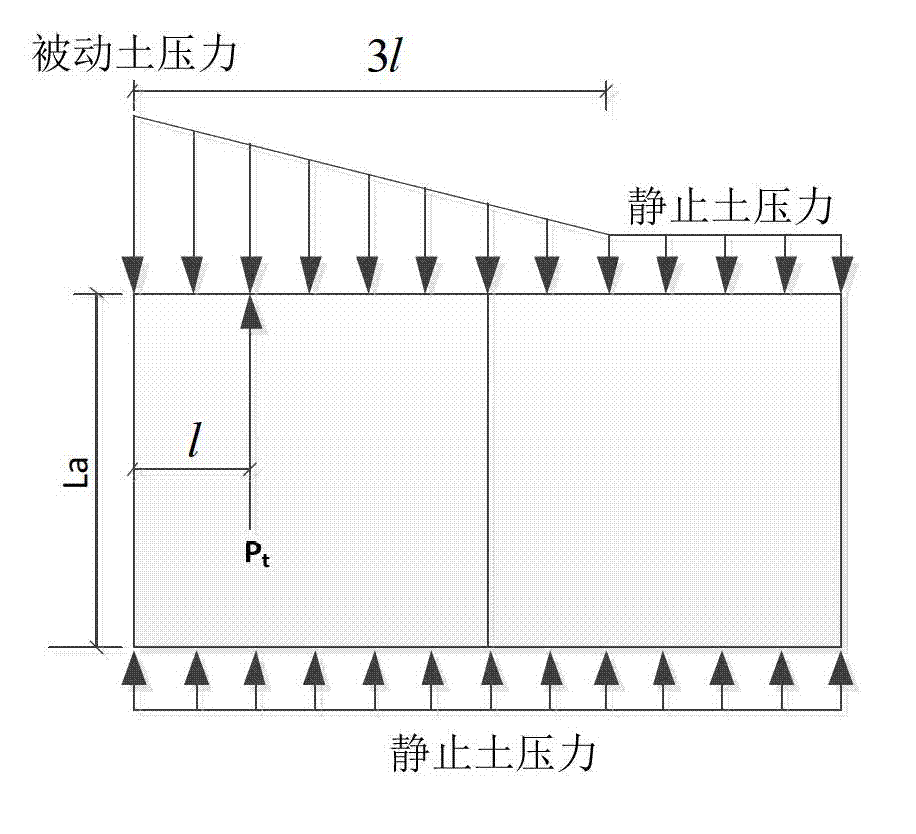

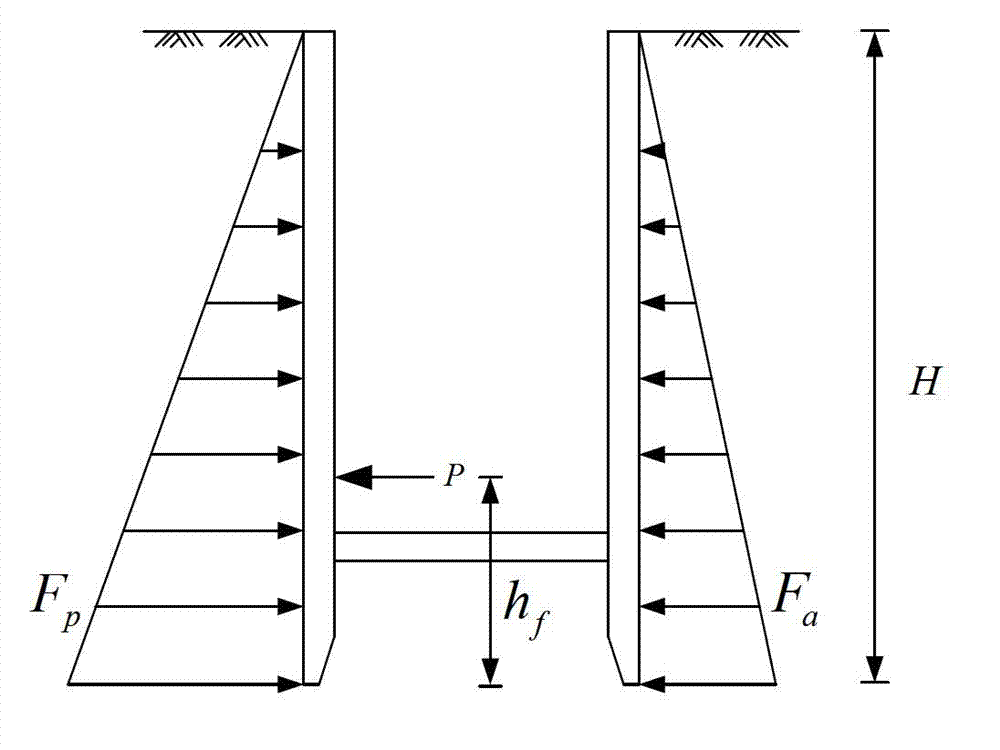

Method for arranging jacking pipe of rectangular open caisson

ActiveCN102829245ASafe and secure settingsPipe laying and repairCable installations in underground tubesEngineeringSoil parameters

The invention provides a method for arranging a jacking pipe of a rectangular open caisson, which comprises the following steps: (a) obtaining soil parameters and open caisson parameters of a region of a working area applying the rectangular open caisson; (b) calculating soil pressure along each direction of the open caisson according to the soil parameters and the open caisson parameters; and (c) calculating an allowed jacking force for eccentrically jacking of the jacking pipe according to a distribution mode of the soil pressure and the soil pressure, and causing a jacking force required by the advancing of the jacking pipe to be less than the allowed jacking force for eccentrically jacking. According to the method provided by the invention, the soil parameters of the working area are confirmed according to the geological data and test data; the soil pressure acted on each direction of a working well is solved by utilizing the jacking force of the pipeline, a soil pressure formula and a given soil pressure distribution shape; the allowed jacking force for eccentrically jacking of the jacking pipe of the working well is finally calculated; and according to the allowed jacking force, the jacking pipe of the rectangular open caisson can be safely arranged.

Owner:SHANGHAI JIAO TONG UNIV

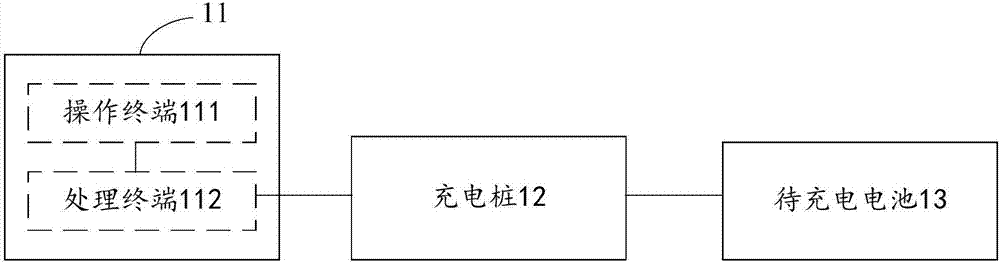

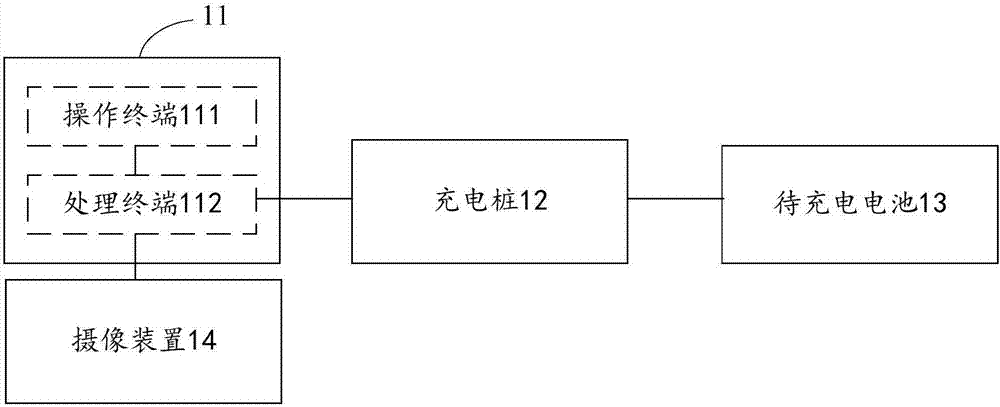

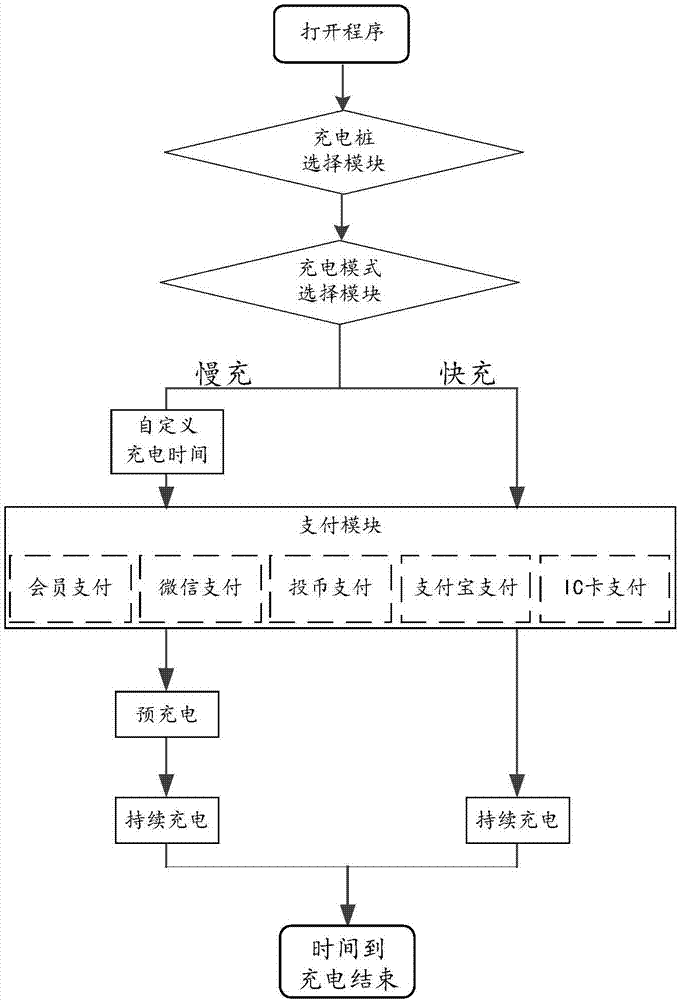

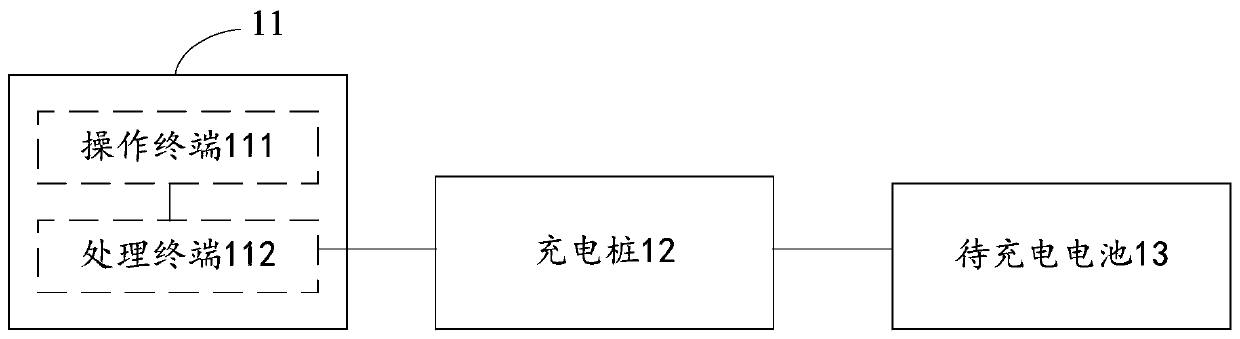

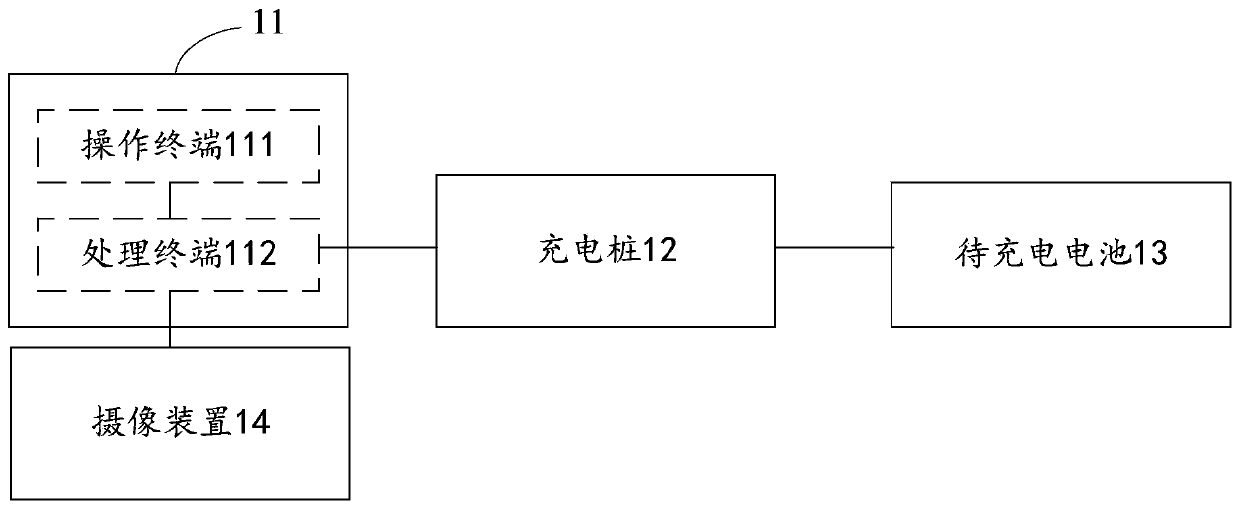

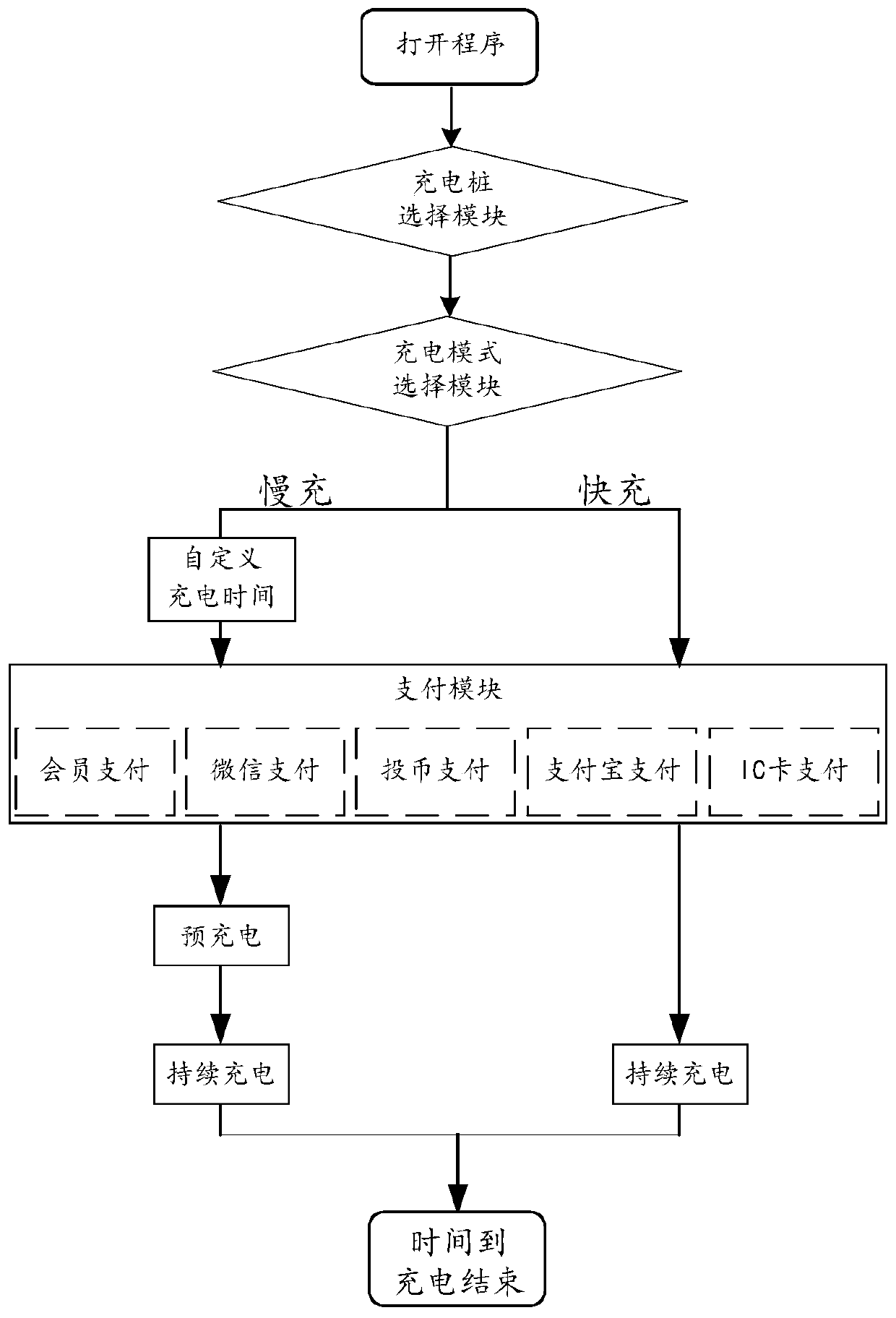

Control system of intelligent charging pile and charging method of storage battery

ActiveCN107161028ASimple processMonitor the charging processCharging stationsElectric powerElectrical batteryControl system

The invention provides a control system of an intelligent charging pile and a charging method of a storage battery. The control system of the intelligent charging pile comprises an operation terminal, a processing terminal and the charging pile, wherein the operation terminal receives a charging instruction transmitted by a user, and transmits the charging instruction to the processing terminal; the processing terminal analyzes the charging instruction to determine the charging pile used for charging a to-be-charged battery; the charging pile detects voltage of the to-be-charged battery, receives a charging mode transmitted by the processing terminal, and determines a charging scheme for the to-be-charged battery according to the voltage and the charging mode. In the control system of the intelligent charging pile, the charging pile can analyze the voltage and the charging mode of the to-be-charged battery to determine the charging scheme for the to-be-charged battery, so that the determined charging scheme is more scientific; a charging process is safer; the technical problems of low safety and poorer intelligent degree of the conventional charging pile during charging of the to-be-charged battery are alleviated.

Owner:罗腾

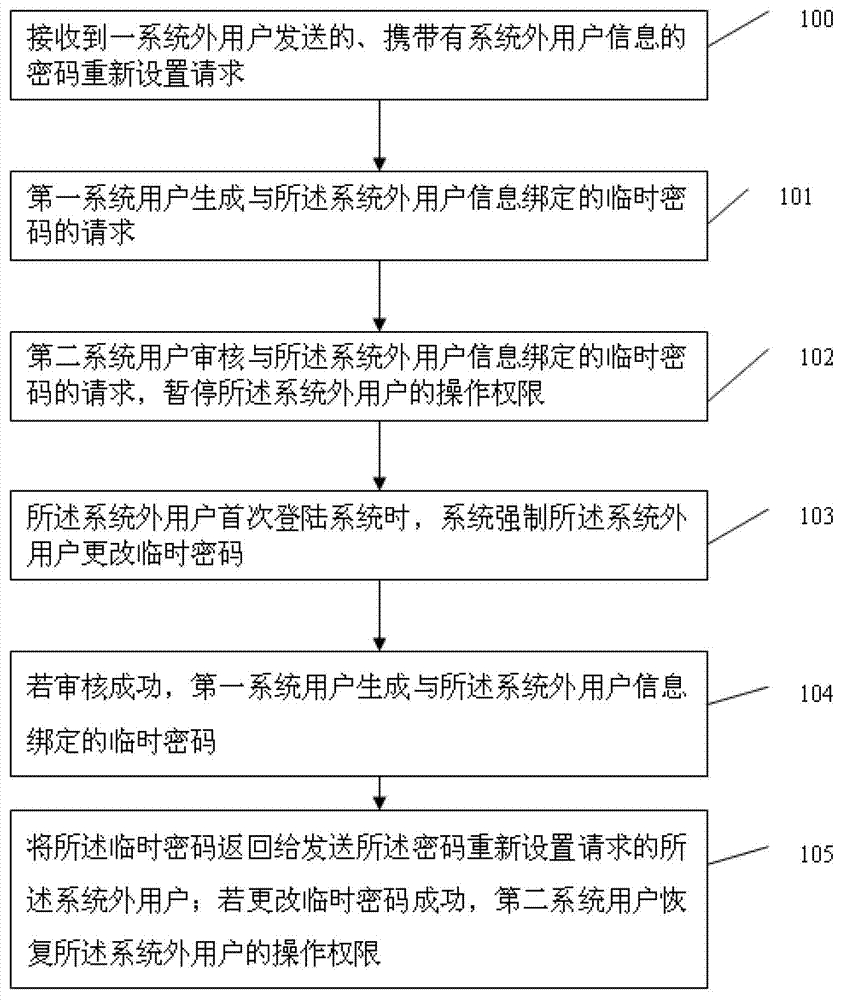

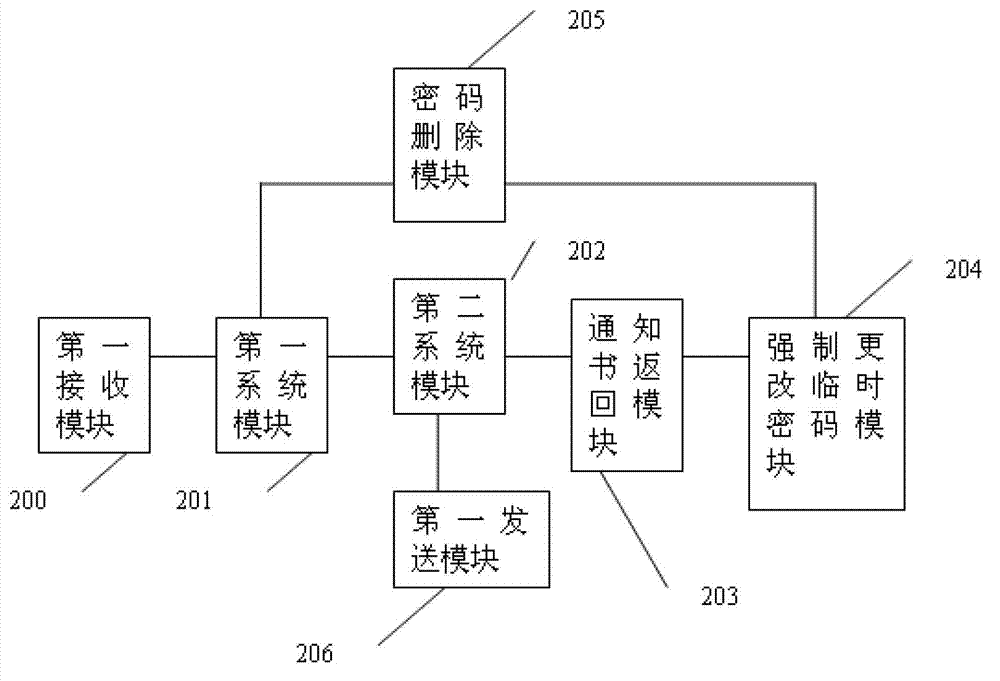

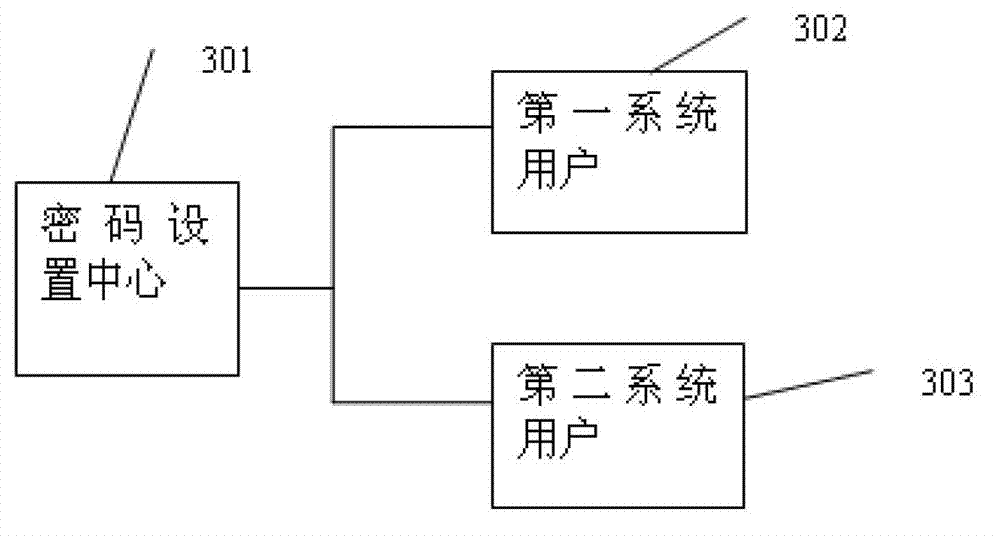

Password setting method and system for users outside system and password setting center

ActiveCN102880819AAvoid economic lossImplement Mutual ExclusionDigital data protectionDigital data authenticationPasswordAuthorization

The invention provides a password setting method and system for users outside a system and a password setting center. The password setting method comprises the following steps: a password resetting request sent by the user outside the system and carrying the information of the user outside the system is received; a first system user generates a request of a temporary password bound to the information of the user outside the system; a second system user reviews the request of the temporary password bound to the information of the user outside the system; the second system user suspends the operating authorization of the user outside the system; when the user outside the system logins the system for the first time, the system forces the user outside the system to change the temporary password; in case of successful approval, the first system user generates the temporary password bound to the information of the user outside the system; the temporary password is returned to the user outside the system, who sends the password resetting request; and if the temporary password is changed successfully, the second system user restores the operating authorization of the user outside the system.

