Patents

Literature

114results about How to "Low injury rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

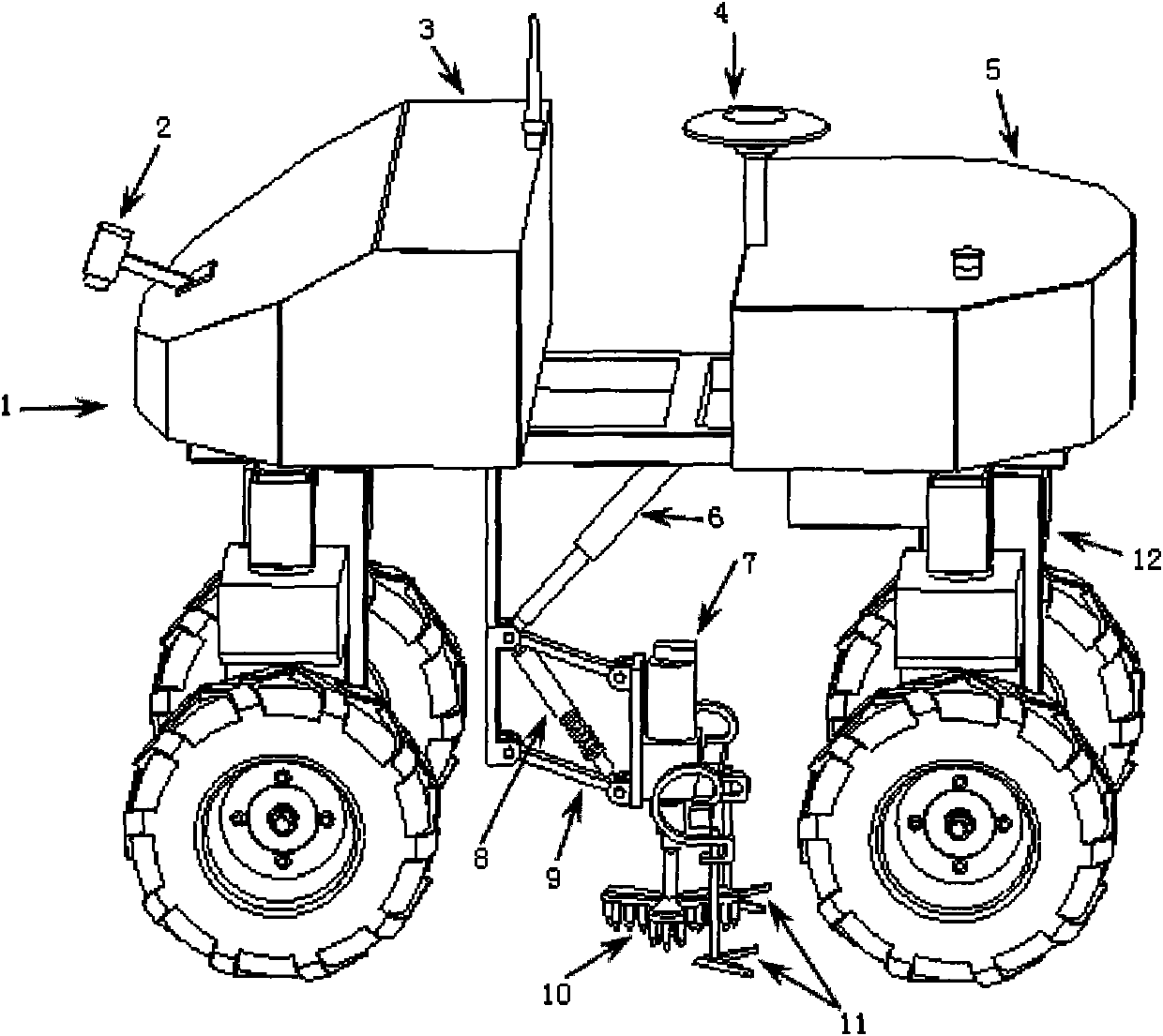

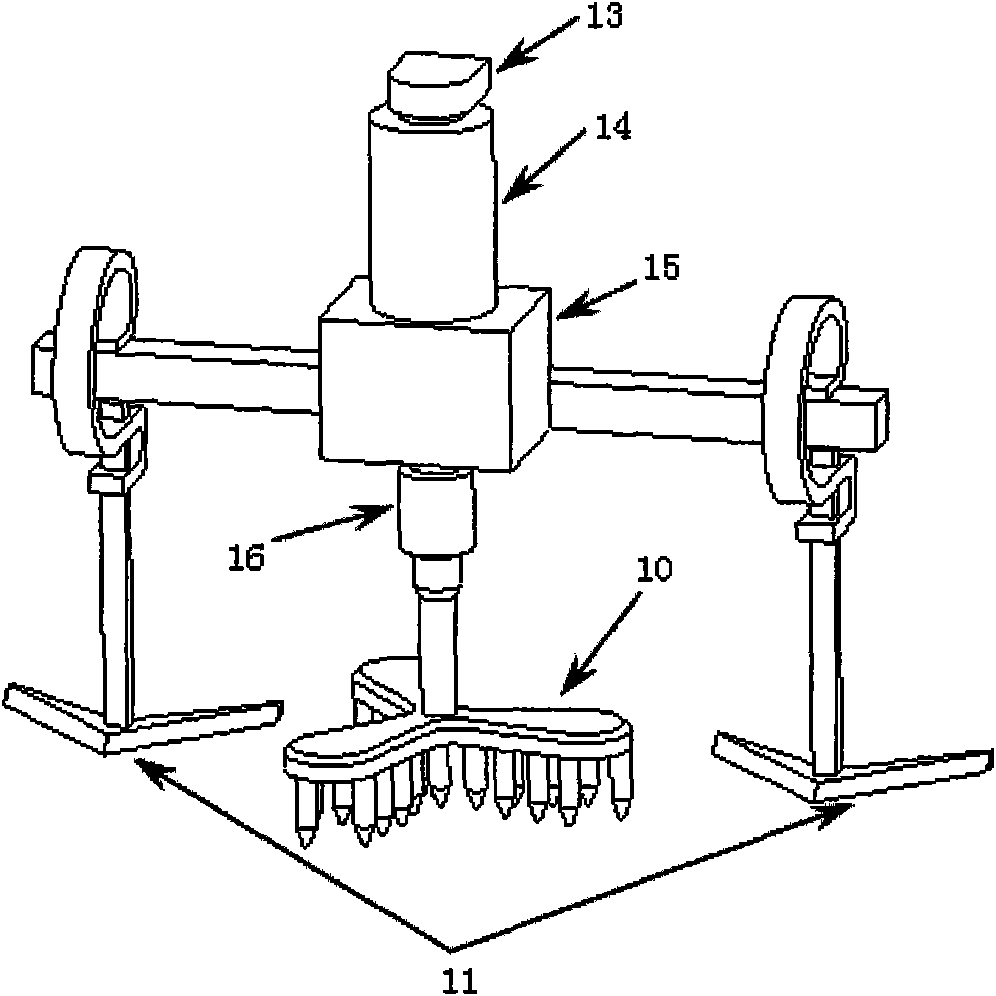

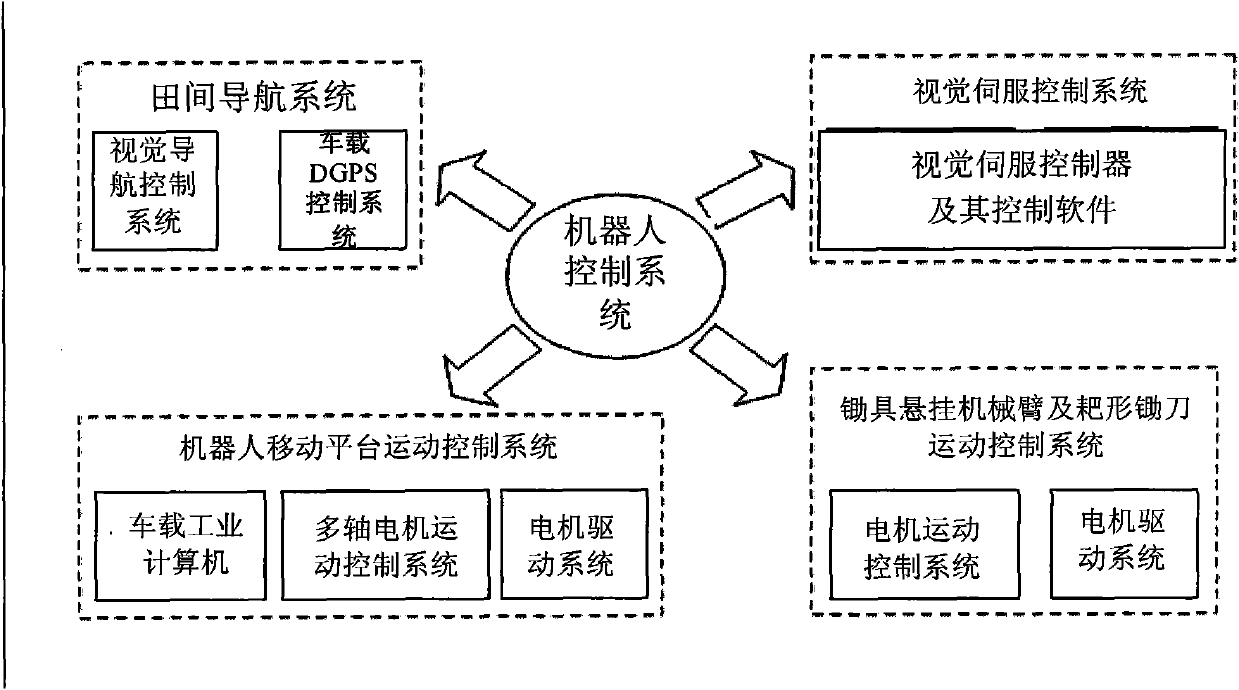

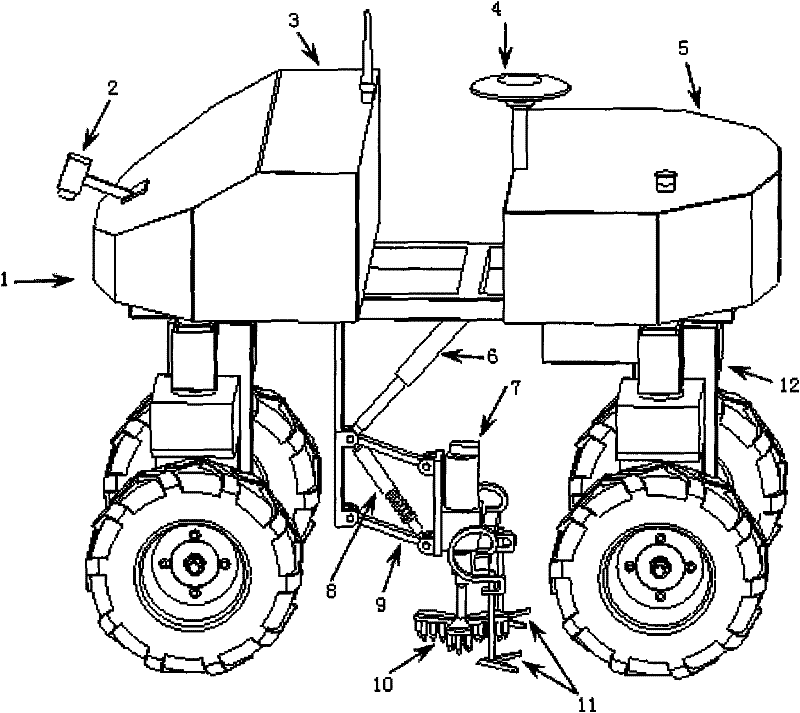

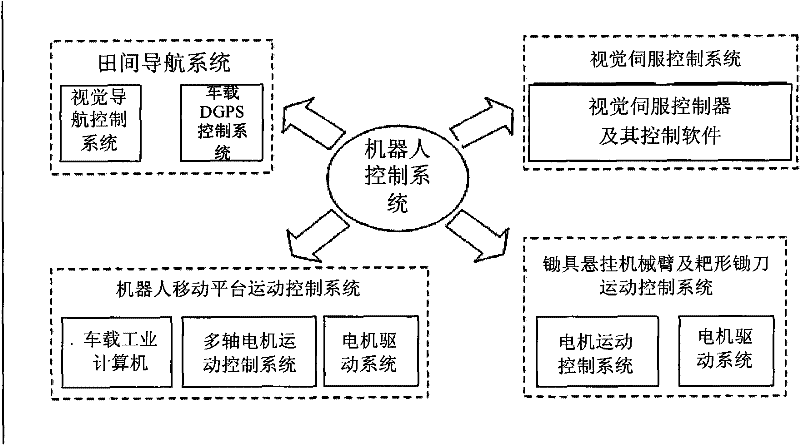

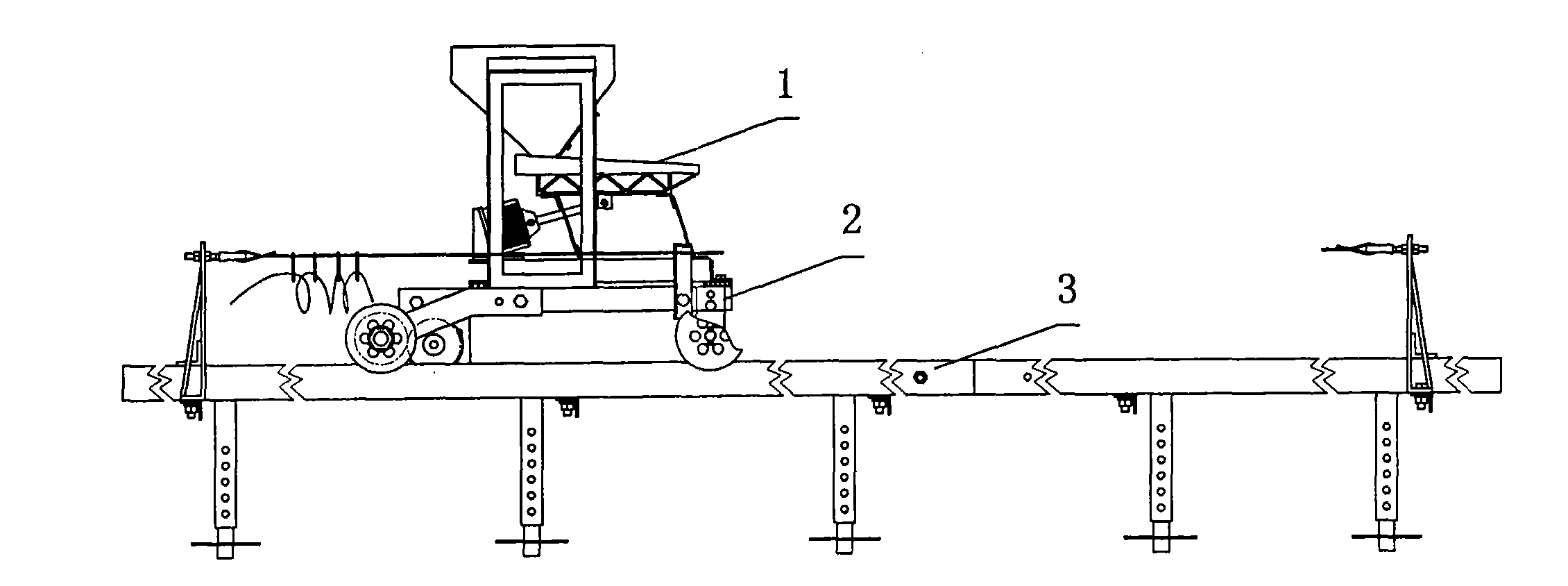

