Patents

Literature

86 results about "Fall rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fall in the exchange rate is known as a depreciation in the exchange rate (or devaluation in a fixed exchange rate system). It means the currency is worth less compared to other countries. When there is a depreciation, and the exchange rate goes down, Exports will be cheaper.

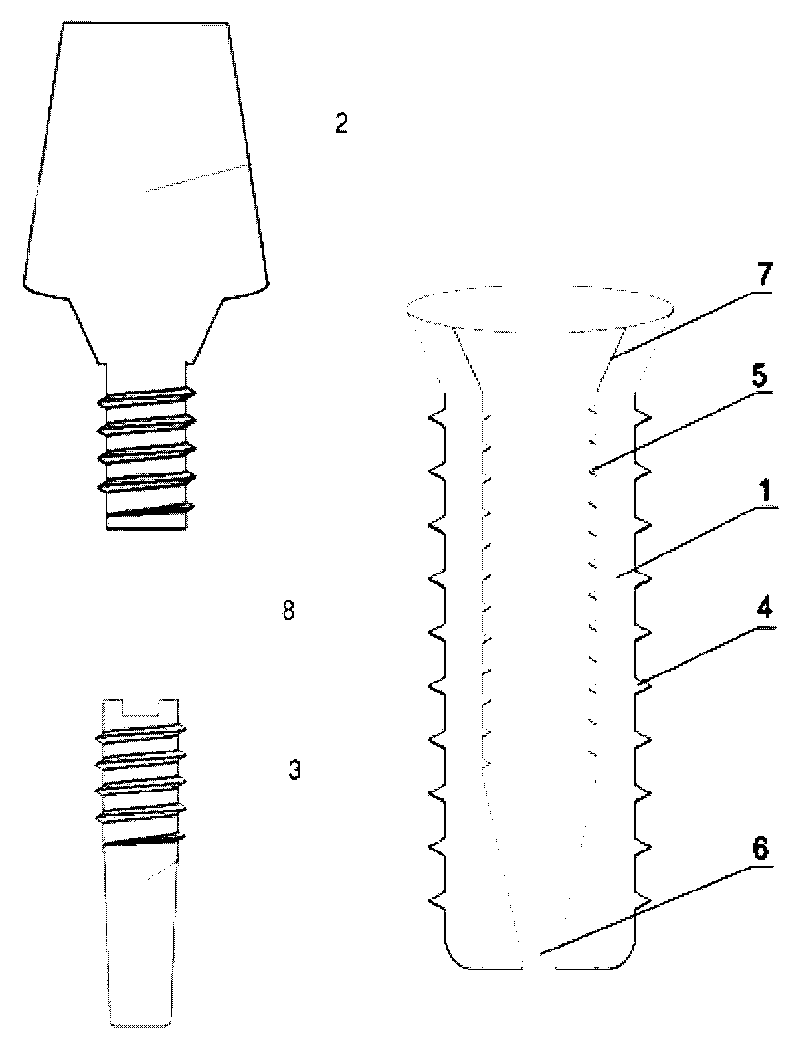

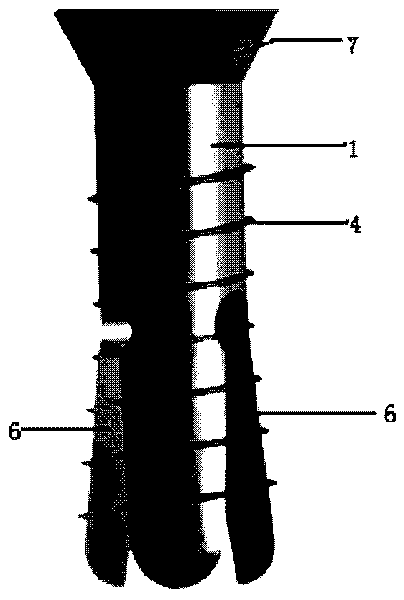

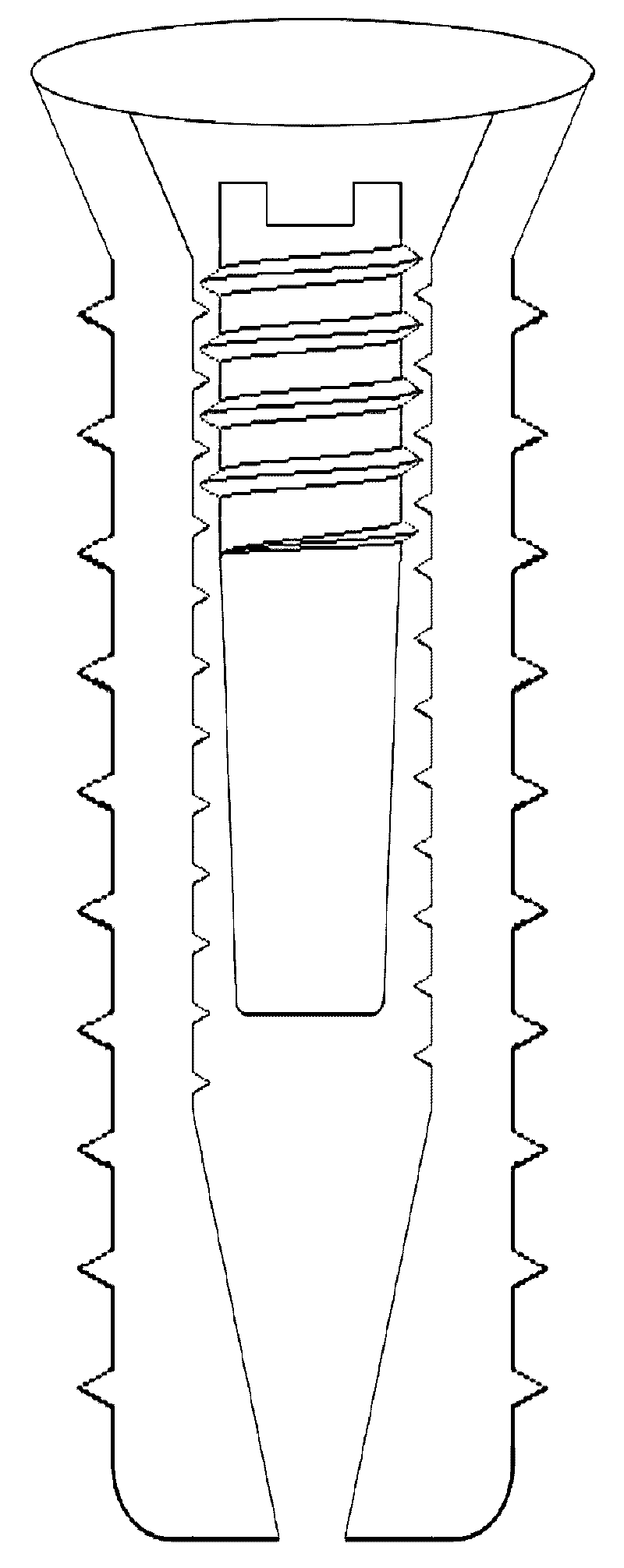

Expanded tooth implant

InactiveCN101690679AImprove gripReduce the probability of looseningDental implantsBiomedical engineeringFall rate

The invention belongs to a medical apparatus, and in particular relates to an expanded tooth implant, which is characterized by consisting of an implant body (1) and an expanded core (3) and a repair base station (2) matched with the implant body (1), which are mutually embedded by threads. The implant can improve the tightness of the implant in bones, particularly under the condition of loose bones so as to improve the initial stability and reduce the loosening and falling rate, and can also be planted immediately after routine exodontia.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

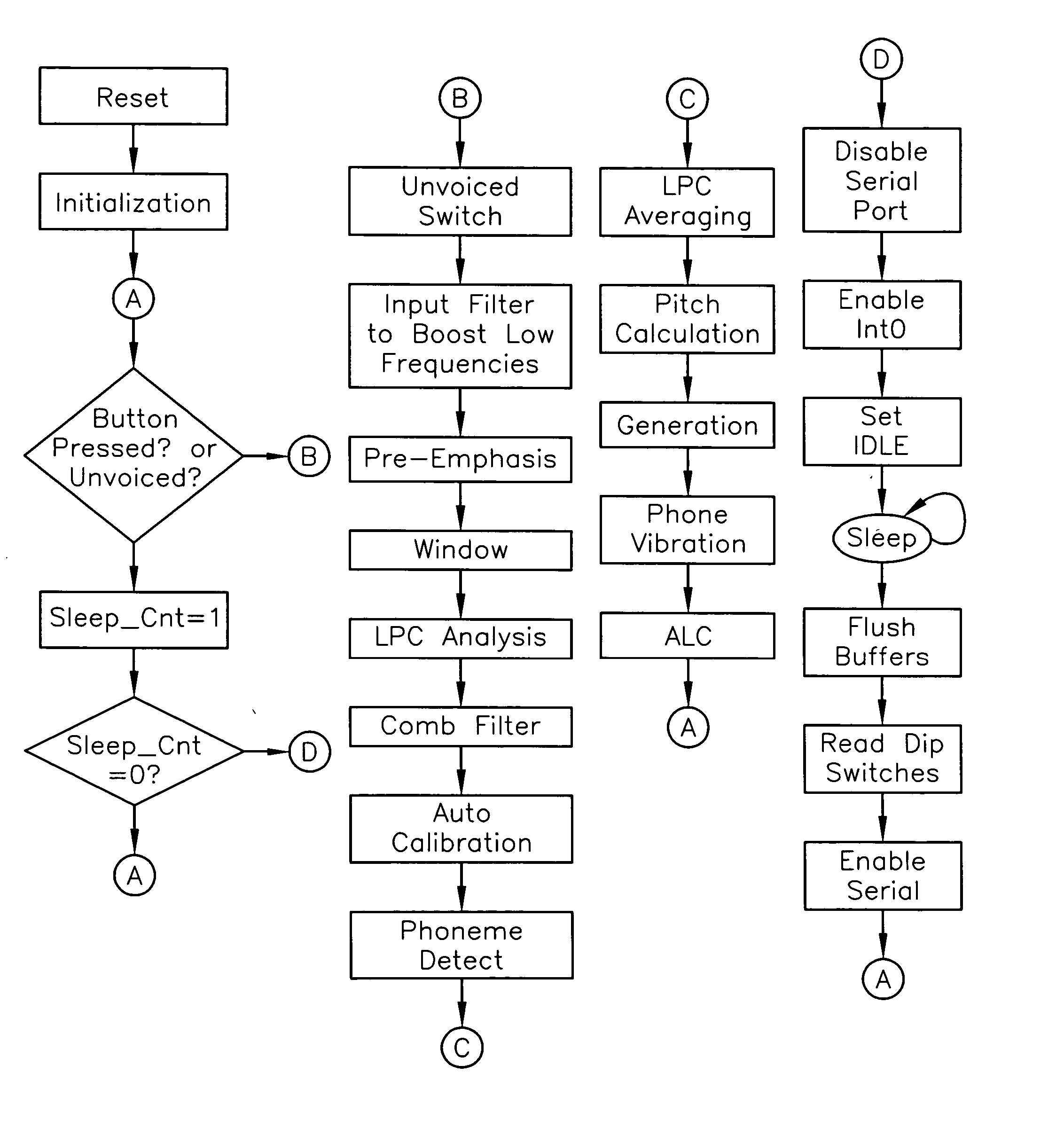

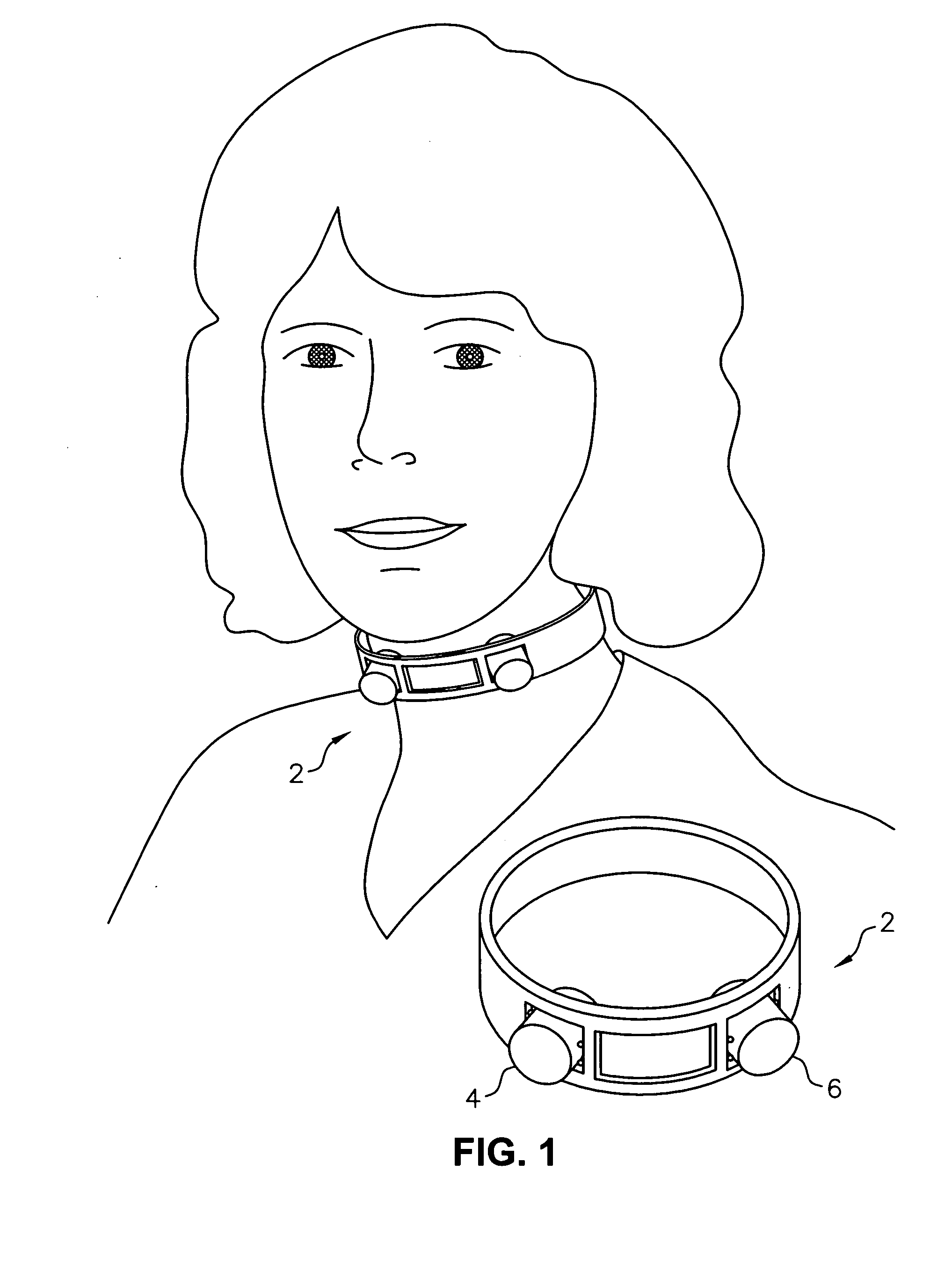

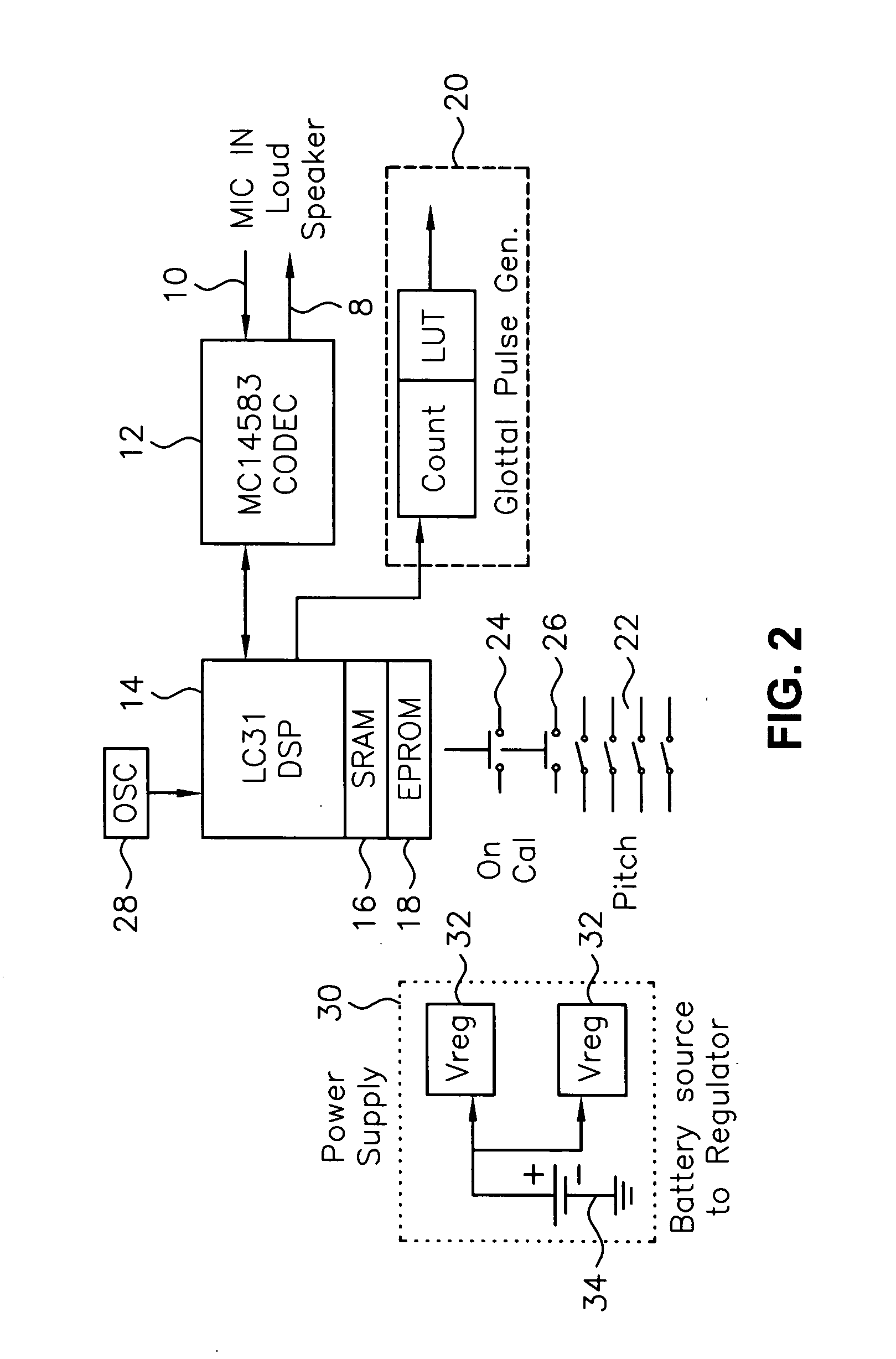

Method and means for creating prosody in speech regeneration for laryngectomees

InactiveUS20050049856A1Improve naturalnessAssist in intelligibilitySpeech synthesisFrequency spectrumGlottis

A device and a method to be used by laryngeally impaired people to improve the naturalness of their speech. An artificial sound creating mechanism which forms a simulated glottal pulse in the vocal tract is utilized. An artificial glottal pulse is compared with the natural spectrum and an inverse filter is generated to provide an output signal which would better reproduce natural sound. A digital signal processor introduces a variation of pitch based on an algorithm developed for this purpose; i.e. creating prosody. The algorithm uses primarily the relative amplitude of the speech signal and the rise and fall rates of the amplitude as a basis for setting the frequency of the speech. The invention also clarifies speech of laryngectomees by sensing the presence of consonants in the speech and appropriately amplifying them with respect to the vowel sounds.

Owner:BARAFF DAVID R

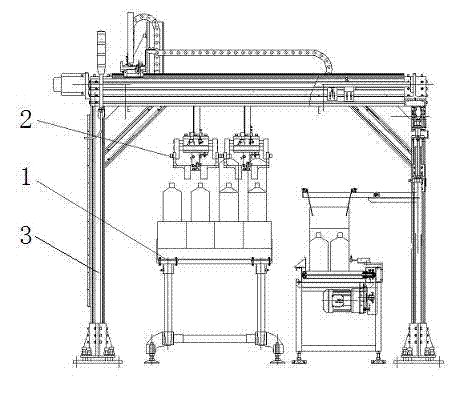

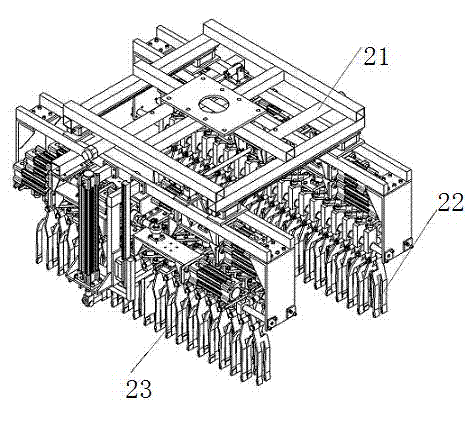

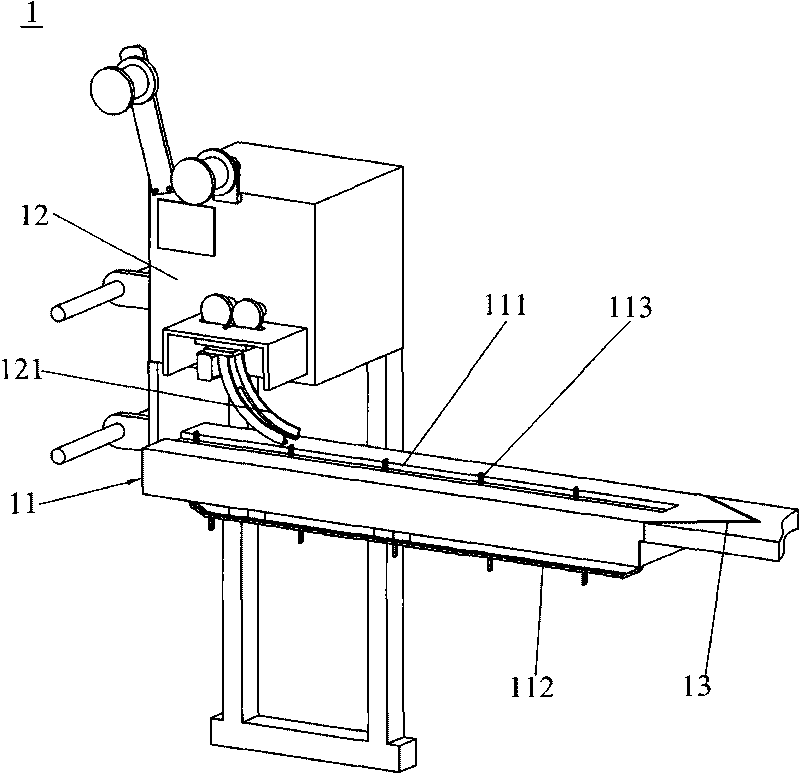

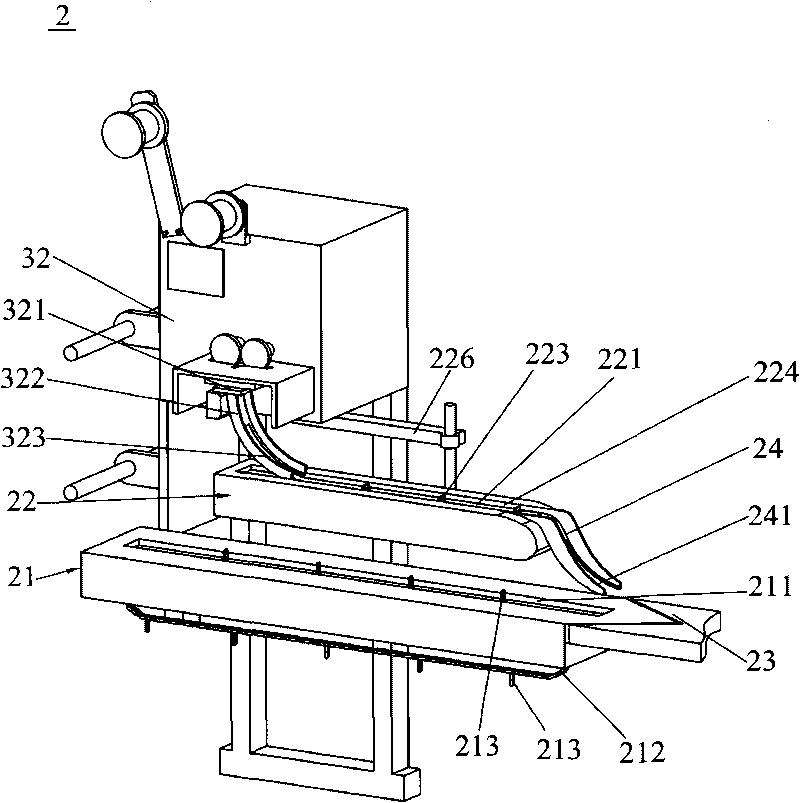

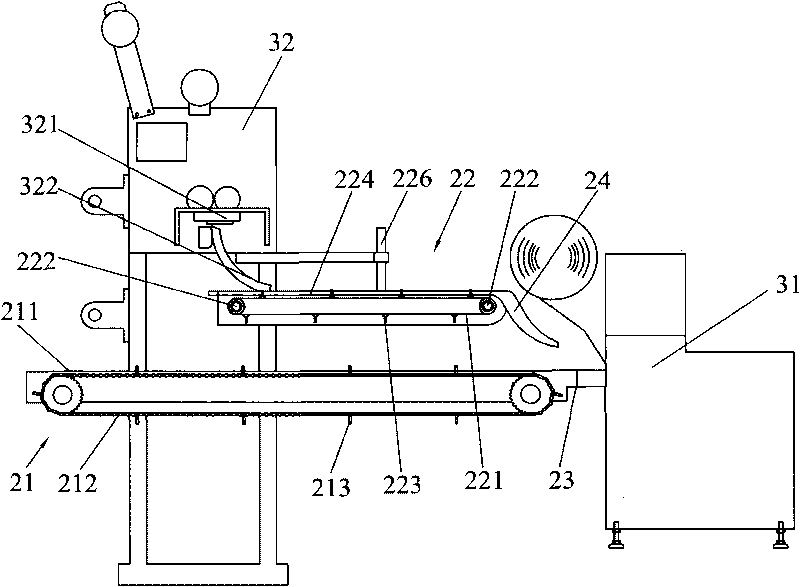

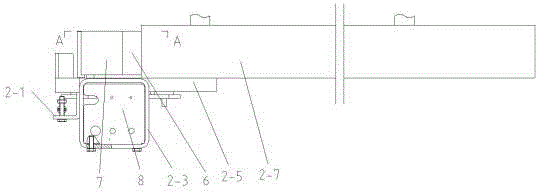

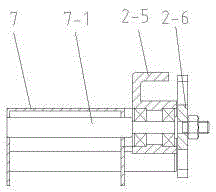

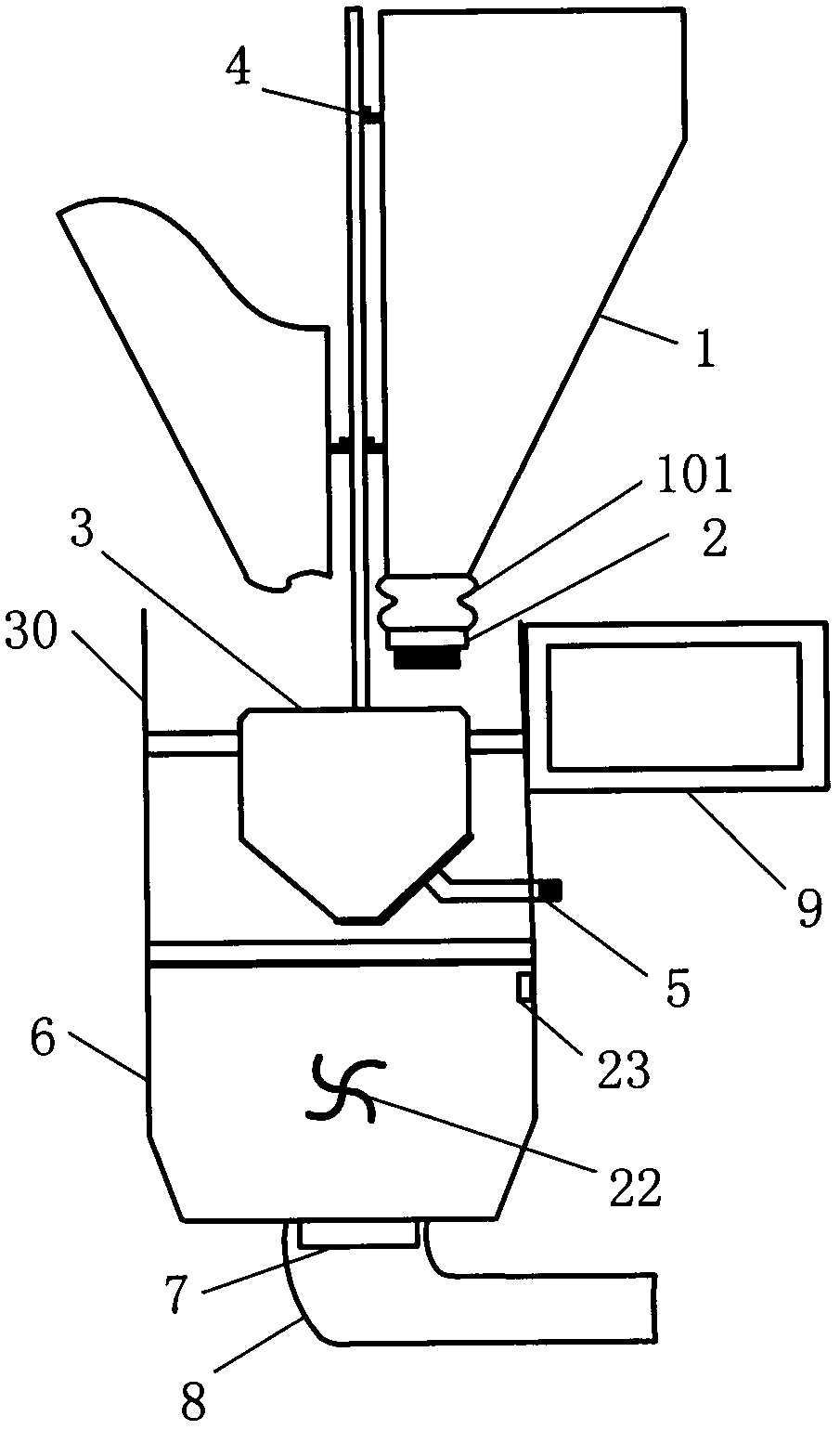

Vertical bag boxing machine

InactiveCN102556386AImprove gripLow bag drop rateIndividual articlesAgricultural engineeringSprocket

The invention discloses a vertical bag boxing machine, which comprises a vertical bag mechanism (1), a grasping mechanism (2) and a frame body (3), wherein the grasping mechanism (2) is arranged on the frame body (3); the vertical bag mechanism (1) is connected on the grasping mechanism (2); the vertical bag mechanism (1) is composed of a servo motor (11), a drive chain wheel (12), a chain (13) and a groove plate (14); the servo motor (11) is connected on the drive chain wheel (12); the chain (13) is arranged on the drive chain wheel (12); the groove plate (14) is fixed on the chain (13); thegrasping mechanism (2) is composed of a lateral face inserting mechanism (21), a hand grip mechanism (22) and a bag spacing control mechanism (23); and the hand grip mechanism (22) and the bag spacing control mechanism (23) are respectively arranged at two sides of the lateral face inserting mechanism (21). The vertical bag boxing machine is stable to grasp, low in bag falling rate and fast in boxing speed, cause no damage to soft bags in a grasping process and can realize full-automatic grasping and boxing of bags.

