Conveying device of a packing machine

A technology of conveying device and packaging machine, which is applied in the direction of packaging, etc., and can solve the problems of small packages easily falling into the gaps, packaging bags without small packages, and increased packaging errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

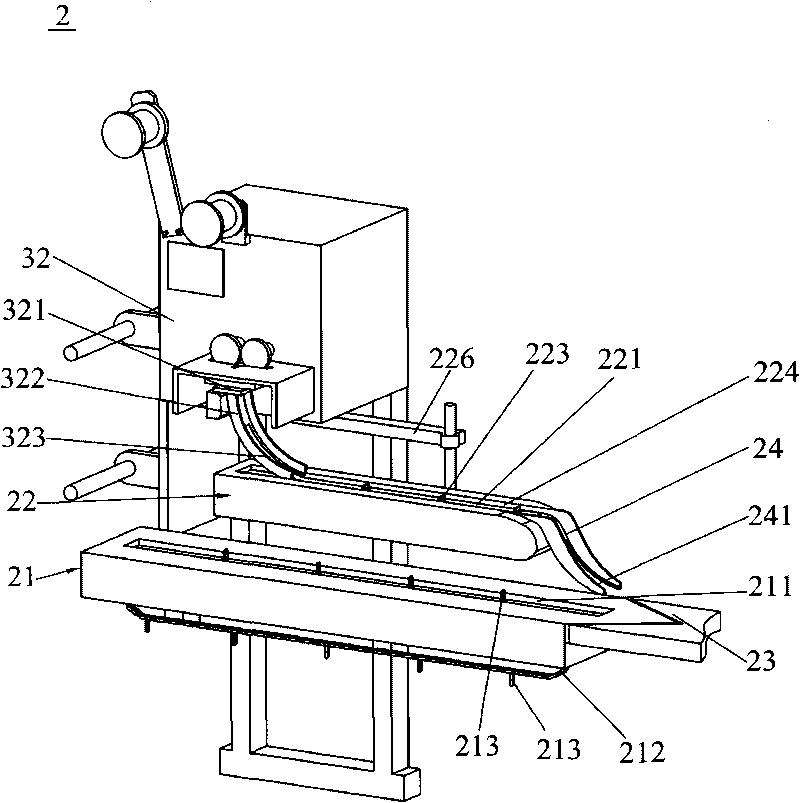

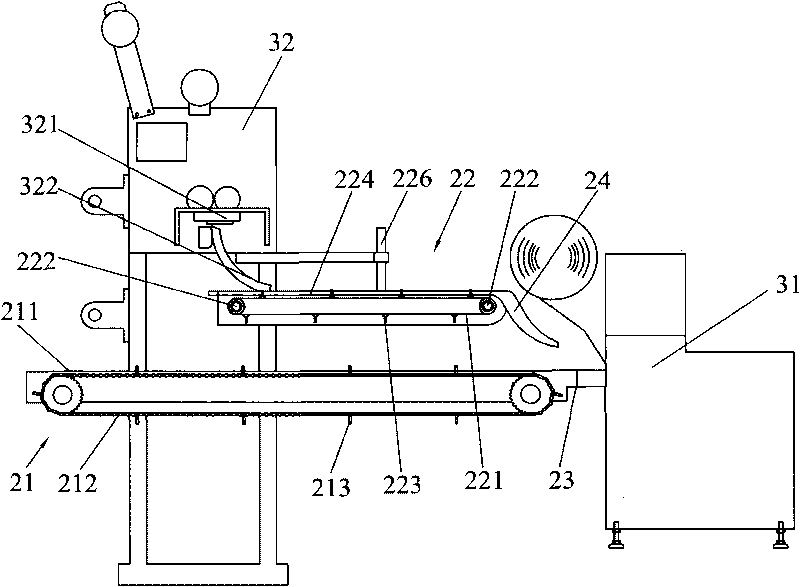

[0021] refer to figure 2 and image 3 , figure 2 and image 3 They are respectively the three-dimensional structure diagram and the plan view of the packaging machine conveying device 2 of the present invention, the packaging machine conveying device 2 includes a main conveying mechanism 21, a dial port 23, a slicer bag feeding machine 32, a secondary feeding conveying mechanism 22 and a feeding chute 24. The dial opening 23 is located between the main conveying mechanism 21 and the entrance of the packaging machine 31. The main conveying mechanism 21 includes a main conveying trough 211 and a main conveying chain 212 installed below the main conveying trough 211. The main conveying mechanism 21 The conveying chain 212 is provided with equidistant push rods 213, and the push rods 213 pass through the main conveying trough 211 and extend upwards to the top of the main conveying trough 211, and the main conveying trough 211 is divided into several equidistant subregions. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com