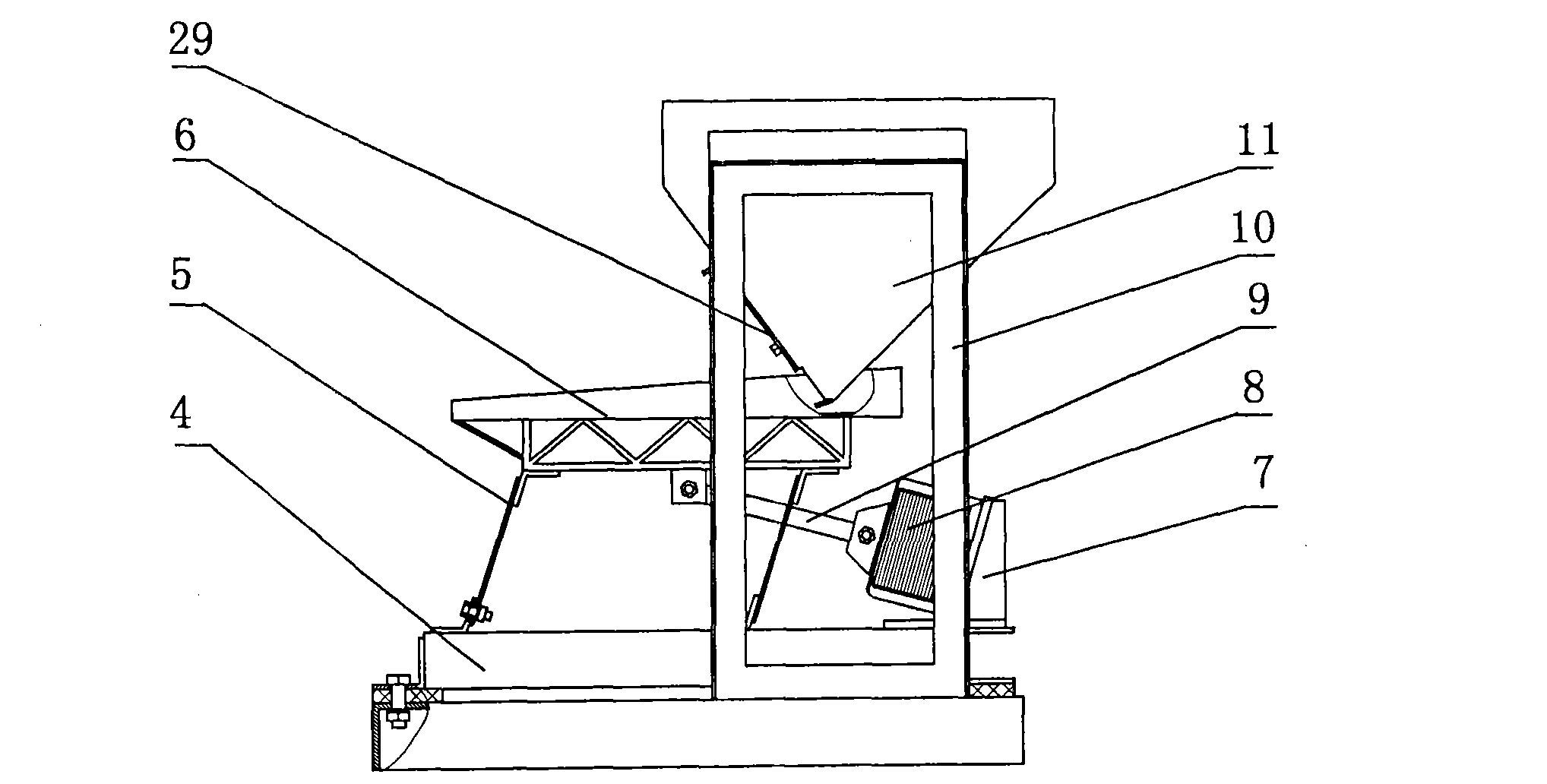

Machine vision based weeding robot system and method thereof

ActiveCN101990796AReduce pollutionEffective Mechanical WeedingSoil-working equipmentsWeed killersData controlRobotic systems

The invention discloses a machine vision based weeding robot system and a method thereof. The system comprises a robot moving platform, a field navigation device, a field grass identifying device, a weeding device and a robot control system; wherein the robot moving platform is used for executing advancing action of the robot system in the field; the field navigation device is used for acquiring navigation parameter required by movement of the robot system and sending the parameter to the robot control system; the field grass identifying device is used for acquiring field grass image information, identifying grass according to the field grass image information, obtaining identification data, calculating grass body coordinates and grass interval and sending the grass body coordinates and grass interval to the robot control system; the weeding device is used for executing weeding action; and the robot control system is used for controlling the robot moving platform to execute advancing action in the field according to the received navigation parameter and controlling the weeding device to execute weeding action according to the grass body coordinates and grass interval. The invention can realize rapid and accurate weeding operation on crop in the field.