Owner:DALIAN JIALIN EQUIP MFG

Conveying device of a packing machine

The invention provides a conveying device of a packing machine, which is used for the conveying of the packing machine with secondary feeding. The conveying device comprises a main conveying mechanism, a connecting opening for connecting the main conveying mechanism and the inlet of the packing machine, a segmented parcel delivery machine used for secondary feeding, a secondary feeding conveying mechanism and a feeding sliding chute. The main conveying mechanism comprises a main conveying chute and a main conveying chain installed below the main conveying chute; the main conveying chain is provided with an equidistant push rod which passes through the main conveying chute and extends upwards above the main conveying chute. One end of the secondary feeding conveying mechanism is connected with the discharge opening of the segmented parcel delivery machine, and the other end is connected with the inlet of the feeding sliding chute; and the outlet of the feeding sliding chute is arranged above the connecting opening. Since the secondary feeding conveying mechanism used for conveying auxiliary products is arranged additionally, the conveying device of the packing machine avoids secondary pollution, reduces the falling rate, performs secondary feeding quality inspection and has the advantages of safety, reliability and no pollution.

Owner:GUANGDONG GUANGYI TECH IND

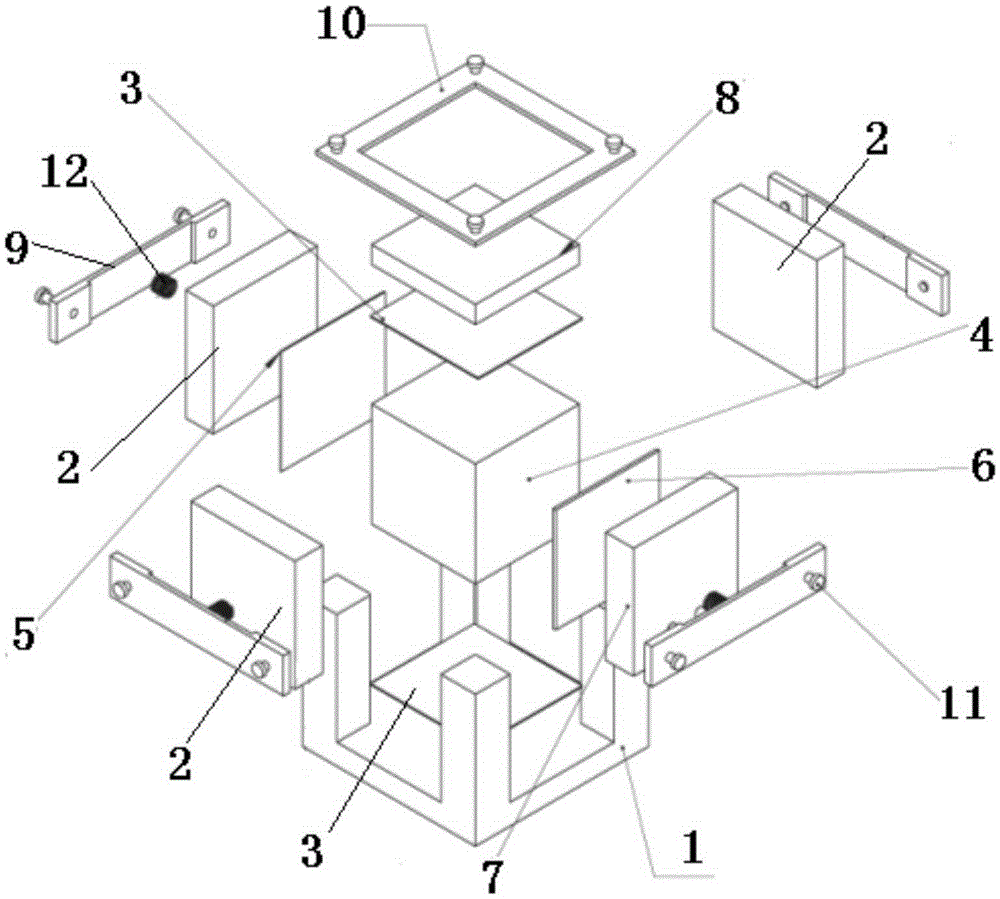

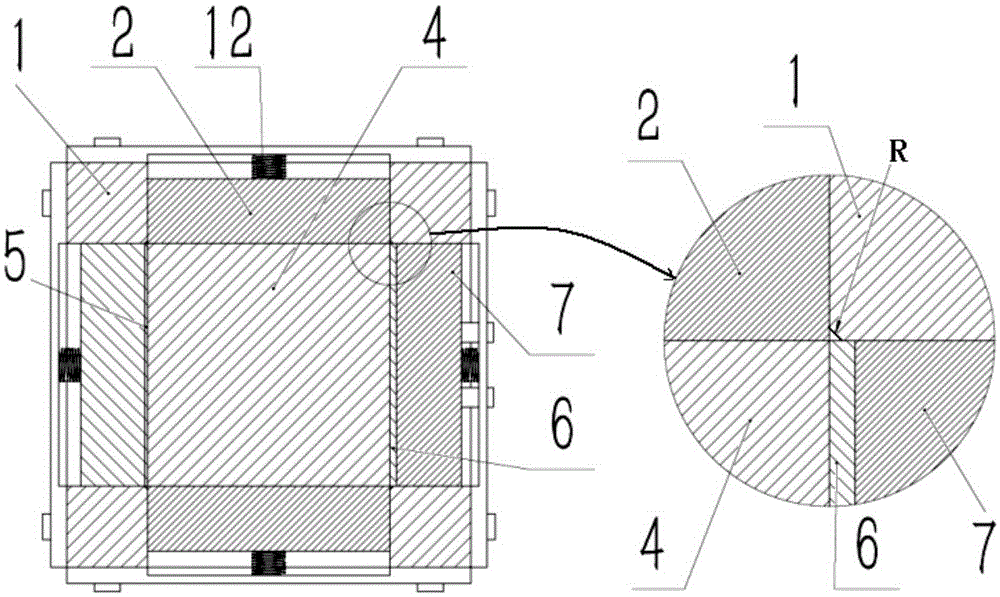

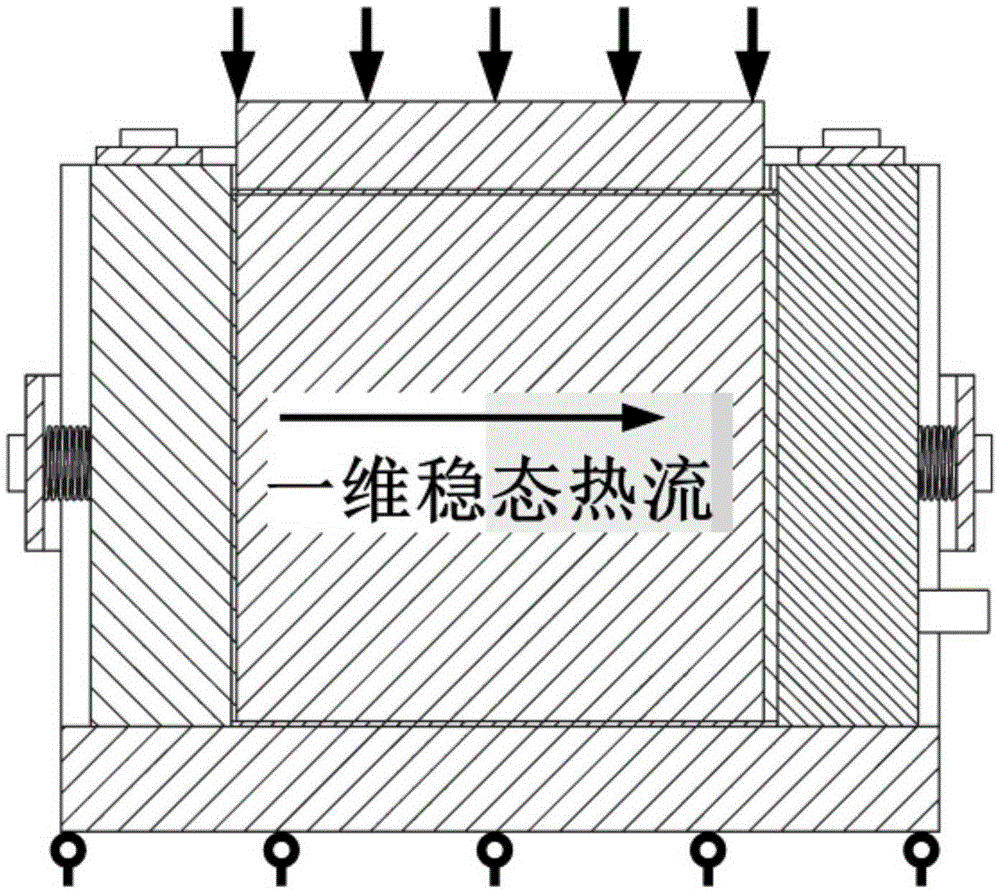

Device and method for measuring heat conductivity coefficient reduction rate of concrete in uniaxial compression process

ActiveCN105259206AIntegrity guaranteedGuaranteed fitMaterial heat developmentReduction rateUniaxial compression

The invention discloses a device and a method for measuring the heat conductivity coefficient reduction rate of concrete in a uniaxial compression process. A concrete test sample is put into a bracket to be subjected to a compression load, and meanwhile a heating unit and a refrigerating unit establish a temperature difference between two planes of the concrete test sample; the bracket is used for fixing relative positions of the concrete test sample with the heating unit, the refrigerating unit, a heat insulating material and heat conduction silica gel; the concrete test sample is deformed under pressure, and extrudes the heat insulating material, the heat conduction silica gel, the refrigerating unit and the heating unit in order that the heat insulating material, the heat conduction silica gel, the refrigerating unit and the heating unit move outwards towards the periphery; peripheral support posts of the bracket are used for determining moving tracks of peripheral materials; spring pressing plates and springs on the support posts provide a proper peripheral pressure not influencing mechanics experiments in order to ensure that the refrigerating unit and the heating unit fit the surface of the concrete test sample, thereby reducing a contact thermal resistance as much as possible. Under the situation that the concrete test sample is under a certain compression load, a thermal flow density inside the concrete test sample reaches a steady state, and the temperature is distributed stably in a one-dimensional form in the concrete test sample.

Owner:HOHAI UNIV

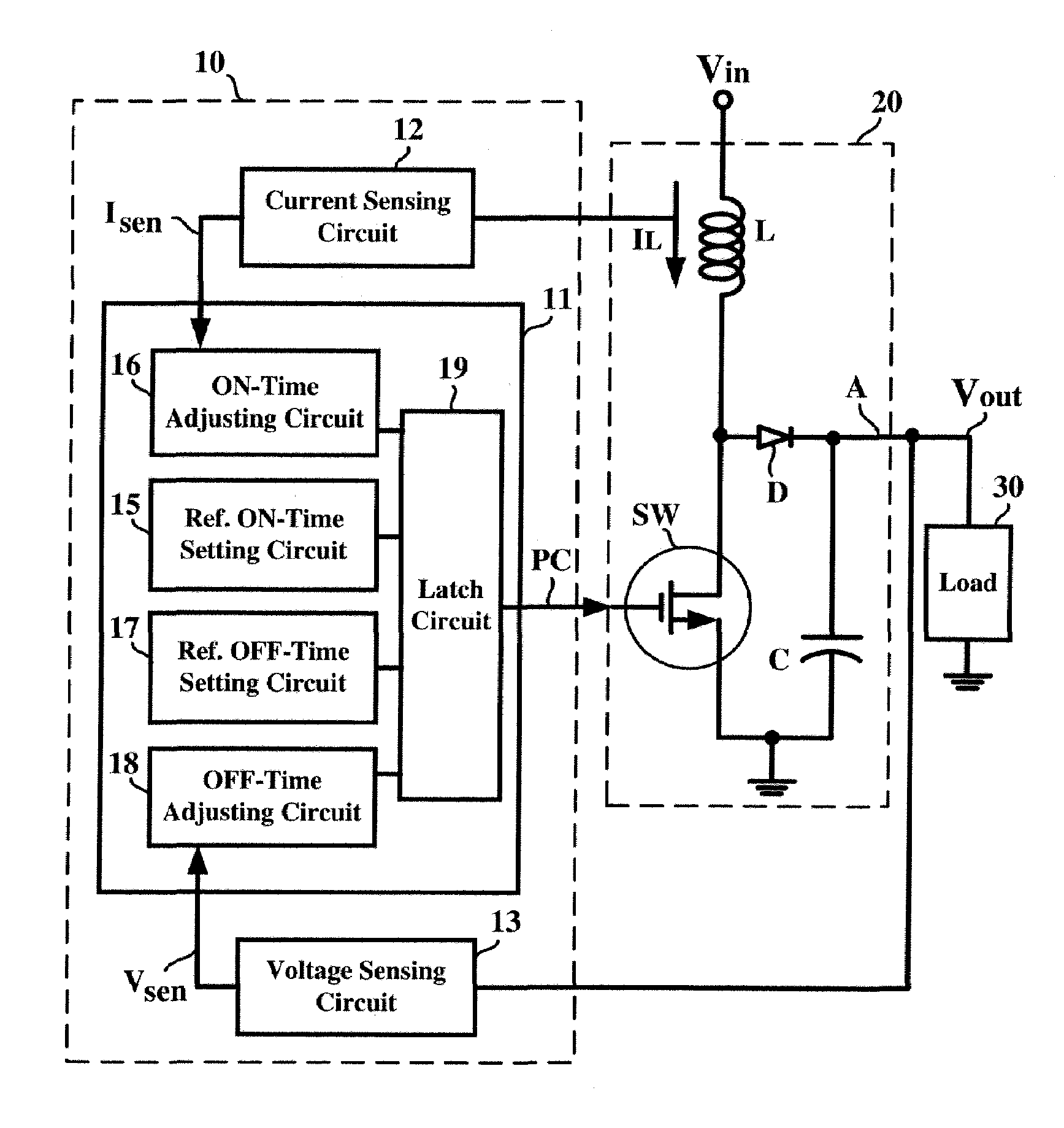

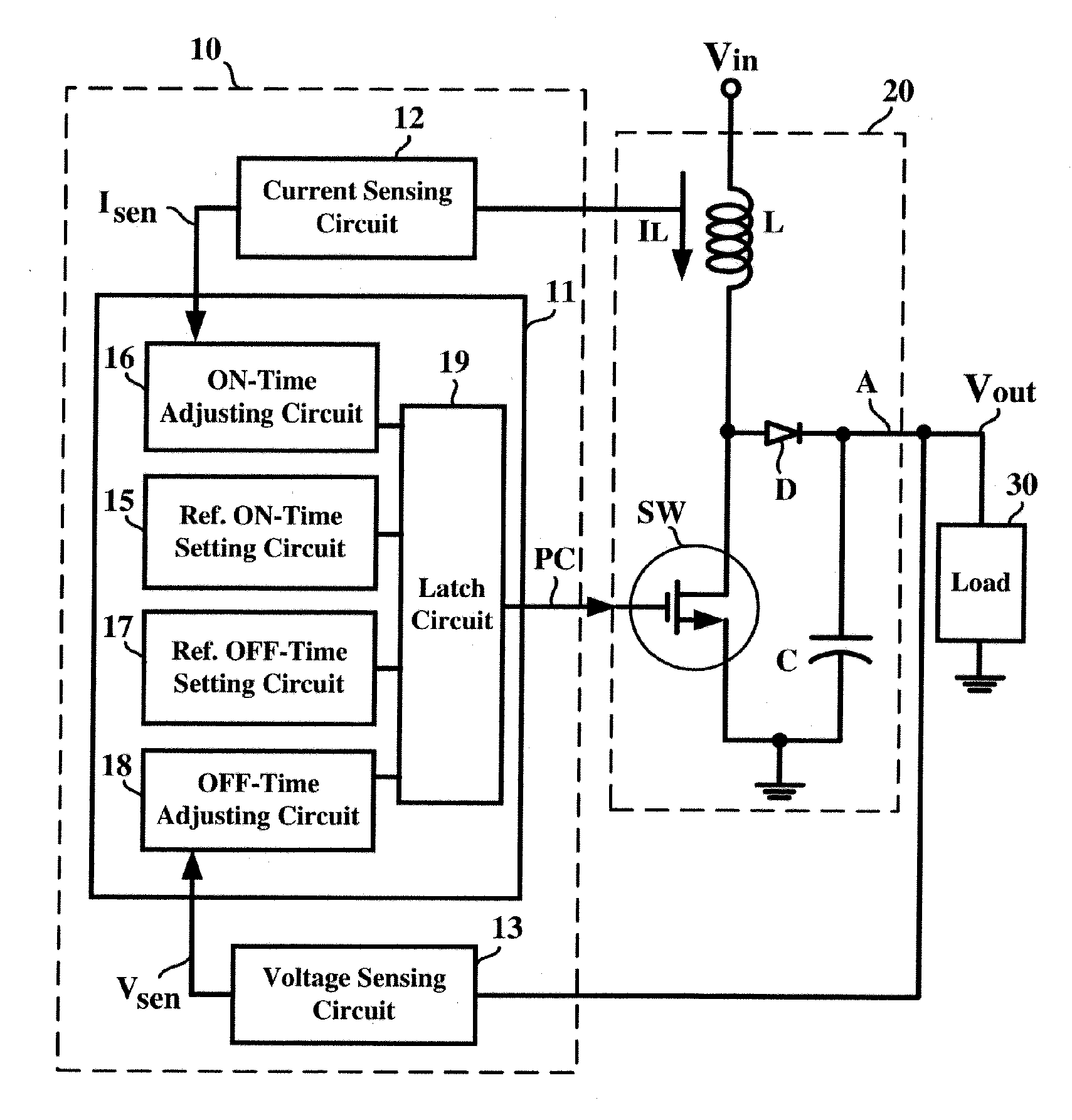

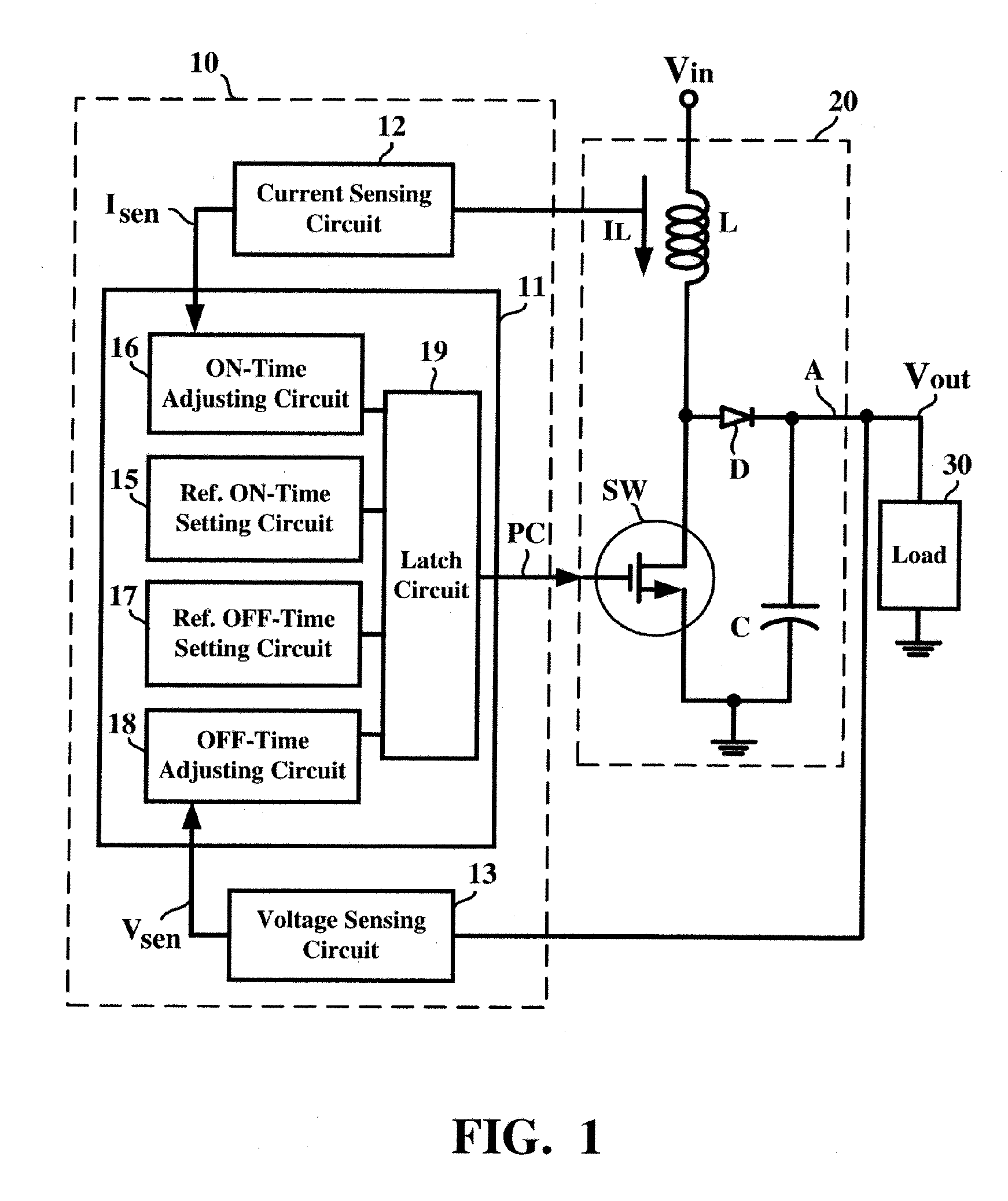

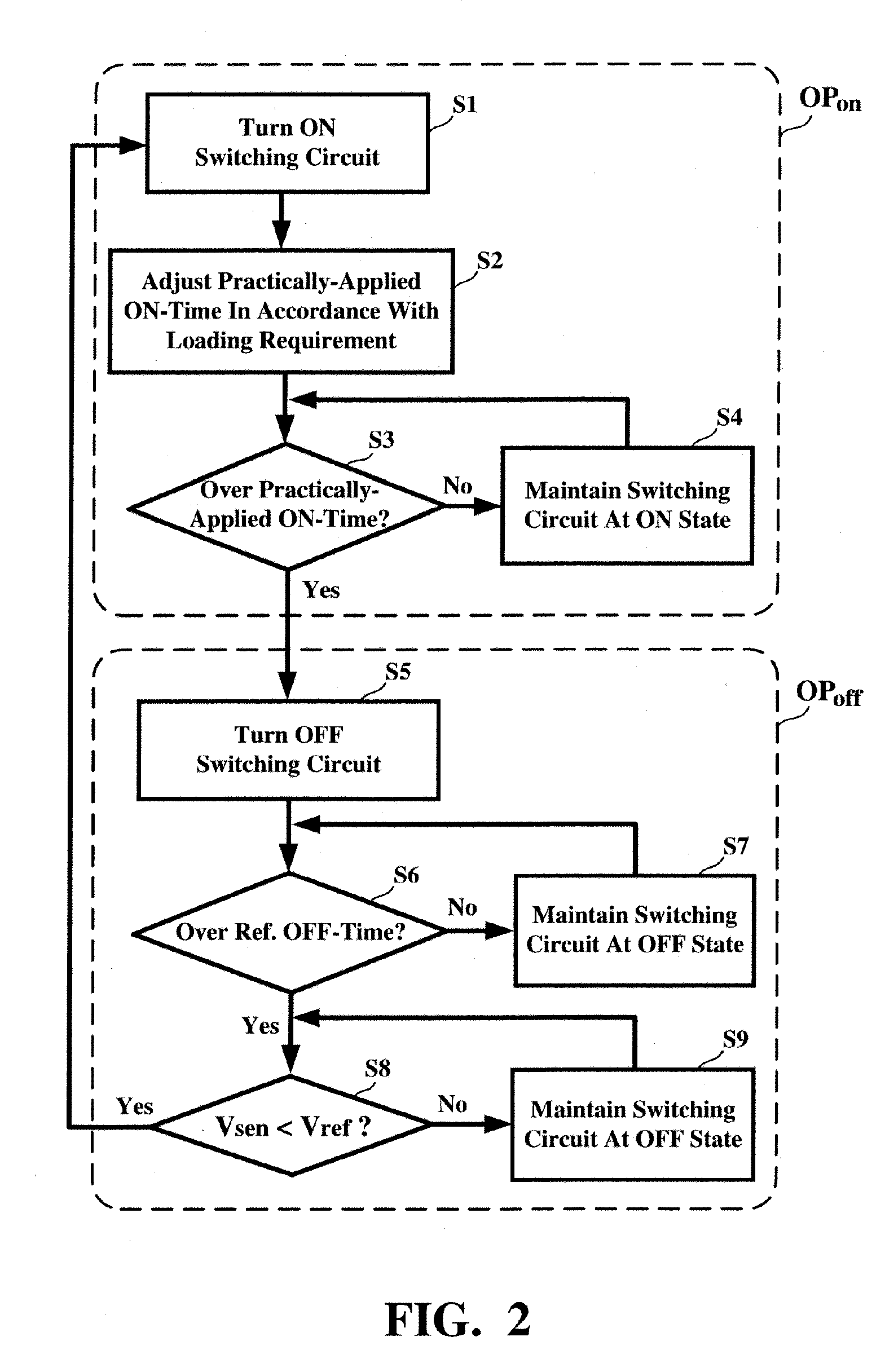

PFM control circuit for DC regulator

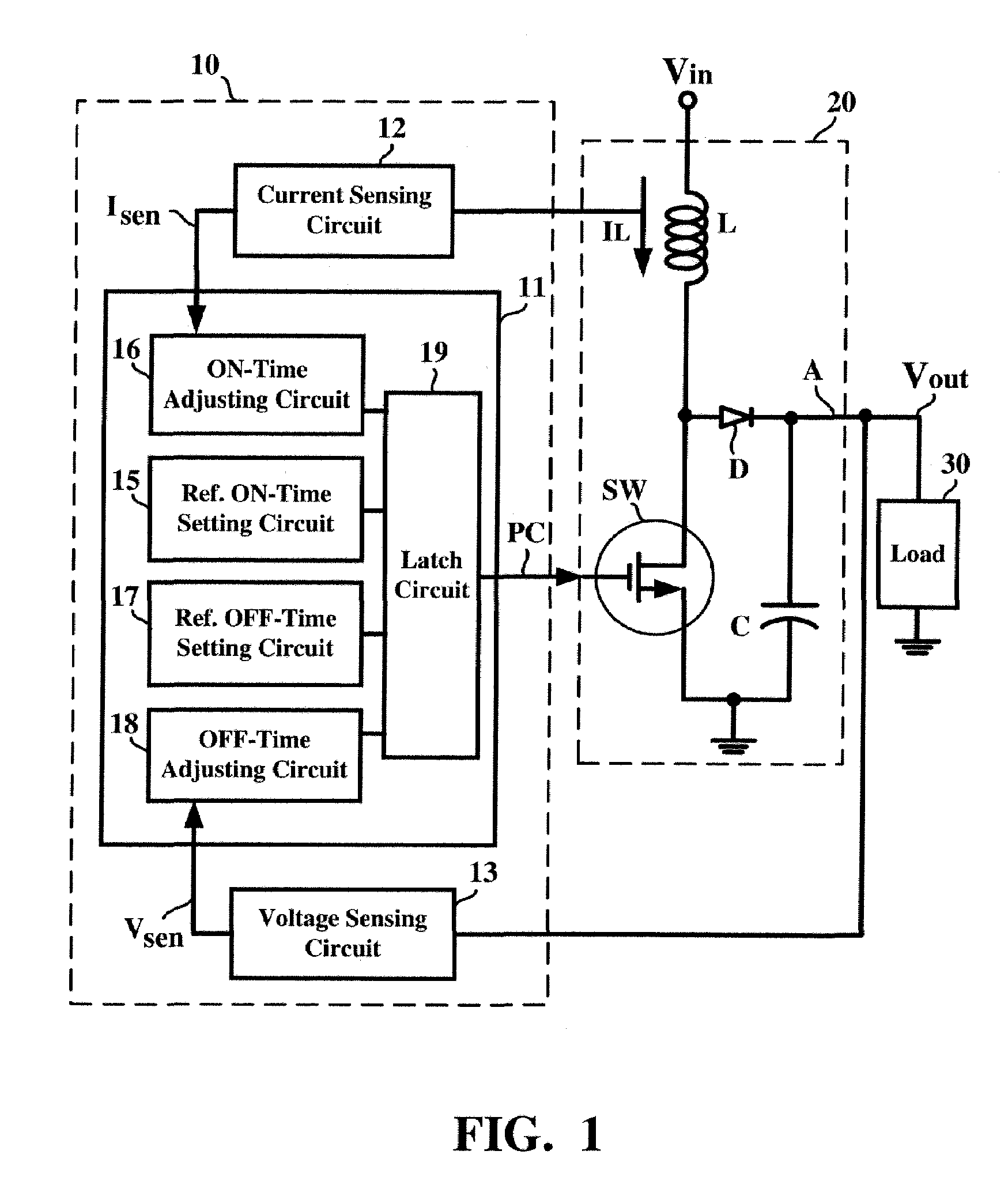

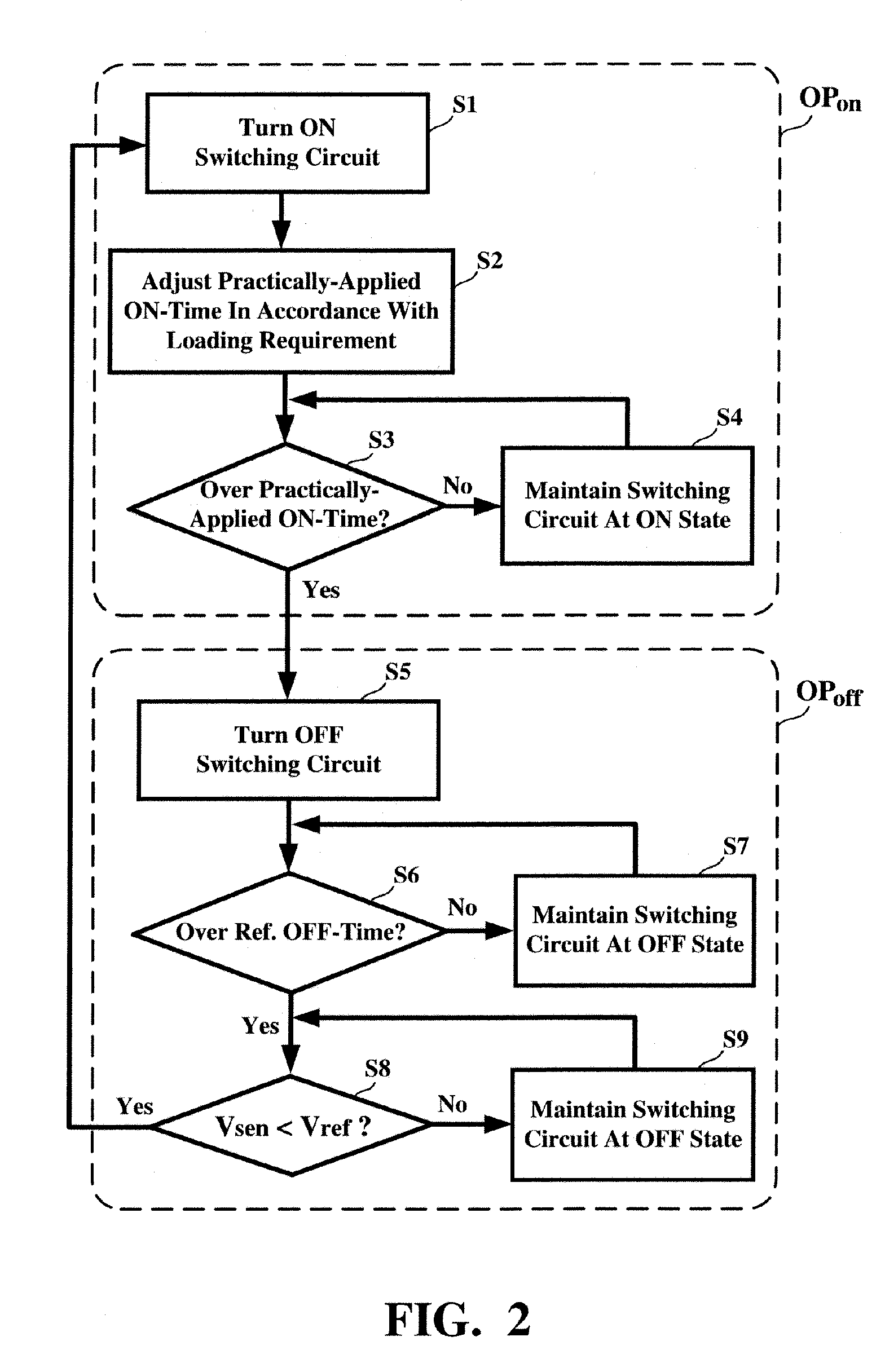

ActiveUS7279869B2Improve efficiencyWide loadDc-dc conversionAmplifier with semiconductor-devices/discharge-tubesPulse controlSwitching cycle

A PFM control circuit generates a pulse control signal for controlling a switching regulator to convert an input voltage into an output voltage. The pulse control signal has a plurality of switch cycles, each of which consists of an ON-time and an OFF-time. The ON-time is applied to turn on a switching circuit of the switching regulator while the OFF-time is applied to turn off the switching circuit. A current detection signal is representative of a current flowing through an inductive device of the switching regulator. The ON-time is prolonged in accordance with an increase of a maximum of the current detection signal. A voltage detection signal is representative of the output voltage. The OFF-time is prolonged in accordance with a reduction of a falling rate of the voltage detection signal.