Owner:BEIJING NINE STAR TECH CORP

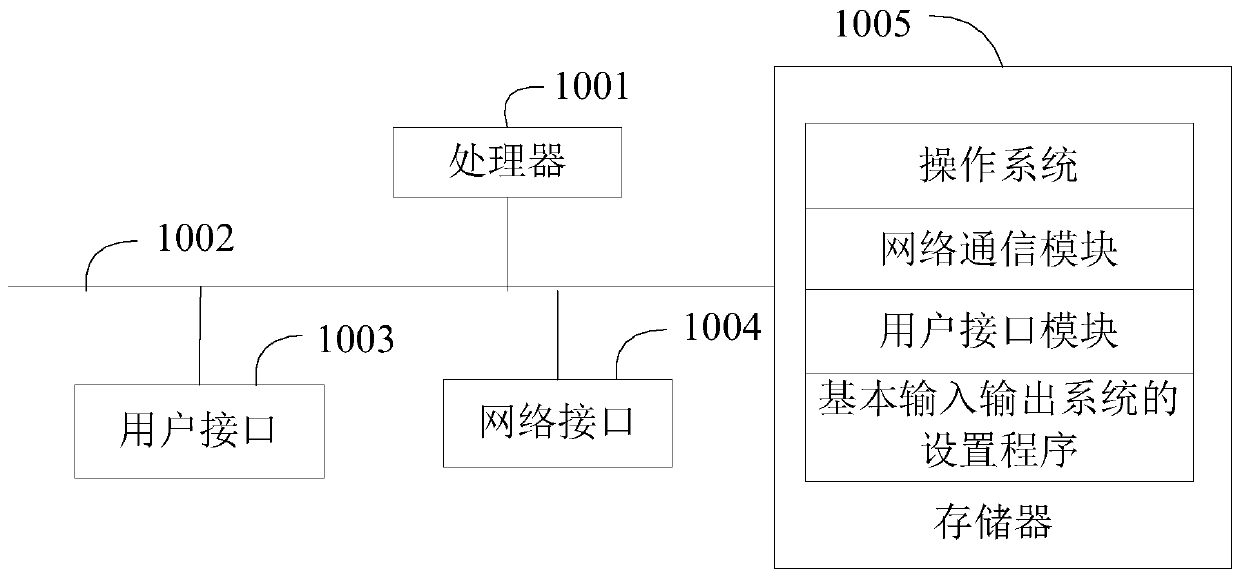

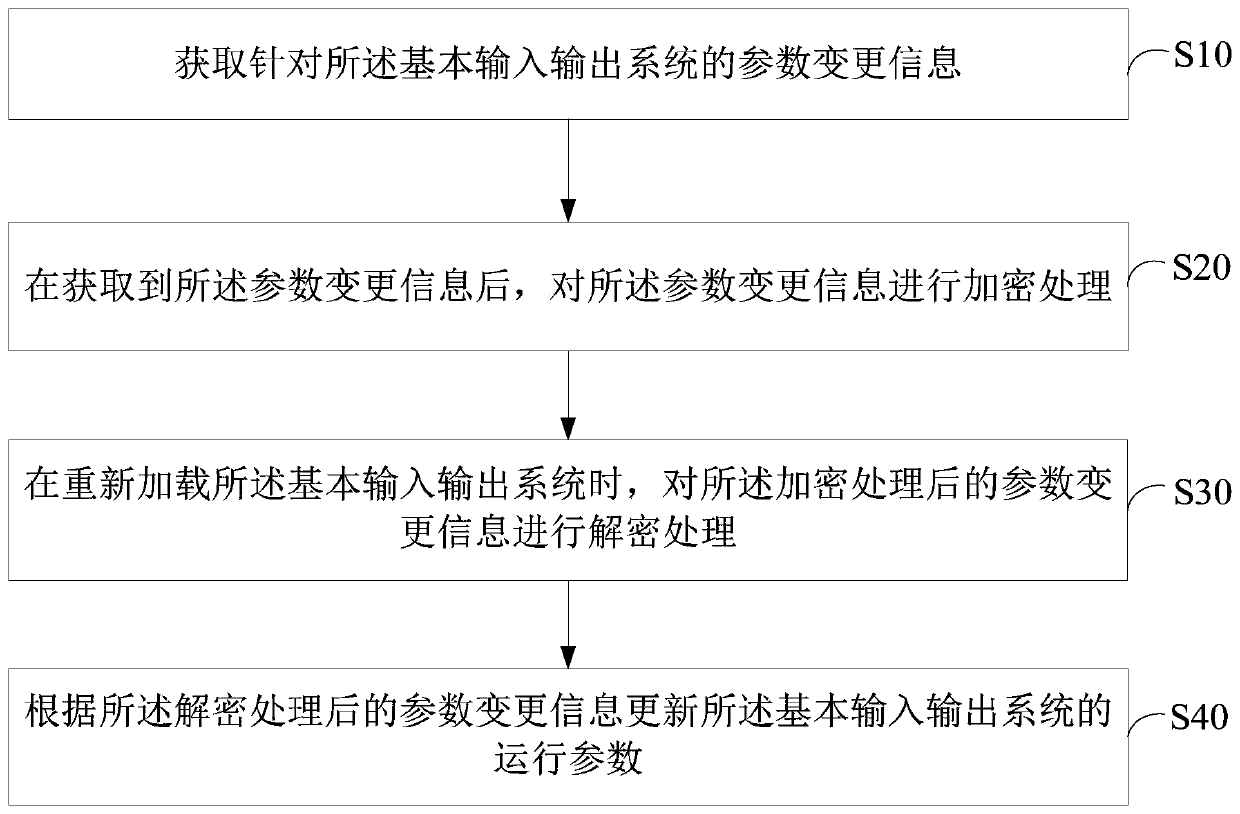

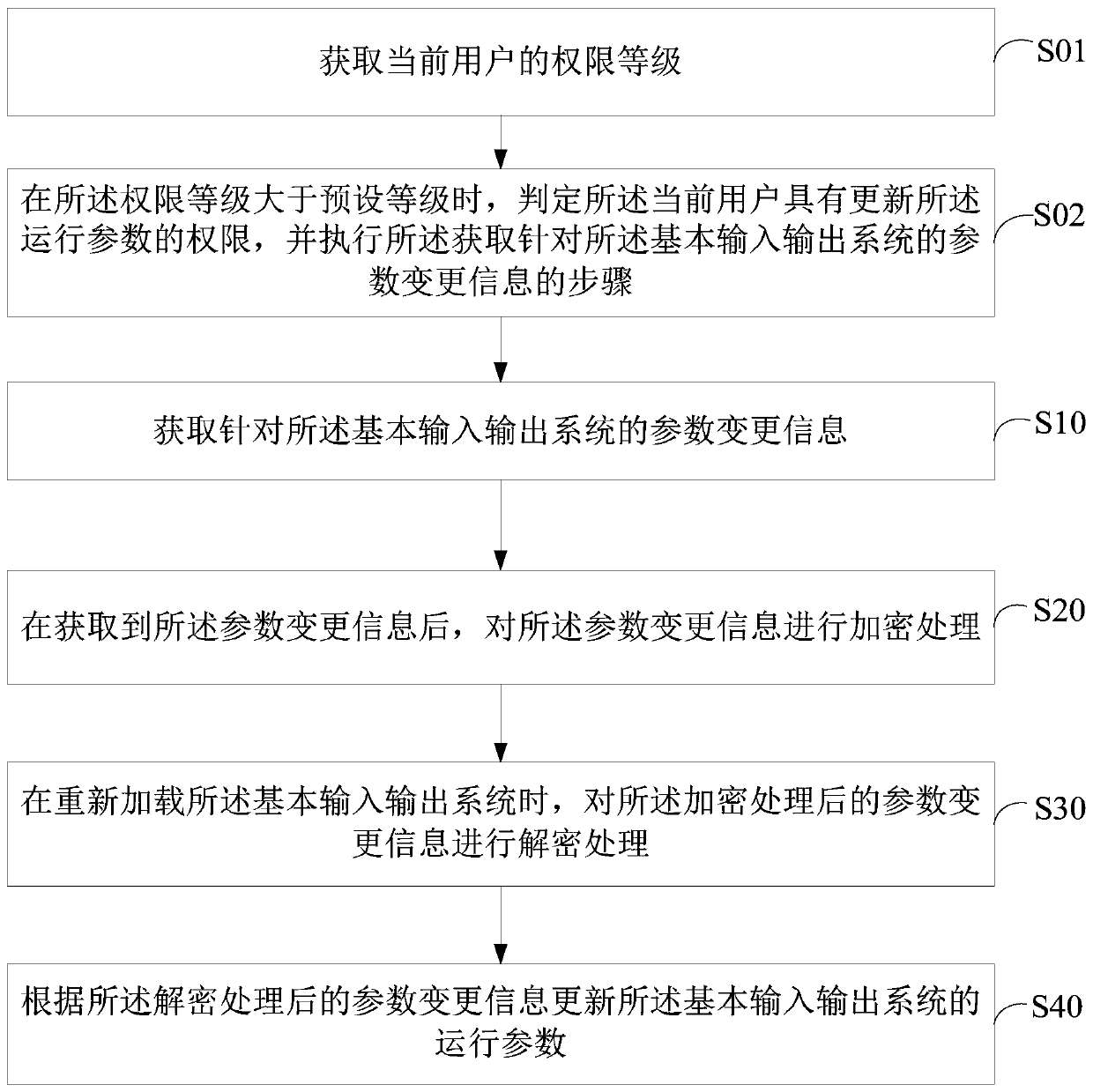

Setting method of basic input/output system, terminal and computer storage medium

ActiveCN110196741ASafe and secure settingsEasy to operateProgram loading/initiatingKey pressingDigital signature

The invention discloses a setting method of a basic input / output system. The setting method of the basic input / output system comprises the following steps: acquiring parameter change information for the basic input / output system; after the parameter change information is obtained, performing encryption processing on the parameter change information; when the basic input / output system is reloaded,decrypting the encrypted parameter change information; and updating the operation parameters of the basic input / output system according to the parameter change information after decryption processing.The invention further discloses a setting terminal of the basic input and output system and a computer storage medium. The parameter change information is directly acquired, and the parameters are operated according to the parameter change information in the digital signature process, so that manual key pressing during startup is avoided, the operation steps of a user are simplified, and the setting of the basic input / output system is safer through digital signature.

Owner:SHENZHEN HAILINKE INFORMATION TECH CO LTD

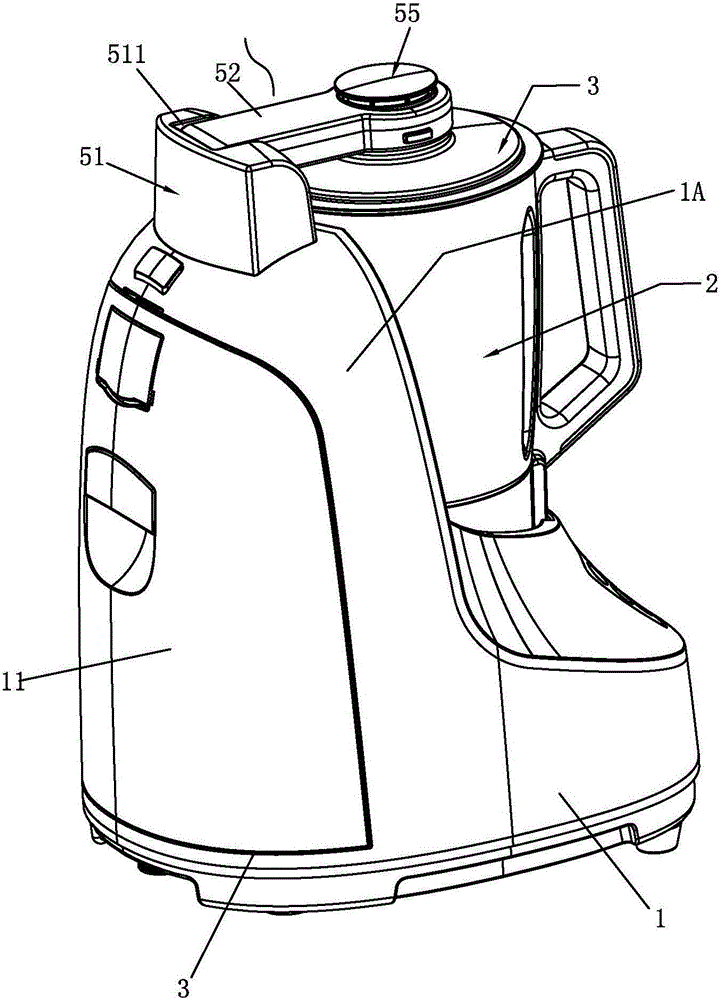

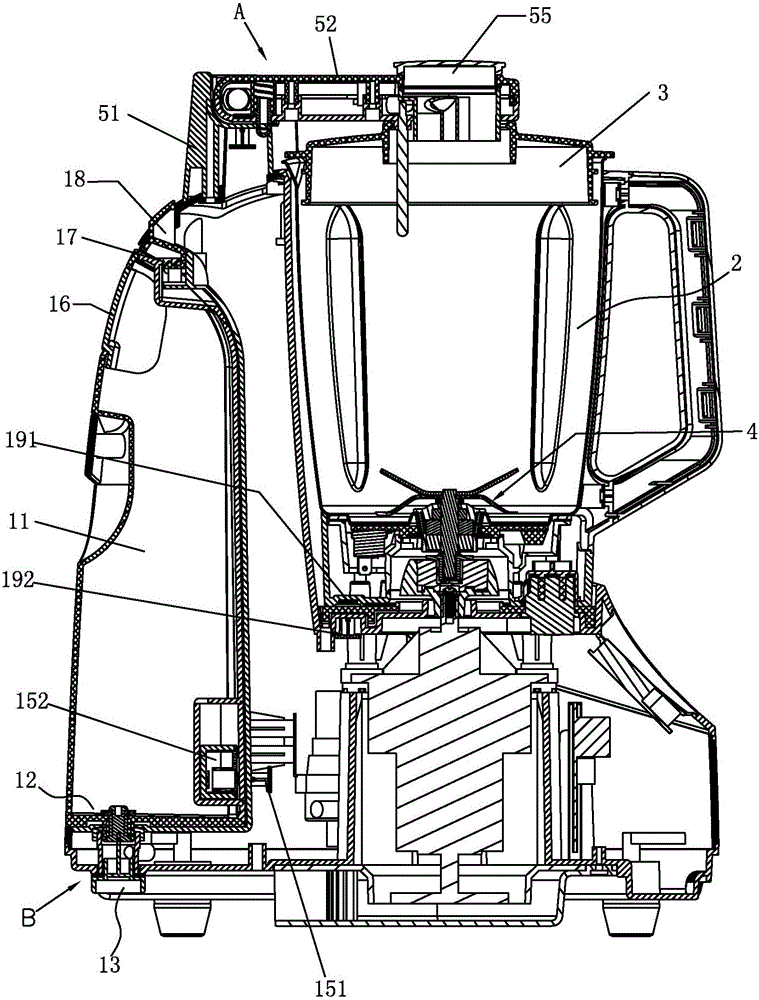

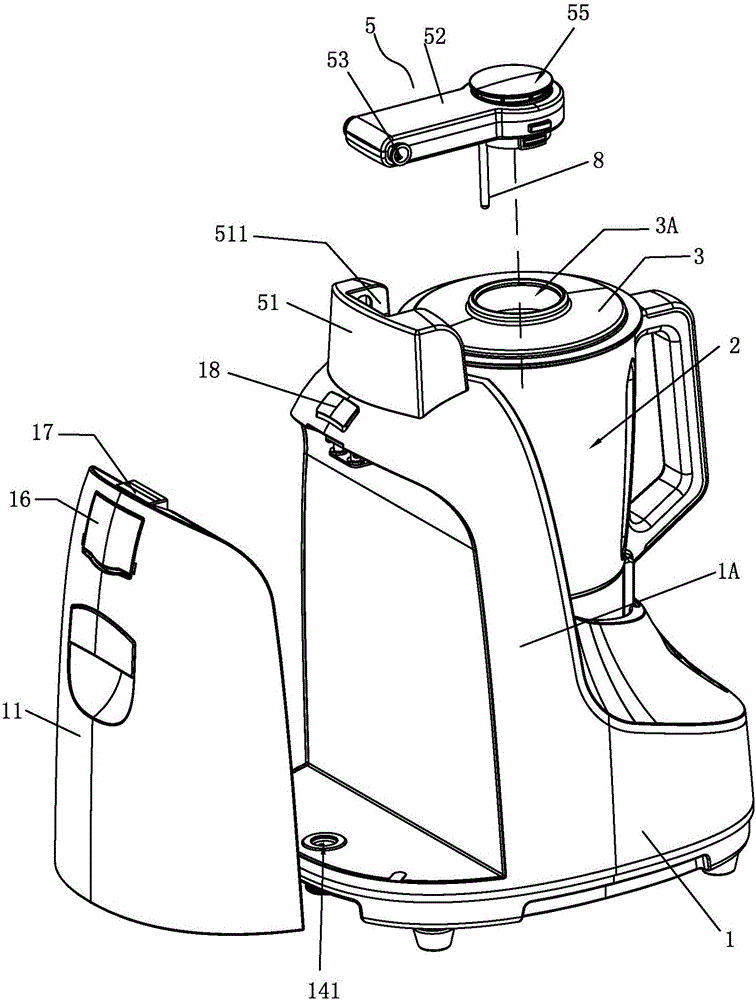

Safe water adding type wall-breaking food processor

A safe water adding type wall-breaking food processor comprises a processor base, a motor, a cup body, a cup lid, a cutter assembly and a control device, wherein the cup body is arranged at a cup body position of the processor base, and the cup lid is buckled with the cup body. The safe water adding type wall-breaking food processor further comprises a water supply device, a water pump and a water adding device, wherein the water pump and the water adding device are arranged in the processor base, and the water adding device is arranged at the top of a supporting seat and is matched with a lid top hole formed in the cup lid. The water supply device is arranged at a water supply device position of the processor base and is communicated with the water pump, and the water pump is communicated with the water adding device. The water adding device further comprises a hollow seat body with a lower opening, a water guiding hose, a rotating arm, a hollow shaft, a water guiding part and a cover body, wherein the rotating arm is in pivoted connection with a pivoting connection groove through the hollow shaft, the water guiding part is arranged in the rotating arm, and the cover body is detachably connected with a cover hole. The food processor is further provided with a magnetic assembly, wherein a magnet and a magnetically controlled switch of the magnetic assembly are arranged in the rotating arm and the seat body respectively, and the magnetically controlled switch is connected with the control device. Due to the adoption of the structure, the wall-breaking food processor has the functions of a water tank and an automatic water adding function and is safe and convenient to use.

