Method of generating metal zinc in stable waste through spinel

A waste and spinel technology, applied in the field of metal zinc, can solve the problems of erosion, huge energy consumption, low content of valuable metals, etc., and achieve good anti-leaching performance, optimized dosage ratio, and good anti-leaching performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The red mud from the aluminum refinery (mainly containing Fe 2 o 3 and Al 2 o 3 ) was dried at 120°C for 10 hours for later use.

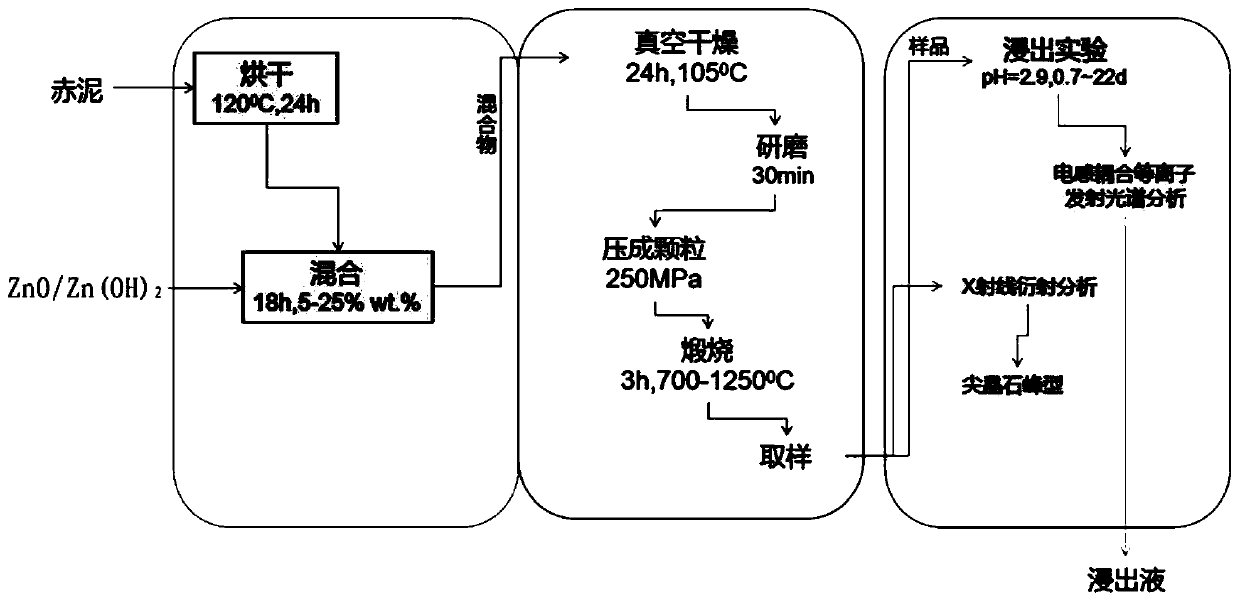

[0031] As a method for stabilizing zinc metal in waste through the generation of spinel as an embodiment of the present invention, the method comprises the following steps:

[0032] (1) Utilize XRF spectrum analysis to measure the components contained in the red mud, and determine the content of iron oxide in the red mud;

[0033] (2) According to the weight ratio, mix the waste containing ZnO and the dried red mud, and use a ball mill to mill at 60rpm for 18h, dry the sample mixture at 105°C for 24h, and then grind it with an agate mortar 10min, further homogenization;

[0034] (3) the above gained sample is pressed into pellets of φ 20mm under a pressure of 250MPa;

[0035] (4) Calcining for 3 hours at a temperature of 1100°C and a temperature rise and fall rate of 10°C / min;