Owner:GLOBAL MIXED MODE TECH

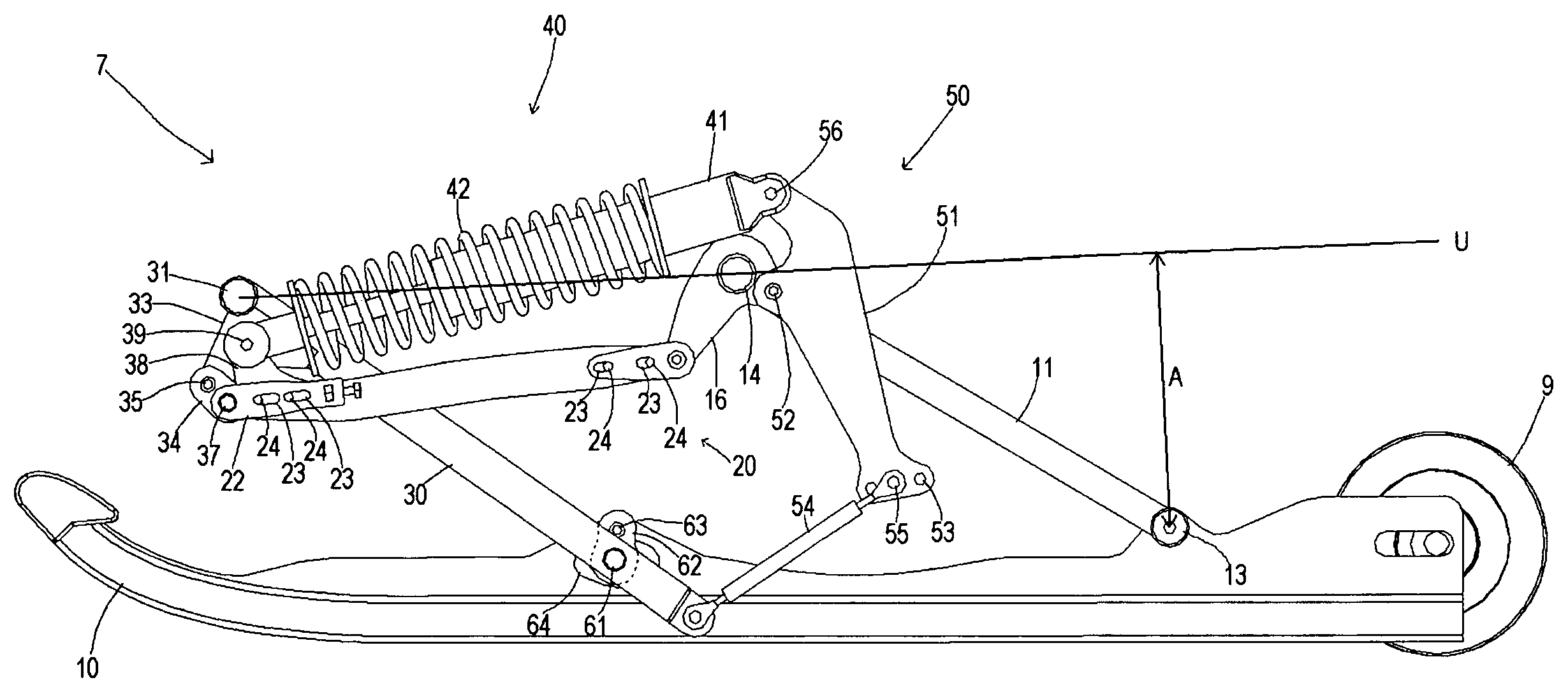

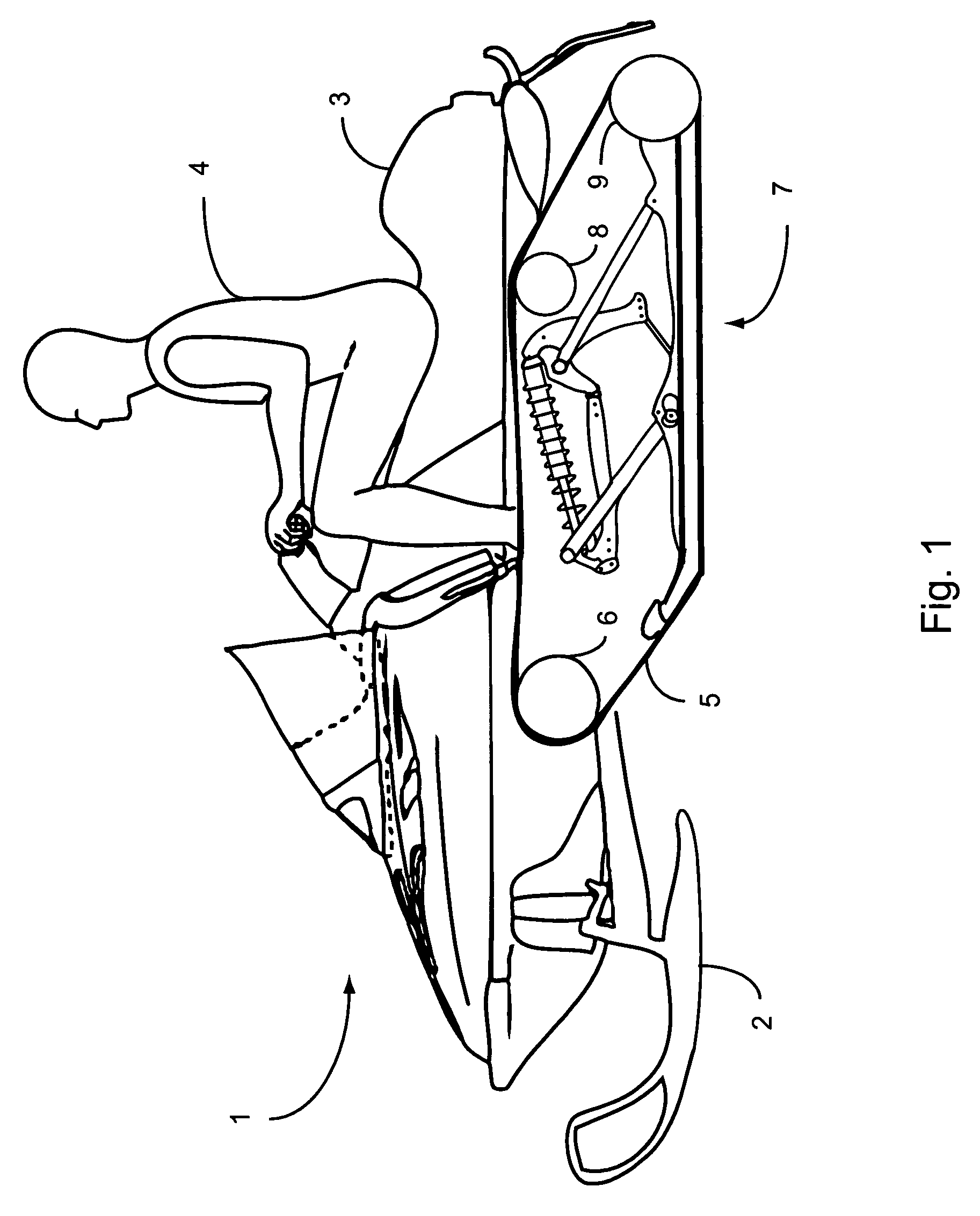

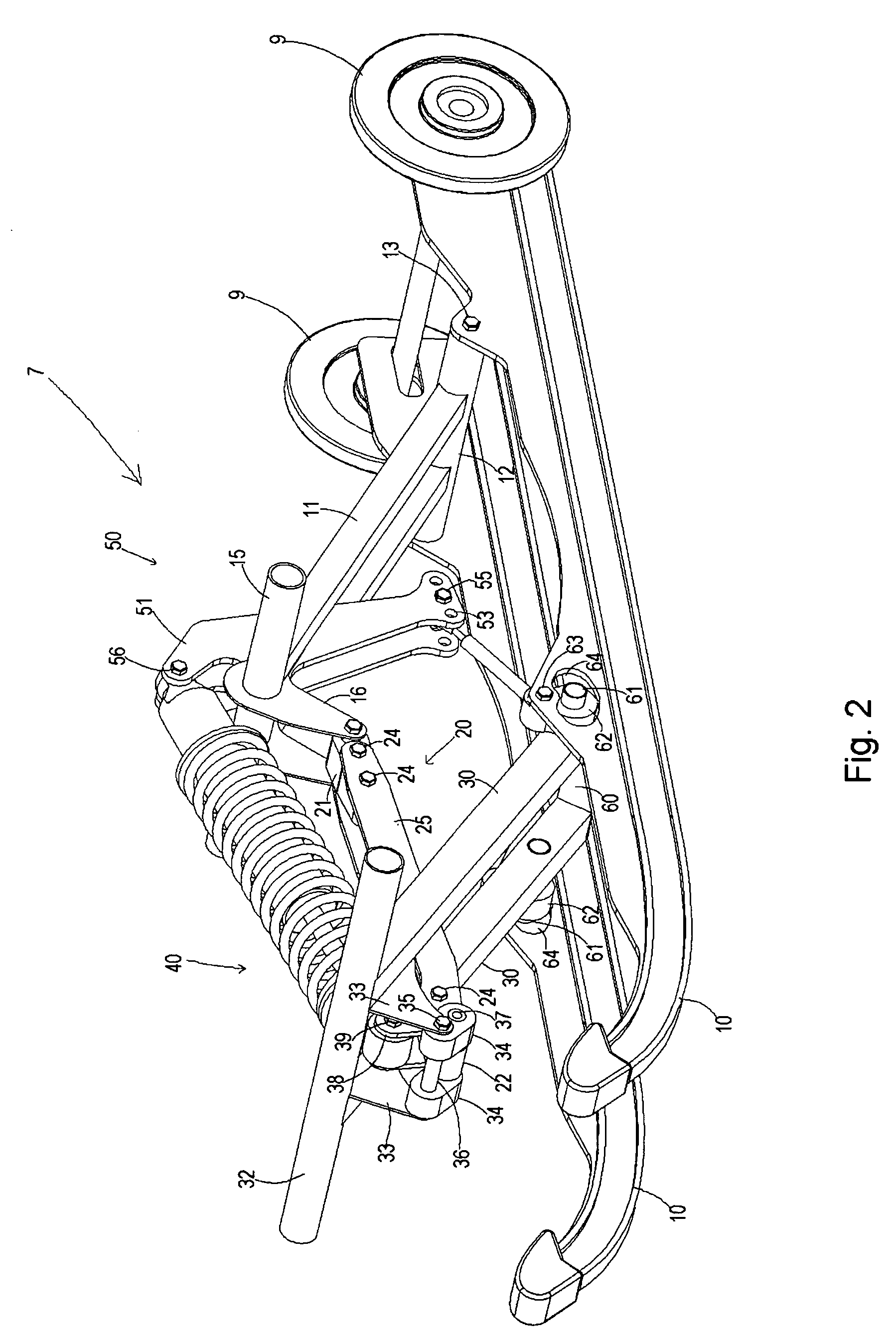

Snowmobile track suspension

A rear track suspension for a snowmobile having a single resilient element for biasing both the front and rear arms. The slide rail is permitted to pitch between first and second pitching constraints in response to terrain obstacles in a gradual manner as the motion constraints are approached. This reduces jarring of the rider when the pitching constraints are met. Suspension compression exhibits an initial falling rate motion ratio, followed by a constant rate motion ratio, followed by a rising rate motion ratio. This U-shaped motion ratio profile advantageously provides cushioning upon landing along with a resistance to bottoming out of the suspension upon full compression. The result is an improved ride without sacrificing suspension performance.

Owner:WESTERN ONTARIO THE UNIV OF

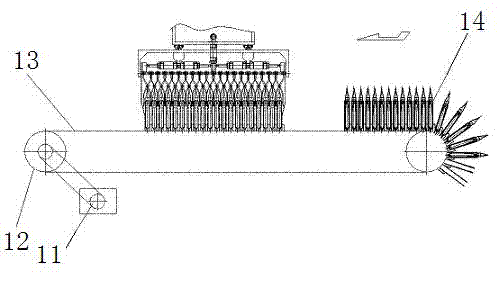

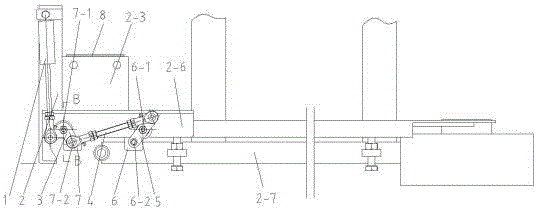

Seedling falling control mechanism of potted seedling transplanting machine

ActiveCN104855013AFalling smoothlyConvenient seedling timeTransplantingAgricultural engineeringSeedling

The invention relates to a seedling falling control mechanism of a potted seedling transplanting machine and belongs to the technical field of agricultural machinery. The seedling falling control mechanism comprises a front opening and closing plate, a rear opening and closing plate and a seedling falling frame; the front opening and closing plate and the rear opening and closing plate are arranged at an output end of a seedling conveying barrel base plate and comprise a folded horizontal plane respectively; the seedling falling frame extends upward from the front end of the seedling conveying barrel base plate; the upper portion of the outer side of the front opening and closing plate and the upper portion of the outer side of the rear opening and closing plate and the middle of an inverted V-shaped lever piece and the middle of a straight lever piece are supported on a fixing plate through a horizontal pin shaft in a hinged mode respectively, wherein the fixing plate is arranged at the front end of the seedling conveying barrel base plate; the lower portion of the folded horizontal plane of the front opening and closing plate is hinged to the inner lower end of the inverted V-shaped lever piece and the lower portion of the folded horizontal plane of the rear opening and closing plate is hinged to the lower end of the straight lever piece; the upper end of the straight lever piece and the inner lower end of the inverted V-shaped lever piece are hinged to two ends of a connecting rod respectively; the upper portion of the seedling falling frame is hinged to a cylinder body of a cylinder; the lower end of a piston rod of the cylinder, which extends downward, is hinged to an outer lower end of the inverted V-shaped lever piece. According to the seedling falling control mechanism of the potted seedling transplanting machine, the accurate control on the seedling falling time of potted seedlings can be facilitated and meanwhile a seedling falling opening is gradually opened, the opening speed can be convenient to control, and accordingly the potted seedlings can reliably fall down and the seedling injury rate and the seedling fall rate are significantly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

PFM control circuit for converting voltages with high efficiency over broad loading requirements

ActiveUS20060250121A1Improve efficiencyWide loadDc-dc conversionAmplifier with semiconductor-devices/discharge-tubesPulse controlSwitching cycle

A PFM control circuit generates a pulse control signal for controlling a switching regulator to convert an input voltage into an output voltage. The pulse control signal has a plurality of switch cycles, each of which consists of an ON-time and an OFF-time. The ON-time is applied to turn on a switching circuit of the switching regulator while the OFF-time is applied to turn off the switching circuit. A current detection signal is representative of a current flowing through an inductive device of the switching regulator. The ON-time is prolonged in accordance with an increase of a maximum of the current detection signal. A voltage detection signal is representative of the output voltage. The OFF-time is prolonged in accordance with a reduction of a falling rate of the voltage detection signal.

Owner:GLOBAL MIXED MODE TECH

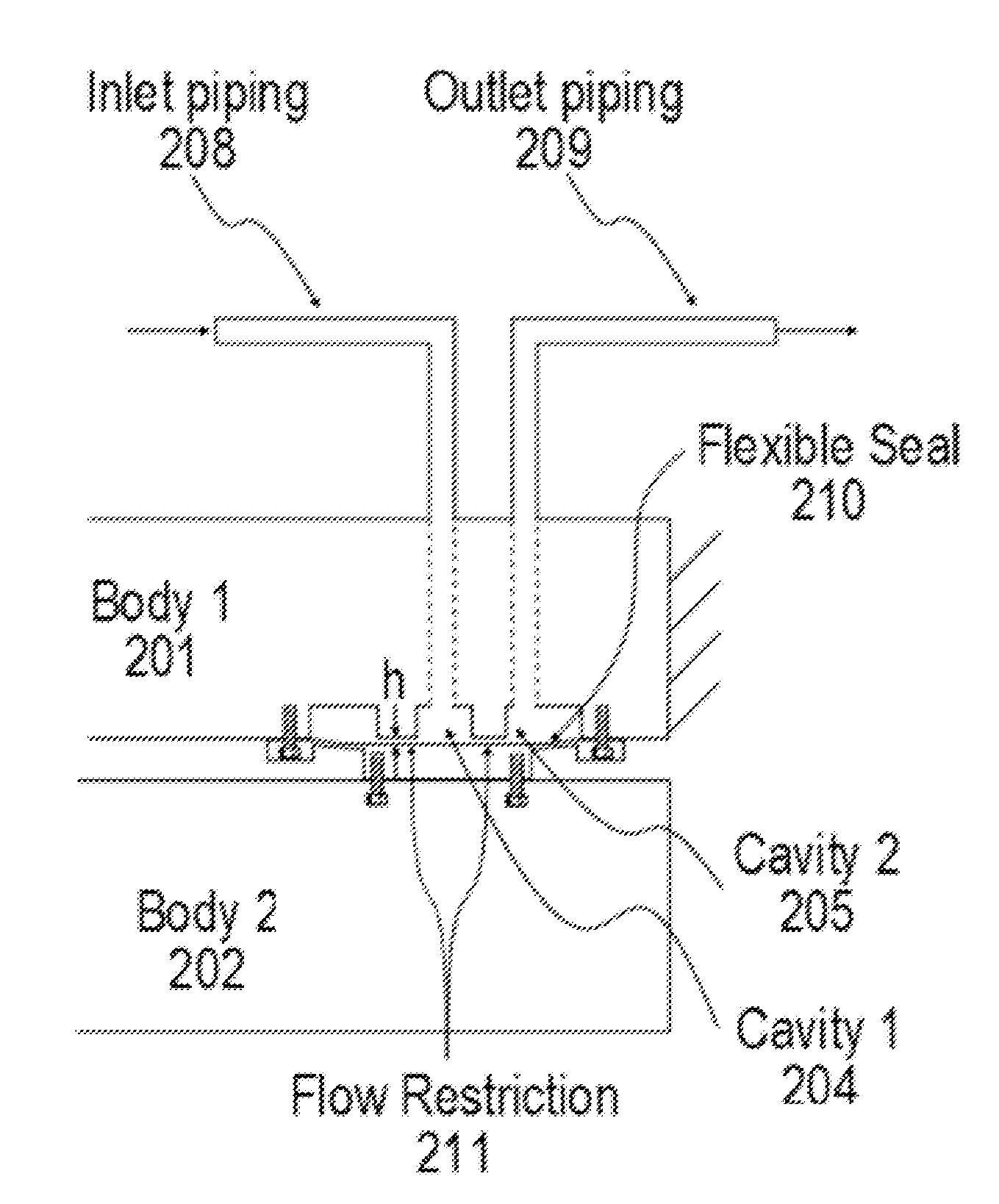

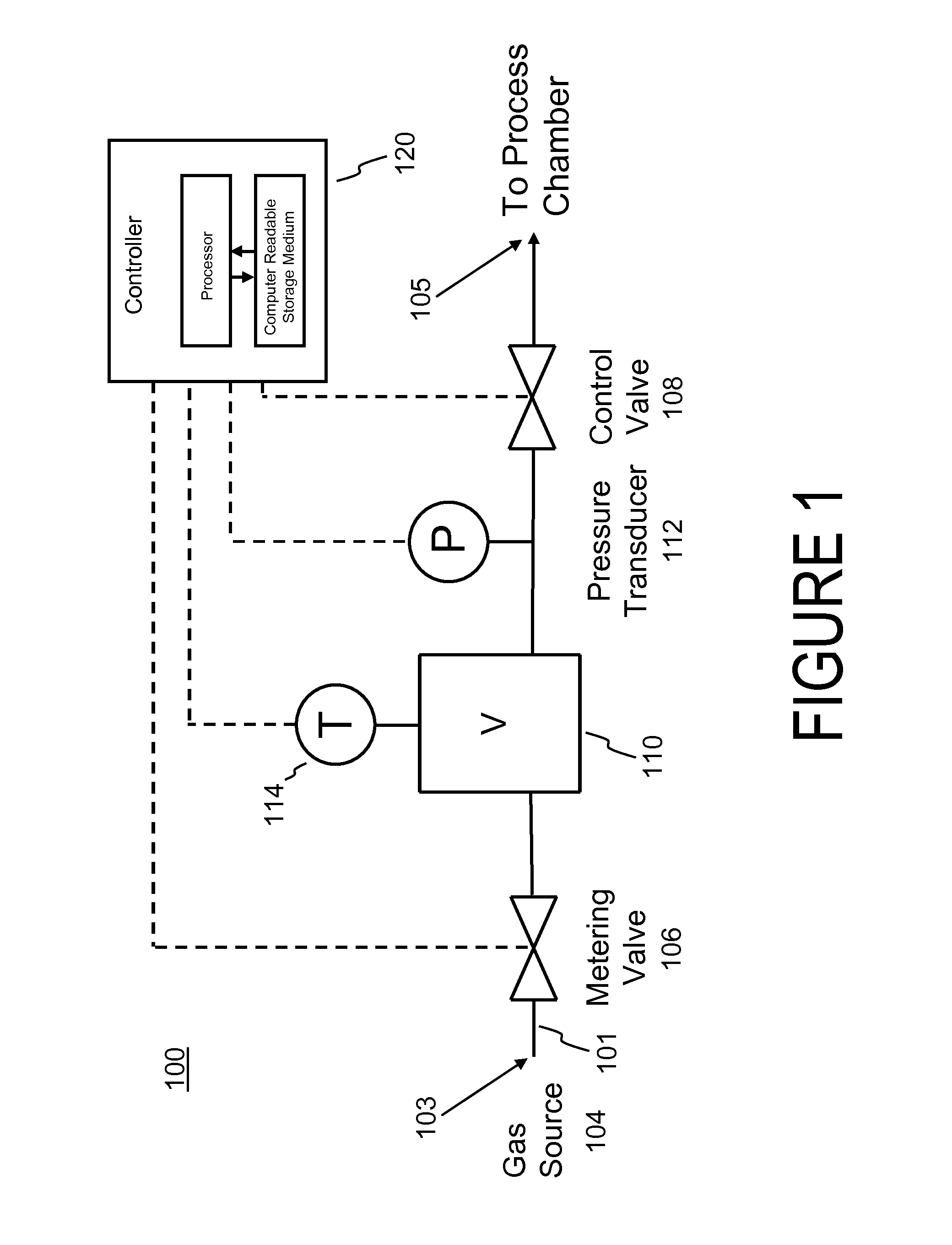

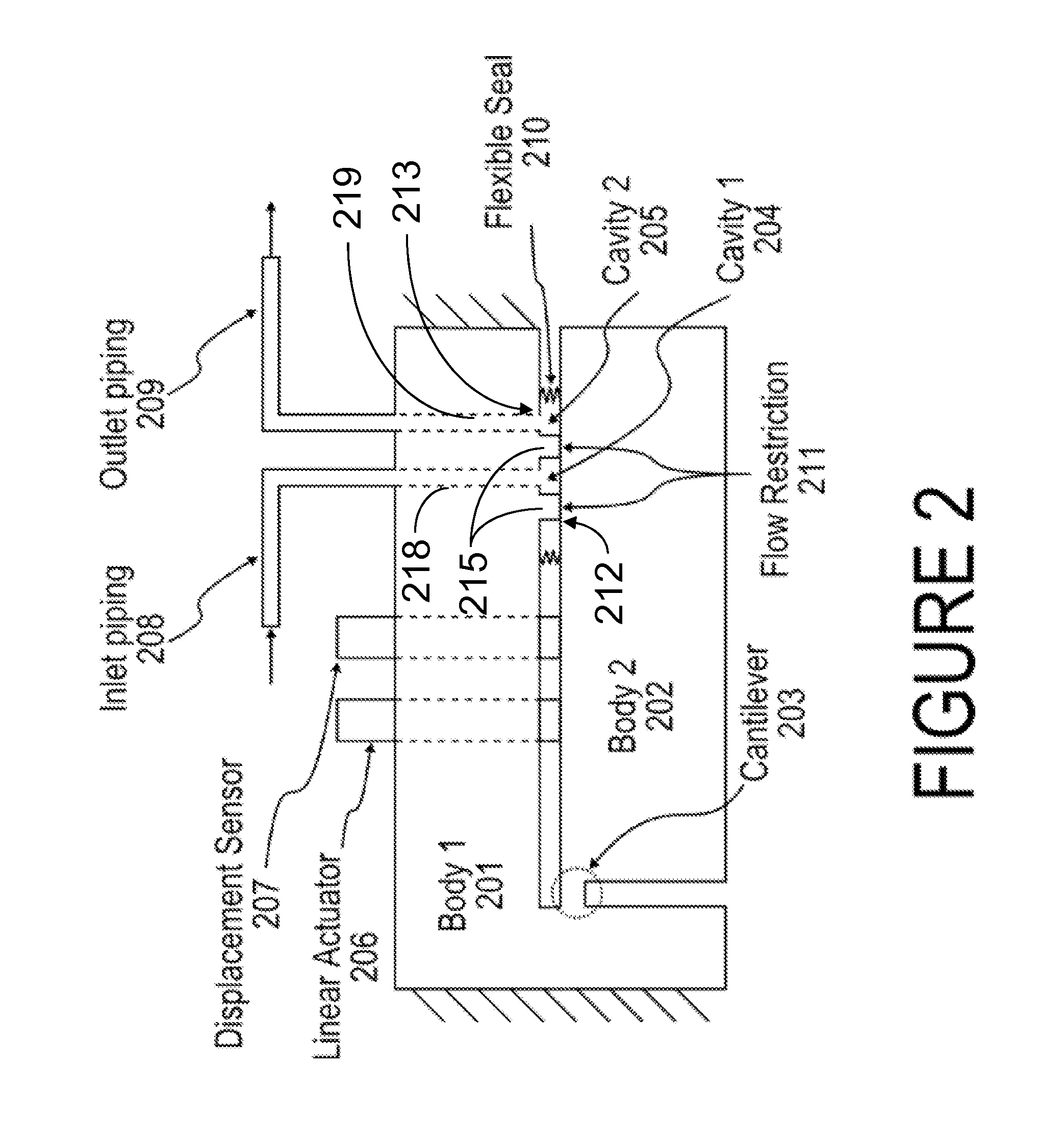

Method and apparatus for gas flow control

ActiveUS20140367596A1Diaphragm valvesOperating means/releasing devices for valvesEngineeringProduct gas