Owner:ZHONGSHAN KUAITE ELECTRICAL APPLIANCES

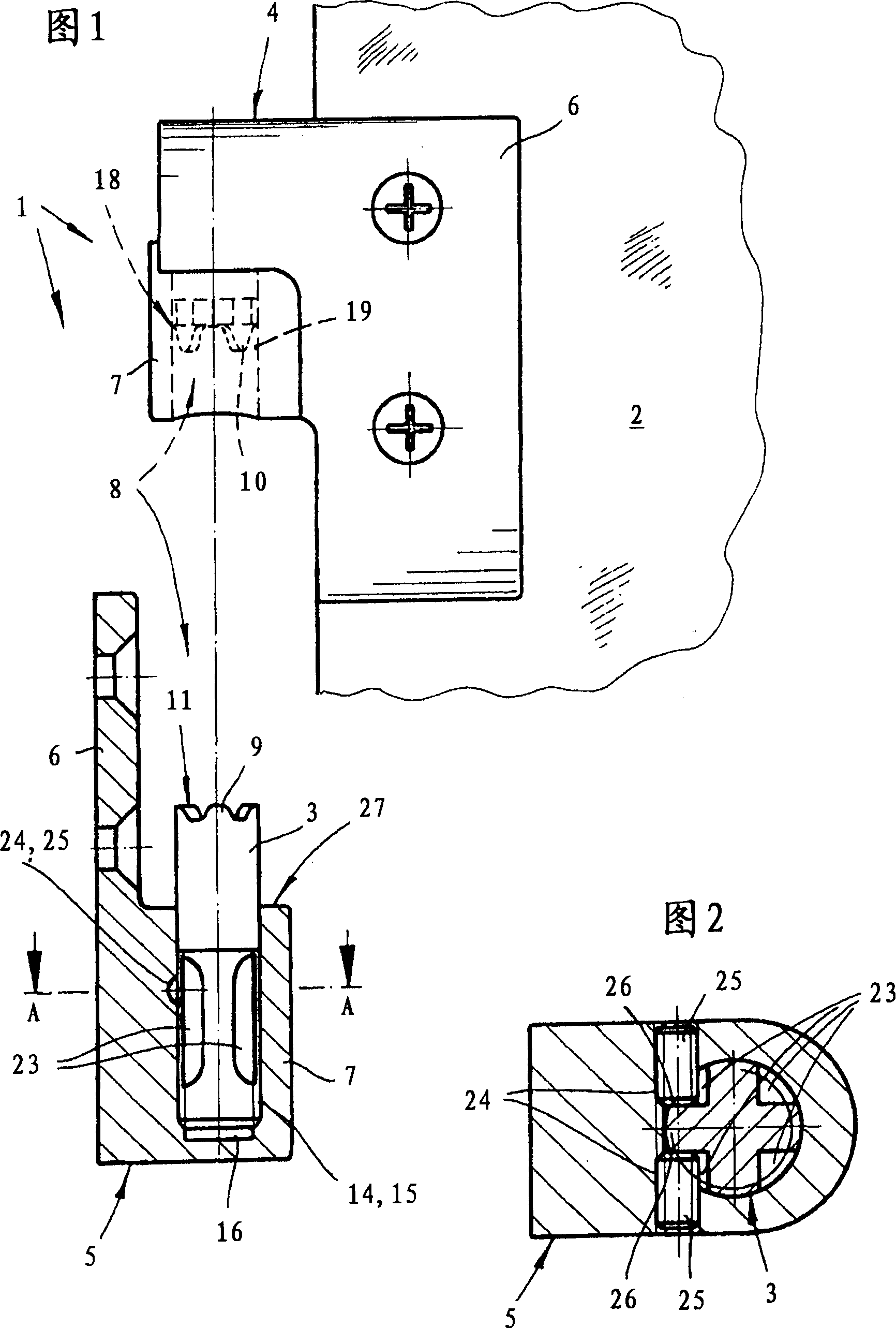

Fitting for fixing a doorwing

Fitting for fastening a door wing, especially a door wing of a shower partition made of glass, plastic or similar material, with a hinge of two hinge leaves joined together by means of a keybolt, wherein each hinge leaf features a fastening plate and a hinge eyelet. The hinge features a detent mechanism with locking profiles which hold the door wing in the default swing position. The locking profiles are provided on each of the two hinge leaves. The locking profiles are provided on the keybolt.

Owner:FOREMOST INT

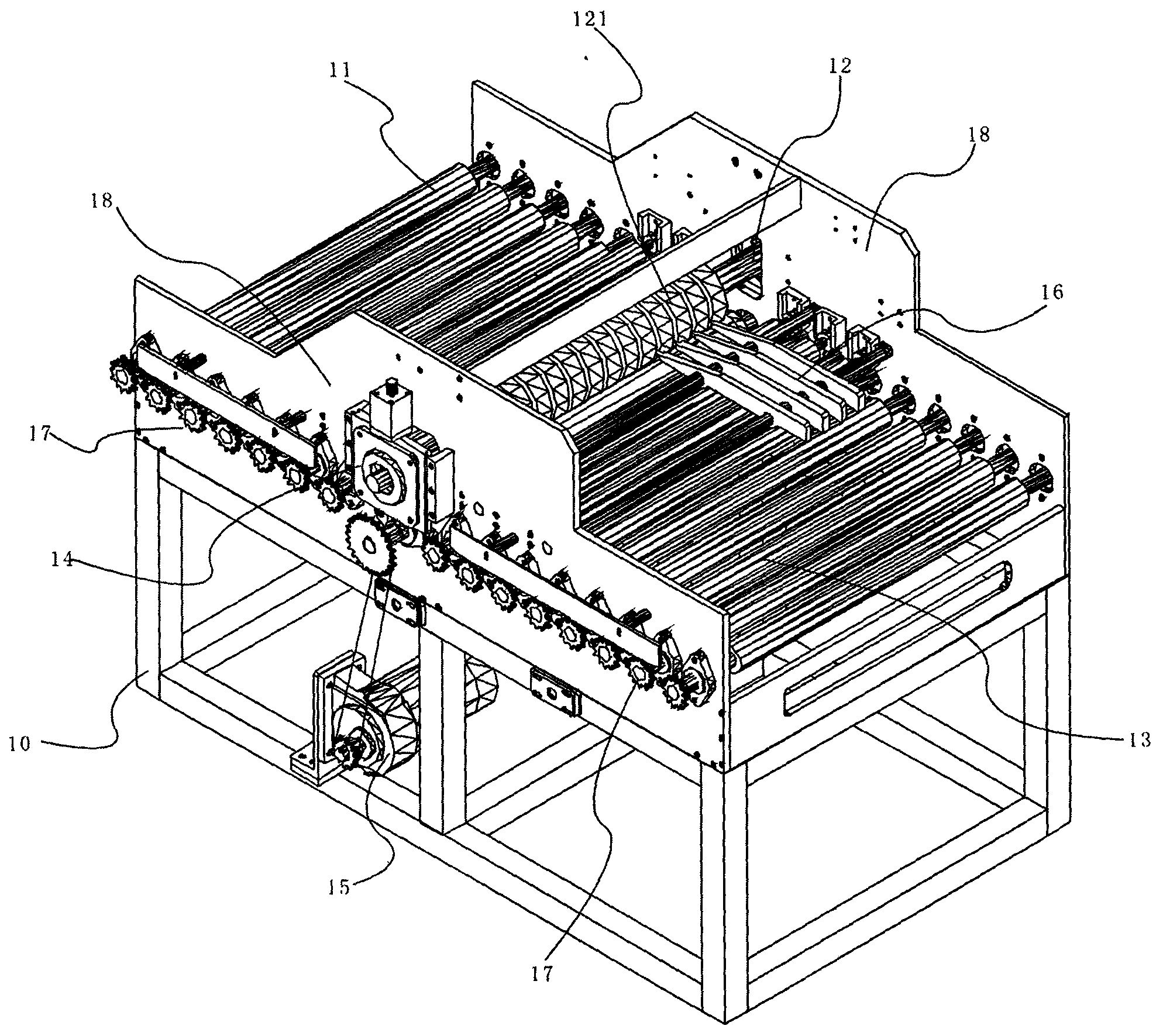

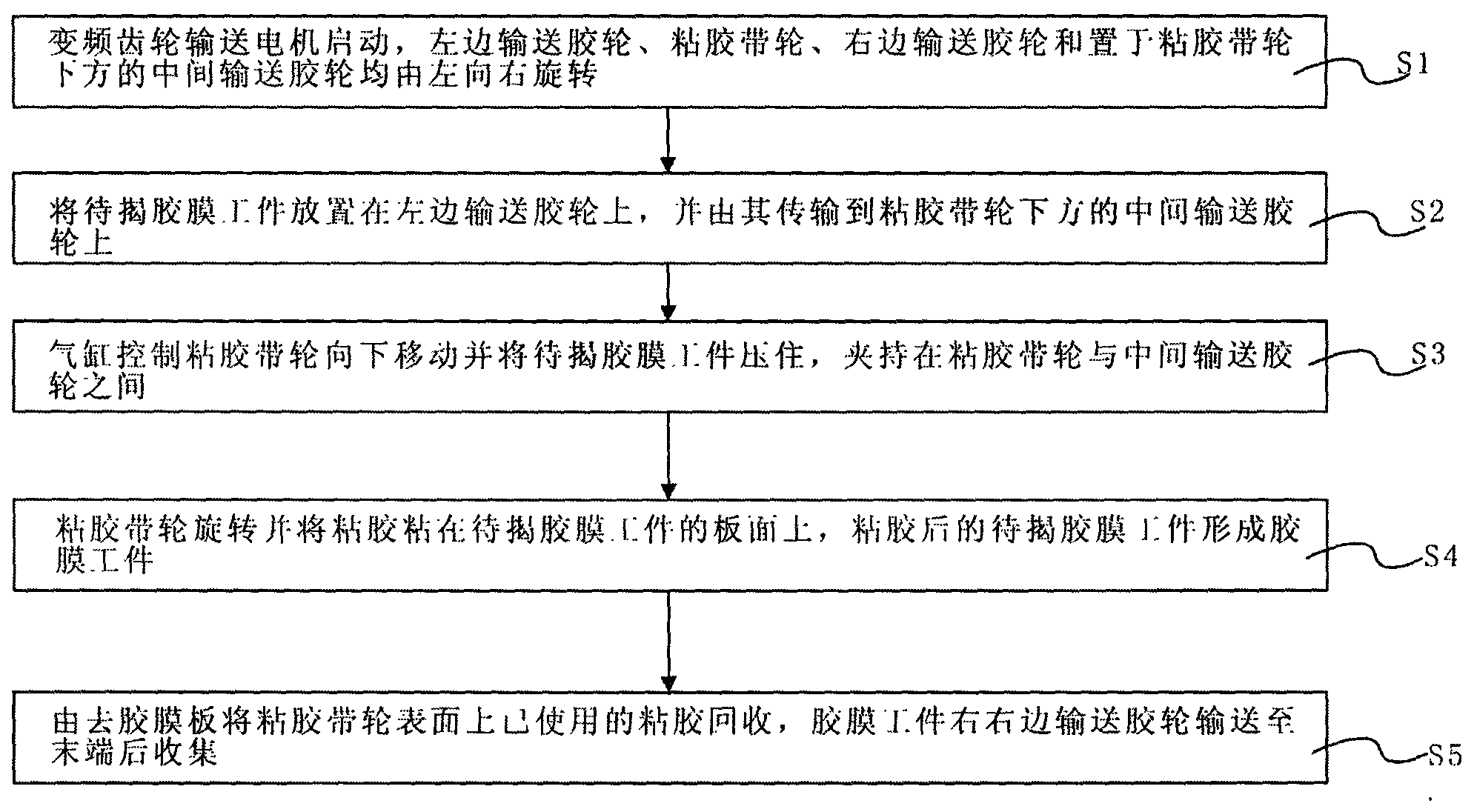

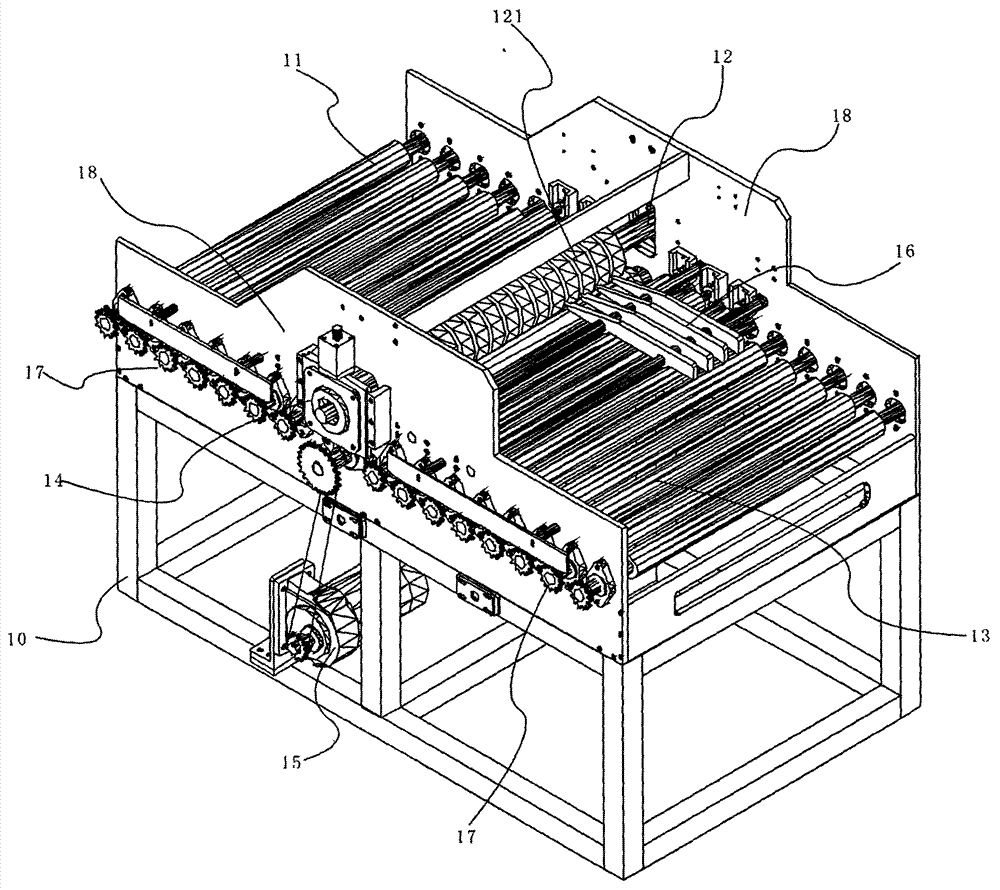

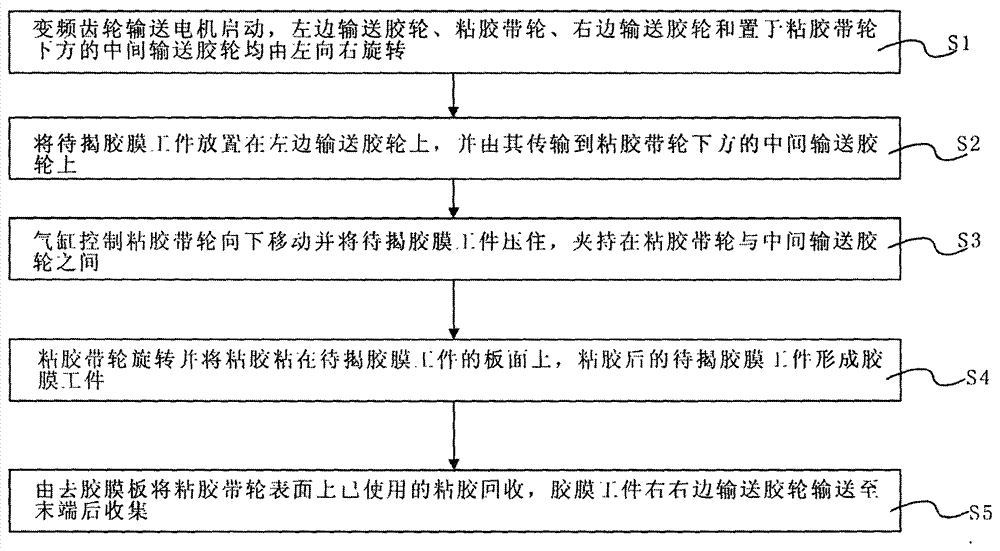

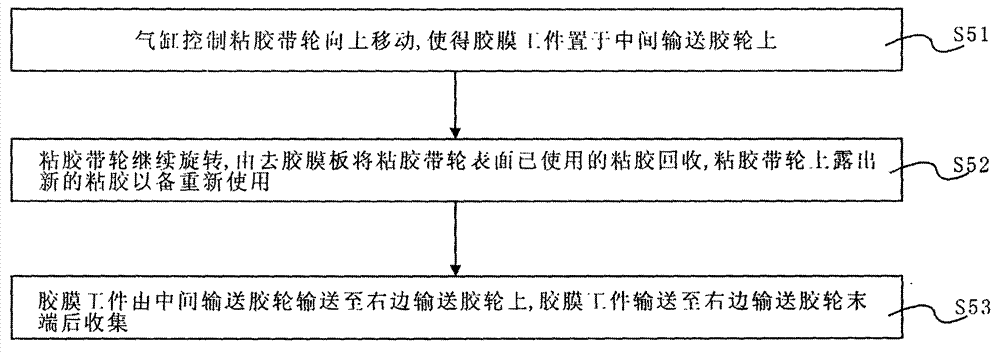

Automatic adhesive tearing-off equipment and method

InactiveCN103522728AReduce pollutionReduce labor costsLamination ancillary operationsLaminationAdhesive beltEngineering

The invention discloses automatic adhesive tearing-off equipment and an automatic adhesive tearing-off method. The equipment comprises a stander, a left adhesive conveying wheel group, an adhesive belt wheel, a right adhesive conveying wheel group, a middle adhesive conveying wheel arranged below the adhesive belt wheel, a cylinder, a variable-frequency gear conveying motor and an adhesive removal template, wherein the left adhesive conveying wheel group, the adhesive belt wheel, the right adhesive conveying wheel group, the middle adhesive conveying wheel and the adhesive removal template are all arranged in the stander; the variable-frequency gear conveying motor is arranged on the stander and is connected with the left adhesive conveying wheel group, the adhesive belt wheel, the right adhesive conveying wheel group and the middle adhesive conveying wheel respectively through conveying gears in a driving manner; the adhesive removal template is arranged on the right side of the adhesive belt wheel. The automatic adhesive tearing-off equipment has the characteristics of convenience in operation, simple technology, high safety coefficient, low labor intensity, low production cost, high automation degree and the like.

Owner:SHENZHEN YONGNENG MACHINERY

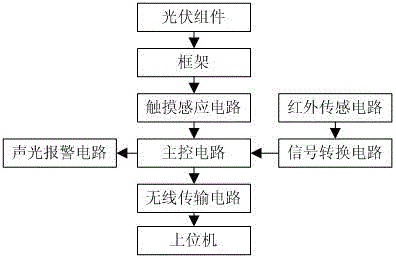

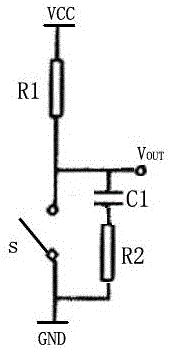

Anti-theft monitoring control system for photovoltaic module

InactiveCN105720909ASafe and secure settingsTouch sensing implementationPhotovoltaic monitoringBurglar alarm mechanical actuationCapacitanceControl signal

The invention discloses an anti-theft monitoring control system for a photovoltaic module. The anti-theft monitoring control system comprises a photovoltaic module, a touch sensing circuit, a main control circuit, a sound-light alarm circuit, a wireless transmission circuit and an upper computer, wherein the photovoltaic module is arranged on a frame; the touch sensing circuit is used for sensing whether the touch sensing circuit is touched or not and generating an excited signal when touched; the main control circuit is used for generating a control signal; the sound-light alarm circuit is used for carrying out sound-light alarm; the wireless transmission circuit is used for transmitting; the upper computer is used for carrying out receiving and displaying; one end of a touch switch in the touch sensing circuit is grounded and the other end of the touch switch is connected with one end of a first resistor and a voltage output end; the other end of the first resistor is connected with a voltage input end; one end of a second resistor is grounded; the other end of the second resistor is connected with one end of a capacitor; and the other end of the capacitor is connected with the voltage output end. The anti-theft monitoring control system achieves touch sensing by a simple circuit, has monitoring and anti-theft functions and improves the safety.

Owner:SUZHOU XUANHE IOT TECH

Junked tire steel wire taking device for regenerated rubber production and using method

The invention relates to a junked tire steel wire taking device for regenerated rubber production and a using method. The device comprises a bottom plate and a supporting base. A horizontal bearing and a first gear are arranged on the side wall of the supporting base, the upper face of the supporting base is connected with a first supporting plate, the center of the first supporting plate is provided with a first air cylinder, the lower end of the first air cylinder is connected with the first supporting plate, the upper end of the first air cylinder is connected with a second supporting plate, a tire fixing device is arranged on the second supporting plate, and a cutting knife is arranged above the tire fixing device. Since the tire fixing device is arranged on the second supporting plate, the wire is fixed through the tire fixing device, jacked up through the first air cylinder, perforated through the cutting knife and then cut through motor rotation. The junked tire steel wire taking device is high in cutting efficiency, uniform in cutting and good in quality.