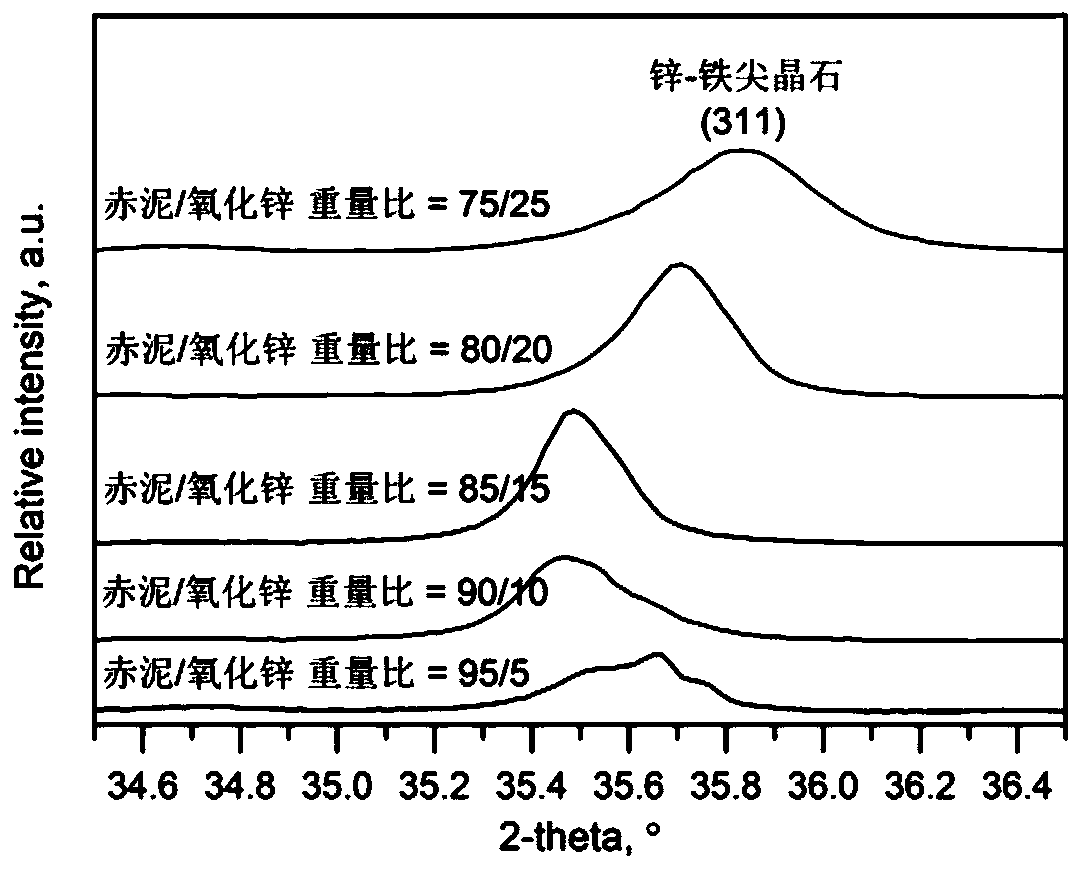

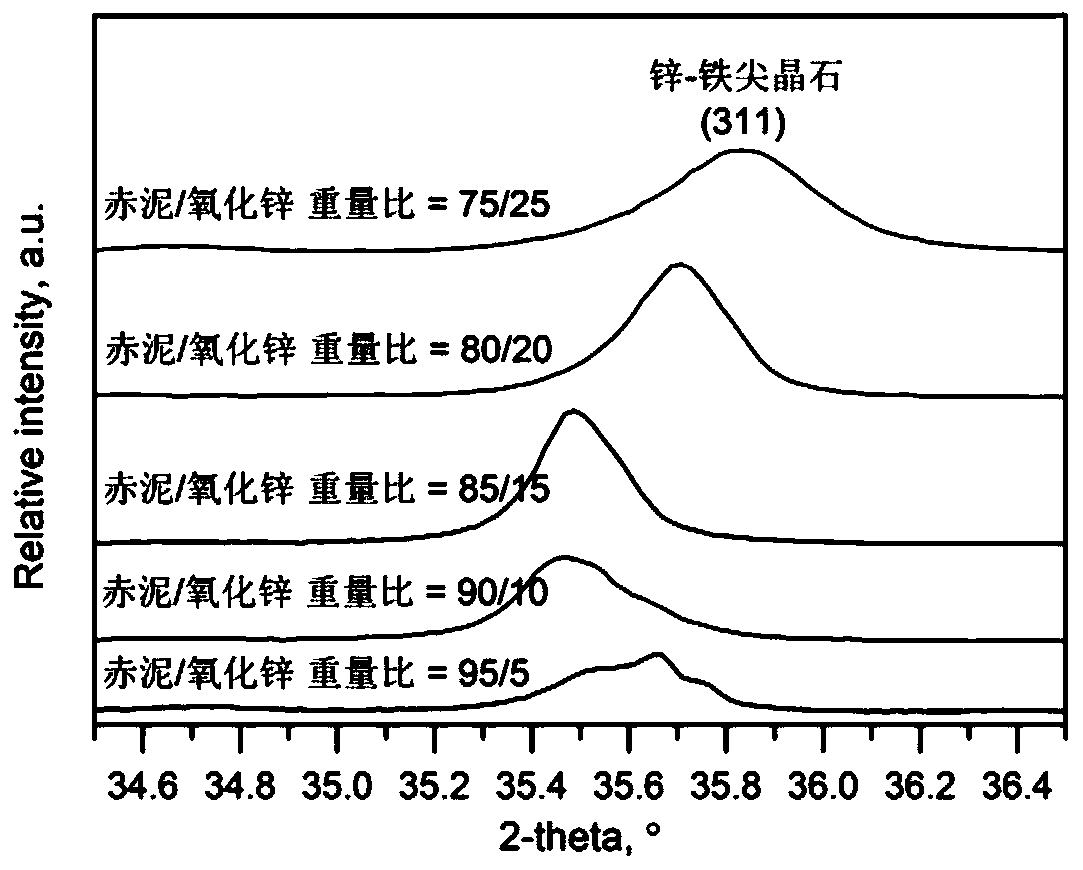

[0036] Wherein, the weight ratio of ZnO and iron oxide i...

Embodiment 2

[0038] As a method of stabilizing metallic zinc in waste through the generation of spinel as an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: the weight ratio of ZnO and iron oxide in the dried red mud is 10 %.

Embodiment 3

[0040] As a method of stabilizing metallic zinc in waste through the generation of spinel as an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the weight ratio of ZnO and iron oxide in the dried red mud is 15 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com