Owner:PIVOTAL SYST CORP

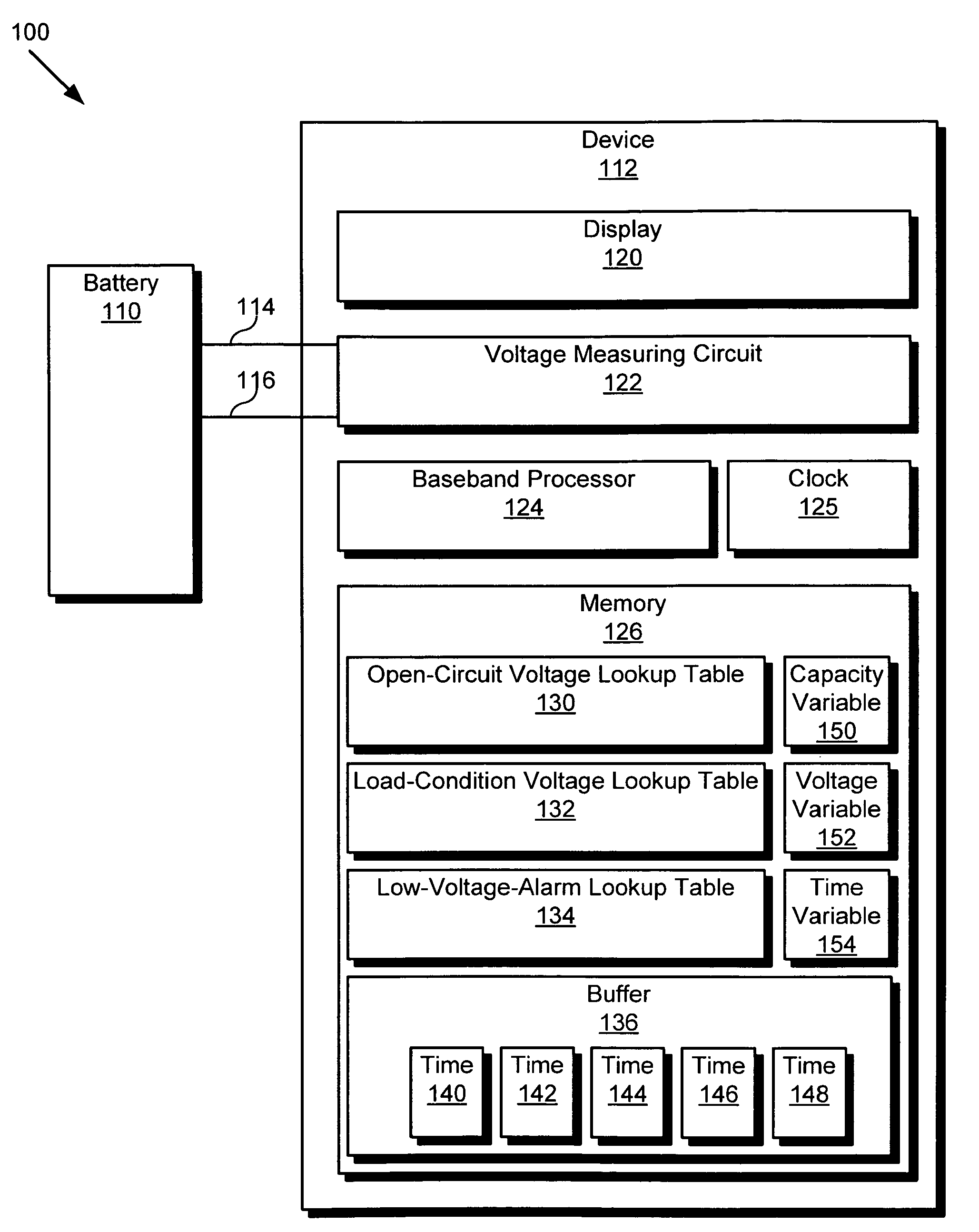

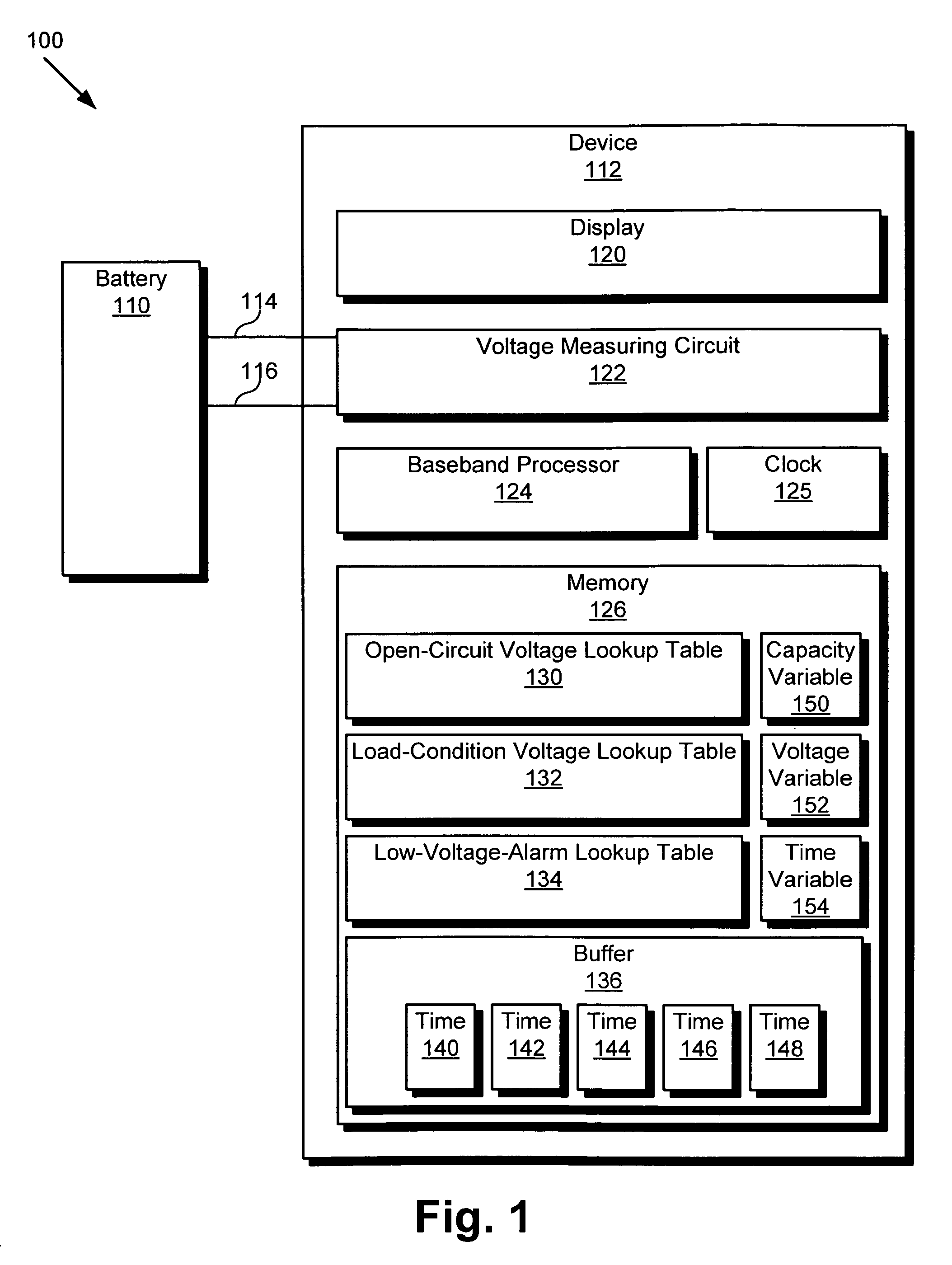

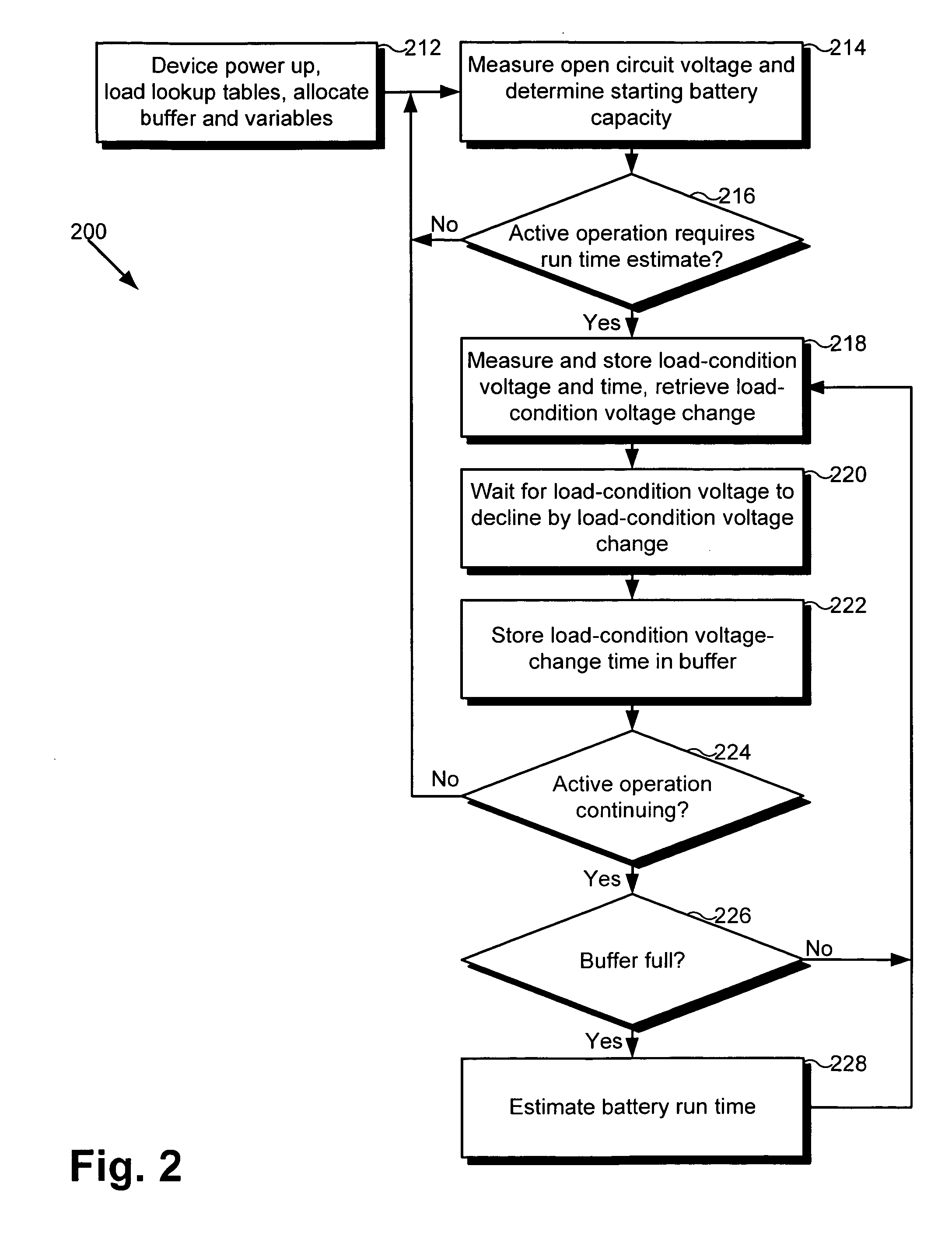

Method for accurate battery run time estimation utilizing load-condition voltage

One disclosed embodiment is a method for accurately estimating a run time of a battery utilized by an electronic device. The method comprises determining a starting battery capacity utilizing an open-circuit voltage of the battery, determining a battery capacity decline rate utilizing a load-condition voltage of the battery, and determining a low-voltage-alarm battery capacity during an active operation of the electronic device. The method further comprises utilizing the starting battery capacity, the battery capacity decline rate, and the low-voltage-alarm battery capacity to estimate the run time of the battery. The run time estimate is determined, in one embodiment, by dividing the difference of the starting battery capacity and the low-voltage-alarm battery capacity by the battery capacity decline rate. One embodiment utilizes an open-circuit voltage lookup table, a load-condition voltage lookup table, and a low-voltage-alarm lookup table that are configured for use with a certain type of battery.

Owner:AVAGO TECH INT SALES PTE LTD

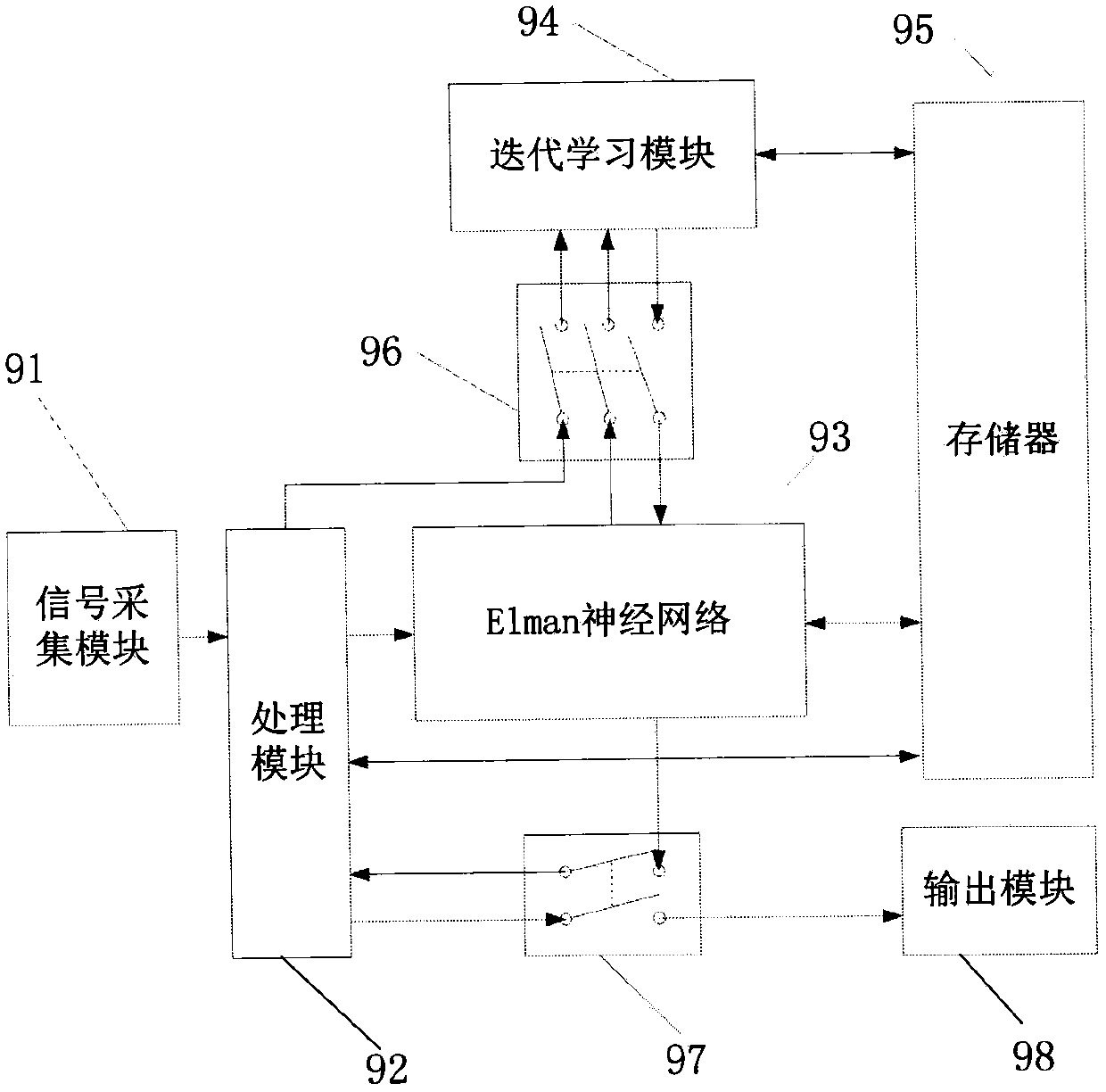

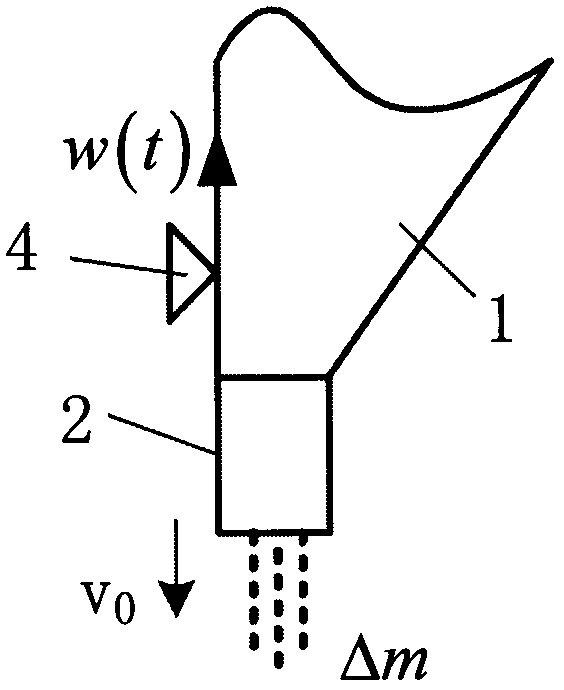

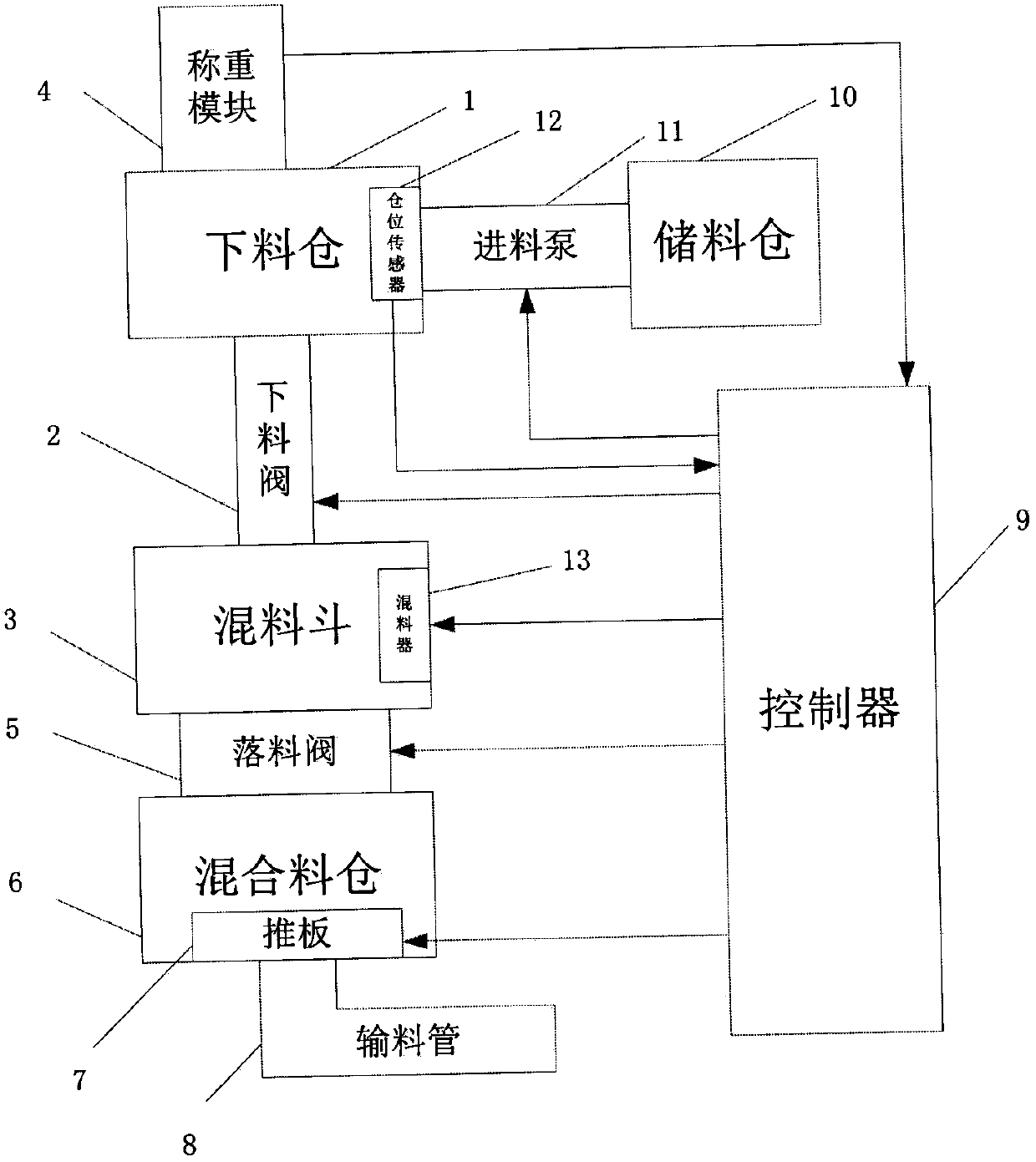

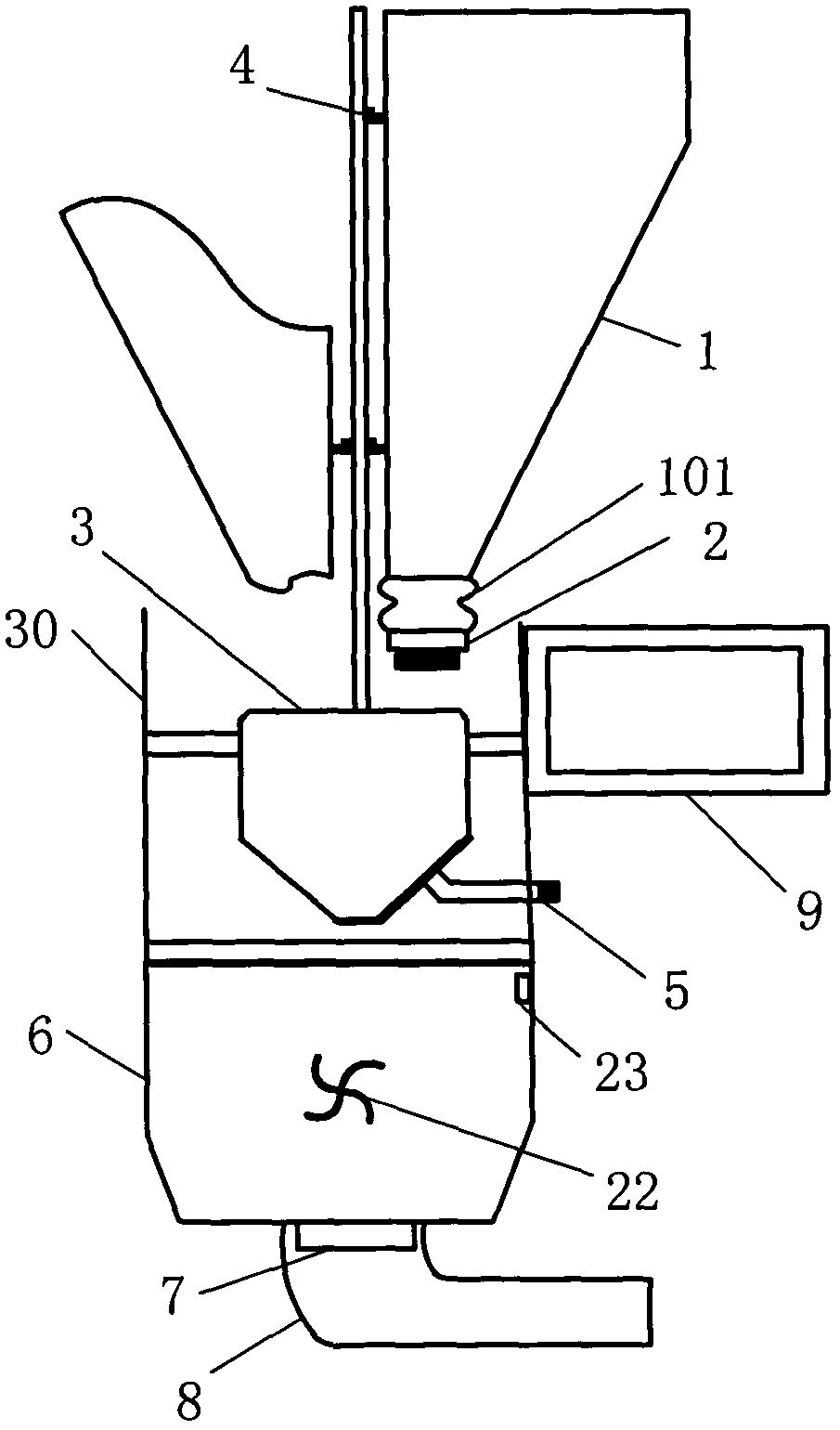

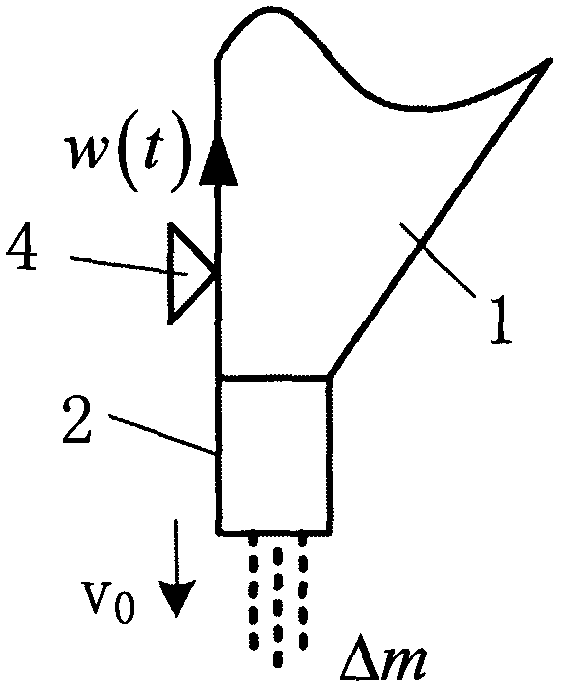

Direct falling weightless type material feeding method based on neural network

ActiveCN107601083APrecise cuttingReduce blanking rate fluctuationsLoading/unloadingLevel sensorWeightlessness

The invention discloses a direct falling weightless type material feeding method based on a neural network. A neural network module is established in a controller, and the four input quantities of thematerial level, the material falling rate, the material density and the opening diameter of a feeding valve are mapped as a fed material weightlessness value by the adoption of the neural network; atraining sample is obtained, and offline training is conducted on the neural network; and when feeding control is conducted online, based on signals collected by a bin level sensor in a feeding bin and a weighing module bearing the feeding bin, the neural network predicts the material falling weightlessness value, a processing module corrects the feeding quantity based on the predicted value and then adjusts the closing time of the feeding valve. According to the direct falling weightless type material feeding method based on the neural network, the material falling weightlessness values at different material falling states are predicted by the adoption of the neural network, direct accurate feeding can be achieved, and the direct falling weightless type material feeding method based on the neural network is suitable for small-batch production; the material accumulation state in the feeding bin is detected and adjusted by the adoption of the bin level sensor and a stirrer, so that thematerial falling rate fluctuation is reduced; and the batch feeding total error is reduced through control over the feeding accumulative error.

Owner:CHINA JILIANG UNIV

Three-drop distance non-steady flow dewatering test method for probing mine hydrogeology

The invention relates to a three-drop distance non-steady flow dewatering test method for probing mine hydrogeology. According to the technical scheme of the invention for solving the problem, steady flow and non-steady flow dewatering tests are combined for a three-drop distance non-steady flow dewatering test; by implementing the dewatering test, the water storage property of a drainage water-bearing layer of a mine is evaluated based on the falling rate of water level of observation holes according to acquired test information; the watery property of the drainage water-bearing layer is evaluated by virtue of unit inflow of each drop distance and the draining property of the drainage water-bearing layer is evaluated according to a ratio of drawdown and the water inflow. The method not only can probe hydrogeological conditions of the mine in multiscales, but also can acquire abundant test data, and provides probability of establishing a mine inflow prediction model and predicting the mine inflow under a drainage water condition in the future by various methods such as a flow-drawdown correlation curve method, a steady flow analytical method, a non-steady flow analytical method and a numerical simulation method, thereby providing guarantee for correctly evaluating hydrogeological conditions of the mine.