Owner:SHUYANG JIASHENG RENEWABLE RESOURCES CO LTD

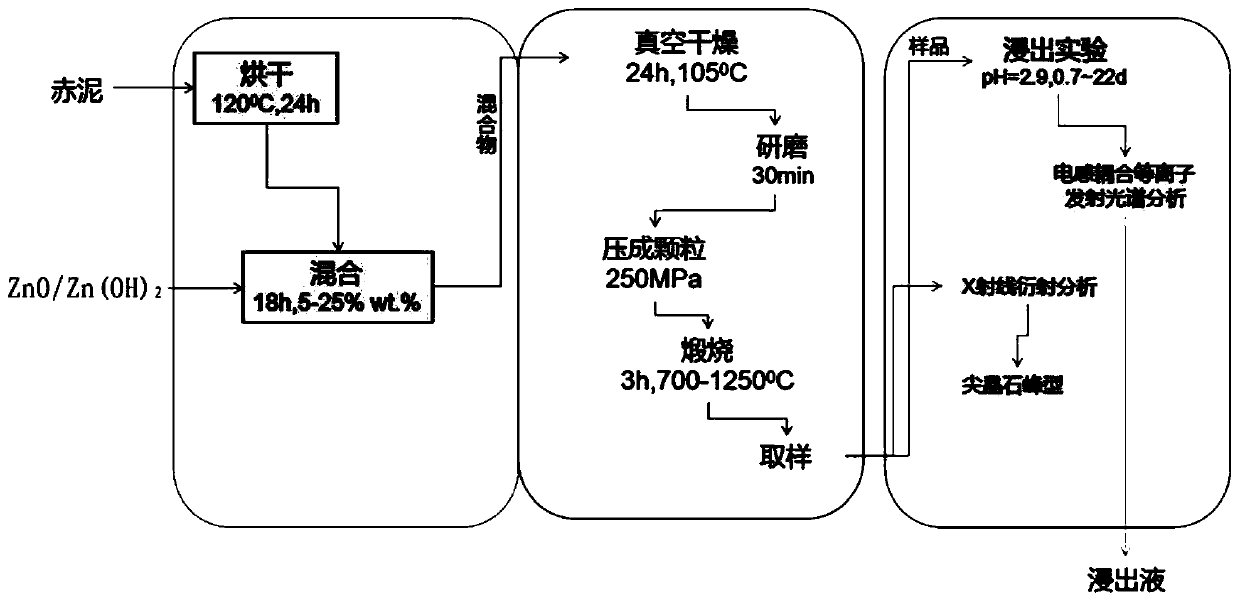

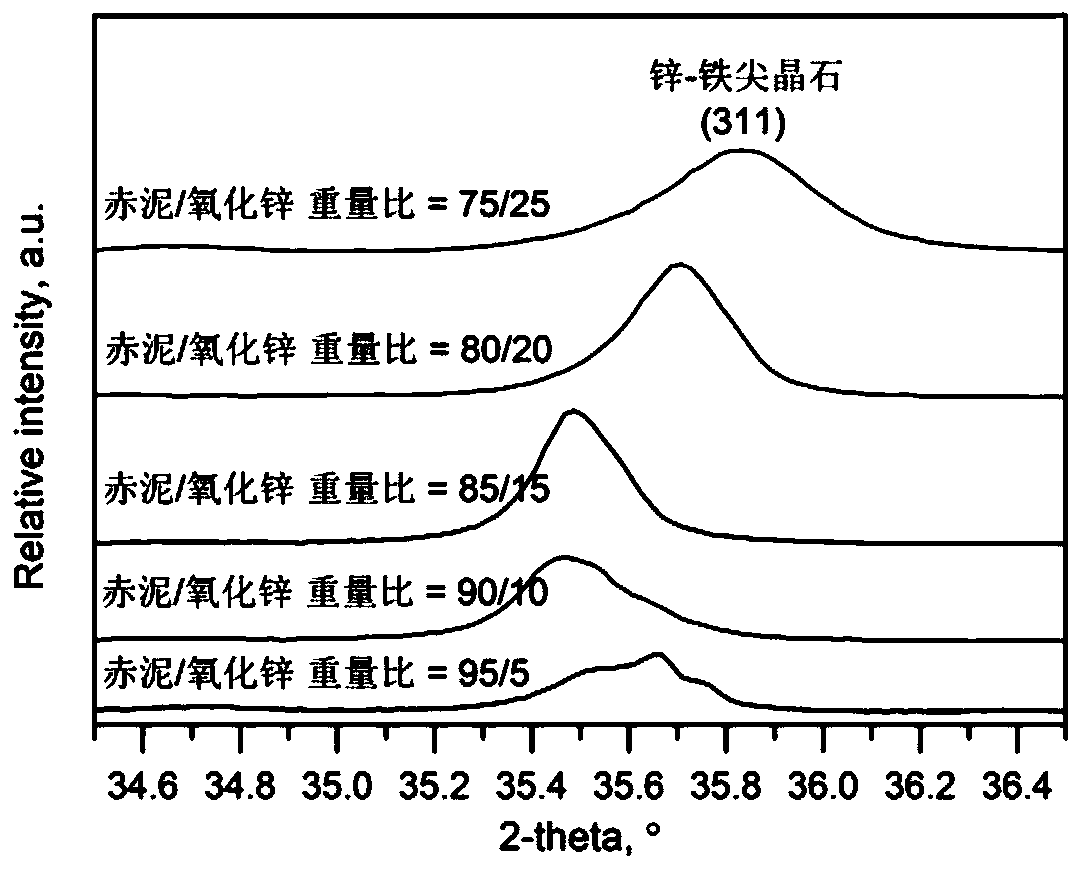

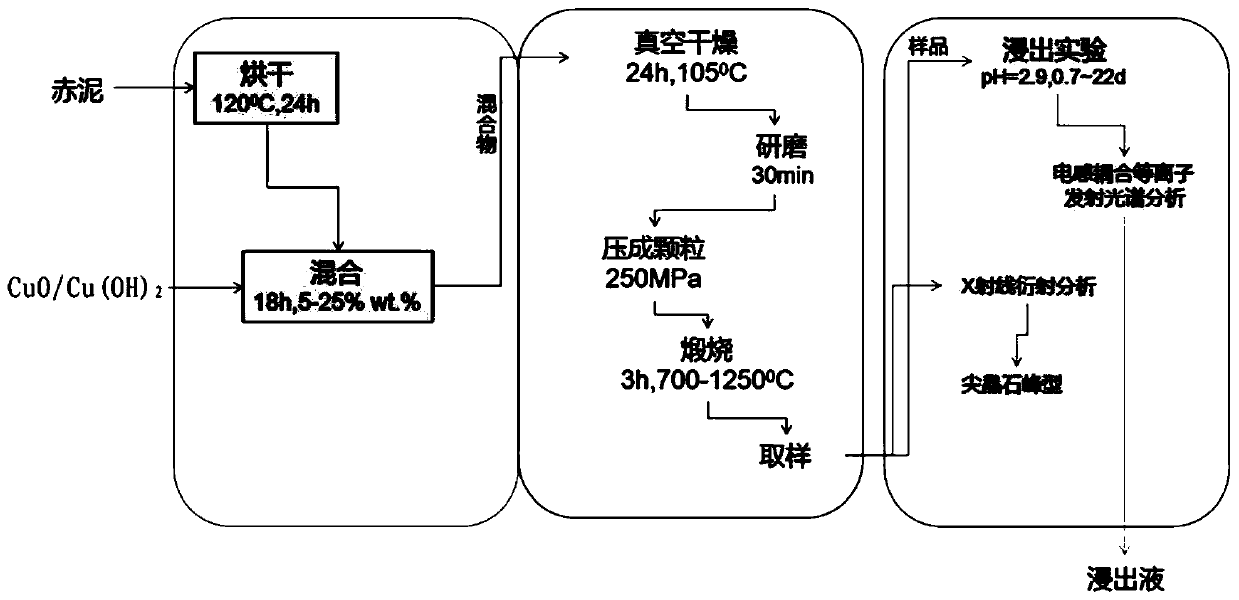

Method of generating metal zinc in stable waste through spinel

InactiveCN110026410AEasy to manageReduce riskSolid waste disposalTransportation and packagingRed mudToxic industrial waste

The invention provides a method of generating a metal zinc in a stable waste through spinel. The method comprises the following steps: (1) measuring the content of ferric oxide in red mud; (2) crushing, mixing and drying the waste containing the metal zinc and red mud in a weight ratio to be further dispersed uniformly to obtain a mixture of waste and red mud; (3) pressing and forming the mixtureobtained in the step (2); and (4) calcining a pressed and formed sample in the step (3) at 900-1100 DEG C. As the industrial waste red mud can be doped into the waste containing the metal zinc continuously, and hazardous wastes can be converted into crystallized products which are stable in chemical property and high in acid resistance by a low-temperature thermal treatment process, so that the waste containing the metal zinc is easily managed, and the risk in an environment is reduced. By means of the red mud, damage of the waste to the environment can be reduced and the waste can be also recycled. The product prepared by the method is good in leaching resistance, small in energy consumption and low in cost in an acidic environment.

Owner:GUANGZHOU UNIVERSITY

Inter-segment-ring anti-shearing structure penetrating through special stratum tunnel and arranging method ofinter-segment-ring anti-shearing structure

PendingCN109958457ASafe and secure settingsImprove the shear resistance between the ringsUnderground chambersTunnel liningStress conditionsPre embedding

The invention discloses an inter-segment-ring anti-shearing structure penetrating through a special stratum tunnel and an arranging method of the inter-segment-ring anti-shearing structure, and belongs to the technical field of tunnel construction. A circular steel ring and a pre-embedded bolt sleeve are separately arranged corresponding to pre-embedding on the end surfaces of two segment rings capable of being matched coaxially, an anti-shearing bolt with buffering pats are further arranged corresponding to the pre-embedded bolt sleeve, so that one end of the anti-shearing bolt can correspondingly connected in the pre-embedded bolt sleeve in a matching mode, the other end of the pre-embedded bolt sleeve can further be embedded into the corresponding circular steel ring after the two segment rings are matched in a corresponding mode, and then the inter-ring anti-shearing structure of a shield tunnel is formed after the two segment rings are matched. According to the inter-segment-ringanti-shearing structure, the structure is simple, the arrangement is simple and convenient, the inter-ring anti-shearing capability of the shield tunnel can be effectively improved, the stability andsafety of the shield tunnelis guaranteed, the inter-segment-ring anti-shearing structure is accurately suitable for the various stress conditions of the shield tunnel, the flexibility of the arrangement is high, the stability is high, the safety and stability of the arrangement of the shield tunnel is greatly improved, and the application prospect and popularization value are comparatively good.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

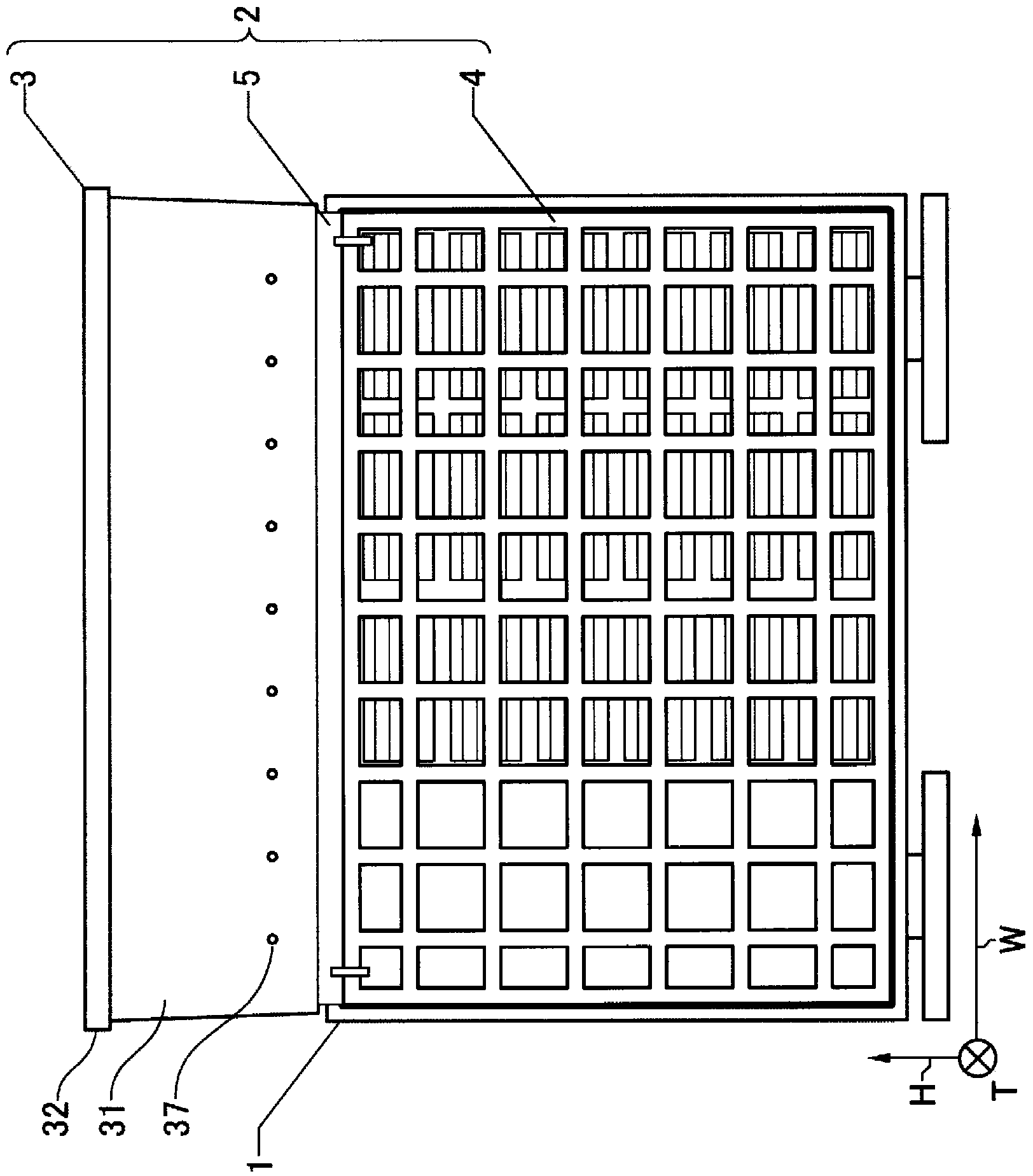

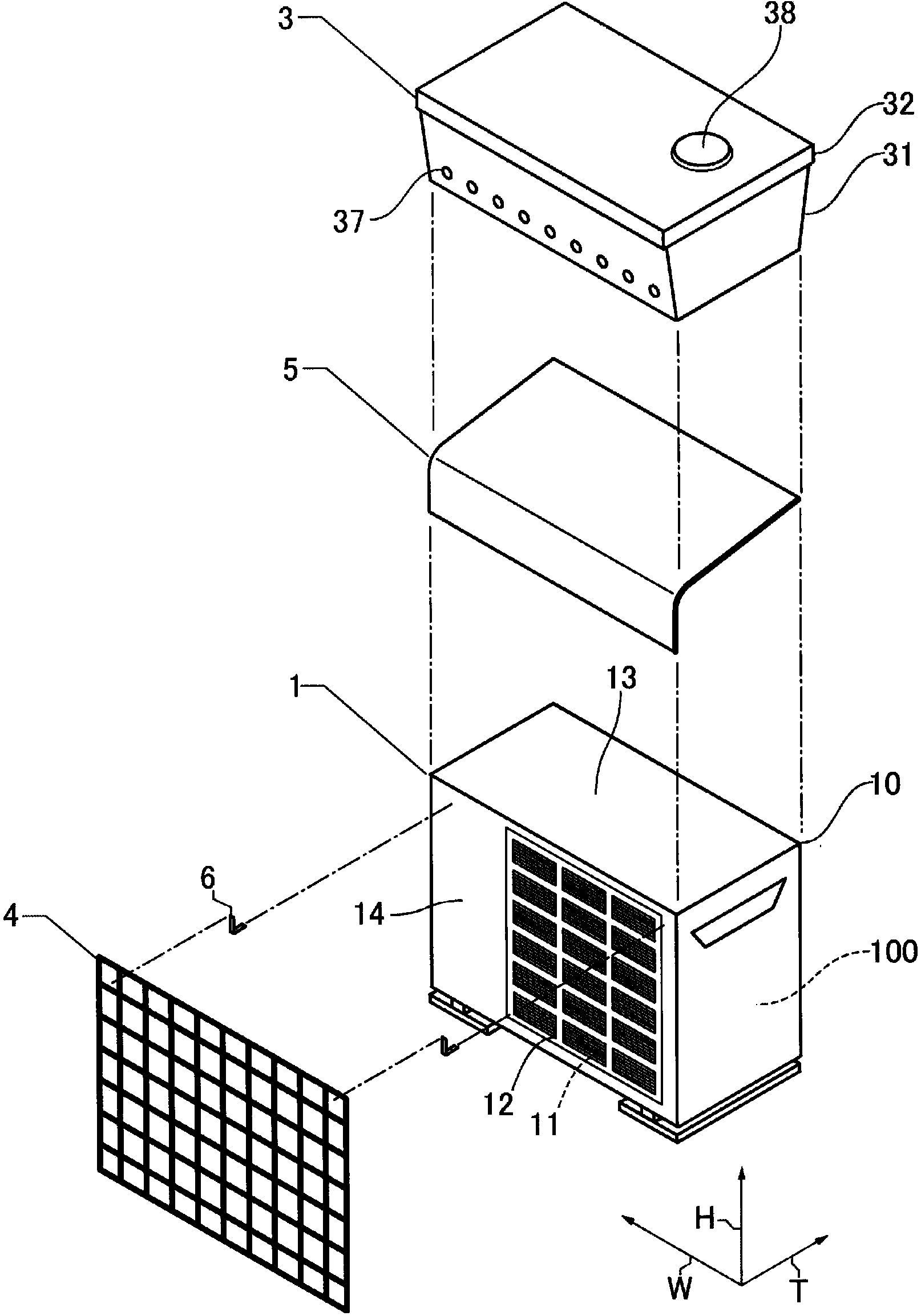

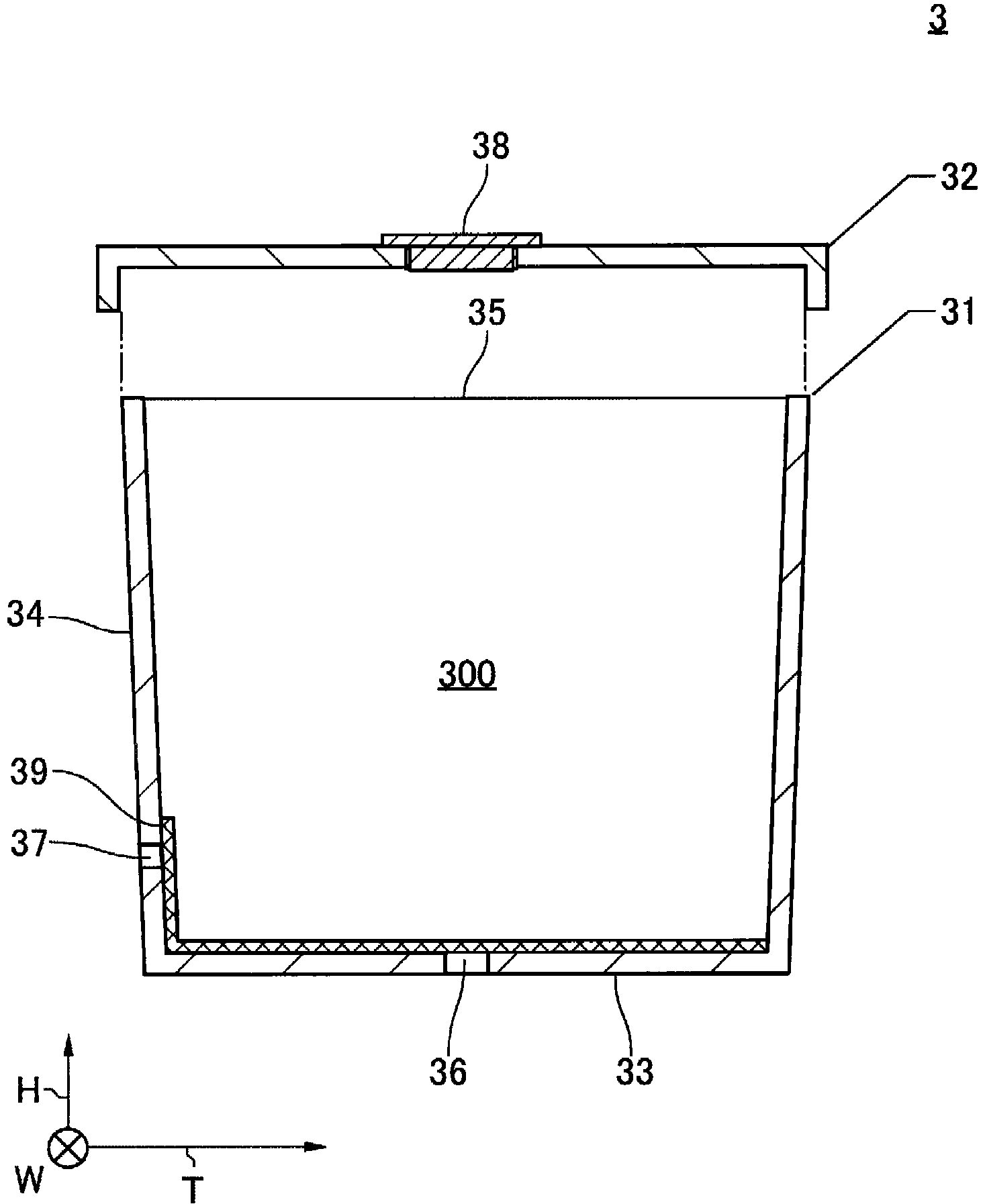

Cooling device for air conditioner outdoor unit, and air conditioner outdoor unit using same

InactiveCN103748420AEasy to handleReduce construction costsLighting and heating apparatusFree-cooling systemsWater storageWater discharge

A cooling device for an air conditioner outdoor unit and an air conditioner outdoor unit using the same are provided. The cooling device includes a support base, a water storage tank, a cooling section, and a water permeable sheet. The support base has a sloped surface, the height of which decreases in one direction, and which is mounted to the top surface of the outdoor unit body in such a manner that the lowest end of the sloped surface faces the side on which the air suction opening of the outdoor unit body is located. The water tank has a water storage space and a water discharge hole and is disposed on the sloped surface with the water permeable sheet provided therebetween. The water discharge hole is open at the bottom of the water tank and connects to the water storage space. The cooling section has a base body section and a water retention section and is mounted on the side on which the air suction opening of the outdoor unit body is located. The water retention section consists of a porous material, is mounted to the base body section, and has air passage holes. The water permeable sheet consists of a porous material and is placed on the sloped surface in such a manner that the upper surface of the water permeable sheet faces the water discharge hole and that the water permeable sheet is in direct contact with the outer surface of the bottom of the water storage tank. One end side of the water permeable sheet is in contact with the water retention section at a position on the lowest end side of the sloped surface.

