Seedling falling control mechanism of potted seedling transplanting machine

A technology of a control mechanism and a transplanting machine, which is applied to the device on the transplanting machine, and in the field of seedling control mechanism of pot seedling transplanting machine, which can solve the problems of poor active control ability of pot seedlings, low uniformity of pot seedling transplanting, High seedling injury rate and seedling fall rate, to achieve the effect of reducing seedling injury rate and seedling fall rate, convenient control, reasonable and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

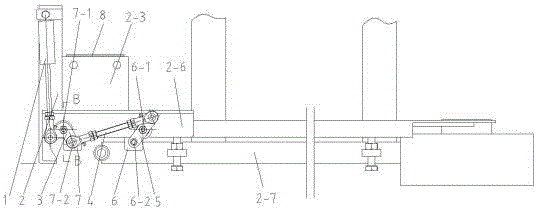

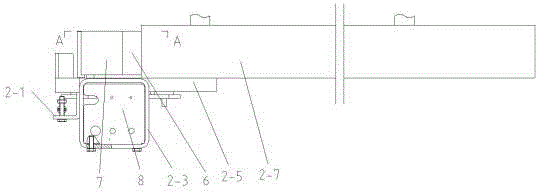

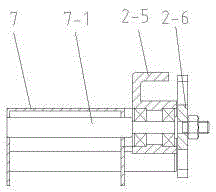

[0021] The basic structure of the seedling drop control mechanism of the bowl seedling transplanting machine of the present embodiment is as follows: Figure 1 to Figure 5 Shown, comprise and be installed on the horizontal seedling transporting barrel bottom plate 2-7 output end and have the front and rear opening and closing plates 7,6 of the horizontal plane, and the falling seedling frame 2 extended upwards by the seedling transporting barrel bottom plate 2-7 front end.

[0022] The concrete structure of this falling seedlings frame 2 is as Figure 5 As shown, it mainly contains a horizontal bearing positioning plate 2-5 and a vertical plate 2-2 positioned at the front end of the bearing positioning plate. There are two front and rear bearing sleeves 2-4 on the bearing positioning plate 2-5, and the upper bearing positioning plate 2-5 And vertical plate 2-2 one side is fixedly covered with the box-shaped control valve support 2-3 of cover plate 8, and fixed plate 2-6 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com