Owner:HENAN POLYTECHNIC UNIV

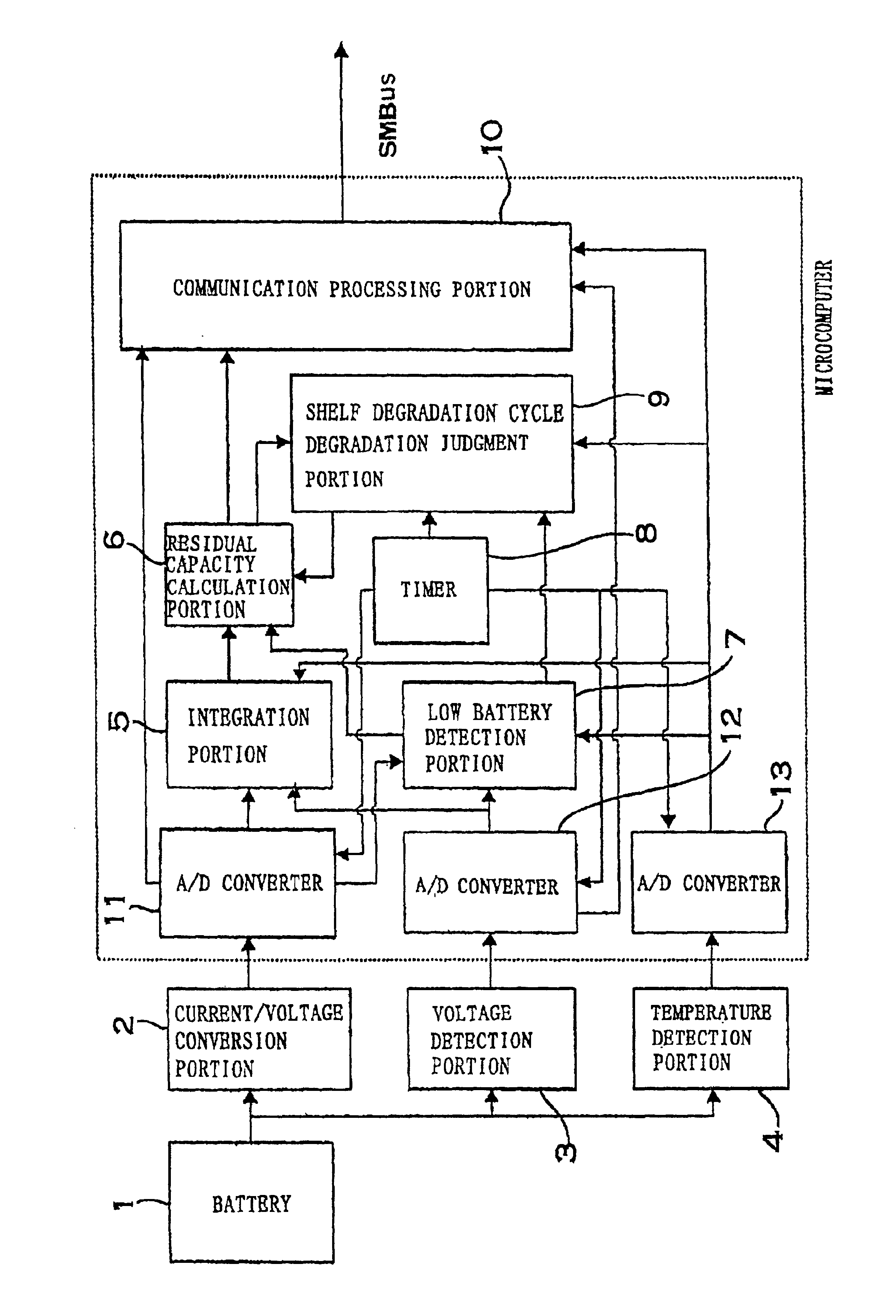

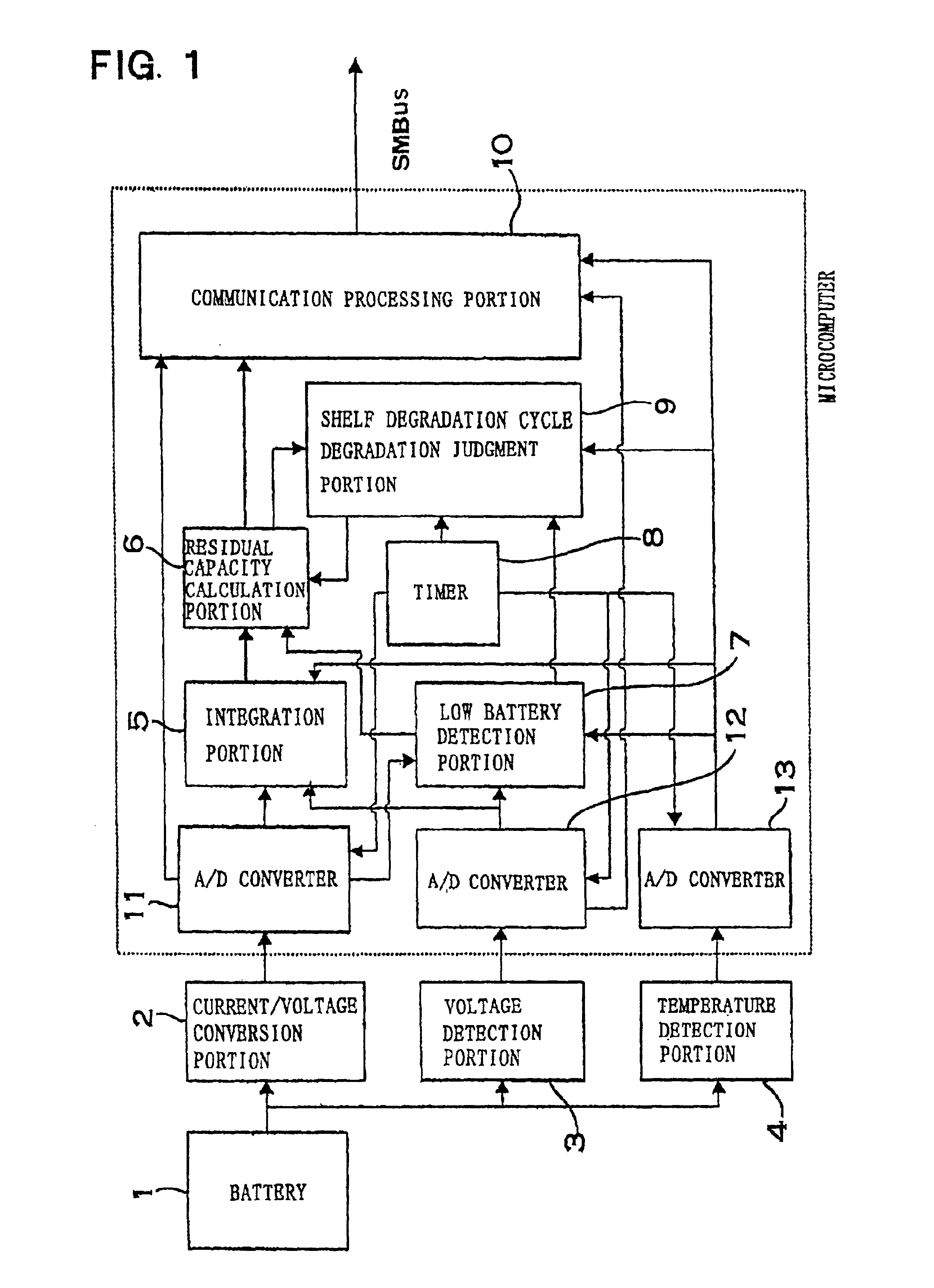

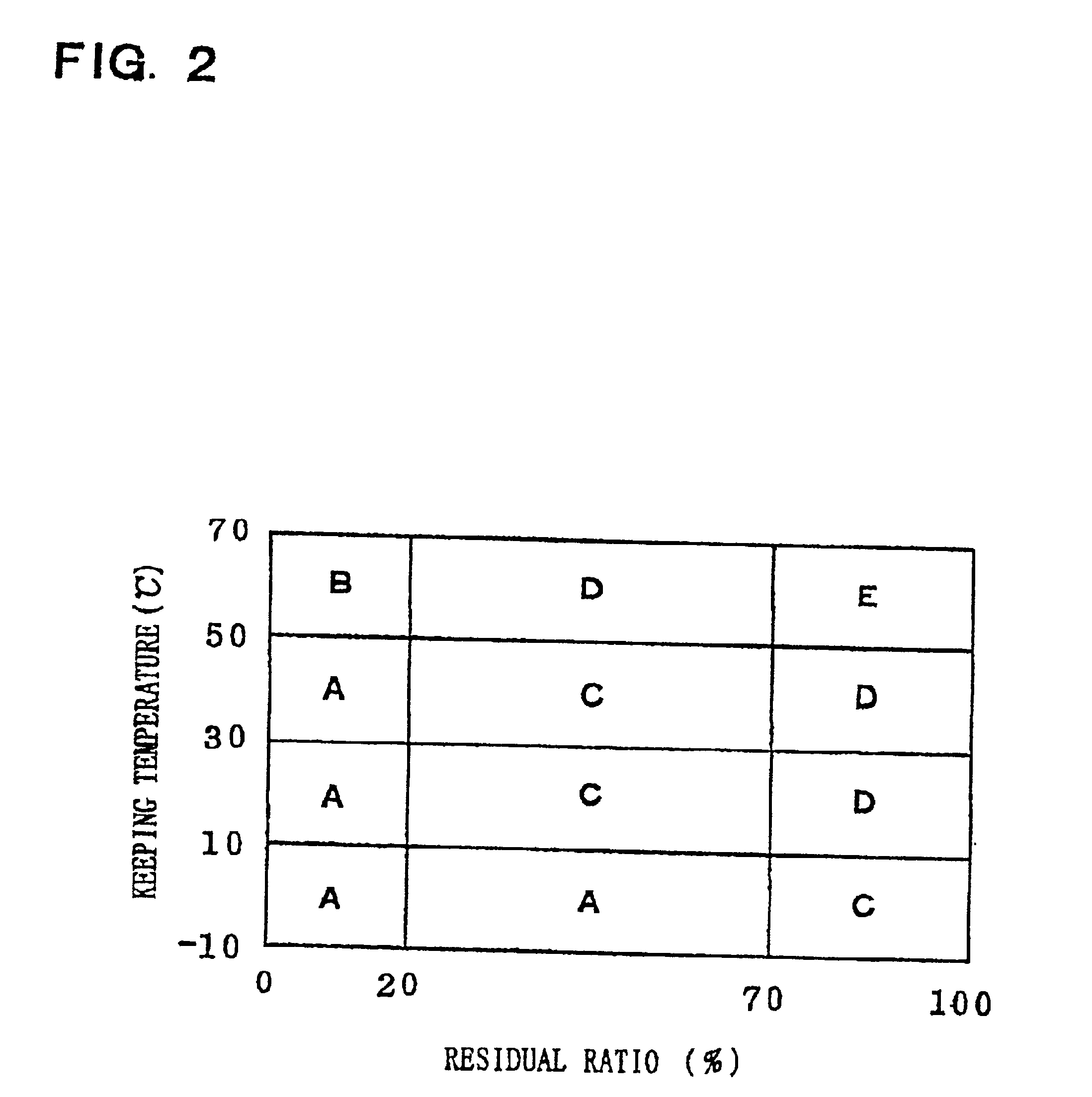

Residual capacity correction method for battery

InactiveUS6930465B2Reduce probabilityLearning capacity is decreasedCircuit monitoring/indicationDifferent batteries chargingControl theoryCorrection method

In a residual capacity correction method for a battery, a count of one cycle is made each time an accumulated quantity of a charge capacity of a battery reaches a learning capacity of the battery at that time, and the learning capacity is decreased by a specified cycle degradation capacity per charge of the one cycle, alternatively a decreasing rate of the learning capacity is specified as a keeping degradation capacity while a keeping temperature and a residual capacity of the battery are used as parameters, and as a keeping time passes, the learning capacity is decreased by the keeping degradation capacity specified from the keeping temperature and the residual capacity of the battery.

Owner:SANYO ELECTRIC CO LTD

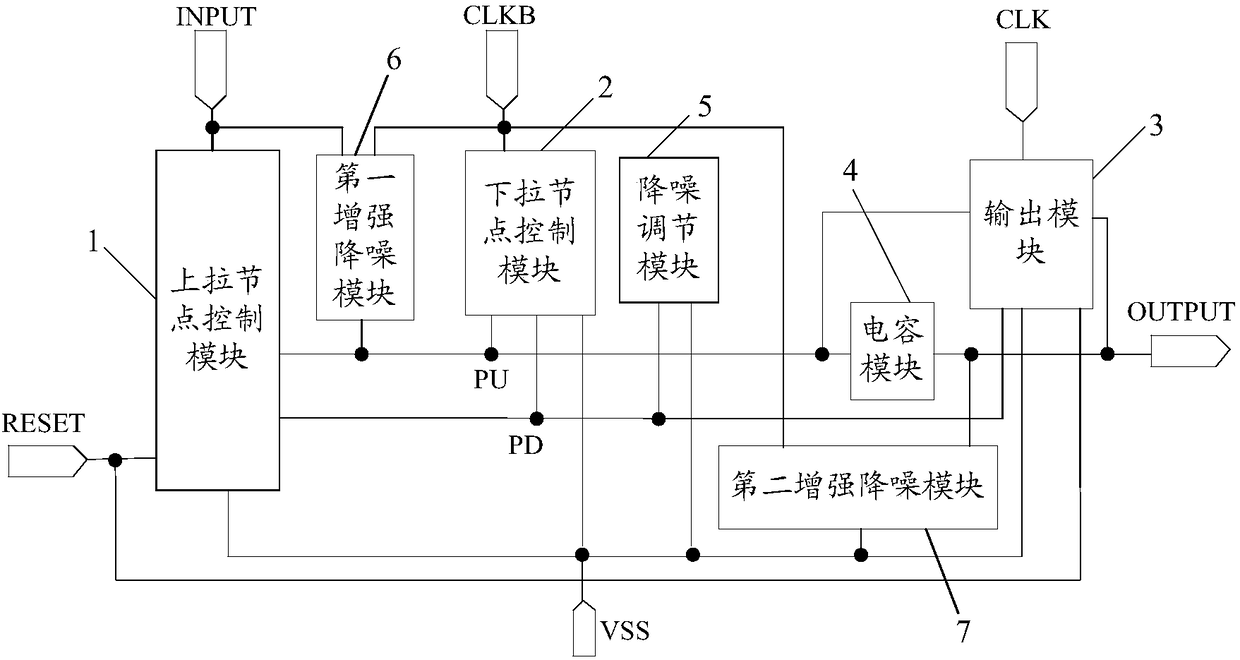

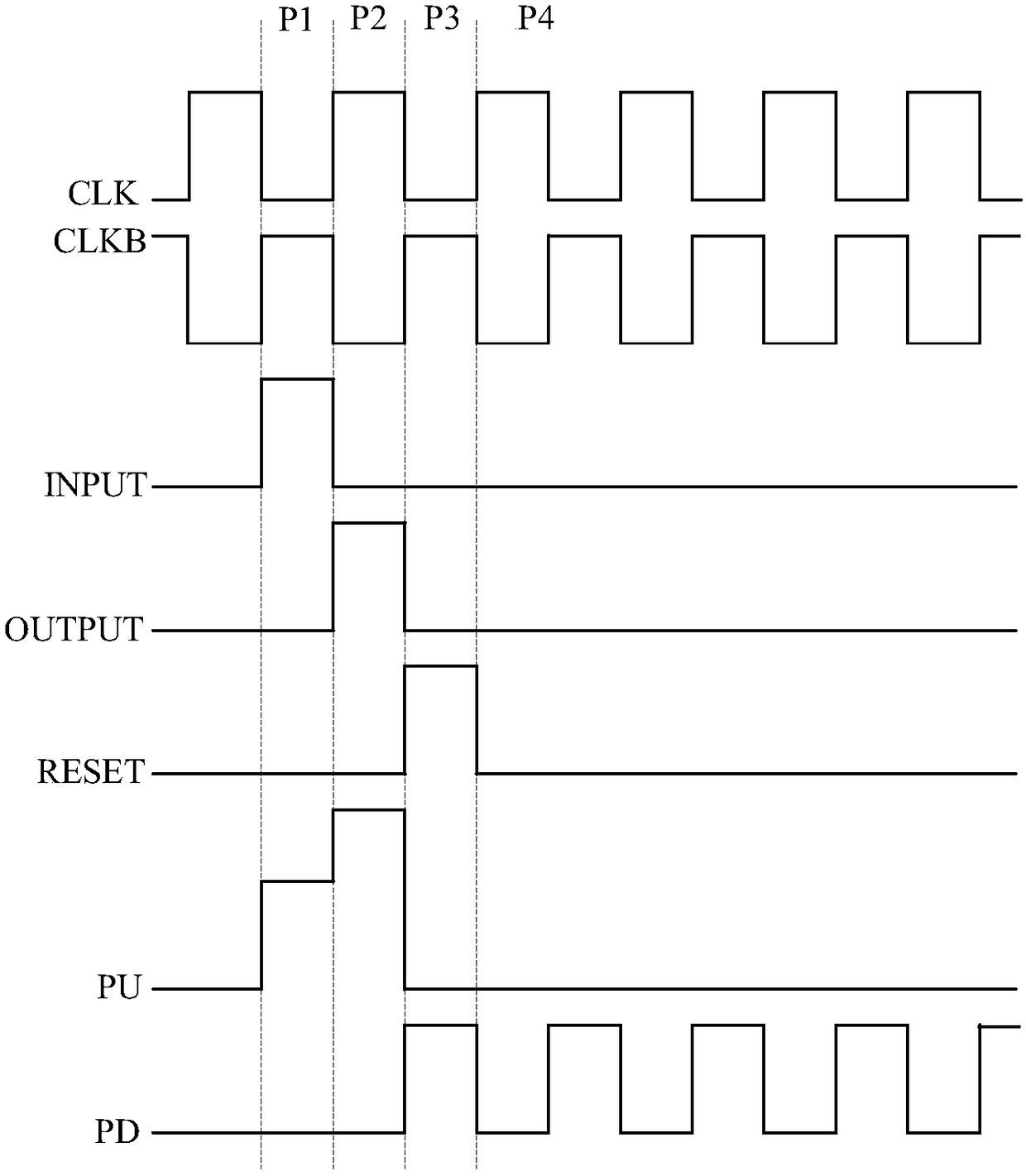

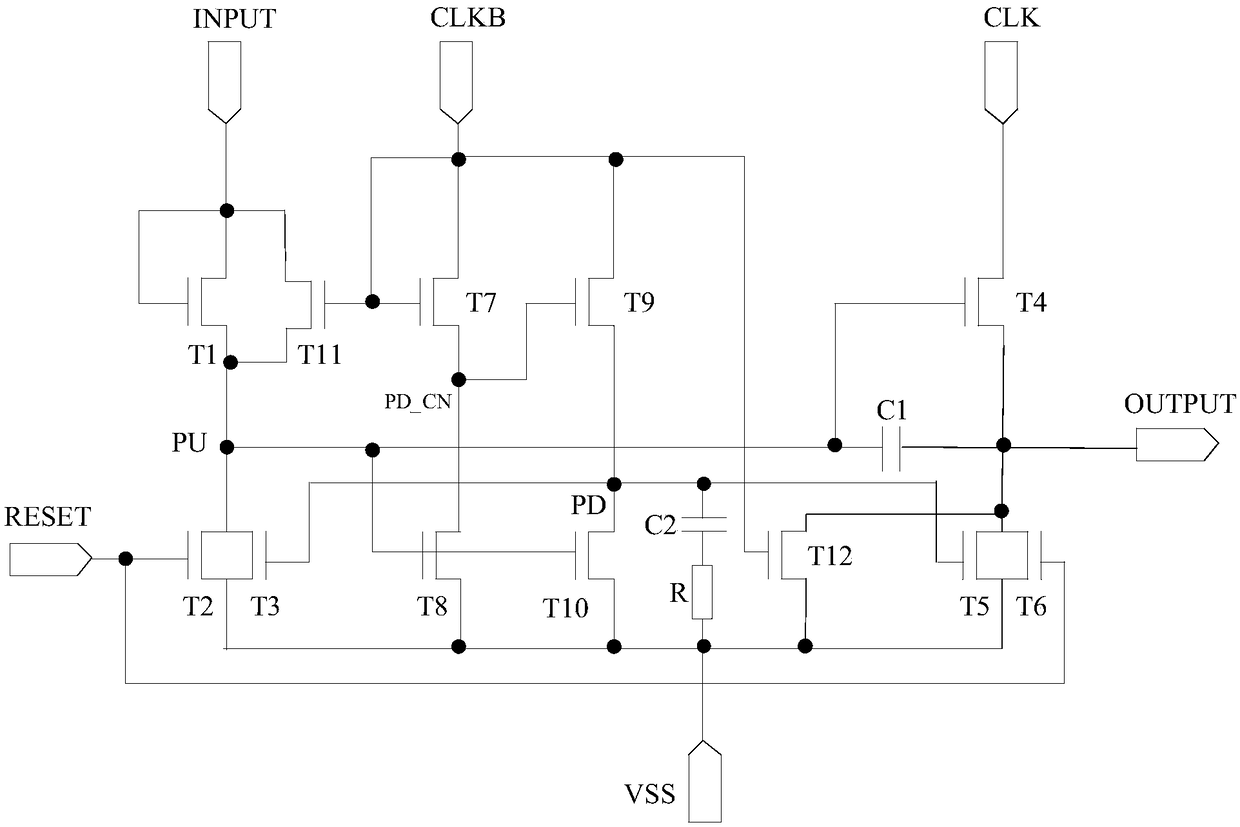

Shift register unit and driving method thereof and gate driving circuit

ActiveCN108389542AControl rate of ascentControlled rate of ascentStatic indicating devicesDigital storageCapacitanceShift register

The invention discloses a shift register unit and a driving method thereof and a gate driving circuit, which relate to the technical field of display and aim at solving the problems that the existingshift register unit is likely to meet electric leakage increase and lose noise reduction capability in a retaining time period. The shift register unit comprises a pull-up node control module, a pull-down node control module, a capacitor module, an output module and a noise reduction adjustment module, wherein the noise reduction adjustment module is connected with a pull-down node and a first level input terminal respectively; and the noise reduction adjustment module is used for controlling to reduce the rising rate of potential of the pull-down node in a noise reduction time period in the retaining time period and controlling to reduce the falling rate of potential of the pull-down node in a non-noise reduction time period in the retaining time period. The shift register unit provided in the invention is used for providing gate driving signals.

Owner:BOE TECH GRP CO LTD +1

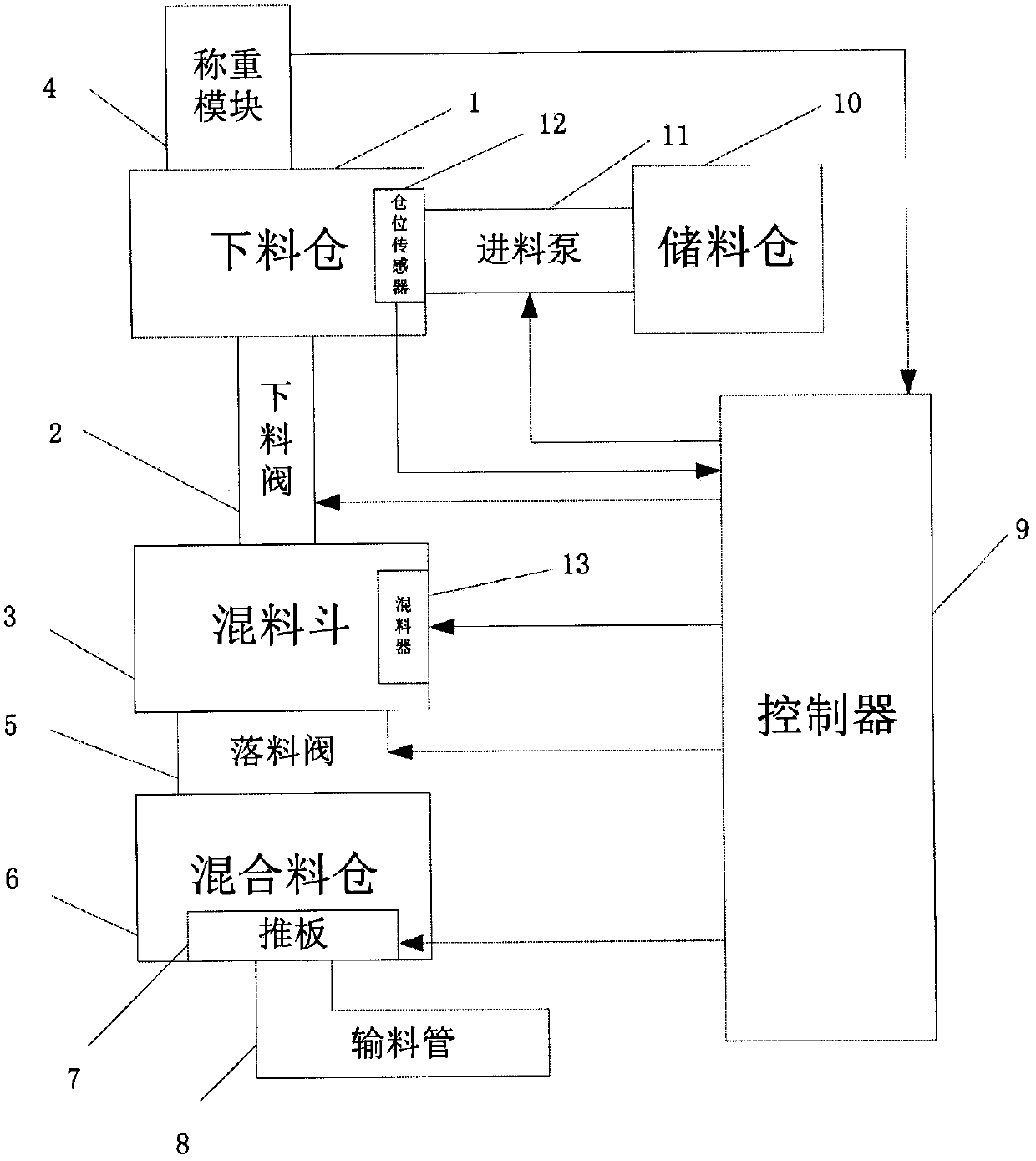

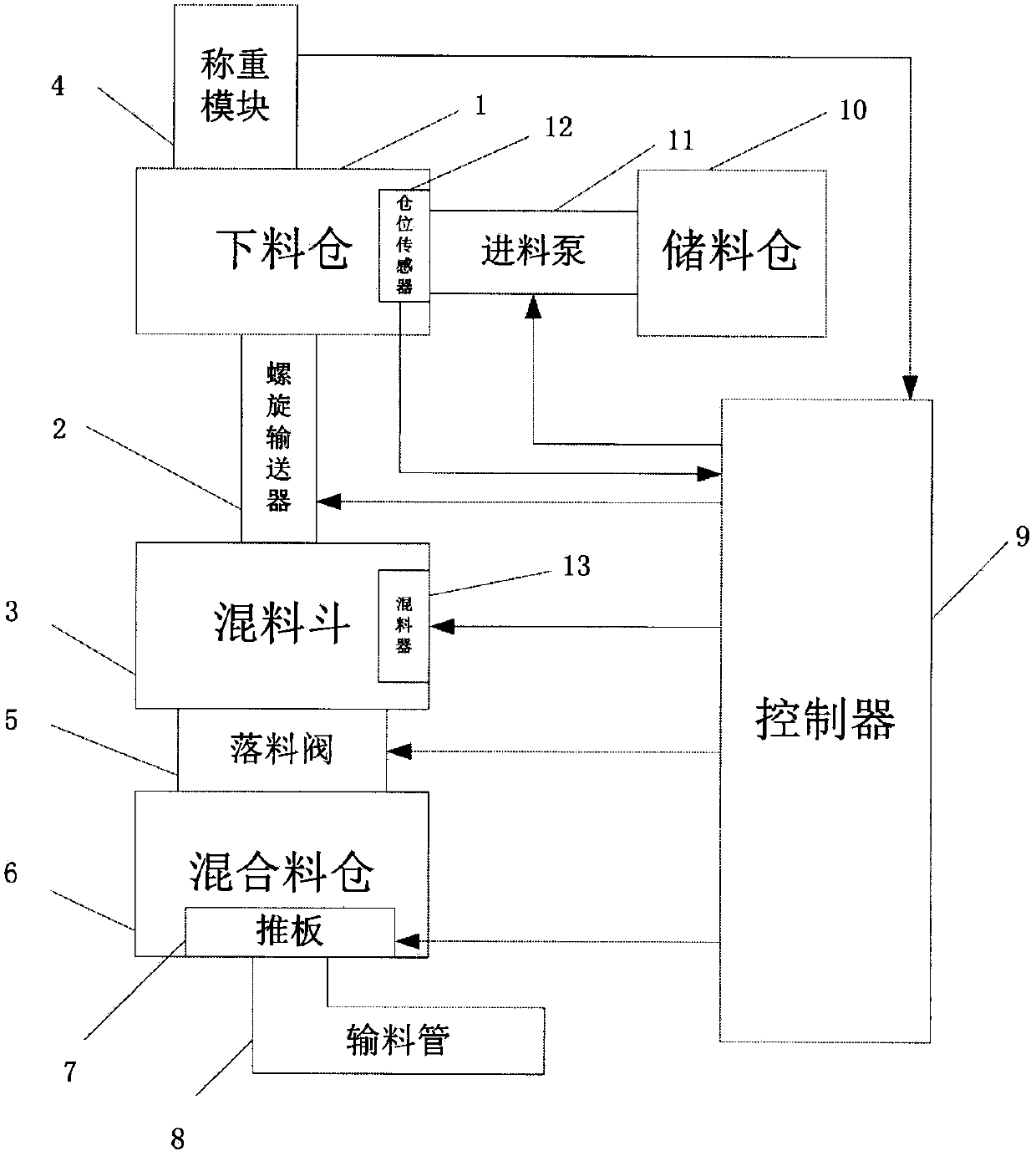

Screw rod weightless type material discharging machine based on neural network and controller of screw rod weightless type material discharging machine

ActiveCN107720311AHigh speedPrecise cuttingLarge containersControl devices for conveyorsSpiral bladeEngineering

The invention discloses a screw rod weightless type material discharging machine based on a neural network and a controller of the screw rod weightless type material discharging machine. The materialdischarging machine comprises a rack, a discharging bin, a spiral conveyor, a material mixing hopper, a weighing module, a material falling valve and the controller. The controller adopts a neural network module and predicts the weightless value of a material based on a material level, a material falling rate and the material density of the discharging bin and the spiral blade diameter, the screwpitch and the maximum rotating speed of a screw rod of the spiral conveyor, so that the closing time of the spiral conveyor is adjusted. According to the screw rod weightless type material dischargingmachine based on the neural network and the controller of the screw rod weightless type material discharging machine, modeling is conducted on discharging weighing by adopting the neural network, theweightless value of the falling material under different material falling states can be accurately predicted through the trained network so that direct and accurate discharging can be achieved, and the screw rod weightless type material discharging machine is suitable for small batch production; a bin position sensor and a vibrating rod are used for detecting and adjusting the material accumulative form in the discharging bin, and fluctuation of the material falling rate is reduced; and the total error of batch discharging is reduced by controlling the discharging accumulative error, and thedischarging efficiency is improved due to the fact that the screw rod can maintain the high running speed.

Owner:CHINA JILIANG UNIV

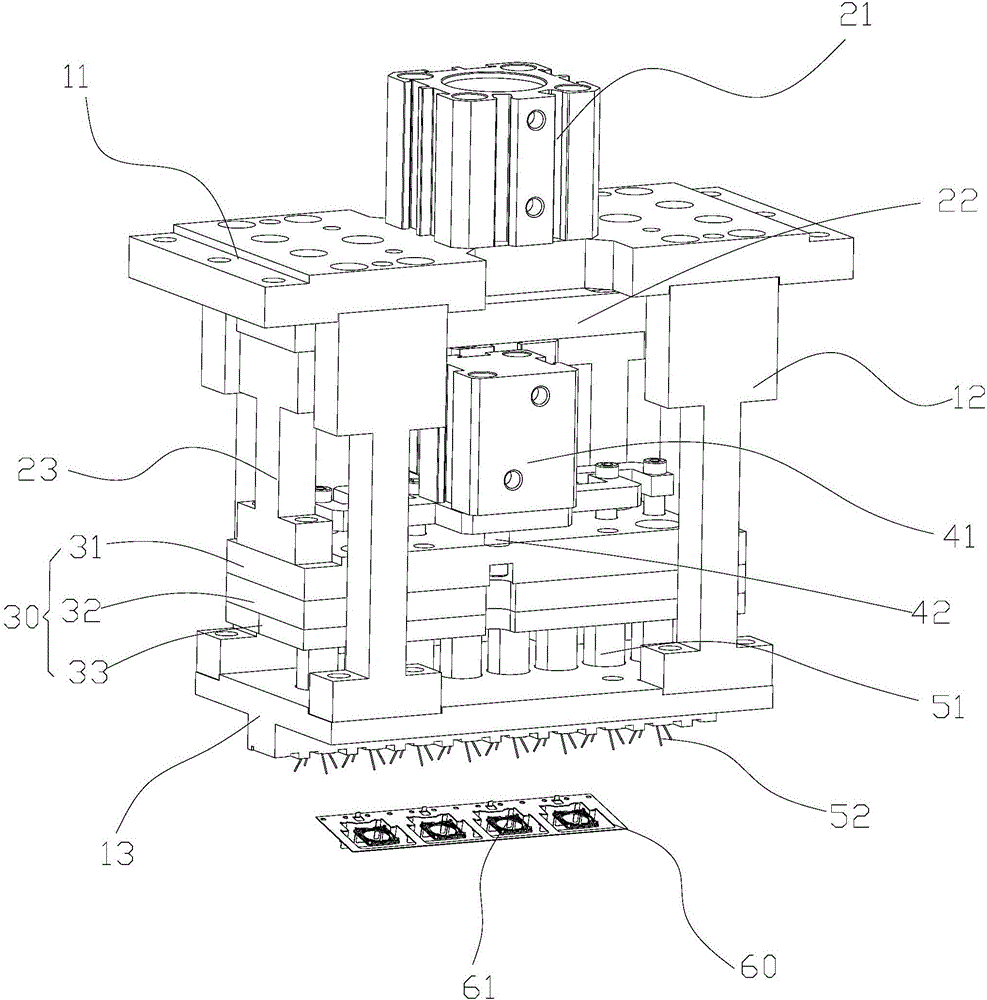

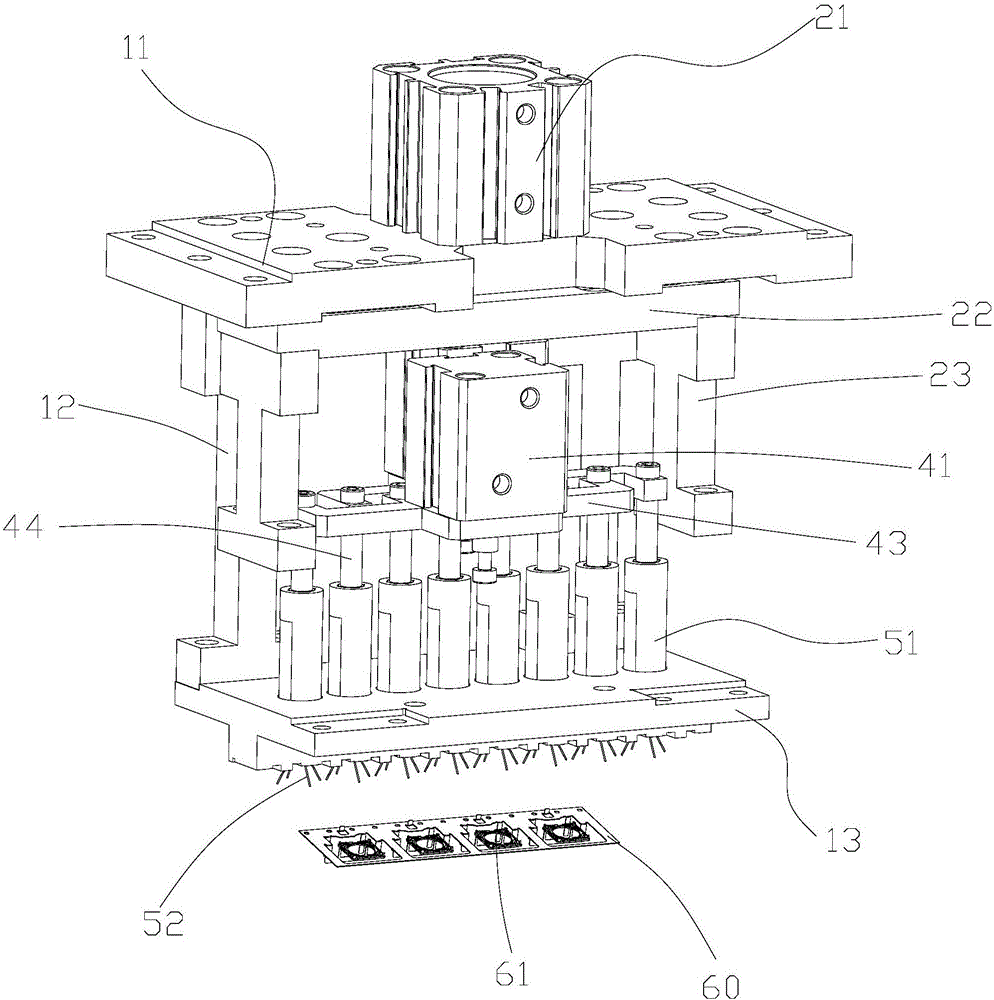

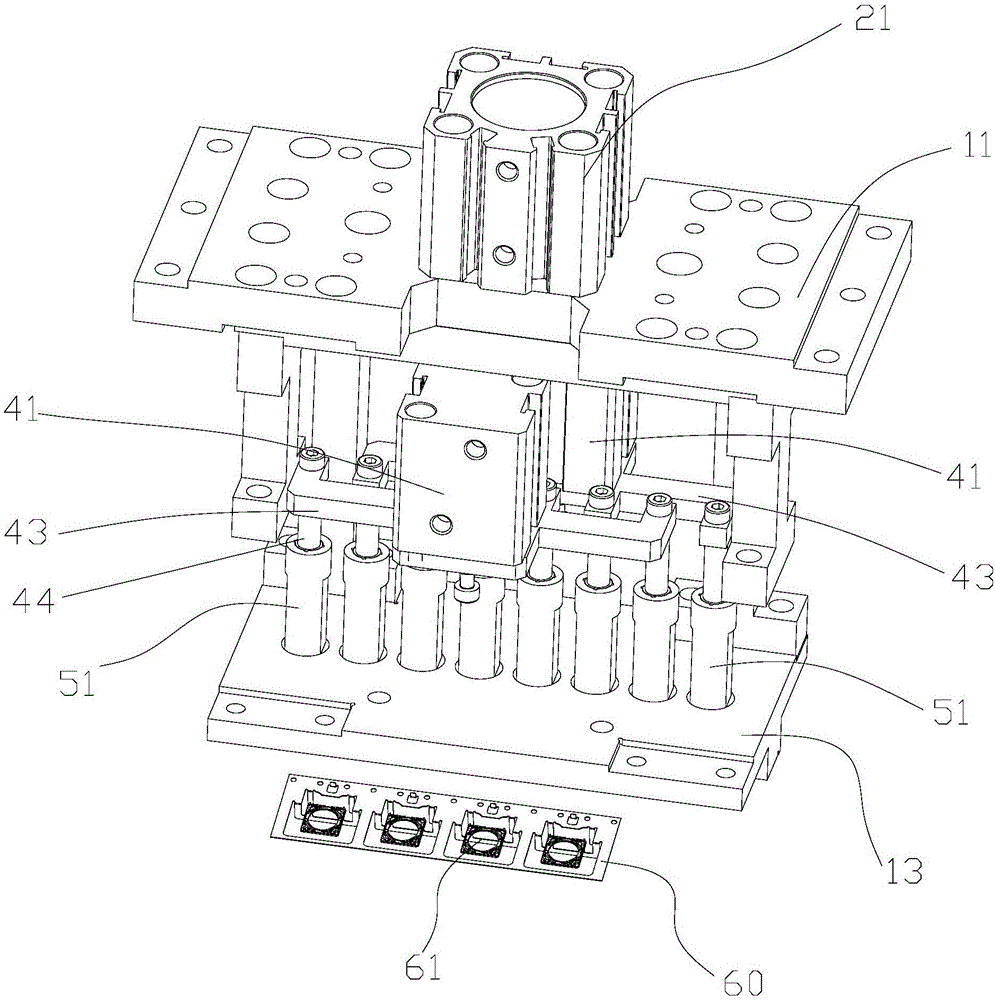

Material taking device and material taking method

ActiveCN106393576AWith elastic self-recovery forceRealize reclaimingCoatingsSelf recoveryRelative motion

The invention provides a material taking device and a material taking method using the material taking device to achieve material taking. The material taking device comprises a machine body, a lifting mechanism and at least one set of material taking assembly; the material taking assembly comprises an abutting part and a clamping claw provided with a plurality of claw parts, each claw part has elastic resilience force, and the multiple claw parts of the clamping claw in the non-deformable initial state are of external expanding structures; and the lifting mechanism drives the abutting part or / and the clamping claw to do relative motion, the abutting part abuts against or is separated from the claw parts of the clamping claw, and therefore the multiple claw parts are changed between the internal convergence structures and the self-recovery external expanding structures to achieve material taking and placing. By means of the manner, grabbing of multiple materials is achieved in a single manner, the material taking device is simple in structure and easy and convenient to operate, and the falling rate generated during material taking can be greatly decreased.