Owner:长谷川 研二

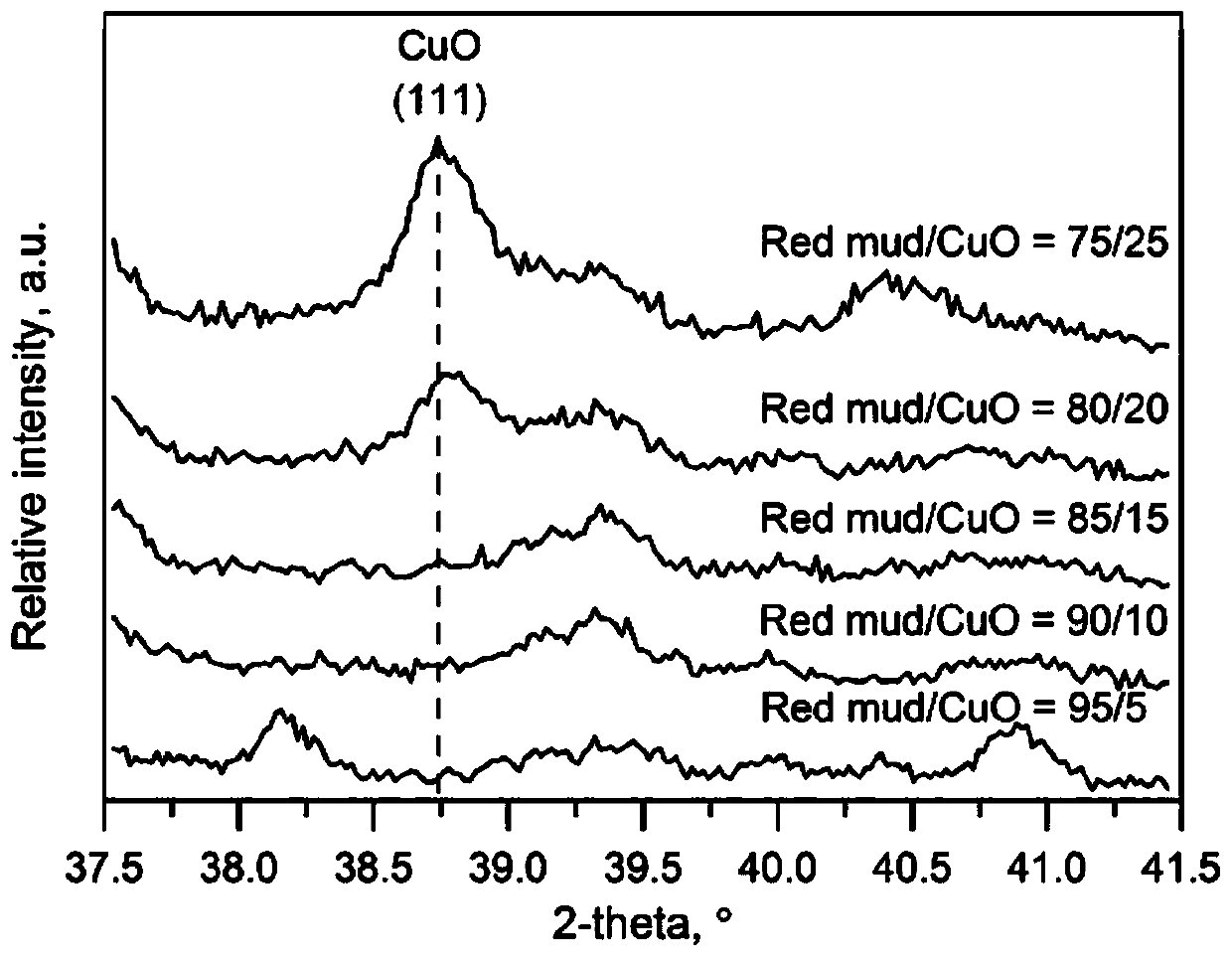

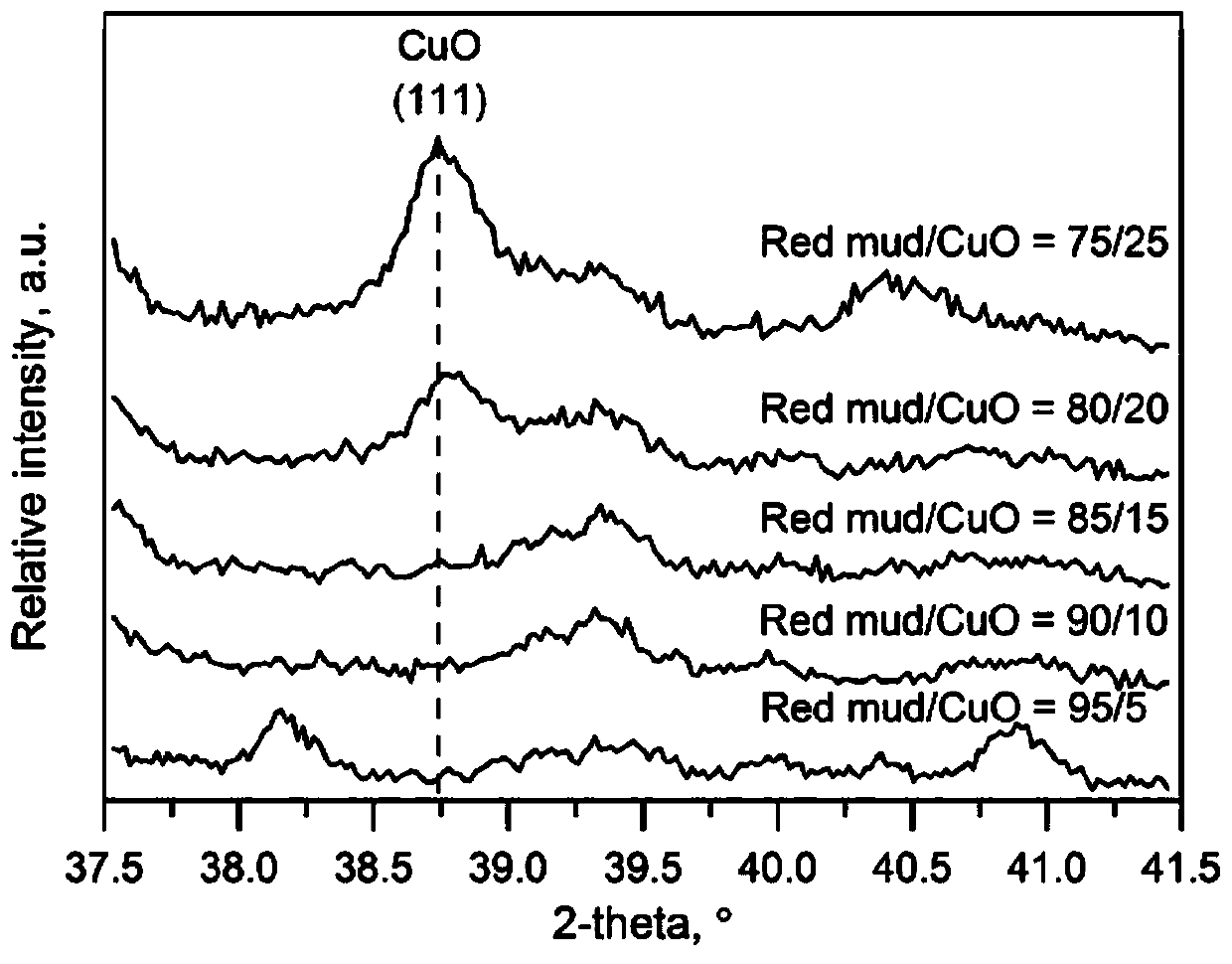

Method for stabilizing metal copper in waste through generation of spinel

InactiveCN110041048AEasy to manageReduce riskCeramic materials productionClaywaresRed mudToxic industrial waste

The invention provides a method for stabilizing metal copper in waste through generation of spinel. The method comprises the following steps: (1) determining the content of ferric oxide in red mud; (2) smashing the waste containing the metal copper and the red mud according to a weight ratio, mixing, drying a mixture, and further dispersing uniformly to obtain a mixture of the waste and the red mud; (3) molding the mixture obtained in step (2) by pressing; (4) calcining a press-molded sample obtained in step (3) at 900 to 1100 DEG C. According to the method, the industrial waste red mud can bemixed with the waste containing the metal copper continuously, and the dangerous waste can be converted into a crystal product with stable chemical property and high acid resistance by adopting a low-temperature thermal treatment process, so that the waste containing the metal copper is easy to manage, and the risk in environment is lowered; furthermore, through utilization of the red mud, harm of the waste to the environment can be reduced, and the waste can be recycled. A product prepared by the method provided by the invention has the advantages of good leaching resistance, low energy consumption and low cost in an acid environment.

Owner:GUANGZHOU UNIVERSITY

Open biogas burning torch

The invention discloses an open biogas burning torch comprising a vertical pipeline, an ignition device, a windshield and a central control unit, wherein a sprayer is arranged on the top of the vertical pipeline, the sprayer and the ignition device are all arranged in the windshield, the top of the ignition device is arranged on the side of the top of the sprayer, when being used, the ignition device is convenient and safe to ignite, and can make full biogas burning, in addition, the central control unit controls ignition and quench of torch, thereby realizing automation control. According to the design provided by the invention, full biogas burning can be realized and methane emission is reduced, the production cost is lowered, the installation setting is flexible, and the open biogas burning torch is safe and practical.

Owner:武汉天颖环境工程股份有限公司

Improved welding gun

InactiveCN103567679ANot easy to shakeSafe and secure settingsWelding/cutting auxillary devicesAuxillary welding devicesGas pipelineEngineering

The invention discloses an improved welding gun which comprises a gun head, a connecting rod and a gas supply pipe. The connecting rod is connected with the gas supply pipe. The gun head is connected with a valve body through a gas pipeline. The valve body is mounted on the connecting rod. A spring is sleeved outside the gas pipeline. Two ends of the spring are respectively in contact with the gun head and the valve body. An outer pipeline is sleeved outside the spring. A temperature sensor is mounted outside the gas pipeline. An alarm and a cooler are mounted on the surface of the valve body. A valve is disposed at the tail end of the gas supply pipe. An electronic scale for measuring current intensity is disposed at the tail end of the gas supply pipe. The improved welding gun has the advantages that the gun head is replaceable, the spring is sleeved outside the gas pipeline, two ends of the spring are respectively in contact with the gun head and the valve body, the welding gun is less prone to shaking during operation due to the spring, safety and reliability are achieved by the alarm and the electronic scale, and emergency can be dealt with.

Owner:吴中华

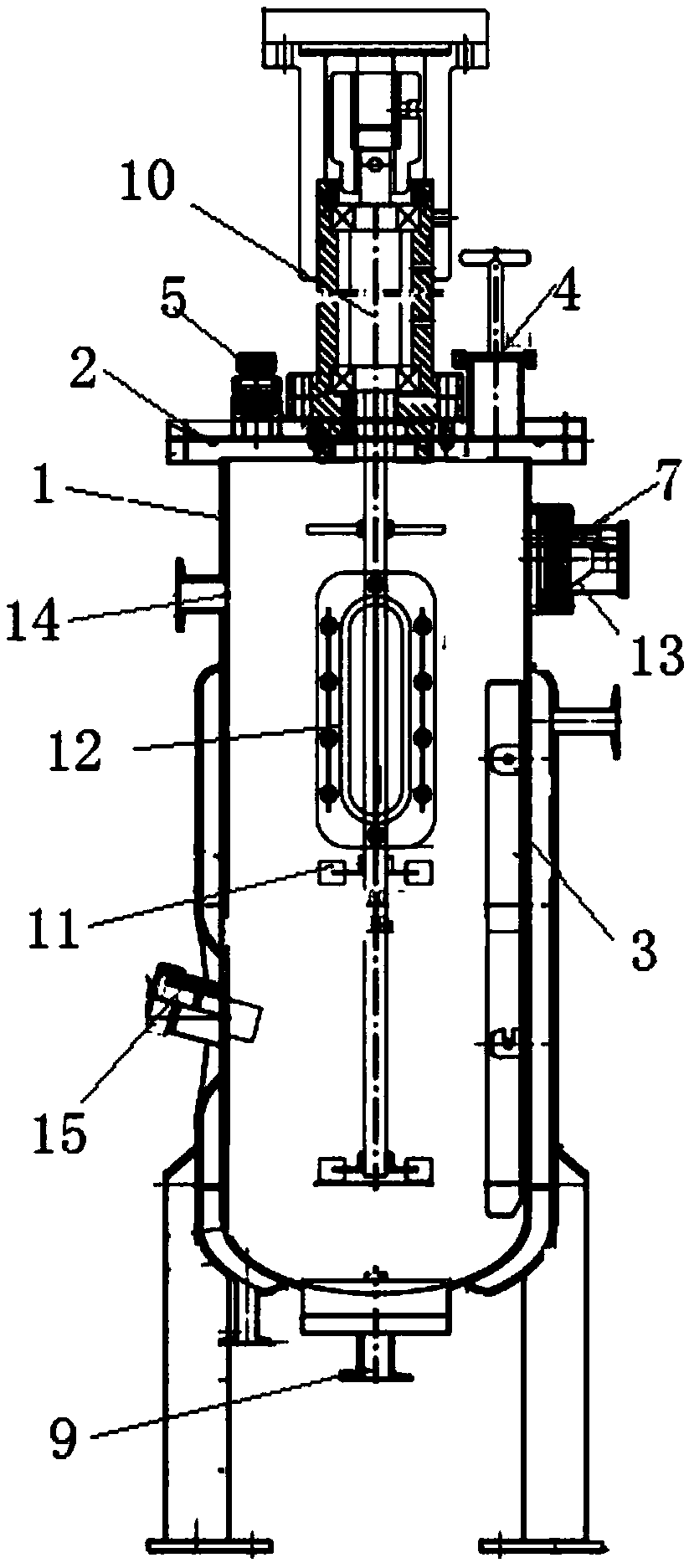

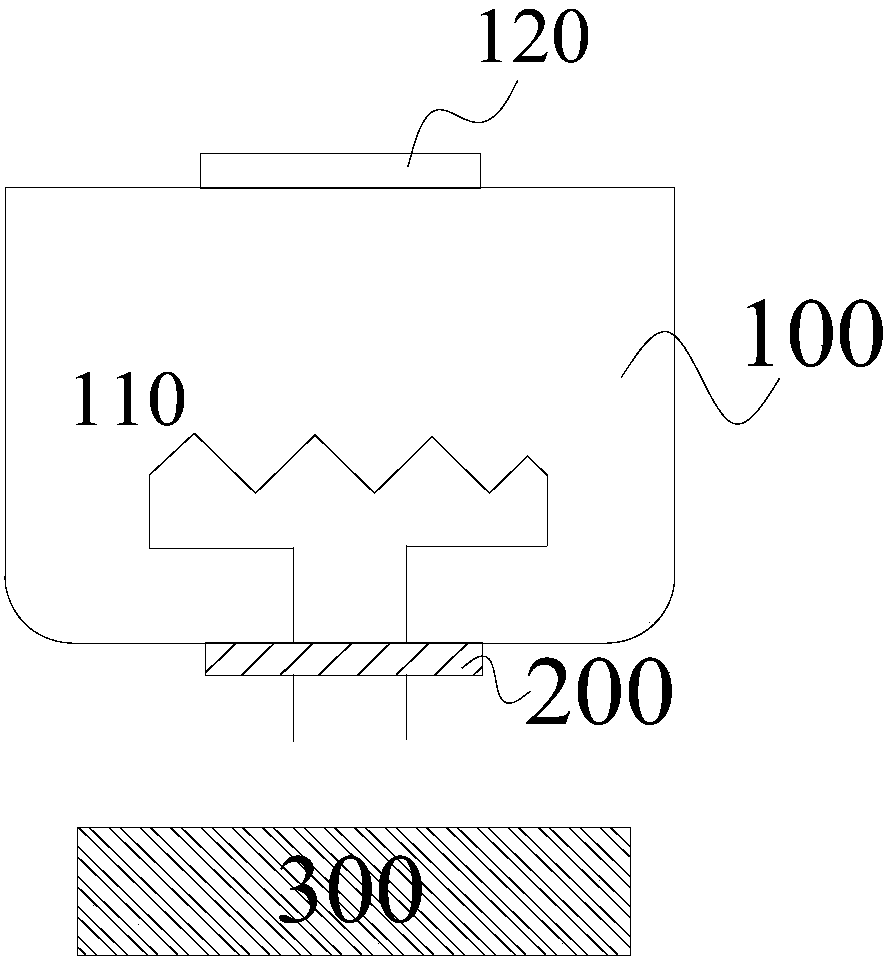

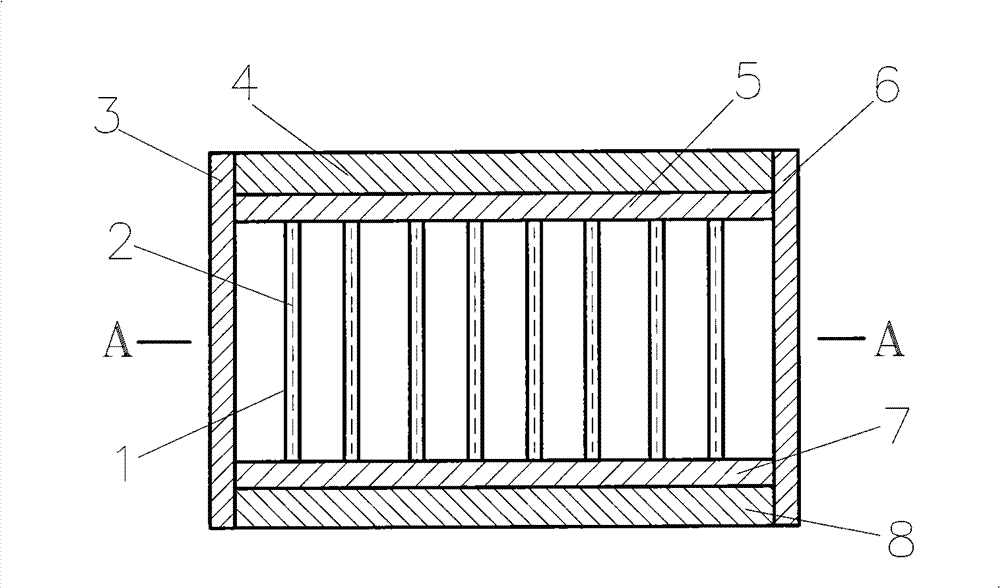

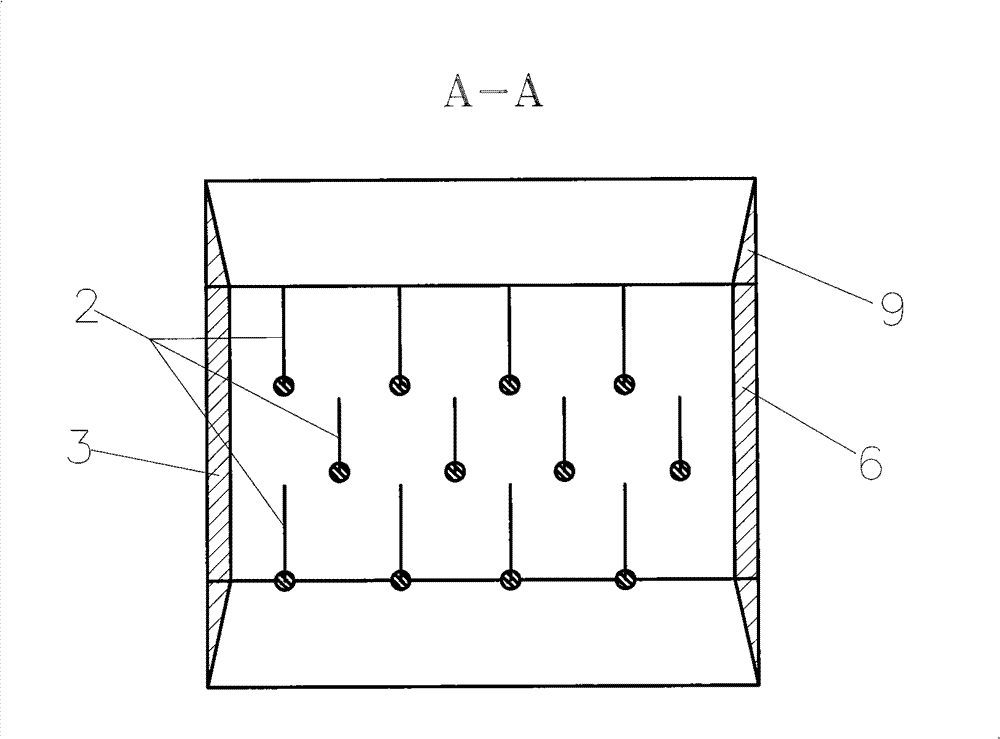

Bioreactor for soil restoration

InactiveCN107937250AEasy to joinEasy to installBioreactor/fermenter combinationsBiological substance pretreatmentsSoil remediationBiochemical engineering

The invention discloses a bioreactor for soil restoration. The bioreactor for soil restoration comprises a tank body, wherein the top of the tank body is provided with a matching cover body; a jacketis welded out of the tank body; a plurality of liquid-adding adapters are arranged on the cover body, and the liquid-adding adapters penetrate the cover body and extend into the tank body; the cover body is further provided with a feeding port, a feed-supplementing port, a spare port and an exhaust port; a feed-supplementing pin is inserted into the feed-supplementing port; an air inlet is formedin one side of the tank body; a through hole is formed in one side of the body; a side-view mirror is sealed in the through hole; a discharge outlet is formed in the bottom of the tank body; a stirring shaft is arranged on the cover body; the upper end of the stirring shaft is driven by a motor, and the lower end of the stirring shaft penetrates the cover body and extends to the lower part of thetank body; a cylindrical microporous screen sleeves the stirring shaft; the inner side of the cover body is provided with an LED illumination lamp with adjustable light intensity and a lamp view mirror; and the side wall of the tank body is provided with an overflow port, a temperature sensor interface, a PH meter interface and a pressure gauge port. The bioreactor for soil restoration is simple in structure, convenient to use and good in restoration effect.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

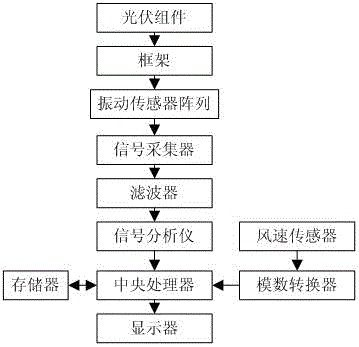

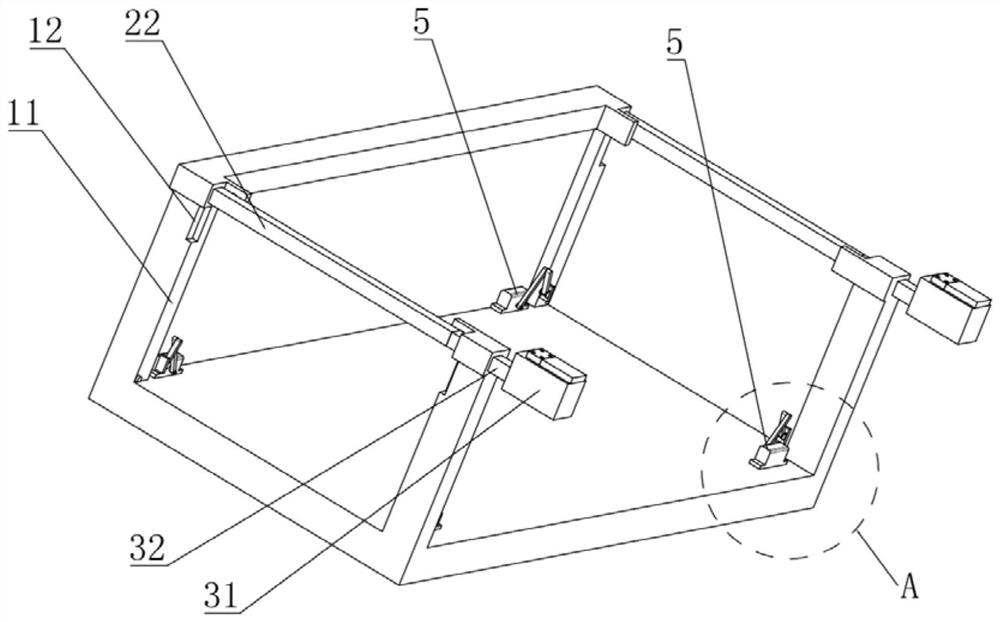

Photovoltaic assembly vibration detection and photovoltaic assembly control device

InactiveCN105846779ASafe and secure settingsSet stablePhotovoltaic monitoringSubsonic/sonic/ultrasonic wave measurementVibration detectionElectric signal

The invention discloses a photovoltaic assembly vibration detection and a photovoltaic assembly control device, comprising a photovoltaic assembly arranged on a framework, a vibration sensor array, a signal collector, a signal analysis instrument, a storage device, a central processing device and a displayer. The vibration sensor array is used for detecting vibration of the framework to obtain an analog signal; the signal collector is used for collecting the analog signal to obtain an electric signal; the signal analysis instrument is used for analyzing the electric signal and calculating and determining an average vibration frequency; the storage device is used for pre-storing a vibration level determination table composing of preset vibration frequency and a corresponding vibration level; the central processor is used for mapping the average vibration frequency to the retrieved vibration level determination table, determining the corresponding vibration level according to the average vibration frequency and outputting a control signal; and the displayer is used for displaying the vibration level according to the control signal. The photovoltaic assembly vibration detection and the photovoltaic assembly control device can realize automation detection and analysis and can accurately detect the vibration condition.

Owner:SUZHOU XUANHE IOT TECH

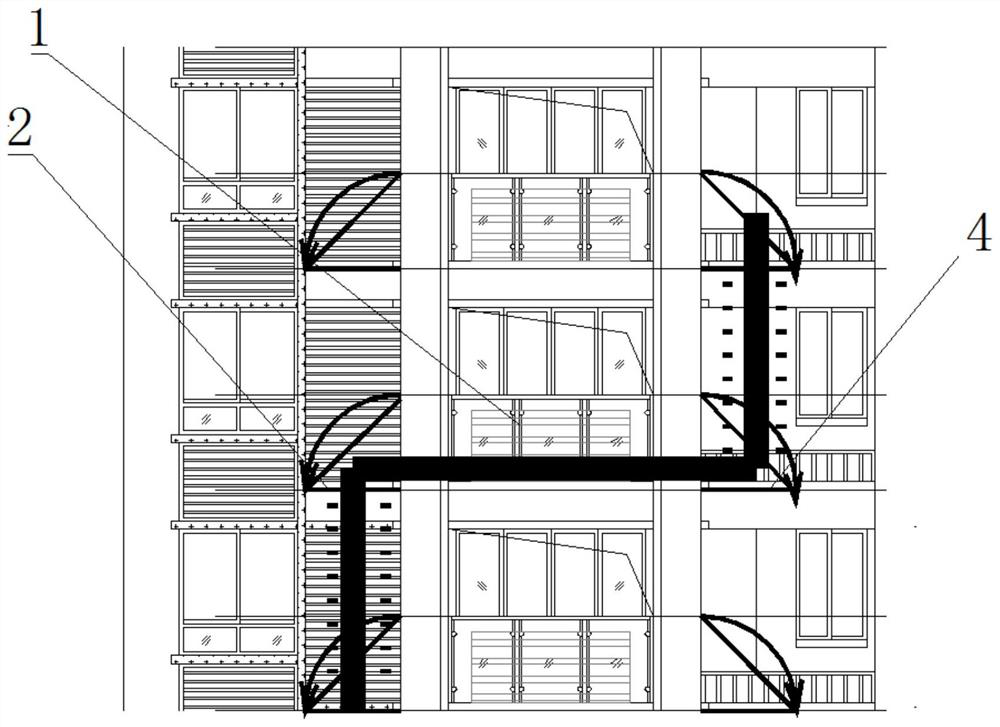

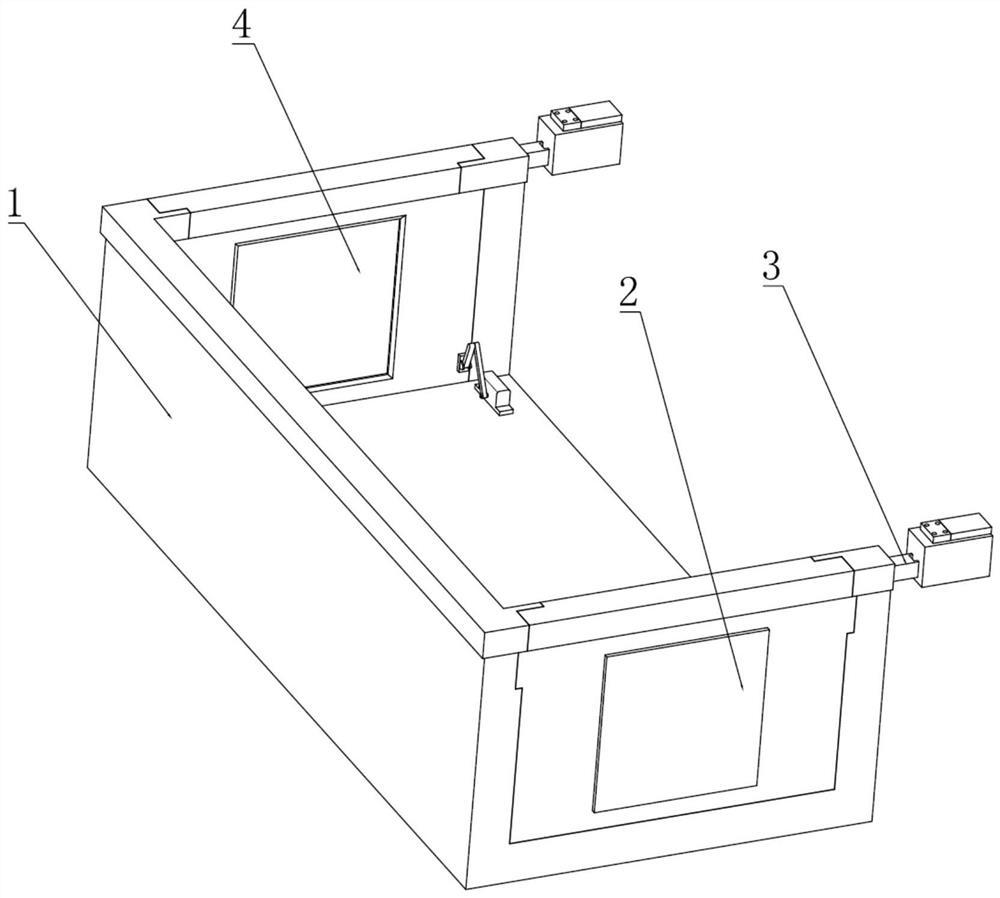

A fire-linked balcony railing escape channel

ActiveCN110694190BSafe and secure settingsImprove structural strengthBuilding rescueFire alarmsFire detectorArchitectural engineering

Owner:CHINA RAILWAY TIMES BUILDING DESIGIN INST CO LTD

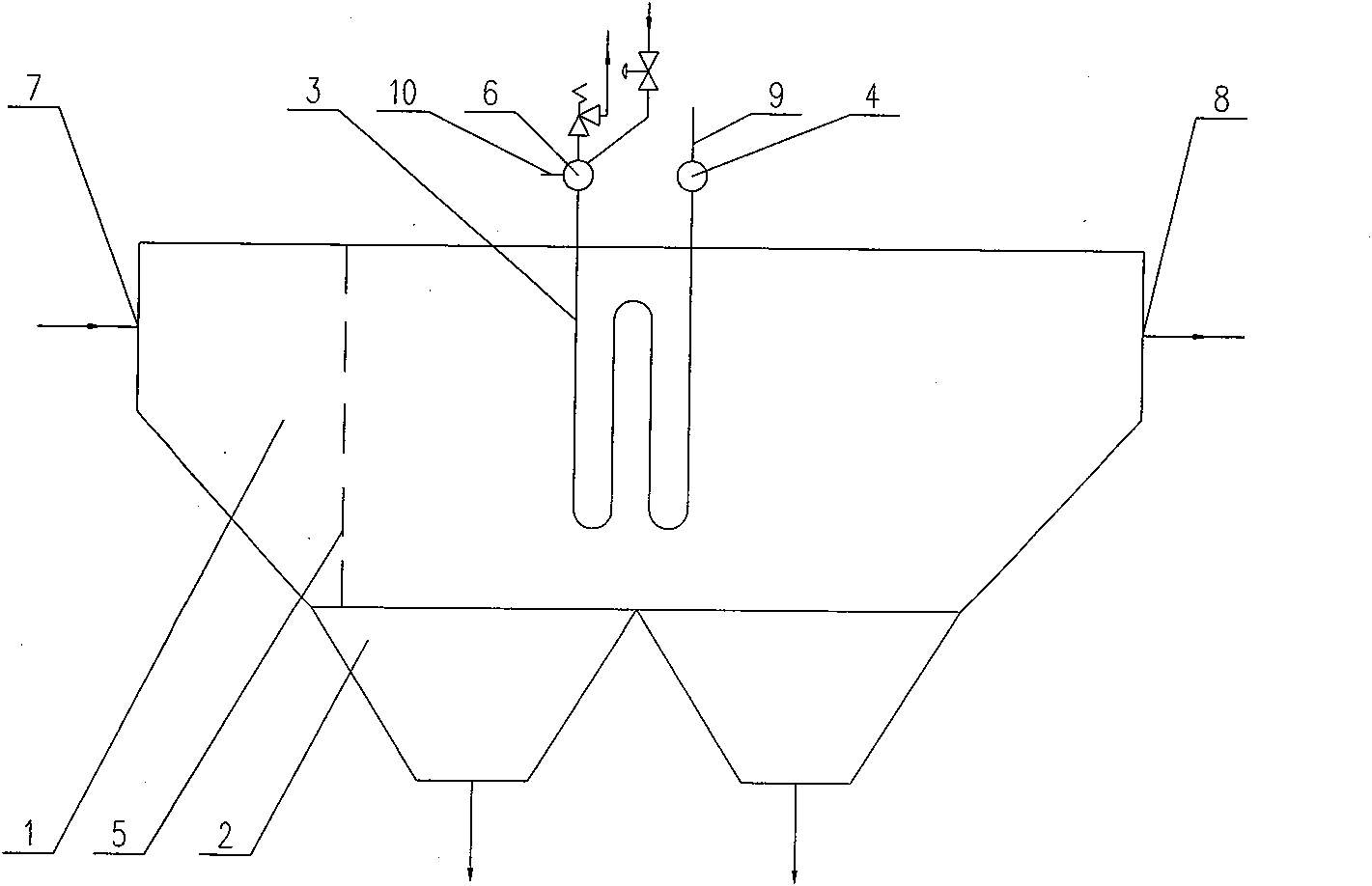

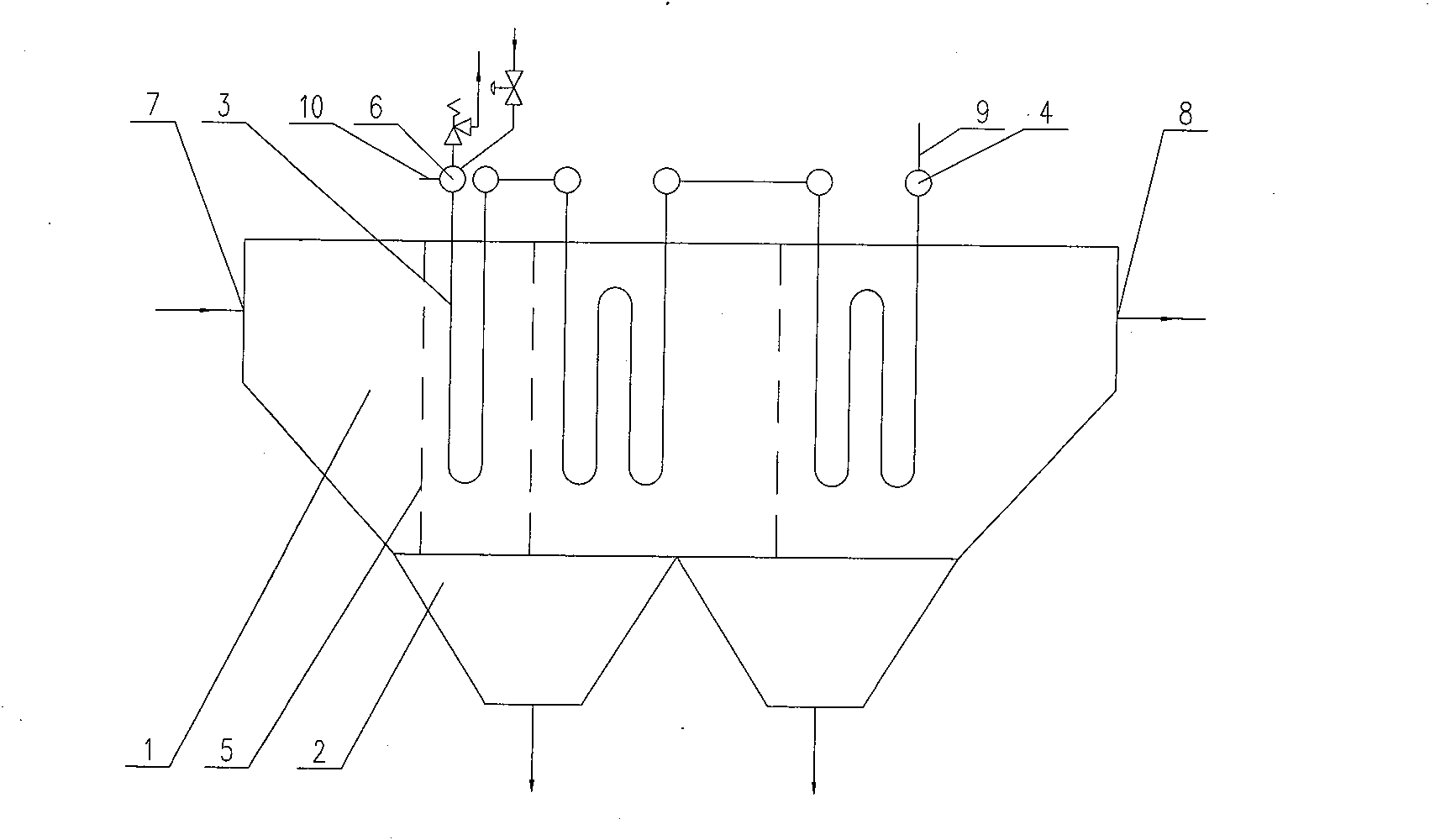

Integrated fume dustfall stem superheater

InactiveCN101551100AGood dust removalGood overheating effectDispersed particle separationIncreasing energy efficiencySmall footprintSuperheater

The invention relates to an integrated fume dustfall stem superheater, and belongs to the mechanical equipment, comprising shell, deposition chamber, tube bundle, tube bundle channel, traverse baffle, safety valve and steam temperature regulating valve. A fume inlet and a fume outlet are arranged on the shell, the shell is provided with a heat exchange screen comprising tube bundle, and two ends of tube bundle passing through the shell are connected with the opposite tube bundle channel, respectively. The traverse baffle is positioned in the shell, steam inlet pipeline and steam outlet pipeline are arranged on the opposite tube bundle channel, respectively. The safety valve and the steam temperature regulating valve are mounted on the tube bundle channel of steam outlet pipeline. The structure of the device can be vertical type, horizontal type or slanting type. The device has advantages of fume dustfall and steam superheating effects, simple structure, convenient installation and disassembly, safe and reliable operation, wear resistance, long service time, small space, low investment cost, etc.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

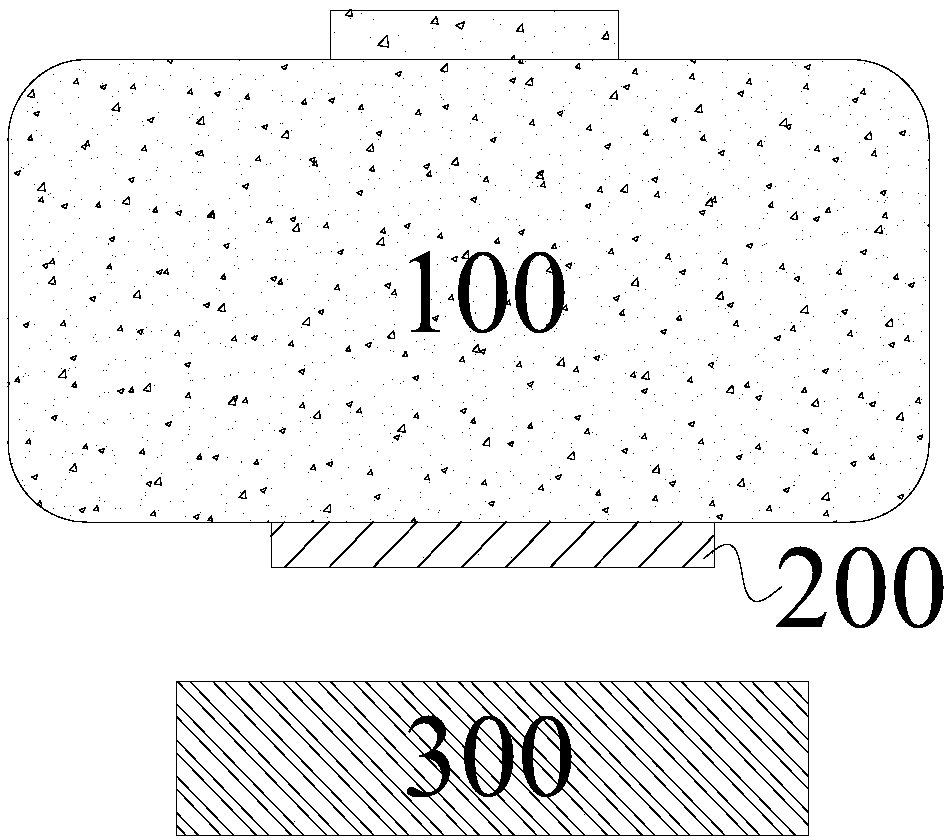

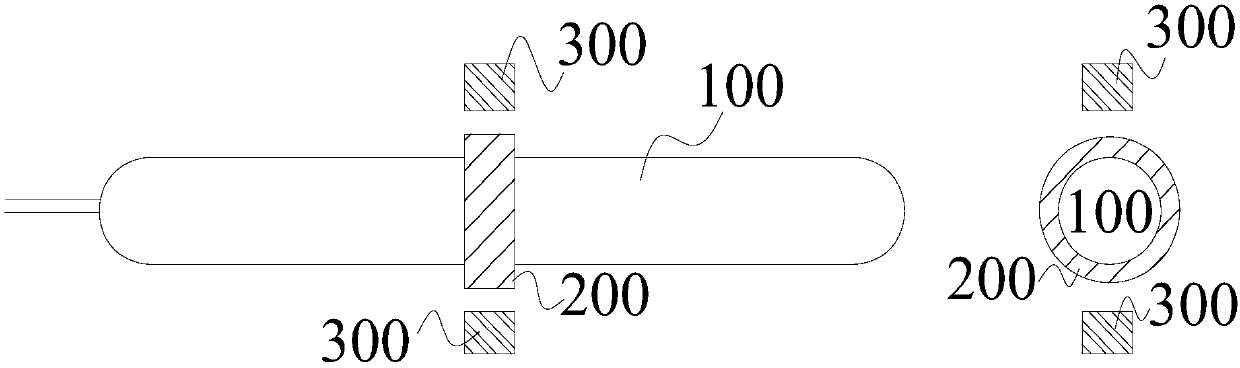

Life electric appliance, and descaling method for water storage container in life electric appliance

ActiveCN109556296ASafe and secure settingsFluid heatersHollow article cleaningElectricityEngineering

The invention provides a life electric appliance, and a descaling method for a water storage container in the life electric appliance. The life electric appliance includes: a water storage container,being provided with a magnetostrictive member; and an alternating magnetic field generating device for supplying an alternating magnetic field to the magnetostrictive member. The life electric appliance is provided with the magnetostrictive member on the water storage container, and the magnetostrictive member can vibrate under the action of the alternating magnetic field provided by the alternating magnetic field generating device, and the magnetostrictive member transmits the vibration to the outer wall of the water storage container. Thus, deposition amount of scale on the water storage container can be greatly reduced, thereby improving long-term service life of the life electric appliance, and the magnetostrictive member has better fatigue resistance, longer service life than those ofa piezoelectric ceramic piece. Compared with an iron piece vibration method, a magnetostrictive vibration method does not have a technical problem of mechanical fatigue of a vibrating piece, and vibration space is not especially reserved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