Owner:厦门控智电子科技有限公司

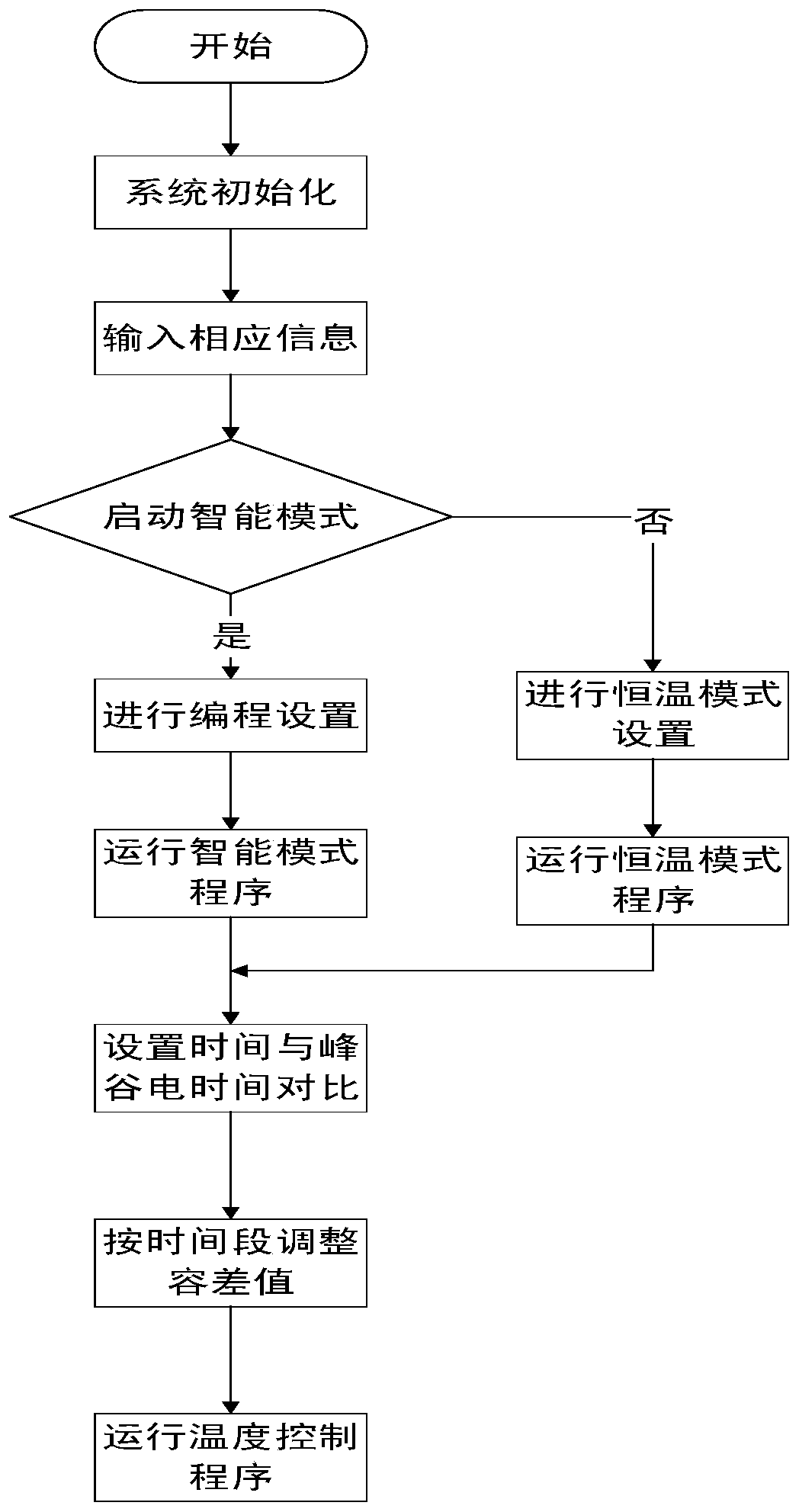

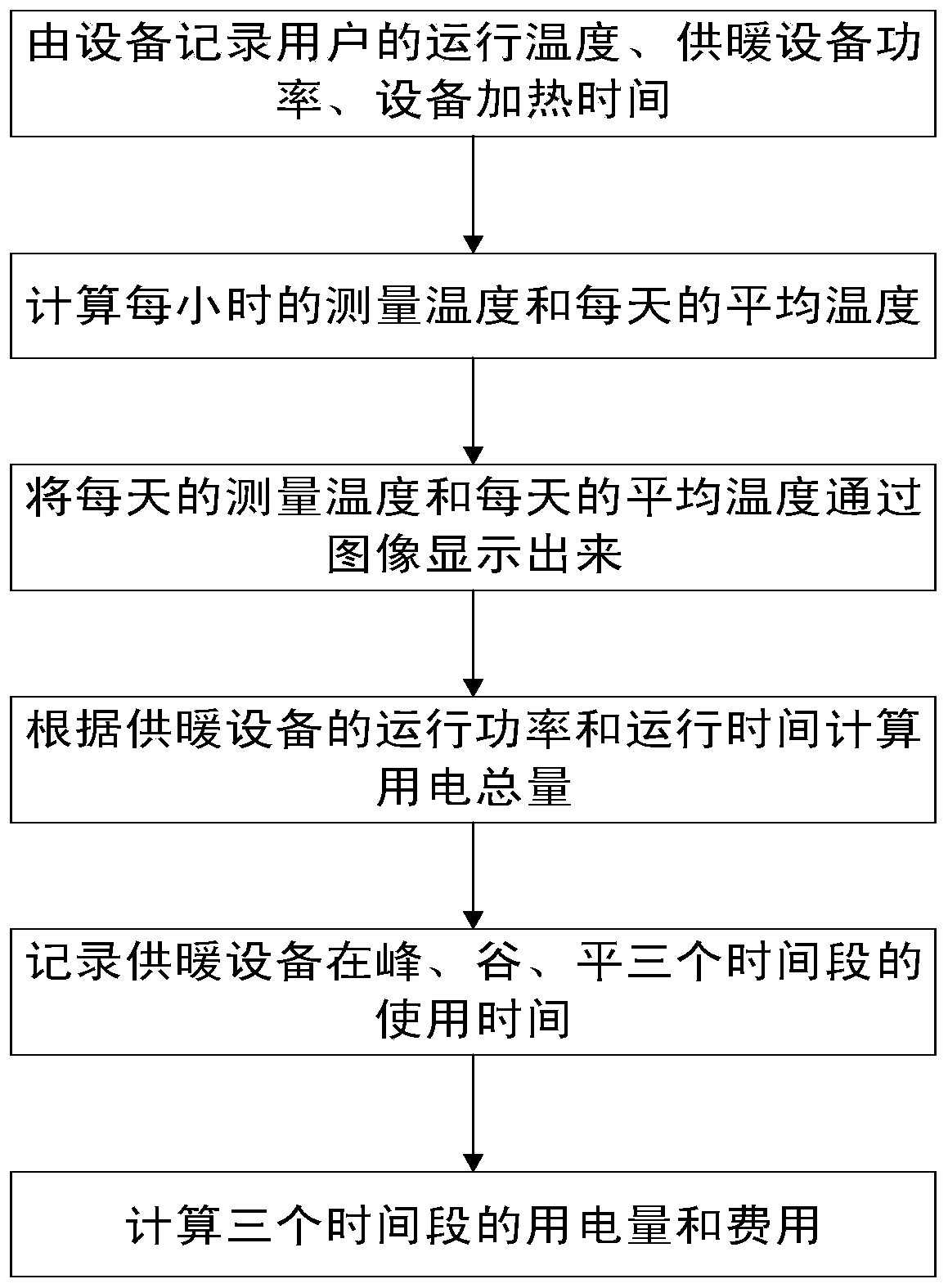

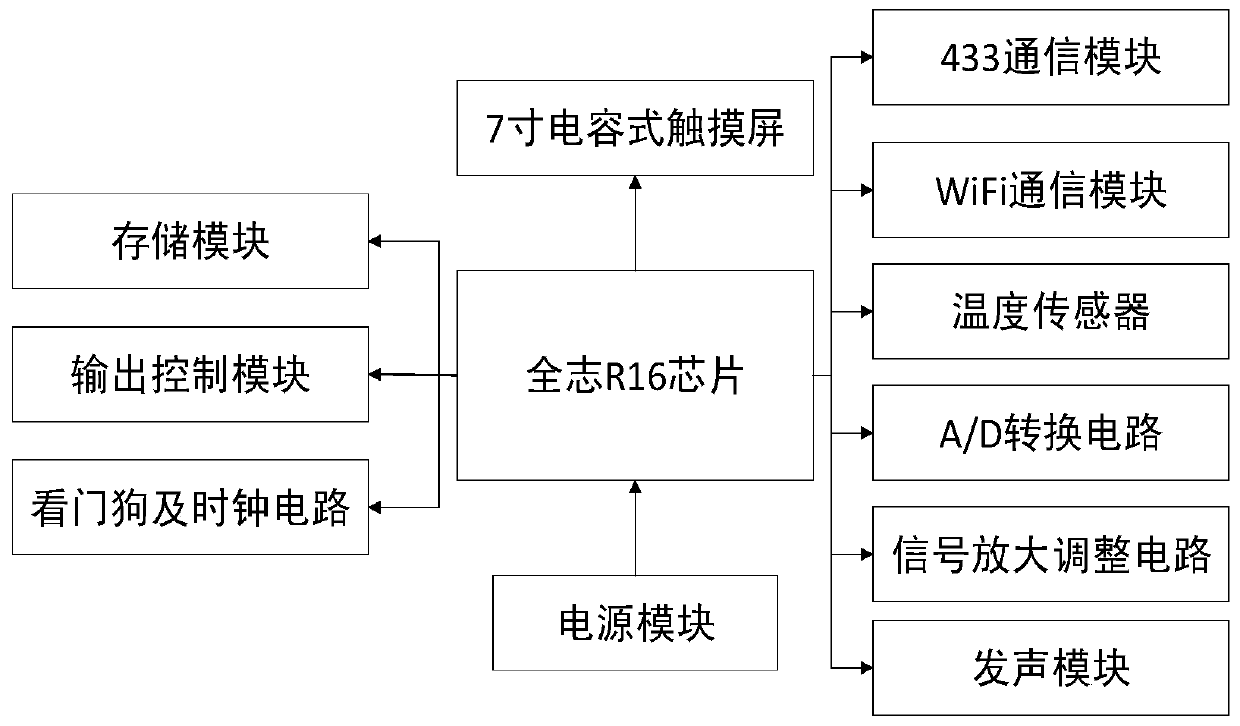

Electric heating temperature control method of peak, valley and flat electricity price operation function

InactiveCN110332602AEasy programming inputEasy to operateData processing applicationsLighting and heating apparatusTemperature controlElectricity price

The invention belongs to the field of electric heating temperature control, and particularly relates to an electric heating temperature control method of the peak, valley and flat electricity price operation function. The electric heating temperature control method includes the steps that firstly, a temperature sensor collects the current room temperature; secondly, a built-in real-time clock canobtain the current time and compare the current time with the peak and valley electricity price time to determine which of the electricity utilization time periods, including the electricity utilization peak period, the electricity utilization valley period and the electricity utilization flat period, is the time period where the moment is located; thirdly, in the electricity utilization peak period, the electricity utilization flat period and the electricity utilization valley period, the current room temperature Wo in the first step is compared with the set value Wp, and when Wo is smaller than or equal to Wp-2, a temperature controller starts the heating mode, and operation of a heating device is controlled through a power module and an output control module; and fourthly, during heating, the temperature controller calculates the time consumed when the temperature rises by every 1 DEG C in a building, and the temperature rise rate delta W1 and the temperature fall rate delta W2 aredetermined. By means of the electric heating temperature control method, utilization of peak period electricity can be reduced through valley period electricity and flat period electricity, the temperature is recorded and displayed to a user, and generated electricity quantities and expenses are displayed in time.

Owner:辽宁省鑫源温控技术有限公司

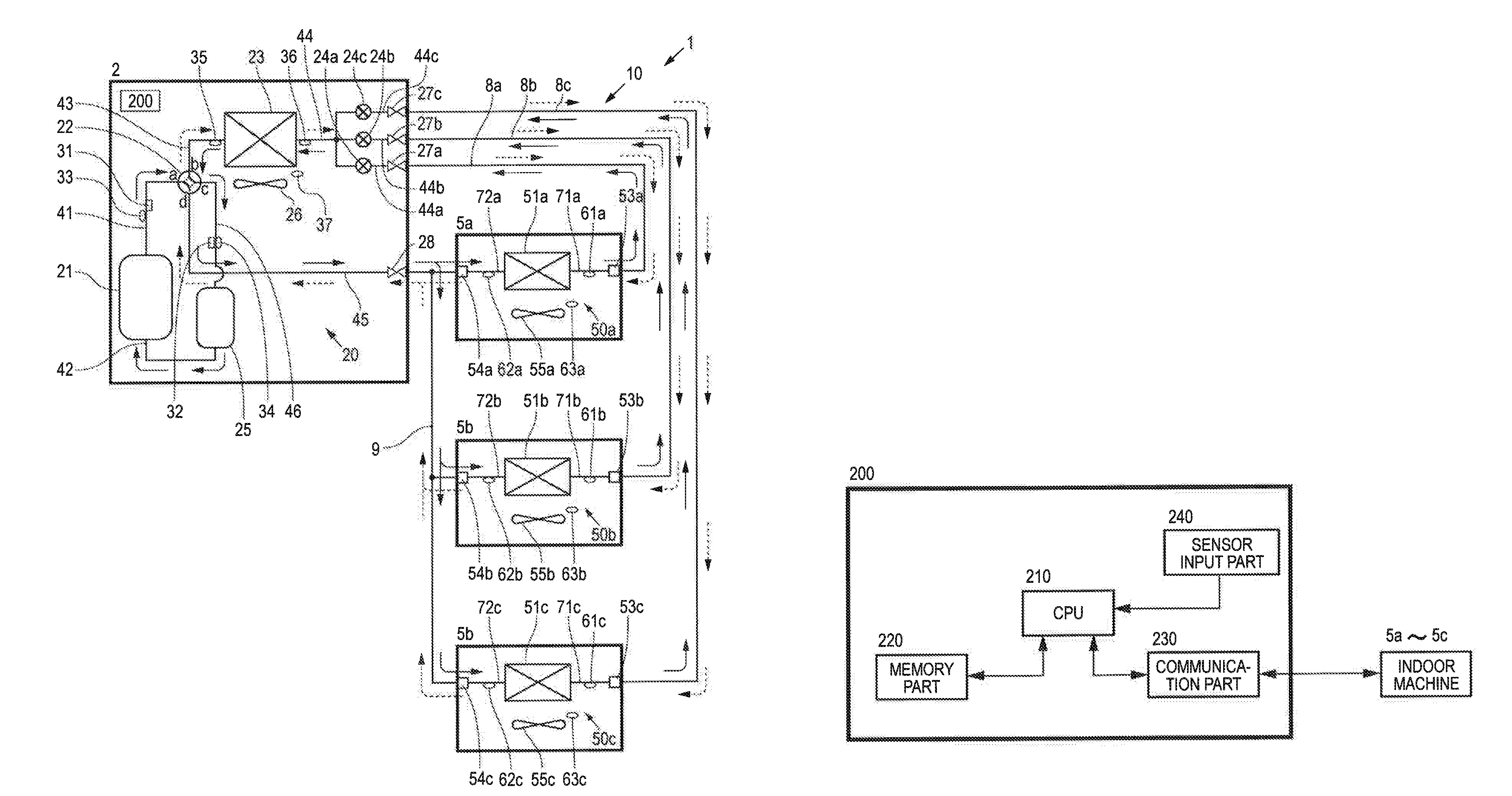

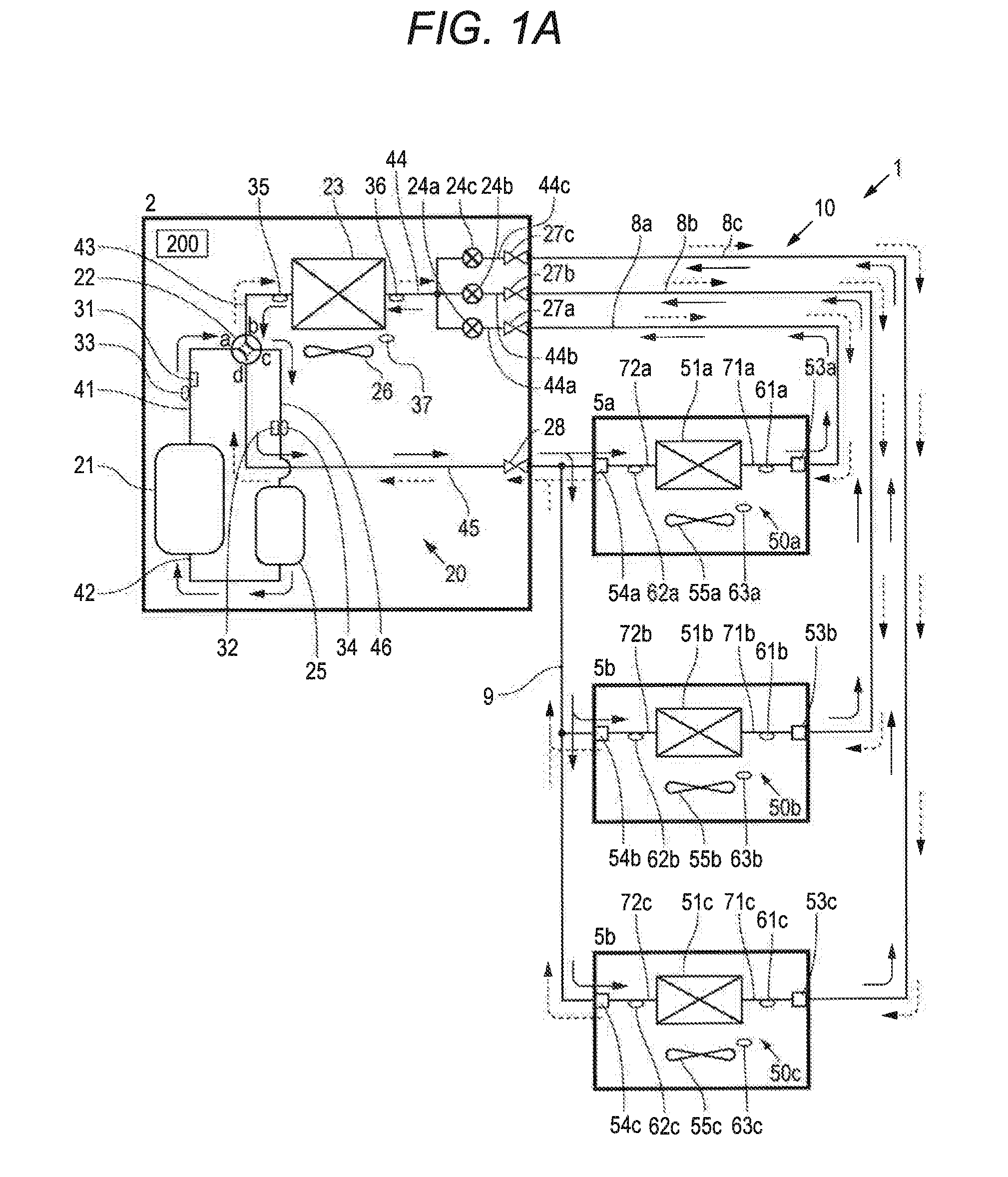

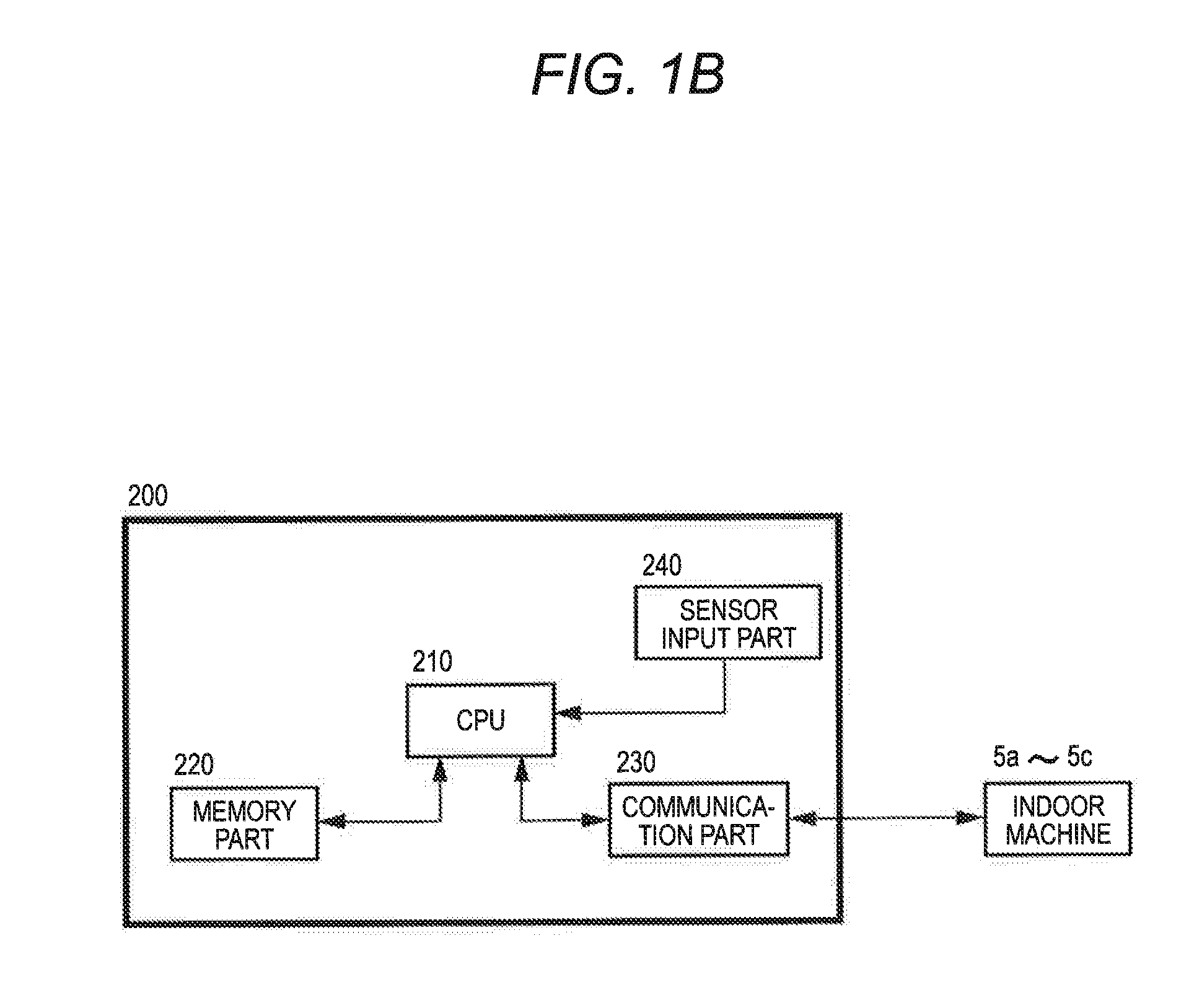

Air conditioner

ActiveUS20160258661A1Mechanical apparatusSpace heating and ventilation safety systemsFrostFour-way valve

CPU of an air conditioner reads out a heat exchanger outlet temperature stored in time series into a memory part to check whether the current heat exchanger outlet temperature is a second threshold temperature or lower or not, whether the drop rate of the heat exchanger outlet temperature calculated using the latest heat exchanger outlet temperature and the second-to-the-latest heat exchanger outlet temperature is a specific drop rate or higher or not, and whether the number of indoor units in operation of indoor units has increased or not during calculation of the drop rate of the heat exchanger outlet temperature. And, when the second frost forming condition is satisfied, CPU switches a four-way valve to set a refrigerant circuit into a cooling cycle to thereby execute a defrosting operation preparation processing and, on completing the defrosting operation preparation processing, resumes a compressor to start a defrosting operation.

Owner:FUJITSU GENERAL LTD

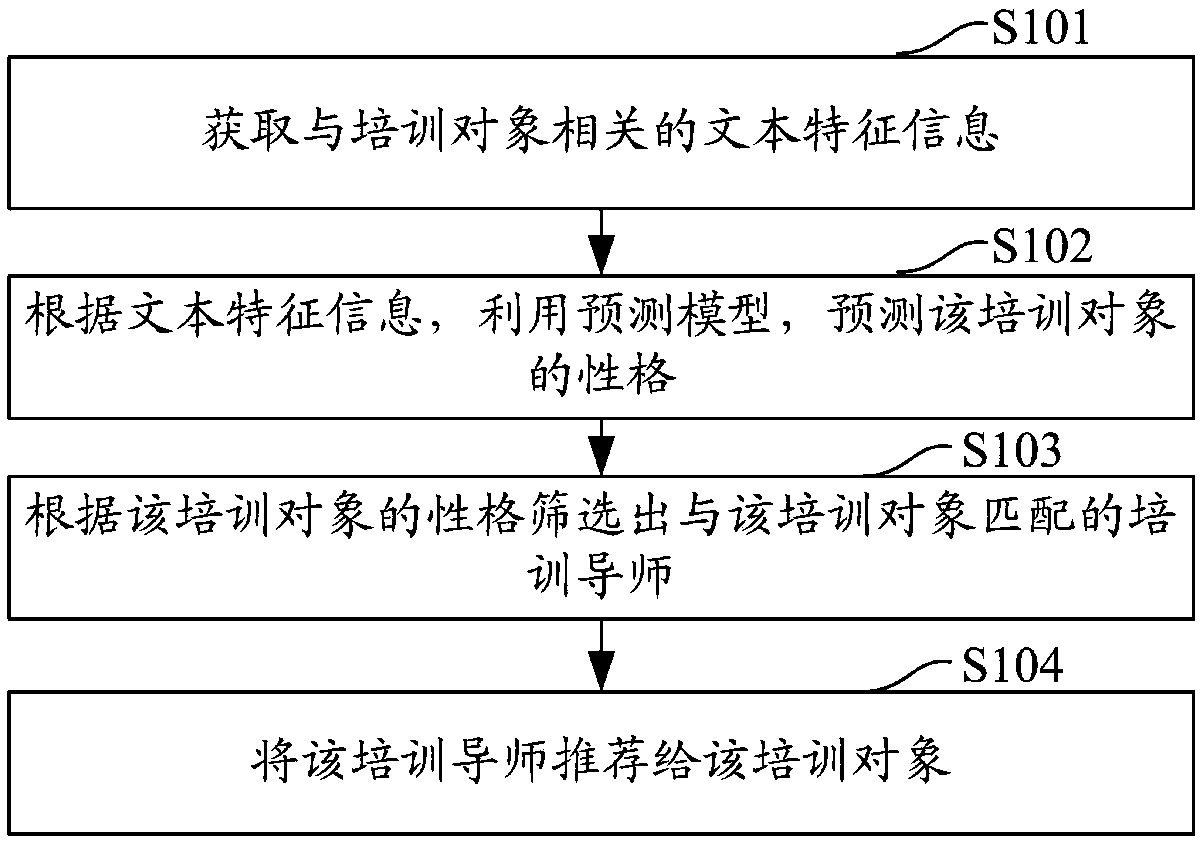

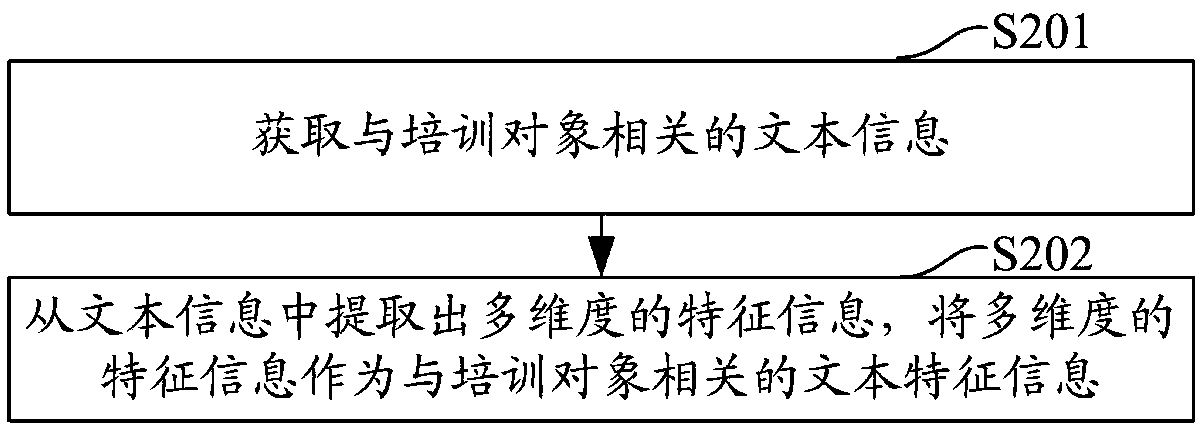

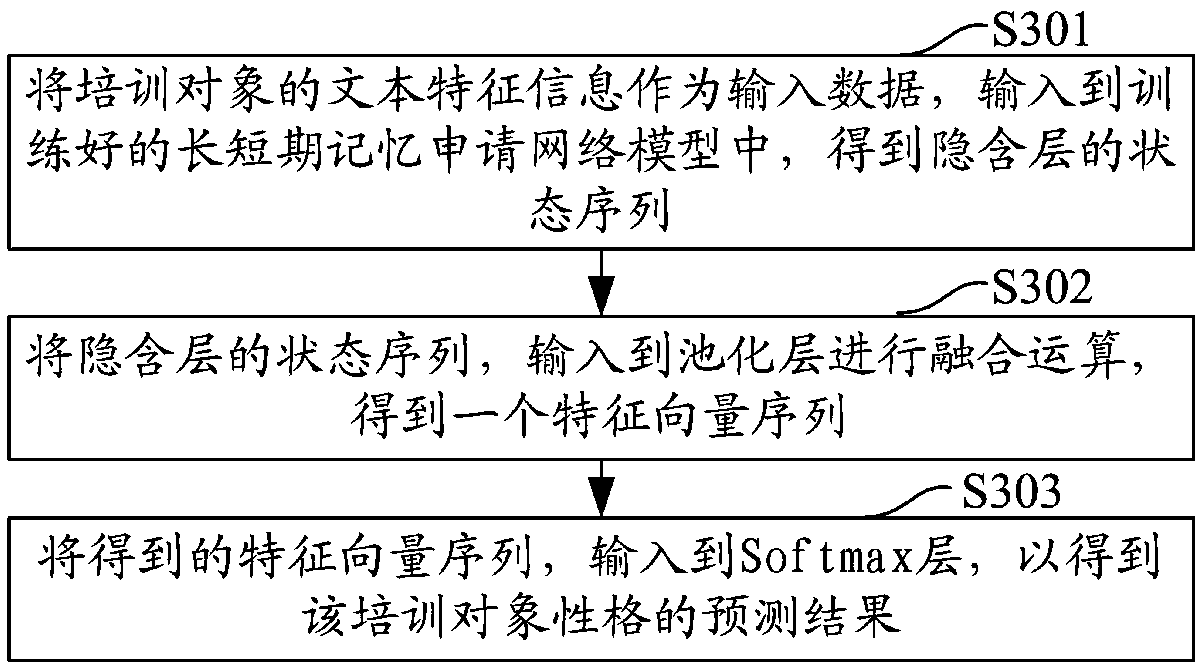

Recommending method, device, computer equipment and storage medium

PendingCN108776846APromote the development of personal abilitiesImprove customer service skillsForecastingOffice automationSkill setsData mining

The embodiment of the invention provides a recommending method, device, computer equipment and a storage medium. The method comprises steps: text feature information related to a training object is acquired; according to the text feature information, a prediction model is used to predict the character of the training object; according to the character of the training object, a training tutor matched with the training object is screened; and the training tutor is recommended to the training object. In the embodiment of the invention, according to the text feature information of the training object and the character of the training object predicted by the prediction model, the character prediction efficiency and the prediction result accuracy are improved; the training tutor matched with thetraining object is recommended according to the character of the training object, guidance and communication between the training object and the training tutor are facilitated, the development of theindividual ability of the training object is promoted, the skill of serving a customer by the training object is also improved, the loyalty of teh training object is improved, and the falling rate ofthe training object is reduced.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

Magnetic recording medium and method for manufacturing the same

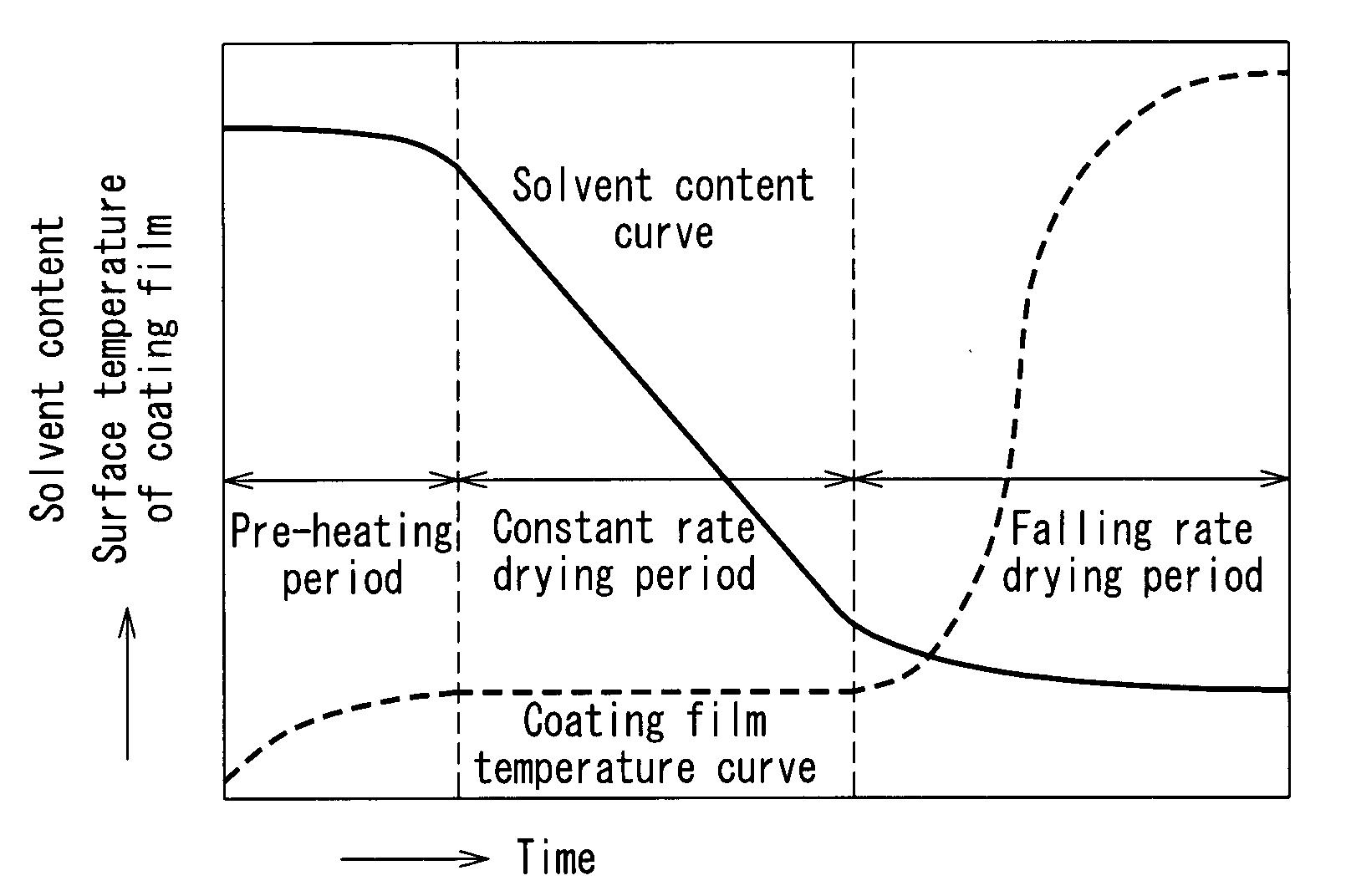

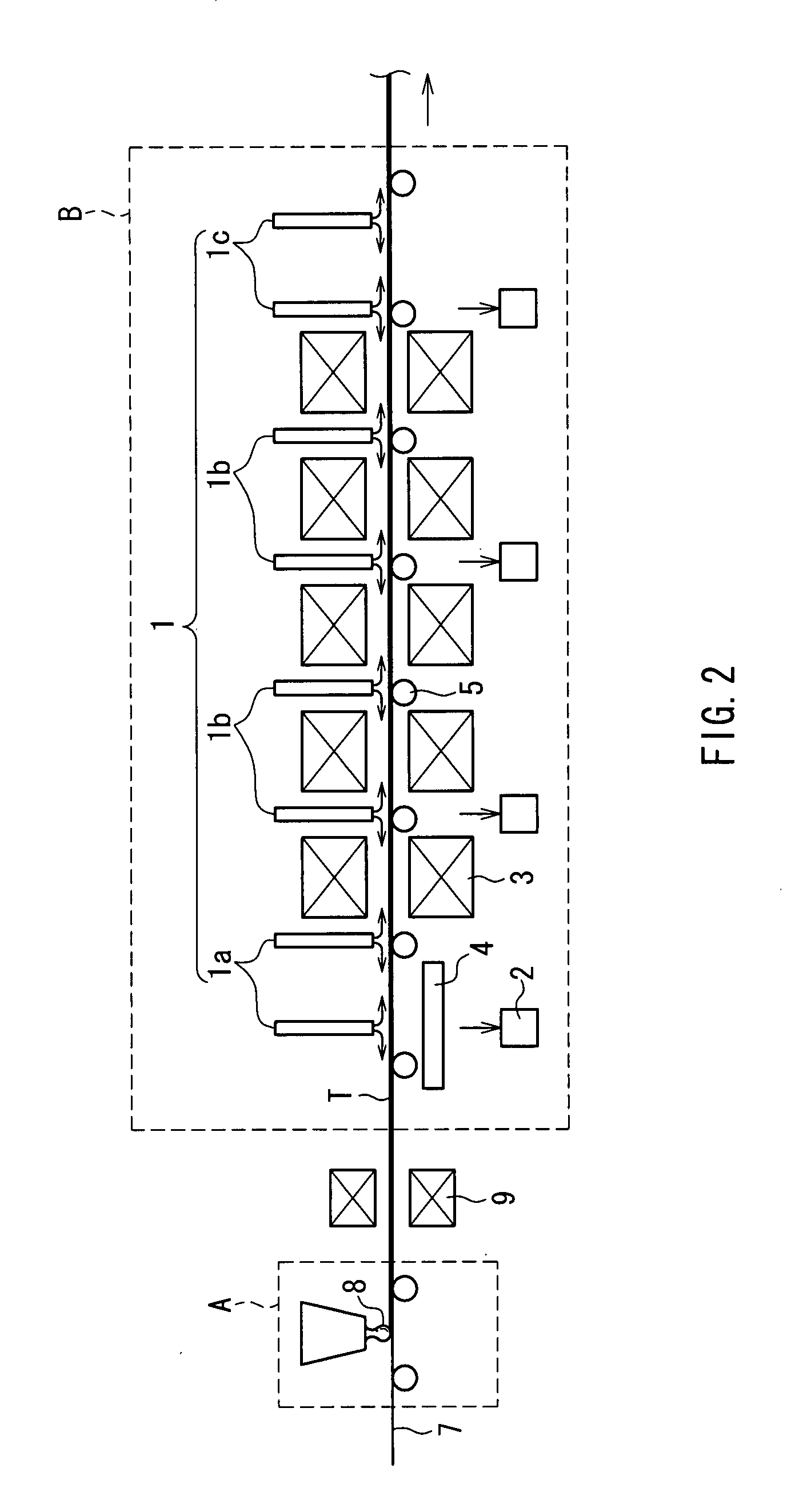

A method for manufacturing a magnetic recording medium of the present invention includes a magnetic layer forming step in which a drying process is performed. The drying process includes: a pre-heating stage in which a magnetic coating film is heated until the surface temperature of the magnetic coating film stops rising and reaches a substantially constant temperature; a constant rate drying stage that is performed after the pre-heating stage in which the surface temperature of the magnetic coating film is held substantially constant; and a falling rate drying stage that is performed after the constant rate drying stage in which the surface temperature of the magnetic coating film is increased to be higher than the surface temperature during the constant rate drying stage to harden the magnetic coating film. The constant rate drying period in which the constant rate drying stage is performed is 0.2 seconds or more. The first solvent is made of one solvent or two or more solvents having different boiling points, and the difference (Tb−Ts) between the boiling point Tb of the solvent having the lowest boiling point among the solvents contained in the first solvent and the surface temperature Ts of the magnetic coating film during the constant rate drying period is 1 to 50° C.

Owner:HITACHT MAXELL LTD

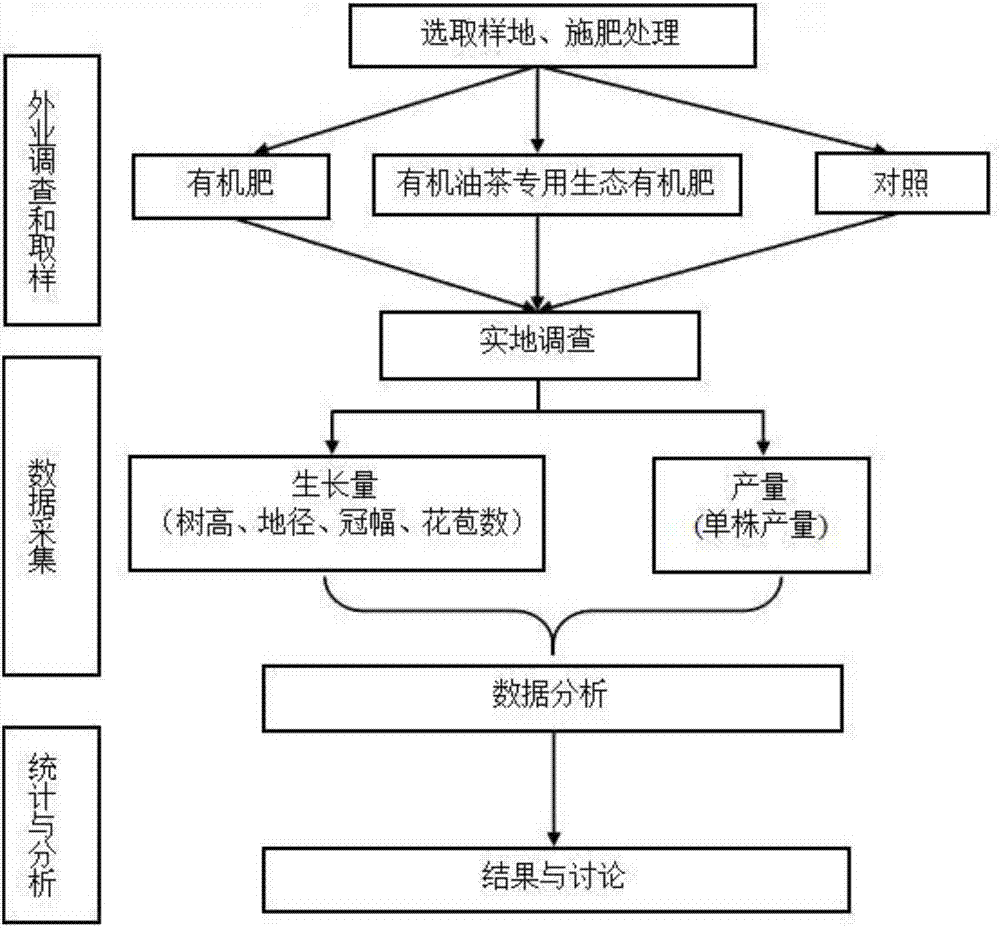

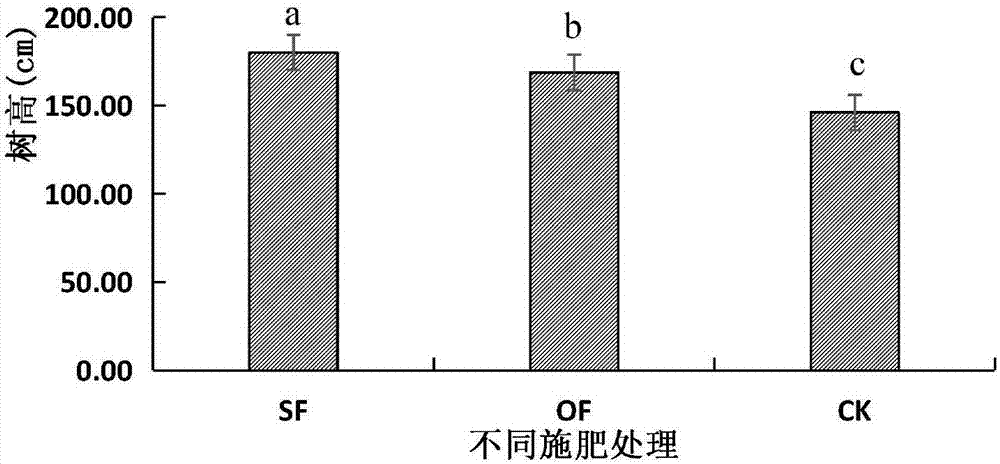

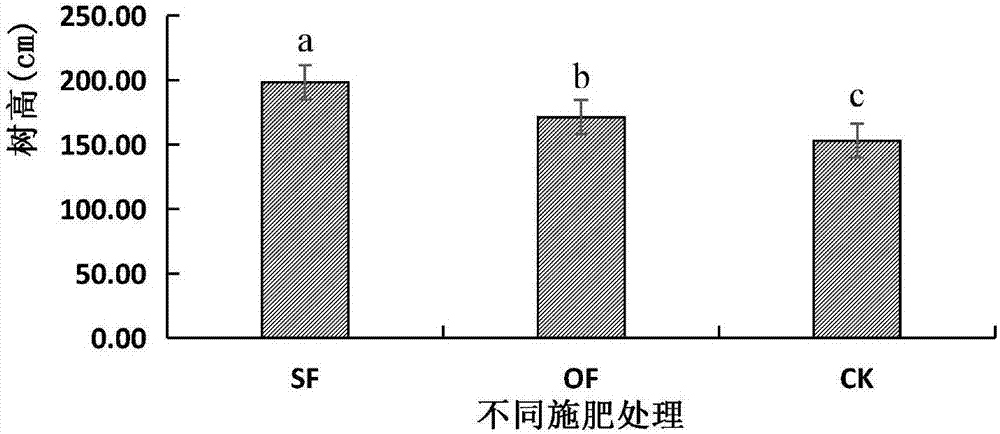

Special organic fertilizer for organic oil tea and preparation method and application thereof

InactiveCN107500910AEnsure hygiene and safetyIncrease the granular structureBioloigcal waste fertilisersFertilising methodsCamellia oleiferaPhosphate

The invention discloses a special organic fertilizer for organic oil tea. The special organic fertilizer is prepared from the following components in percentages by mass: 30-55% of compost, 5-15% of peat, 15-30% of potassium magnesium sulfate, 9-17% of powdered rock phosphate, 0.5-2% of borax, 0.5-1% of a seaweed extraction liquid and 5-15% of clay. The special organic fertilizer disclosed by the invention not only can provide crops with nutrients directly, but also can improve the cold resistance of the oil tea obviously, reduce the flower and fruit falling rates, reduce the plant diseases and insect pests and improve the stress resistance of plants, so that the crops bloom better and bear more fruits, a lot of nutrients are absorbed in a flowering and fruit-bearing later period, a purpose of bearing more fruits to promote production is achieved, the output of the oil tea is improved obviously, and a purpose of production and yield increase is achieved; moreover, the special organic fertilizer which can be used as a soil improver improves the organic matters of soil, regulates the pH value of the soil and improves the granular structures of the soil, and achieves the purposes of improving the soil and increasing the fertilizer efficiency.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

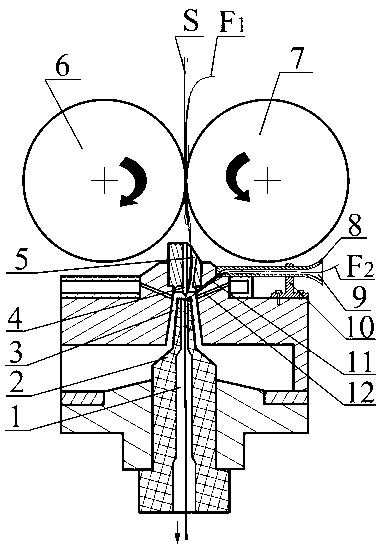

Vortex composite spinning method for producing structured yarns

InactiveCN103215700ARealize intermittent feedingRealize feeding with periodic change in tensionContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention relates to a vortex composite spinning method for producing structured yarns, which belongs to the technical field of textile processing. According to the method, a yarn conveying channel which forms an included angle of 15-65 degrees with a guide pin is formed on each vortex spinning device outer tube of a vortex spinning machine; the yarn conveying channel is positioned on the same side as a front rubber roll; a yarn outlet of the yarn conveying channel is positioned at the fiber outlet of a fiber conveying channel and the yarn inlet of a yarn channel; the yarn inlet of the yarn conveying channel is communicated with a yarn leading channel of a yarn leading tube; and decorative yarns F2 are directly fed into the yarn inlet of the yarn channel without passing through a front jaw, and are wound on the surfaces of vortex core-spun yarns formed by F1 and short fiber rods S, so that the vortex composite structured yarns are formed. Due to the adoption of the method, short fibers produced in the conventional vortex spinning process can be prevented from being taken away by air flow, the fiber falling rate of short fibers is lowered, the yarn forming capacity during vortex composite spinning is improved greatly, end breakage of resultant yarns is eliminated, the requirements of vortex resultant yarns on a short fiber raw material are lowered, and the spinnable fiber raw material range of the vortex spinning is expanded greatly.

Owner:WUHAN TEXTILE UNIV +1

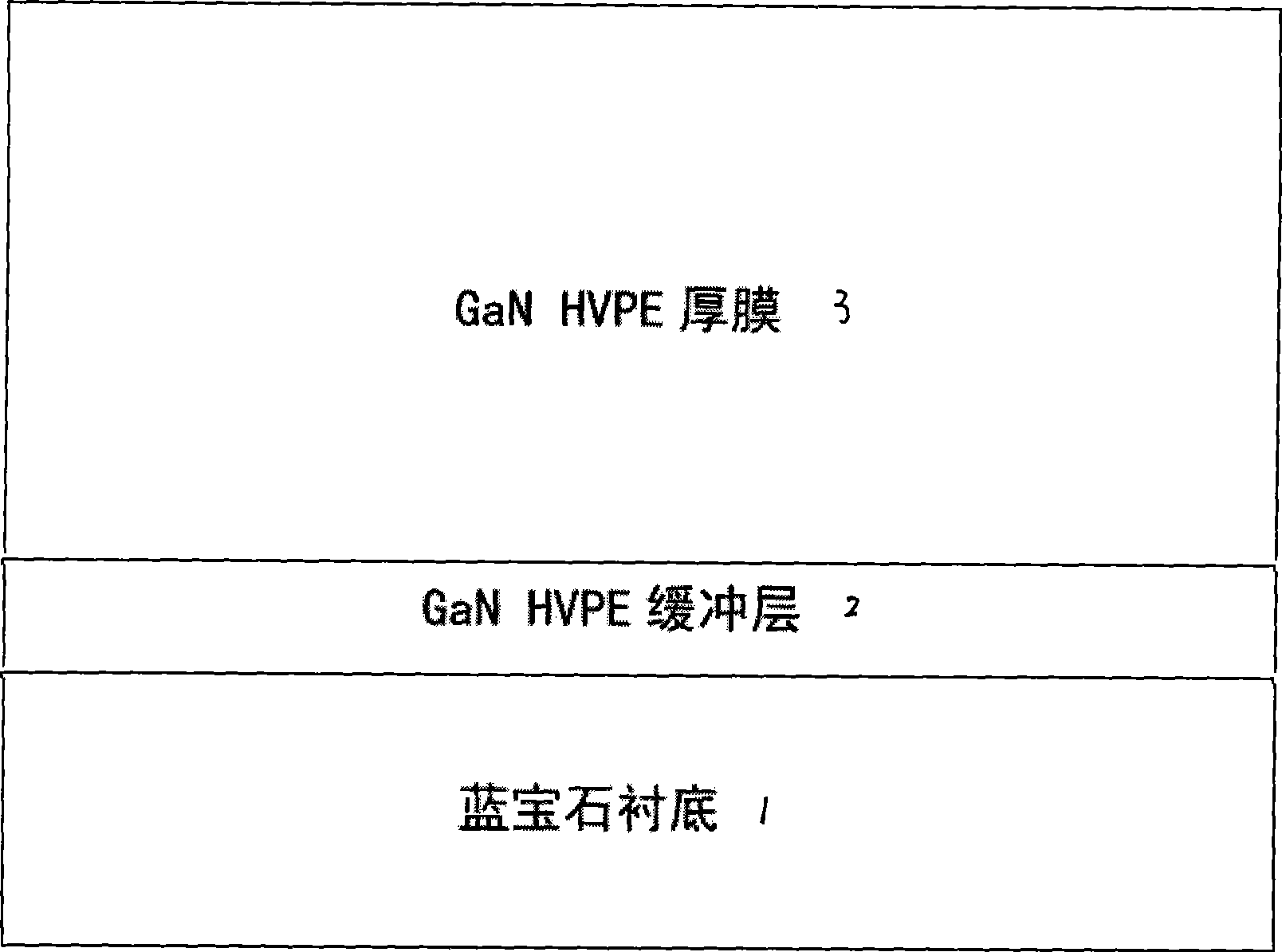

Method for in-situ preparation of self-supporting gallium nitride underlay

InactiveCN101429650AAvoid secondary damageQuality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSource materialRoom temperature

The invention relate to a method for preparing a self-supporting gallium nitride substrate at the home position. A GaN buffer layer film grows on a sapphire in a HVPE growth mode; a reaction source material is gallium metal, highly pure HCl or trimethyl gallium or other organic gallium sources; and the carrier gas is N2 and NH3. The growth temperature is 550 to 750 DEG C; and the thickness of the buffer layer is 50nm to1mu m. When the growth of the buffer layer is completed, the HCl gas or trimethyl gallium gas is closed; the temperature is increased under the protection of ammonia gas to reach 1,000 to 1,100 DEG C within 15+-4 minutes; and GaN starts to grow till reaching the required thickness. The HCl gas is closed to stop the growth; the temperature is decreased under the protection of ammonia gas, and the temperature fall rate is maintained between 5 and 20 DEG C / min; and the temperature fall mode is to maintain the temperature for 10 to 30 minutes when the temperature is reduced to 650 to 750 DEG C and then to naturally cool down to a room temperature so as to obtain the self-peeling self-supporting GaN substrate.

Owner:NANJING UNIV

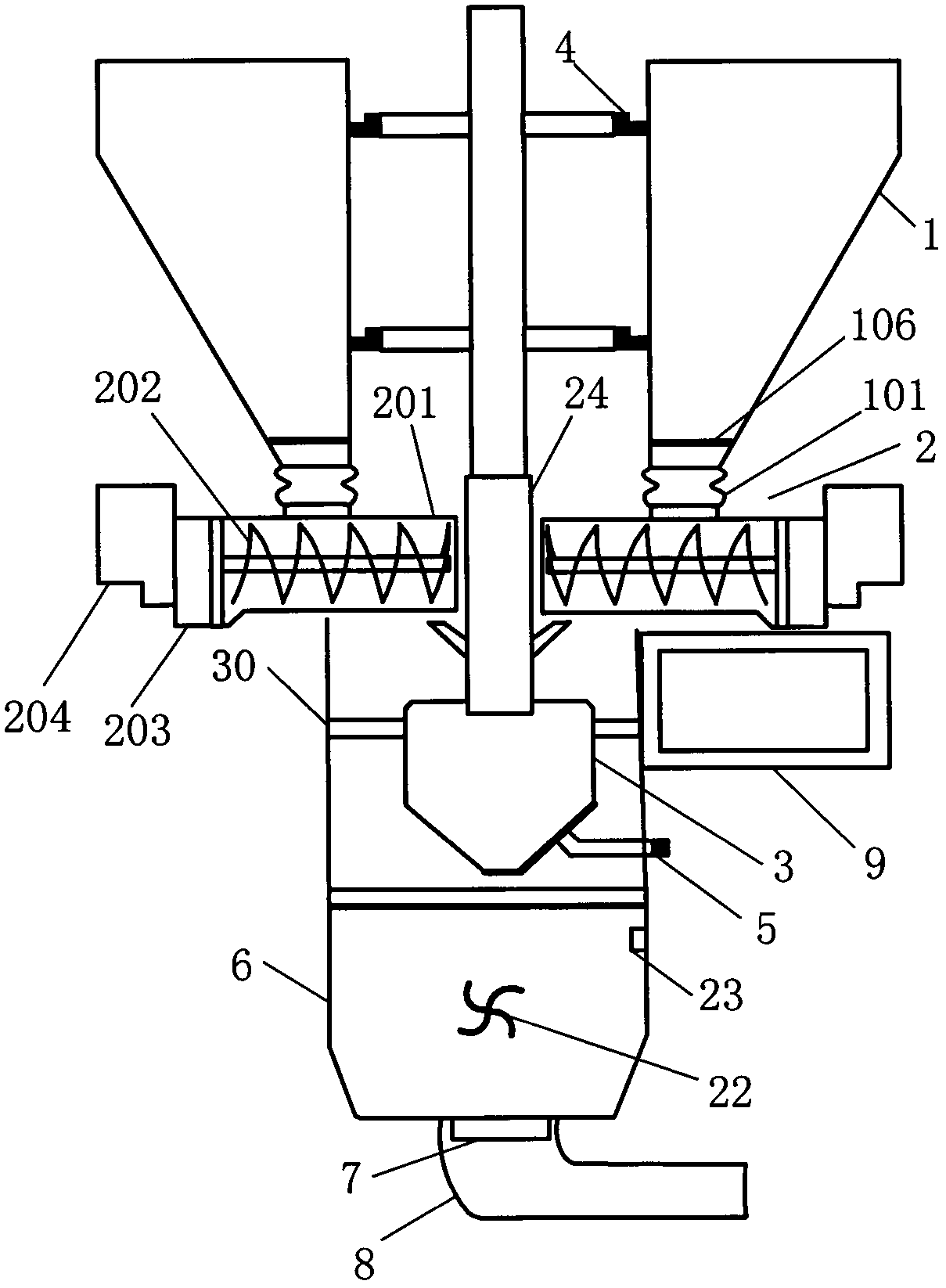

Direct falling weightlessness type material discharging machine based on neural network and controller of direct falling weightlessness type material discharging machine

ActiveCN107601064APrecise cuttingReduce blanking rate fluctuationsConveyorsNeural architecturesWeightlessnessEngineering

The invention discloses a direct falling weightlessness type material discharging machine based on a neural network and a controller of the direct falling weightlessness type material discharging machine. The discharging machine comprises a rack, a discharging bin, a discharging valve, a material mixing hopper, a weighing module, a falling valve, a mixed material bin and a controller; and a bin position sensor and a stirrer are installed in the discharging bin, and a mixing device is arranged in the material mixing hopper. A neural network module is adopted in the controller, the material weightlessness value is forecasted based on the material position of the discharging bin, the falling rate, the material density and the opening hole diameter of the discharging valve, and therefore theclosing time of the discharging valve is adjusted. According to the direct falling weightlessness type material discharging machine and the controller, modeling of the weighing behavior in dischargingis carried out through the neural network, the trained network can accurately forecast the falling material weightlessness value in different falling states, direct and accurate discharging can be achieved, and the machine is suitable for small-batch production; the bin position sensor and the stirrer are adopted for detecting and adjusting the material accumulation shape in the discharging bin,and fluctuation of the falling rate is reduced; and the discharging accumulation error is controlled, and the batched discharging total error is reduced.