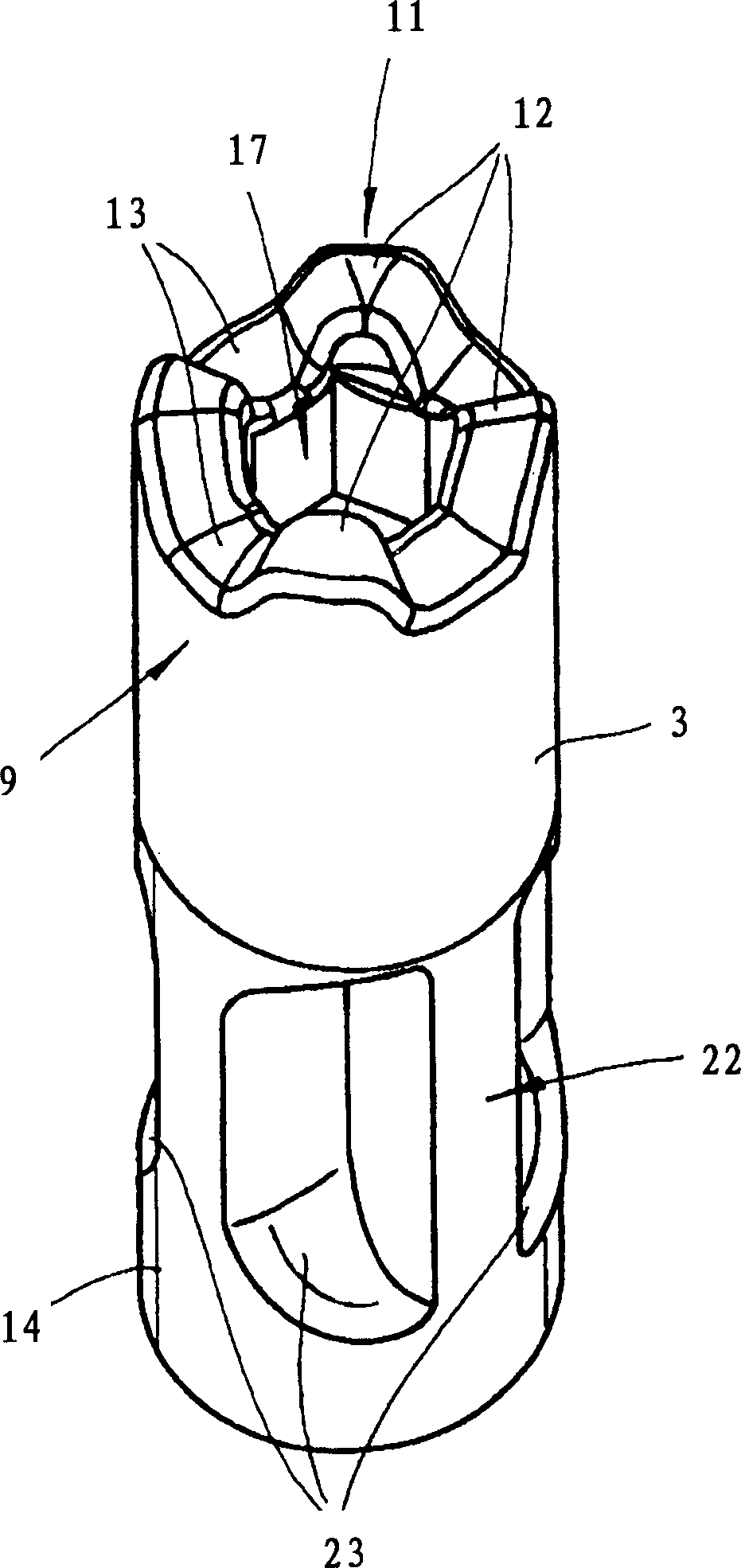

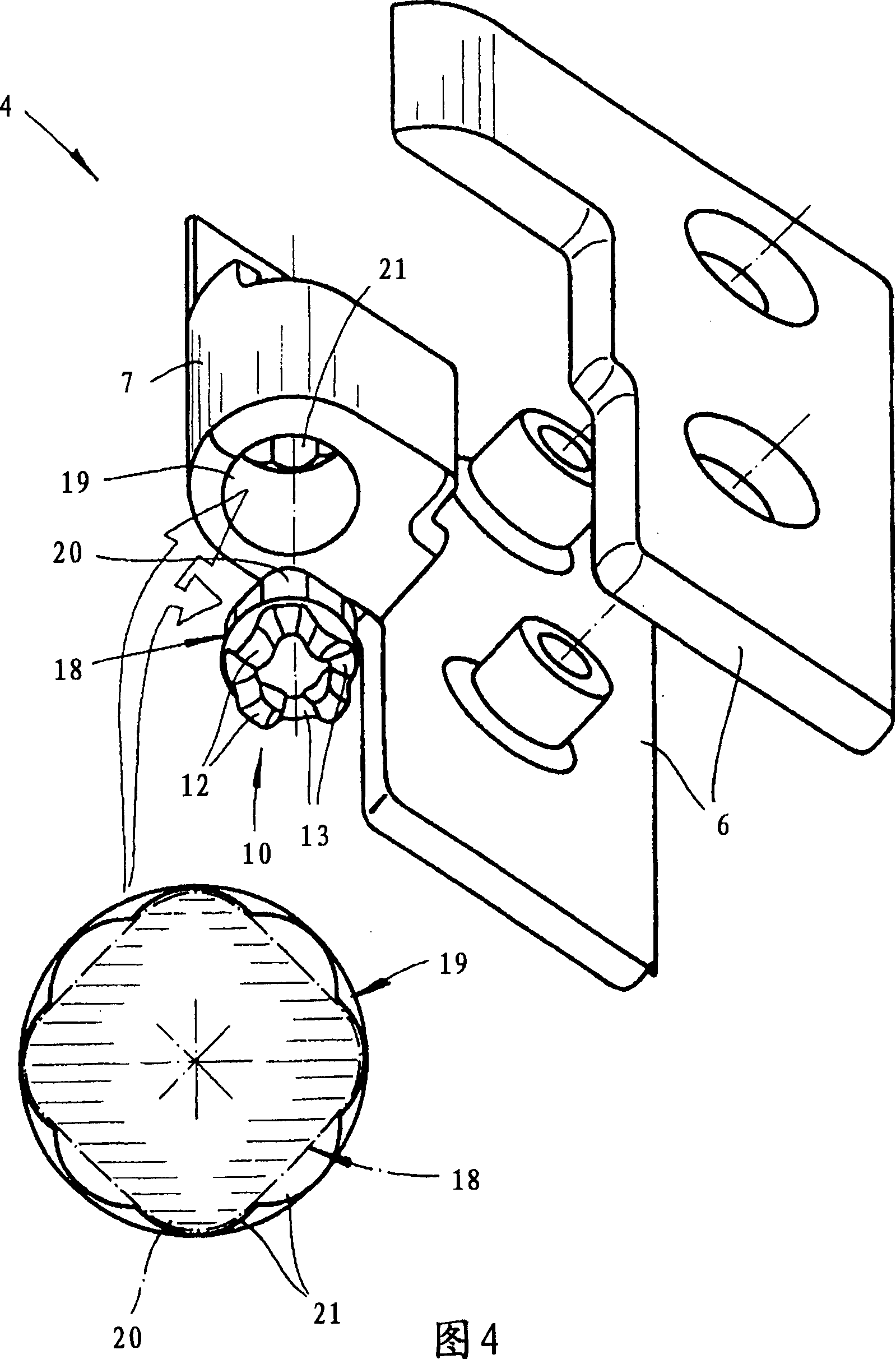

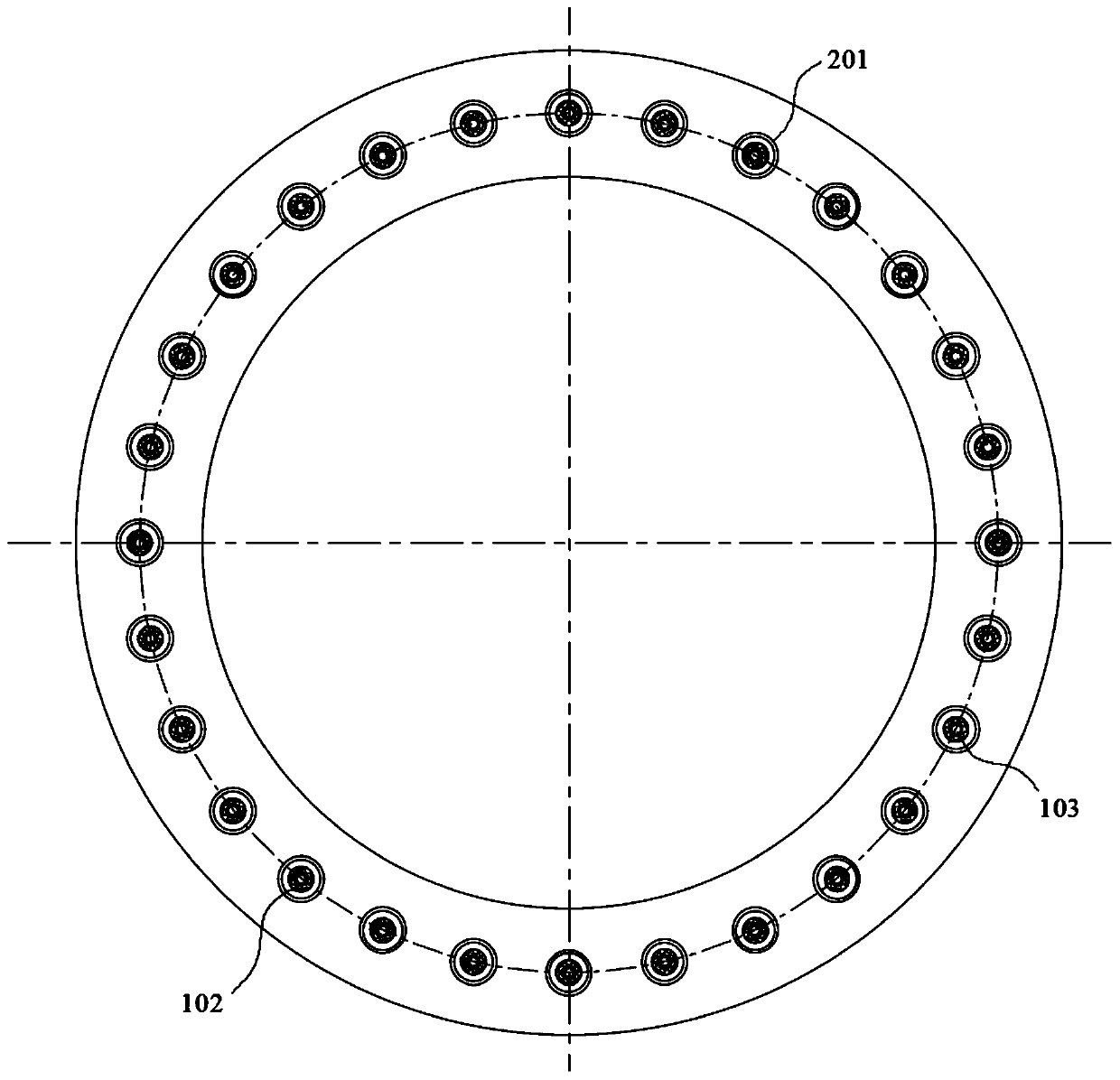

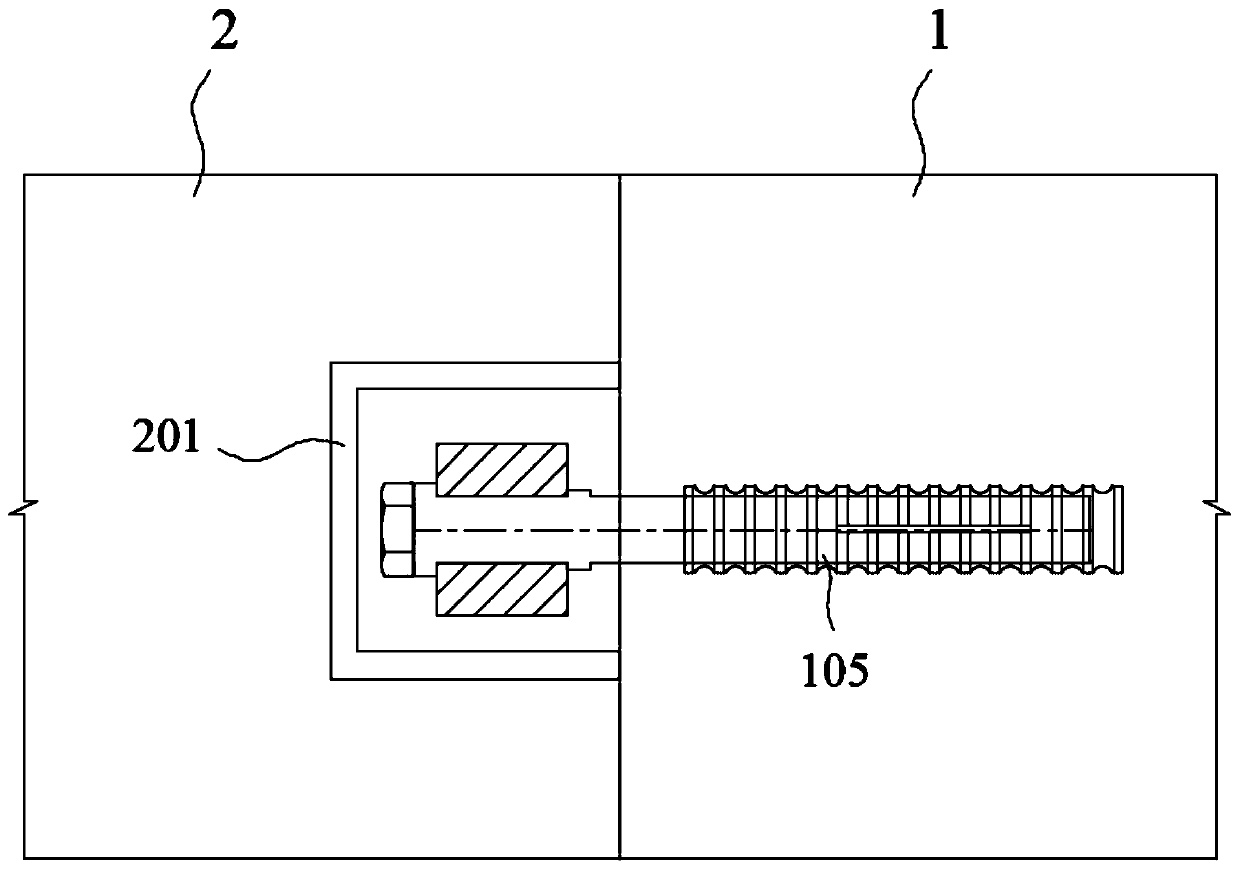

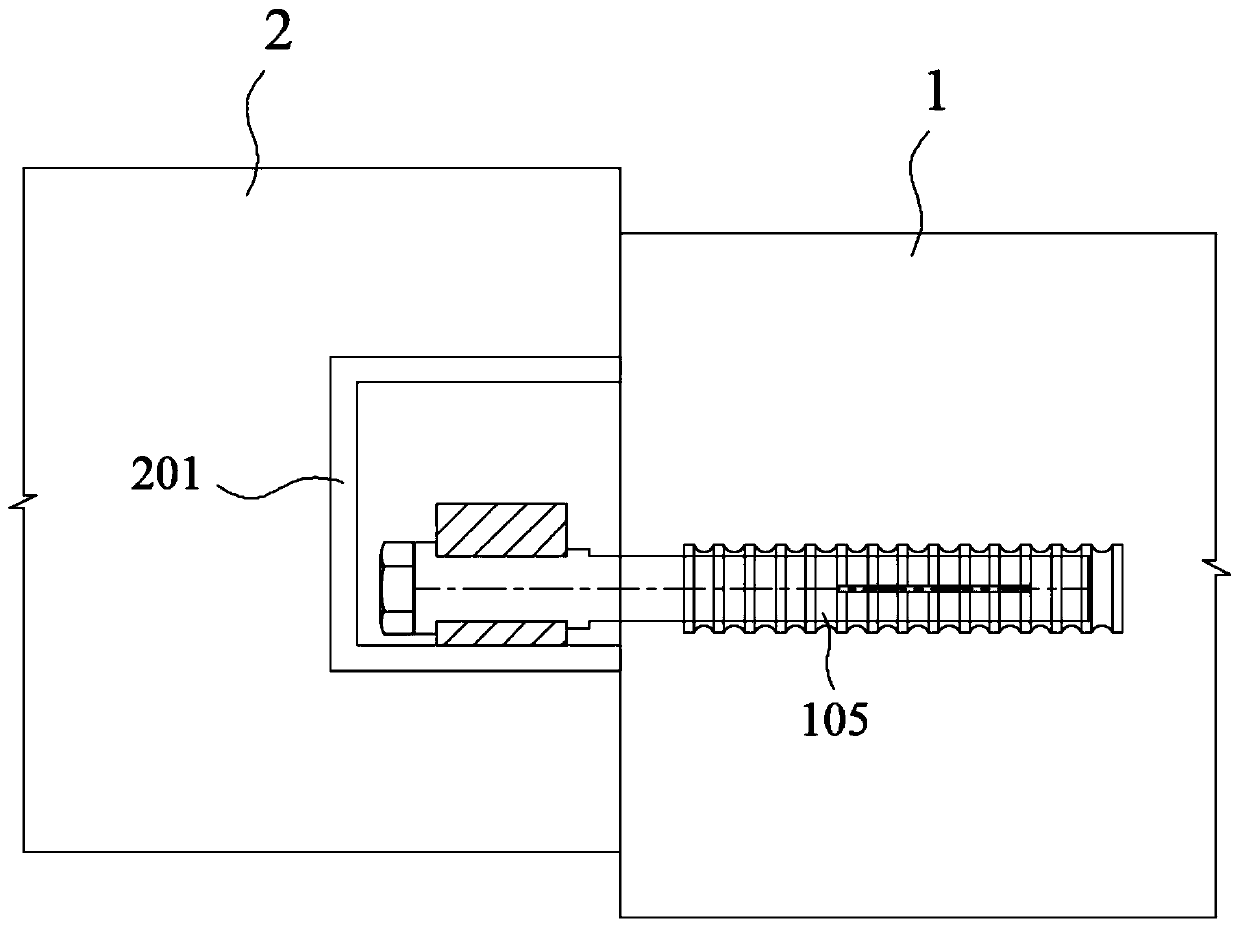

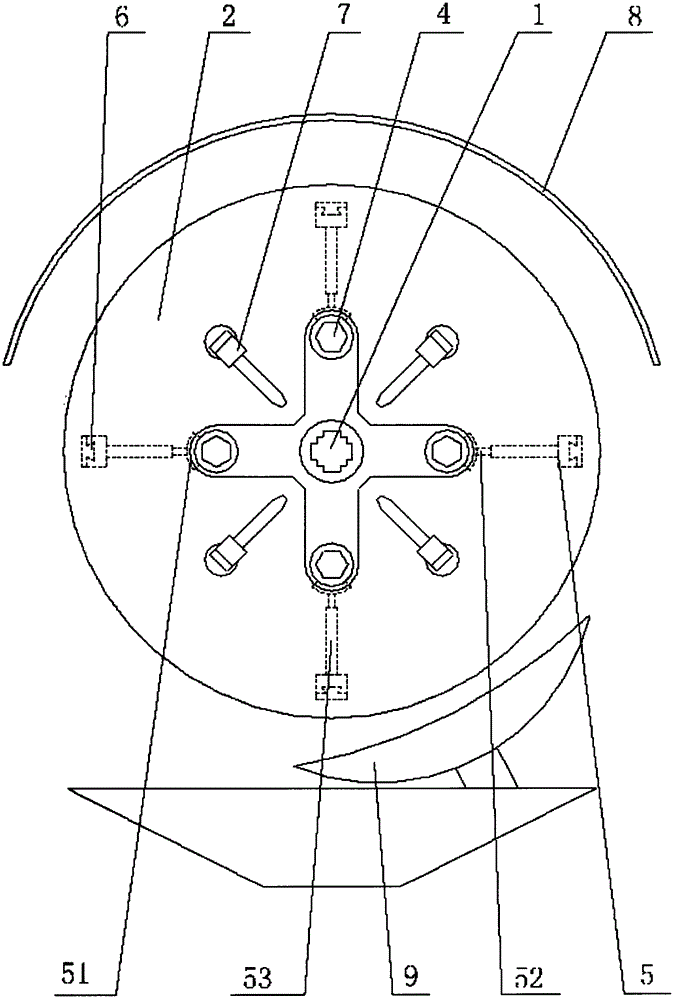

CNC machine tool

ActiveCN105436963BSafe and secure settingsReasonable settingPositioning apparatusMaintainance and safety accessoriesNumerical controlMachine tool

The invention provides a numerical control machine tool. The numerical control machine tool comprises a workpiece clamping mechanism and a cutter clamping mechanism, wherein the cutter clamping mechanism comprises a positioning shaft, the positioning shaft is sleeved with a cutter disc, at least two cutter movement grooves are formed in the cutter disc, and cutters are arranged in the cutter movement grooves in a penetrating mode in the axial direction of the cutter disc; the positioning shaft is located at the center of the cutter disc, a cuter pushing mechanism used for pushing the cutters to the positioning shaft from the direction away from the positioning shaft is arranged in the cutter movement grooves, the cutter pushing mechanism is provided with a cutter locking / automatic unlocking mechanism, a cutter restoration mechanism used for pulling the cutters to be close to the outer edge of the cutter disc along the cutter movement grooves is arranged in the cutter movement grooves, and the cutter pushing mechanism is provided with a sliding guide rail mechanism and a pushing and sliding driving mechanism; a cutter capturing mechanism is arranged on the positioning shaft. The numerical control machine tool has the advantages that multiple groups of cutters are arranged in the cutter disc in a hidden mode, using is safe, actuating units used for cutter change are reasonably arranged, and cutter change is stable and smooth.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