Owner:CHINA JILIANG UNIV

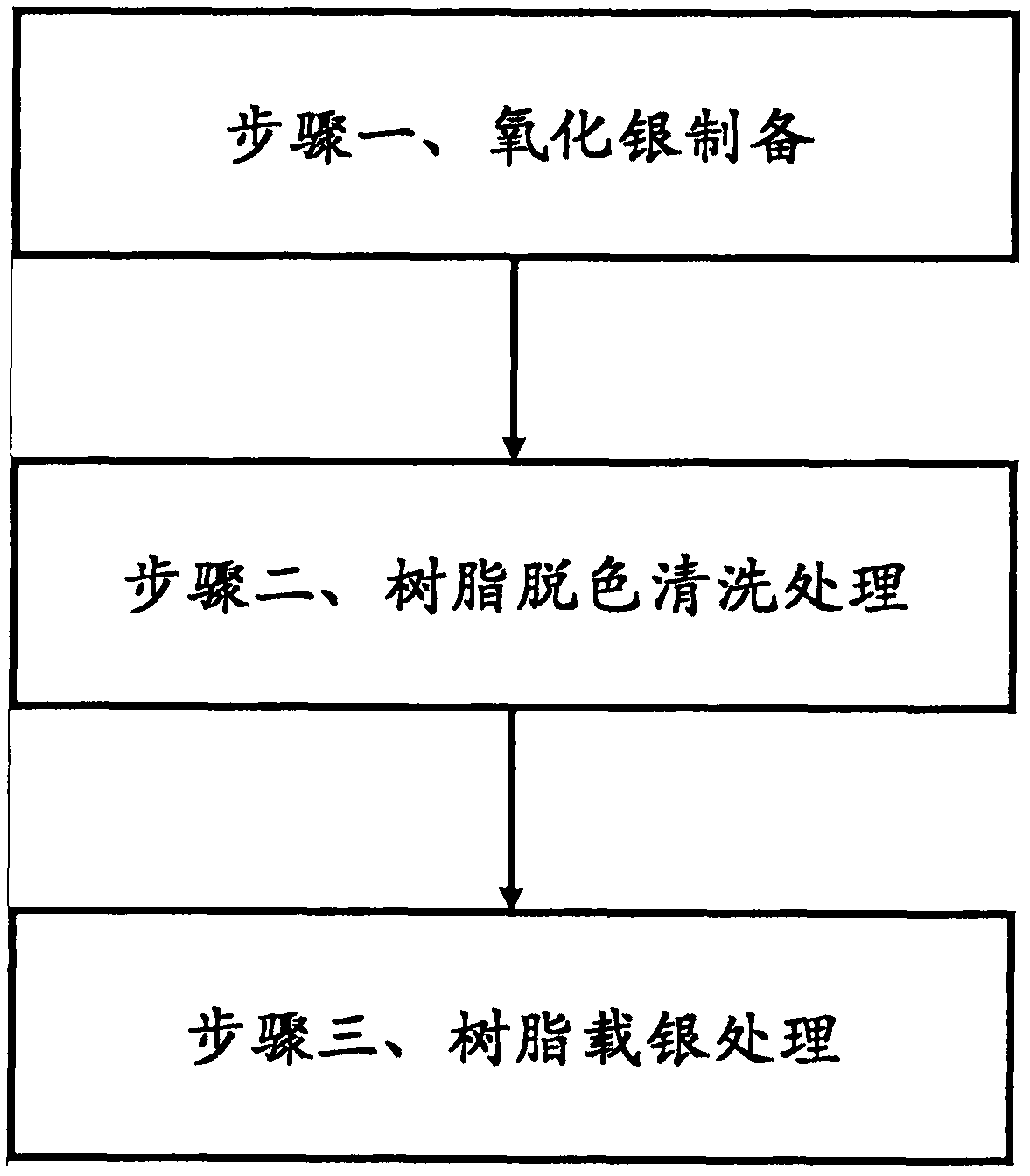

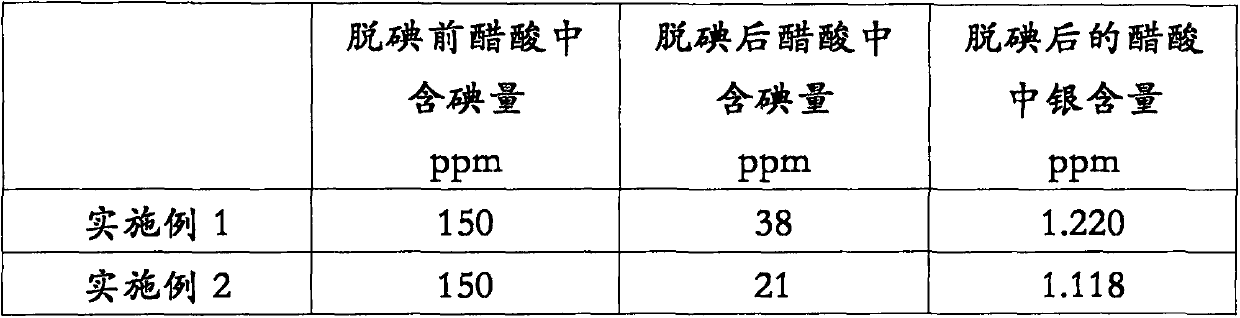

Production technology of silver-loaded resin adsorbent for acetic acid deiodination

InactiveCN107583628AHighlight substantiveIon-exchange process apparatusOther chemical processesAcetic acidSorbent

The invention provides a production technology of a silver-loaded resin adsorbent for acetic acid deiodination. The production technology comprises the following steps: preparing silver oxide, carrying out de-coloring and washing treatment on resin and carrying out resin silver loading treatment. Aiming at the technical problems of a deiodination adsorbent in the prior art that the adsorption is not firm, silver easily falls off in a deiodination process and secondary pollution is caused, the invention innovatively provides the production technology of the silver-loaded resin adsorbent for theacetic acid deiodination. The silver-loaded resin adsorbent prepared by the production technology provided by the invention has remarkable technical effects that the combining capability is strong, and the deiodination efficiency is high, the silver falling rate is low and no secondary pollution is caused when the silver-loaded resin adsorbent is used for carrying out acetic acid deiodination treatment.

Owner:王泽山

Seed clothing coating agent and preparation method thereof

InactiveCN104542657AHigh film forming rateHas a shedding rateBiocidePlant growth regulatorsFilm-forming agentGrowth regulator

The invention discloses a seed clothing coating agent and a preparation method thereof, relates to a preparation method of a seed coating, and belongs to the field of agriculture and forestry. The seed clothing coating agent is characterized by comprising the following raw materials by weight percent: a 60% film-forming agent, 10-30% of a growth regulator and 10-30% of an auxiliary; the main components of the seed coating are the film-forming agent and the growth regulator, wherein the film-forming agent is prepared from plant extract, and has the characteristics of high film-forming rate, low falling rate and low epidermis loss rate; the damage rate of the seed in great transportation can be obviously reduced aiming at the characteristics that the epidermis is rough and thin, the morbidity is reduced, the emergency rate of the seed is improved, and the yield is finally improved; the seed coating is no residue in the soil, the preparation process and the coating method are simple to operate, and the scale production can be easily realized.

Owner:朱和平

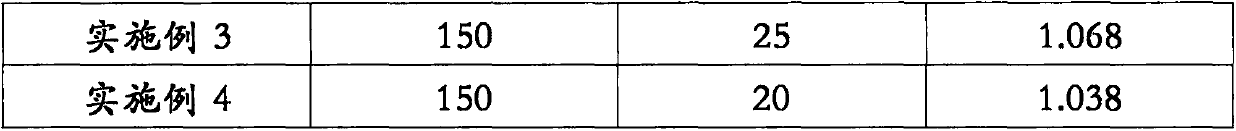

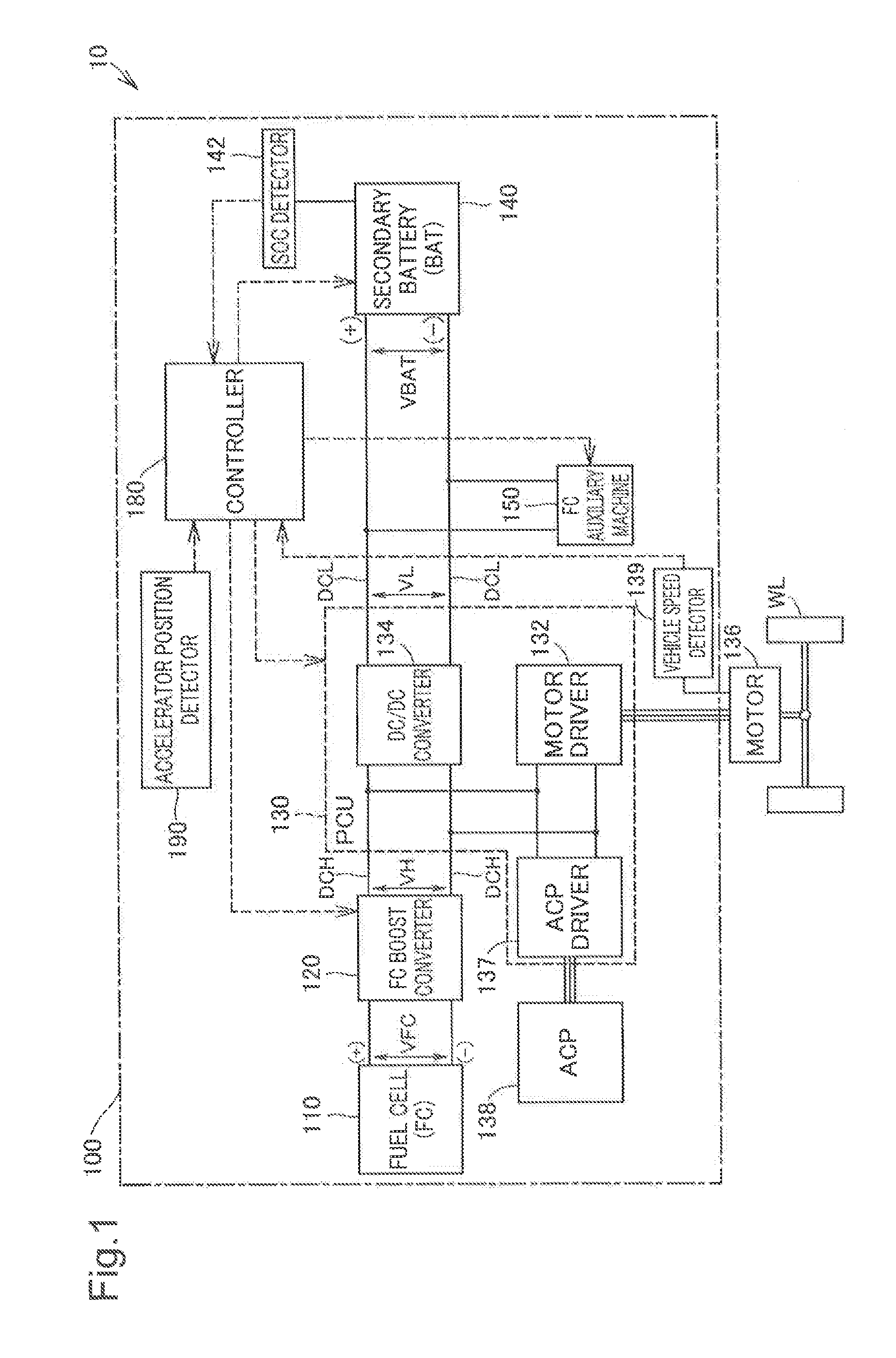

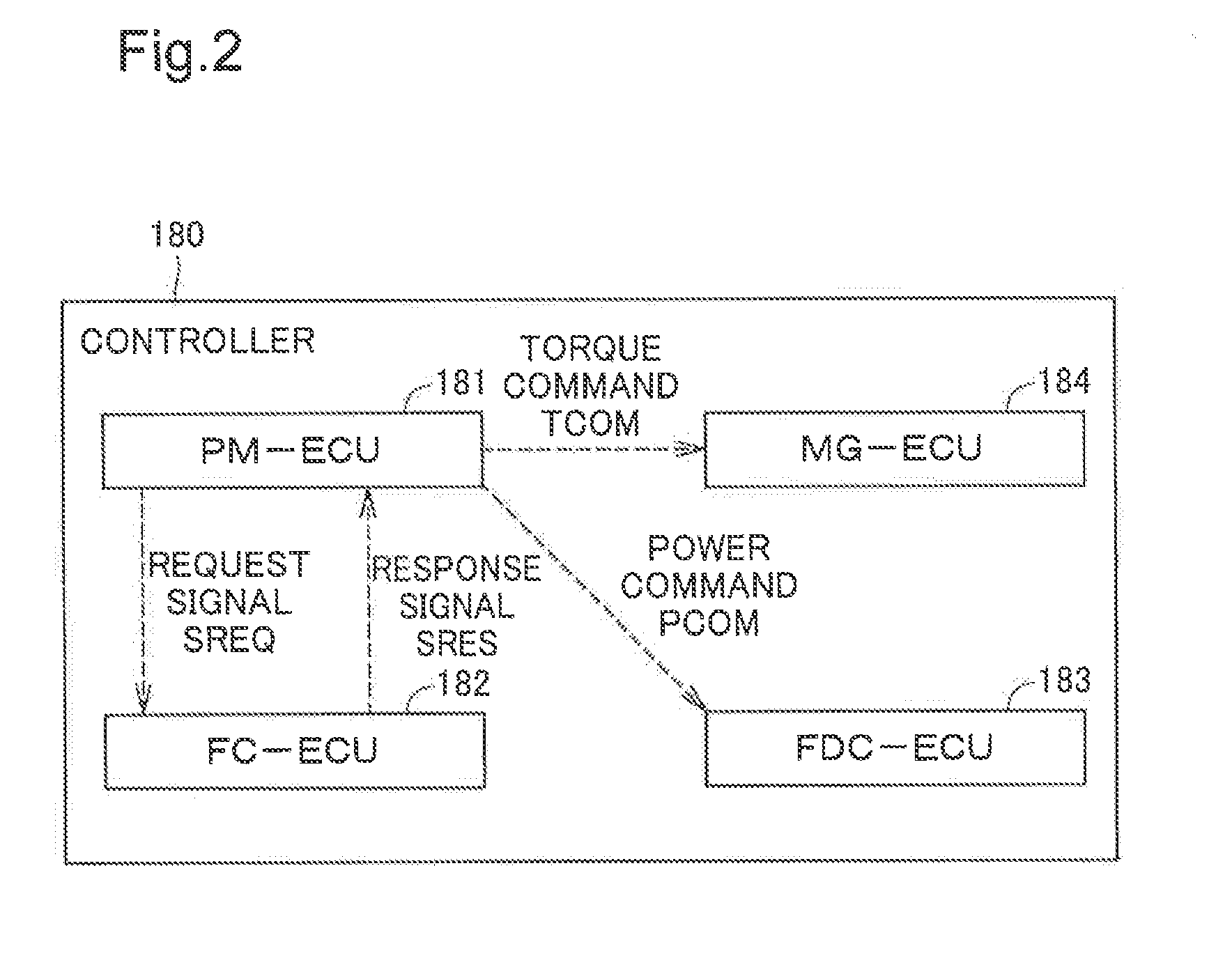

Fuel Cell System, Fuel Cell Vehicle, and Method for Controlling Fuel Cell System

ActiveUS20160141681A1Unnecessary supplying of oxygen to the fuel cell is preventedDry up of the fuel cell can be preventedSpeed controllerReactant parameters controlLower limitFuel cells

A fuel cell system installed in a vehicle includes a fuel cell that supplies power to a motor that drives the vehicle, a pump that supplies oxygen to the fuel cell, an accelerator position detector that detects an accelerator depression amount of the vehicle, and a controller that calculates required generated power of the fuel cell and required driving power of the pump, based on the accelerator depression amount. When a preset condition of causing a sharp drop in the calculated required generated power is satisfied, the controller calculates the required driving power in such a mariner that a drop rate of the required driving power becomes higher than a drop rate of the calculated required generated power, sets a lower limit to the calculated required driving power, and drives the pump in accordance with the lower limit when the required driving power is lower than the lower limit.

Owner:TOYOTA JIDOSHA KK

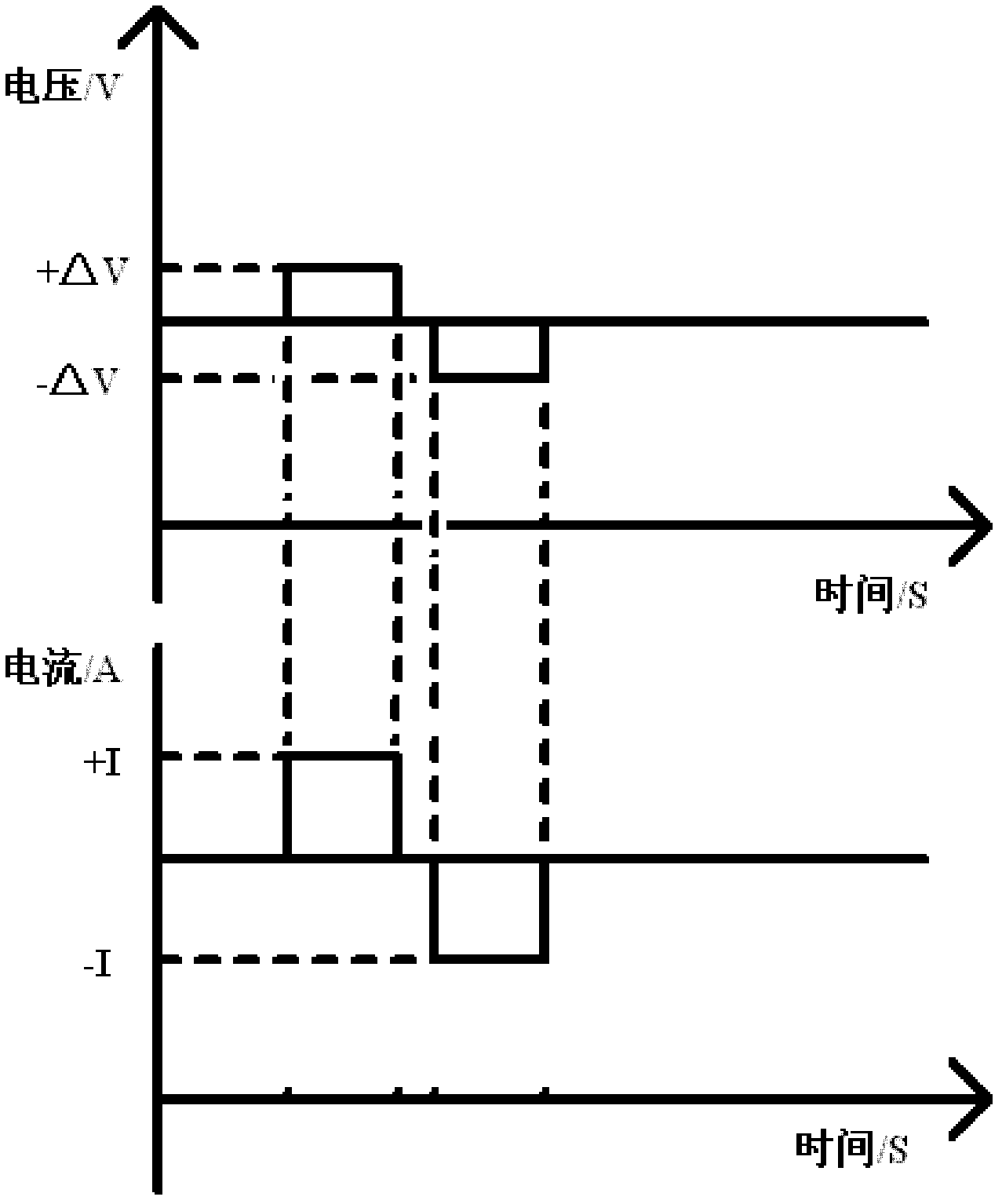

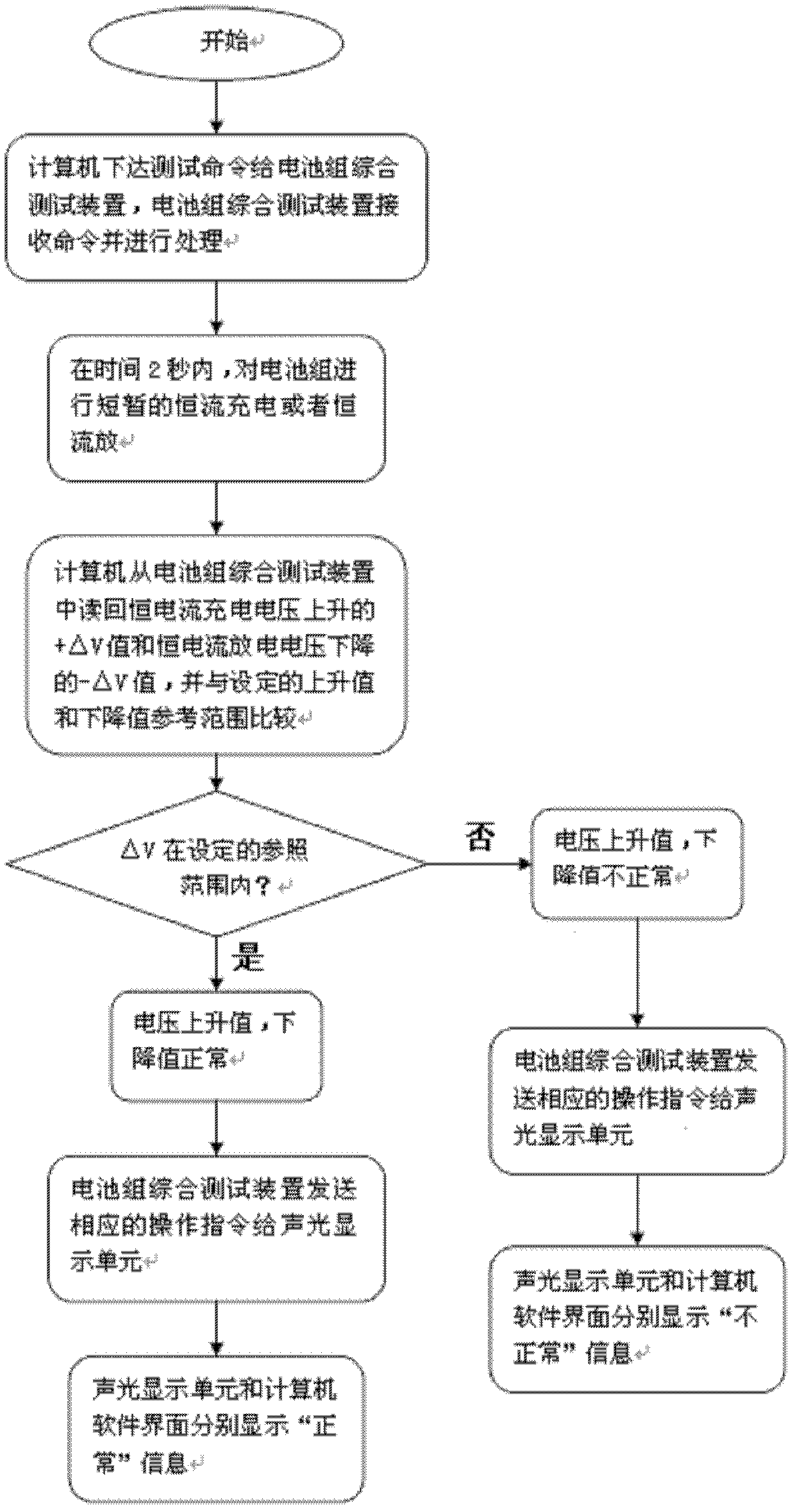

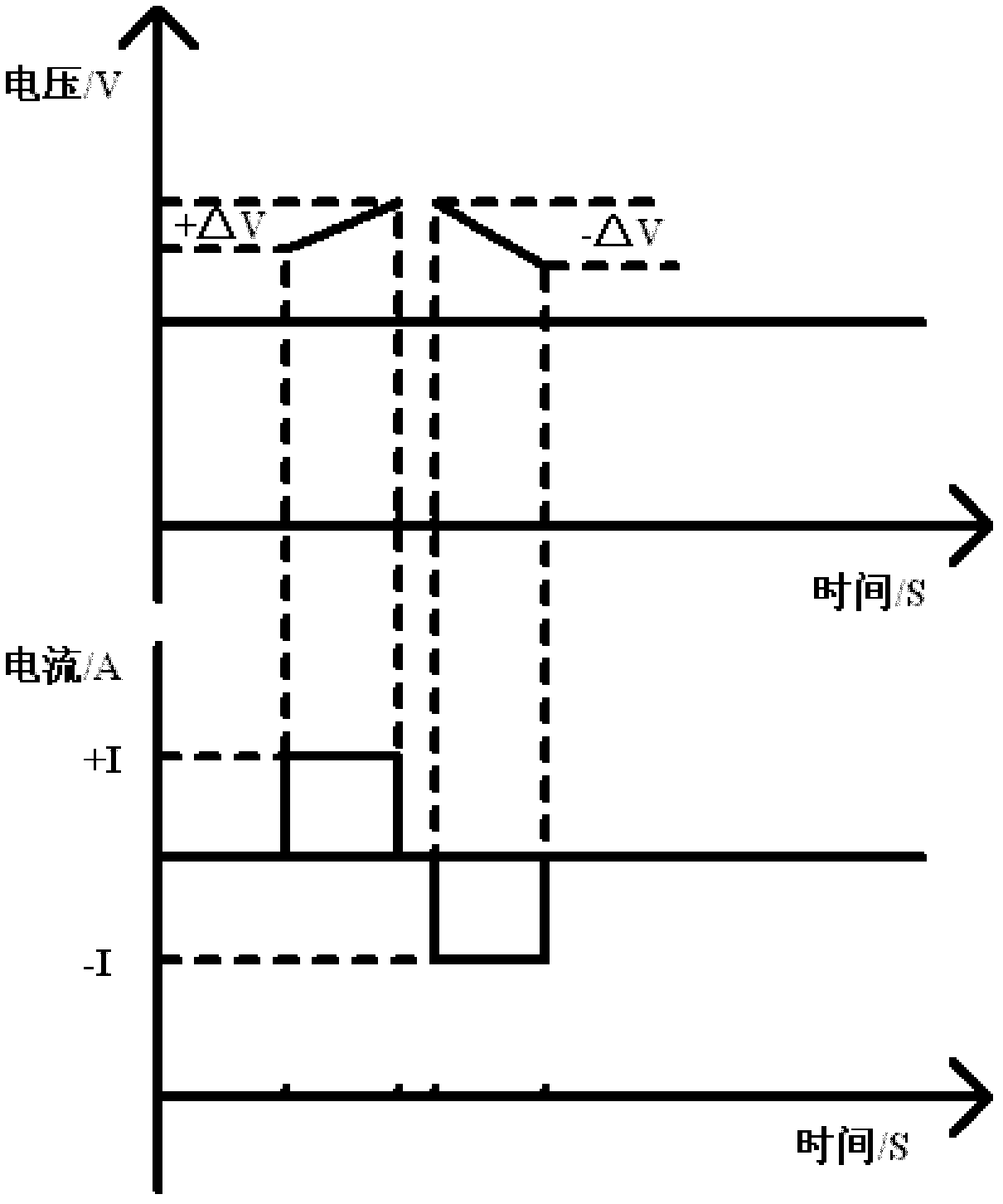

Testing method for voltage increasing rate and decreasing rate of battery pack

InactiveCN102590752AIncrease productivityImprove application efficiencyCurrent/voltage measurementElectrical testingDelta-vFall rate

The invention relates to the technology of battery testing, particularly to a testing method for voltage increasing rate and decreasing rate of a battery pack, which includes the following steps: a data processing device and a battery pack comprehensive test device are prepared; the data processing device transmits a test command to the battery pack comprehensive test device; within the time T, the CDS in the battery pack comprehensive test device charges the battery pack in constant current, and the voltage is increased for plus Delta V; at the same time, within the time T, the CDS discharges the battery pack in constant current, and the voltage is decreased for minus Delta V; the data processing device compares the read plus Delta V voltage value with the set reference value and compares the read minus Delta V voltage value with the set reference value, so as to judge whether the voltage increasing rate and the voltage decreasing rate are normal according to the comparison results. The testing method can easily judge whether the voltage increasing rate and the voltage decreasing rate during the production process of the battery pack are normal, so as to greatly improve the later-stage actual production and application efficiency, and reduce the cost.

Owner:毛广甫

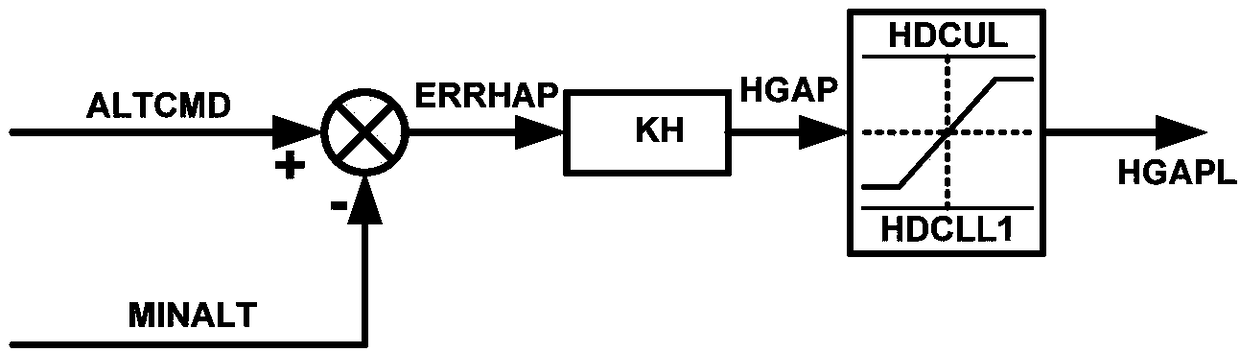

UAV automatic height slow descent control method based on voyage and endurance performance

ActiveCN108241377AFull range performanceReduce lossPosition/course control in three dimensionsUncrewed vehicleFlight time

The invention belongs to the technical field of flight control and relates to an UAV automatic height slow descent control method based on voyage and endurance performance. The method comprises the steps of (1) calculating a horizontal distance from a current position of an aircraft to a target point, (2) calculating a sinking rate required in completing the remaining portion of a current flight segment, and (3) calculating a desired sinking rate HDCLL1. According to the method, a mode of dynamically changing the minimum value of an expected descent rate in real time is designed, and the height descent control with a slow descent function for a UAV is achieved. According to a current state and mission planning of the UAV, an altitude descent rate control command is automatically and dynamically adjusted in real time, the slow descent of the UAV is achieved, thus the energy loss is reduced, the flight time and flight distance of a descent process are improved, and thus the voyage and endurance performance of the UAV are fully delivered.

Owner:中航(成都)无人机系统股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com