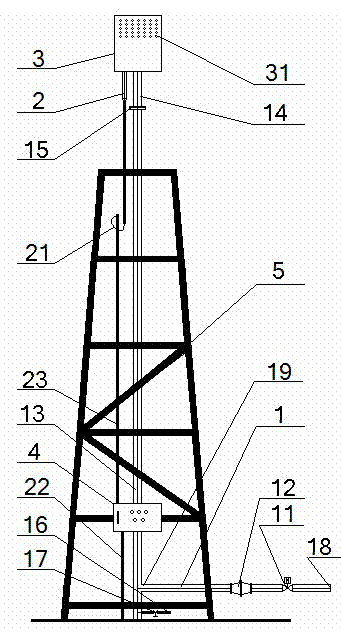

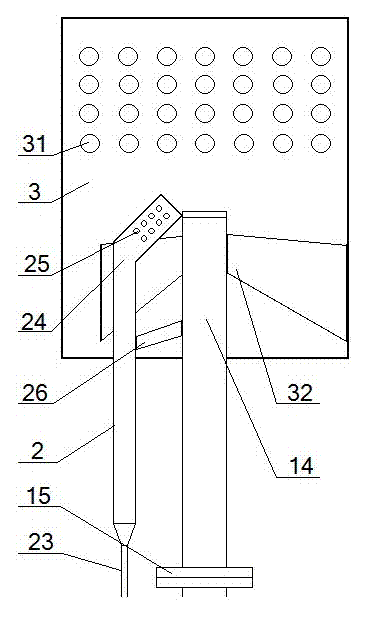

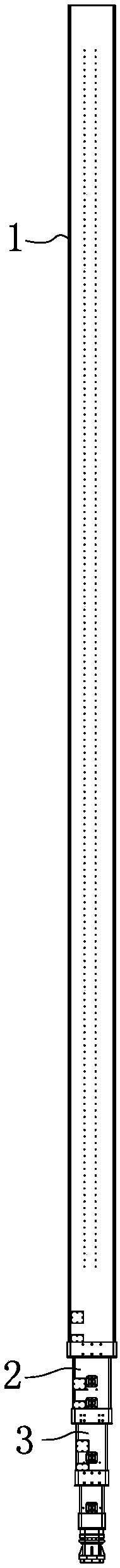

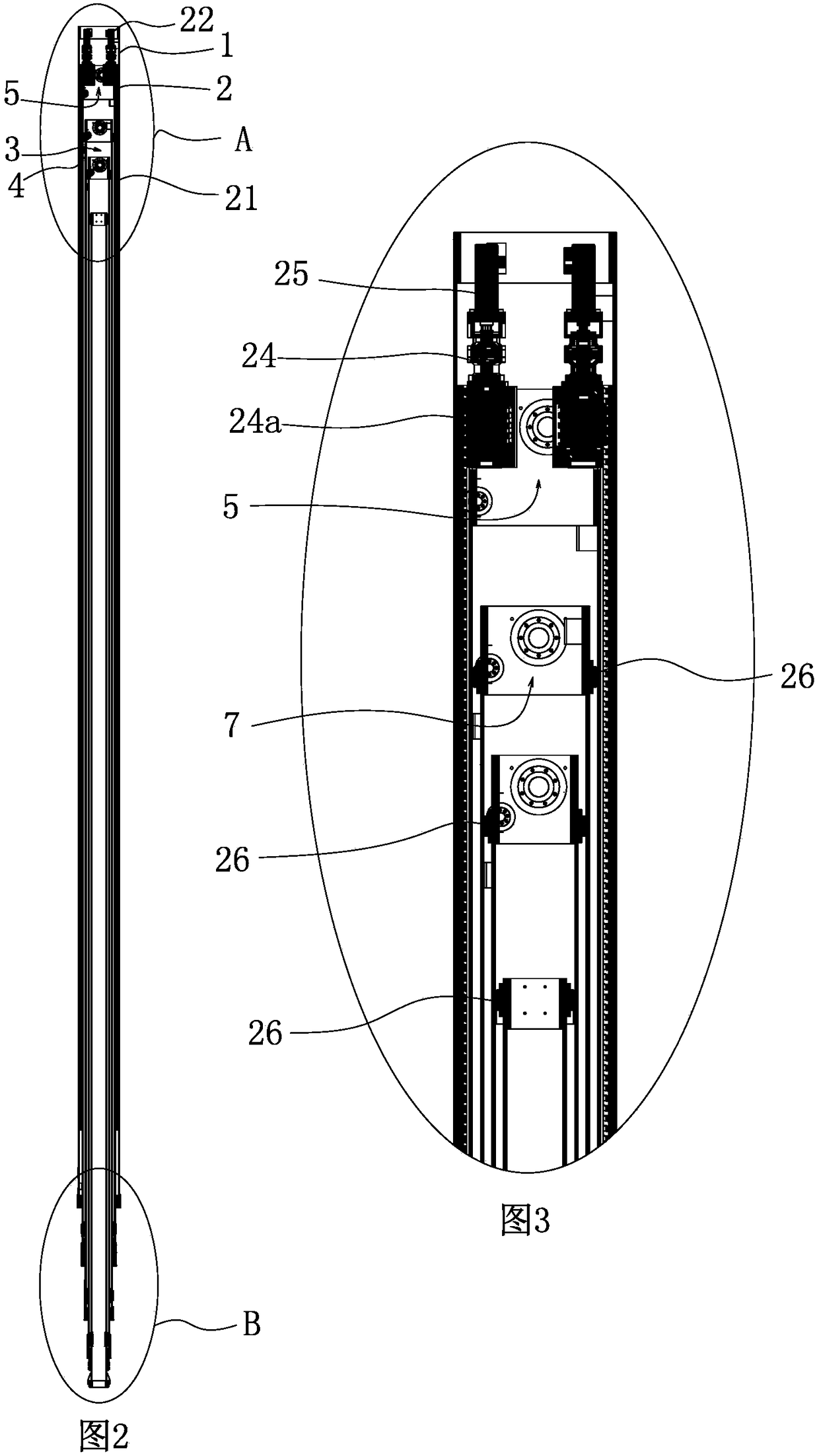

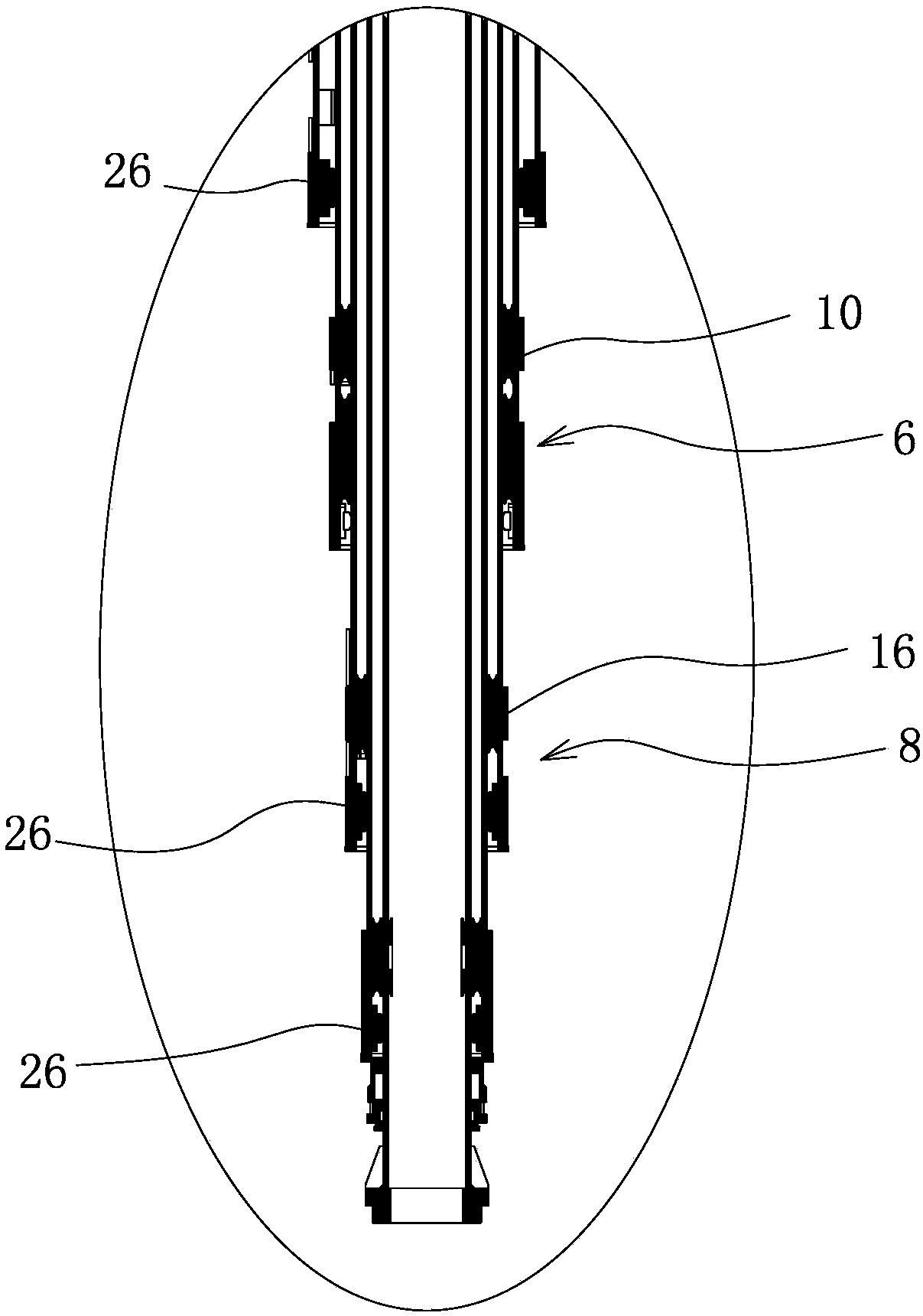

Meshing-telescopic-type telescopic drilling rod assembly

InactiveCN108104731AEasy to adjustReliable and accurate drilling processDrilling rodsDrilling casingsEngineeringPetroleum engineering

The invention belongs to the technical field of buildings and relates to a meshing-telescopic-type telescopic drilling rod assembly. The meshing-telescopic-type telescopic drilling rod assembly comprises an exterior drilling rod located on the outermost portion. A power driving rod meshing with the inner wall of the exterior drilling rod and capable of moving up and down in the axial direction ofthe exterior drilling rod is sleeved with the exterior drilling rod. The telescopic drilling rod assembly is an independent mechanism and can be mounted on certain common large and medium engineeringmachines to be directly used without a special carrier, if the hole diameter of a drilled hole needs to be replaced, a drilling bit on a main drilling rod can be replaced directly, and the drilling rod mechanism does not need to be replaced.

Owner:周兆弟

Control system of intelligent charging pile and charging method of storage battery

ActiveCN107161028BSimple processMonitor the charging processCharging stationsElectric powerControl systemMechanical engineering

The invention provides a control system of an intelligent charging pile and a charging method of a storage battery. The control system of the intelligent charging pile comprises an operation terminal, a processing terminal and the charging pile, wherein the operation terminal receives a charging instruction transmitted by a user, and transmits the charging instruction to the processing terminal; the processing terminal analyzes the charging instruction to determine the charging pile used for charging a to-be-charged battery; the charging pile detects voltage of the to-be-charged battery, receives a charging mode transmitted by the processing terminal, and determines a charging scheme for the to-be-charged battery according to the voltage and the charging mode. In the control system of the intelligent charging pile, the charging pile can analyze the voltage and the charging mode of the to-be-charged battery to determine the charging scheme for the to-be-charged battery, so that the determined charging scheme is more scientific; a charging process is safer; the technical problems of low safety and poorer intelligent degree of the conventional charging pile during charging of the to-be-charged battery are alleviated.

Owner:罗腾

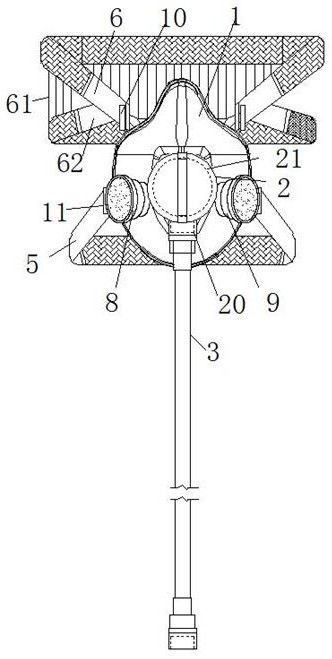

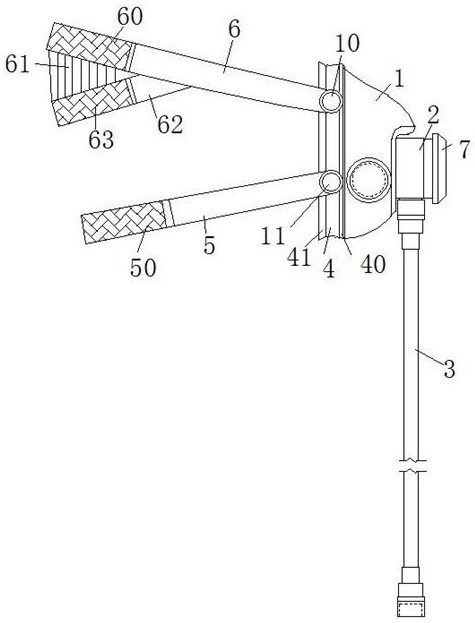

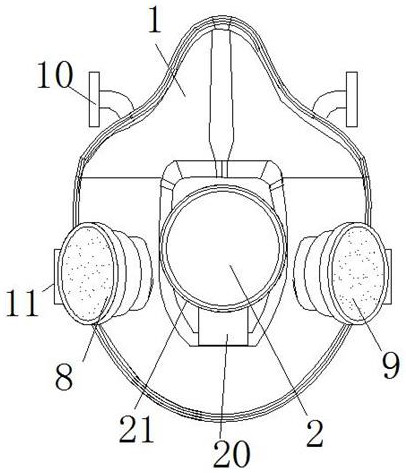

Anti-infection breathing endoscopy auxiliary device

InactiveCN114305306AFacilitate endoscopic respiratory examinationSafe and secure settingsBronchoscopesLaryngoscopesRespiratory capacityEngineering

The anti-infection respiratory endoscopy auxiliary device comprises a mask, an air outlet pipe, a rear lower bandage, a rear upper bandage, a left air inlet pipe and a right air inlet pipe, an auxiliary sleeve is arranged in the middle of the front side face of the mask, an air outlet pipe opening is formed in the lower end of the auxiliary sleeve, and the upper end of the air outlet pipe is twisted outside the air outlet pipe opening; a rear upper bandage is tied between the two groups of upper hanging buckles, and a rear lower bandage is tied between the two groups of lower hanging buckles; a left air inlet pipe is installed outside the left air inlet, and a right air inlet pipe is installed outside the right air inlet. The detachable bandage is arranged, the mask can be conveniently and elastically bound to the back side of the head of a patient, binding is safe and stable, meanwhile, the air inlet pipes are installed on the left side and the right side of the mask, air inlet is rapid, the air inlet amount completely meets the requirement for the respiratory capacity of the patient, and meanwhile the arranged air outlet pipe is long enough and can conveniently extend downwards to be connected with peripheral disinfection and purification equipment; arm spreading during examination of doctors is prevented from being affected, and the medical examination bed is safer and more convenient to use.

Owner:NANYANG SECOND GENERAL HOSPITAL

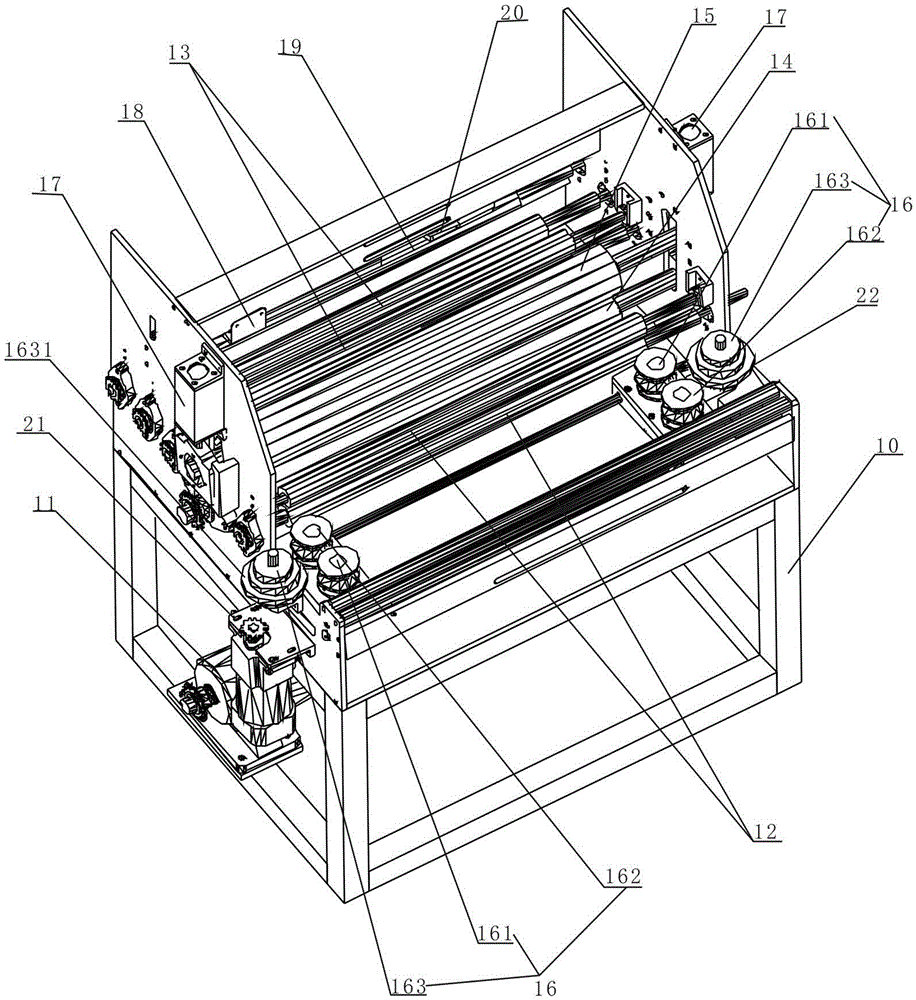

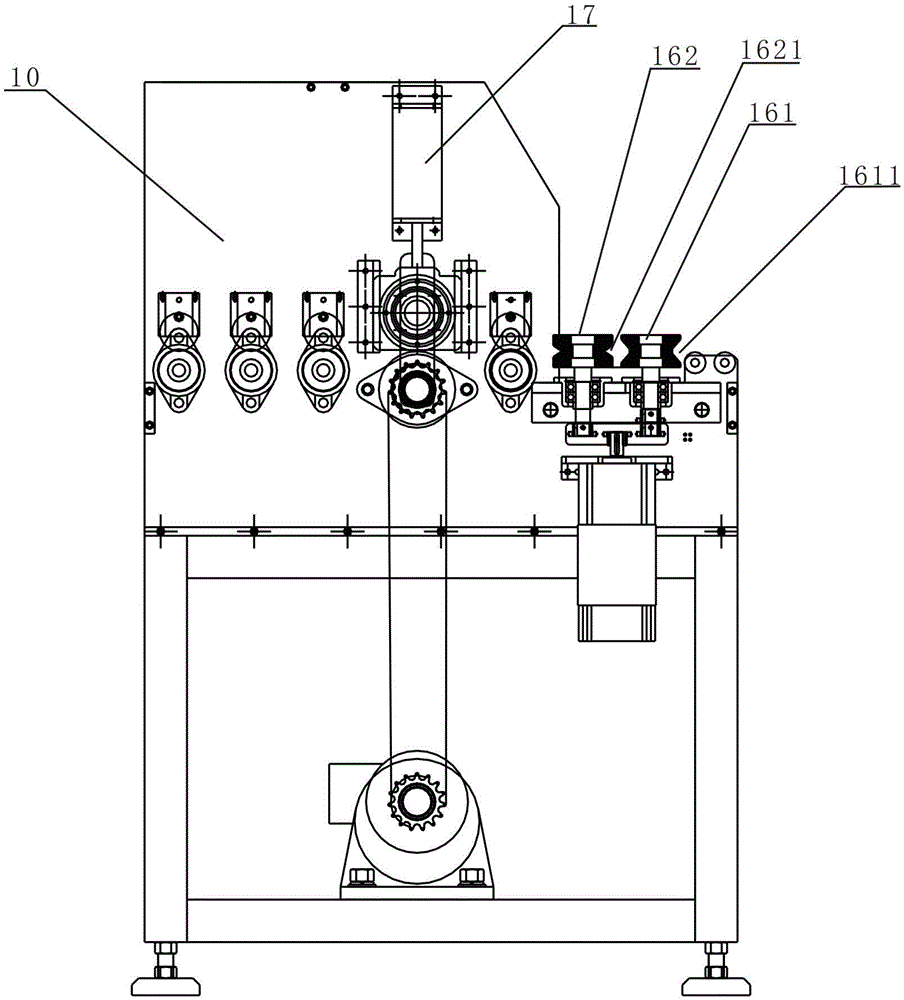

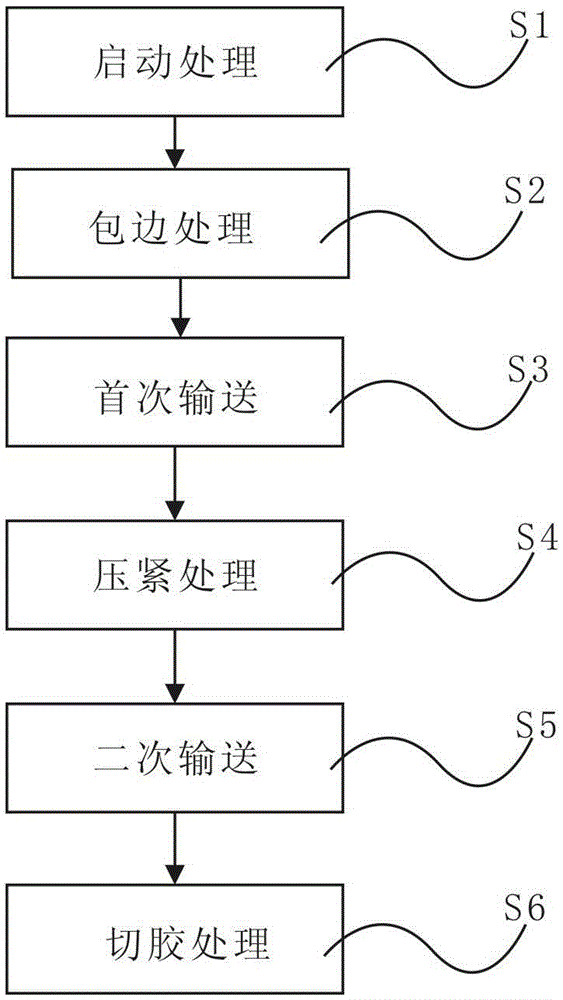

Automatic hemming equipment and method for pcb board

The invention discloses an automatic edge covering device and method for a PCB (printed circuit board). The device comprises a frame, a conveying wheel variable frequency motor, a first conveying wheel set, a second conveying wheel set, a middle lower rubber pressing wheel, a middle upper rubber pressing wheel, a rubber coating device, two rubber pressing cylinders, a rubber cutting sensor, a rubber cutting blade and a rubber cutting cylinder, the middle upper rubber pressing wheel is positioned above the middle lower rubber pressing wheel, the rubber coating device is used for covering edges of the PCB, the two rubber pressing cylinders are used for controlling the middle upper rubber pressing wheel to move up and down, the rubber cutting sensor and the rubber cutting blade are mounted on the frame and arranged at the tail end of the second conveying wheel set, and the rubber cutting cylinder is used for controlling the rubber cutting blade to automatically cut rubber. The conveying wheel variable frequency motor is respectively connected with the first conveying wheel set, the second conveying wheel set and the middle lower rubber pressing wheel in a driving manner, and the PCB with the edges covered is conveyed to a position below the rubber cutting blade sequentially by the first conveying wheel set, the middle lower rubber pressing wheel and the second conveying wheel set. The device has the advantages of convenience in operation, simple process, high safety factor, low labor intensity, low production cost, high automation degree and the like.

Owner:SHENZHEN YONGNENG MACHINERY

Automatic glue removal equipment and method

InactiveCN103522728BReduce pollutionReduce labor costsLamination ancillary operationsLaminationAdhesive beltEngineering

Owner:SHENZHEN YONGNENG MACHINERY

Chatter wind power generation apparatus

The invention relates to a chatter wind power generation apparatus. Two separated and opposite magnetic plates are connected by a magnetic conduction plate to be circulated into a frame-shaped magnetic field with the quadrangular cross section, the magnetic plates are single permanent magnetic plates, or are split into a plate shape by a plurality of permanent magnetic plates, or are split into aplate shape by a plurality of permanent magnetic plates and magnetic conduction bodies, or are electric magnetic plates, a plurality of electric conduction sheets vertical to magnetic force lines of the magnetic field are arranged in the frame-shaped magnetic field, an output electric conduction line is connected on the electric conduction sheets, and the output electric conduction line is externally connected with a controller or an inverter with the current gathering, rectification and voltage regulation functions. The chatter wind power generation apparatus has simple structure, uses the turbulent fluctuation feature of the wind for generating the electricity, and has the advantages of low cost, high efficiency and easy popularization.

Owner:刘新广

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com