Owner:江苏博田机器人有限公司

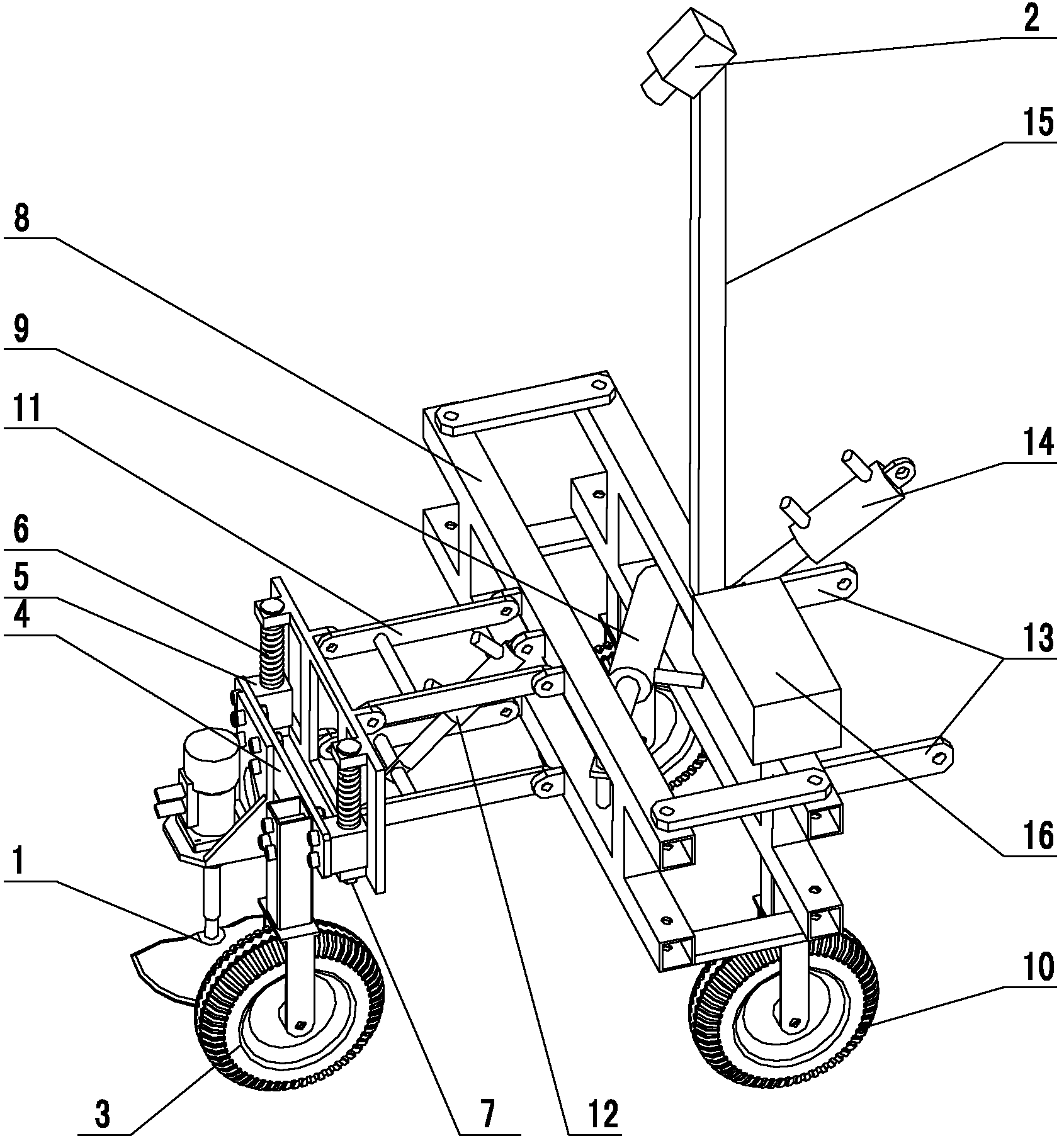

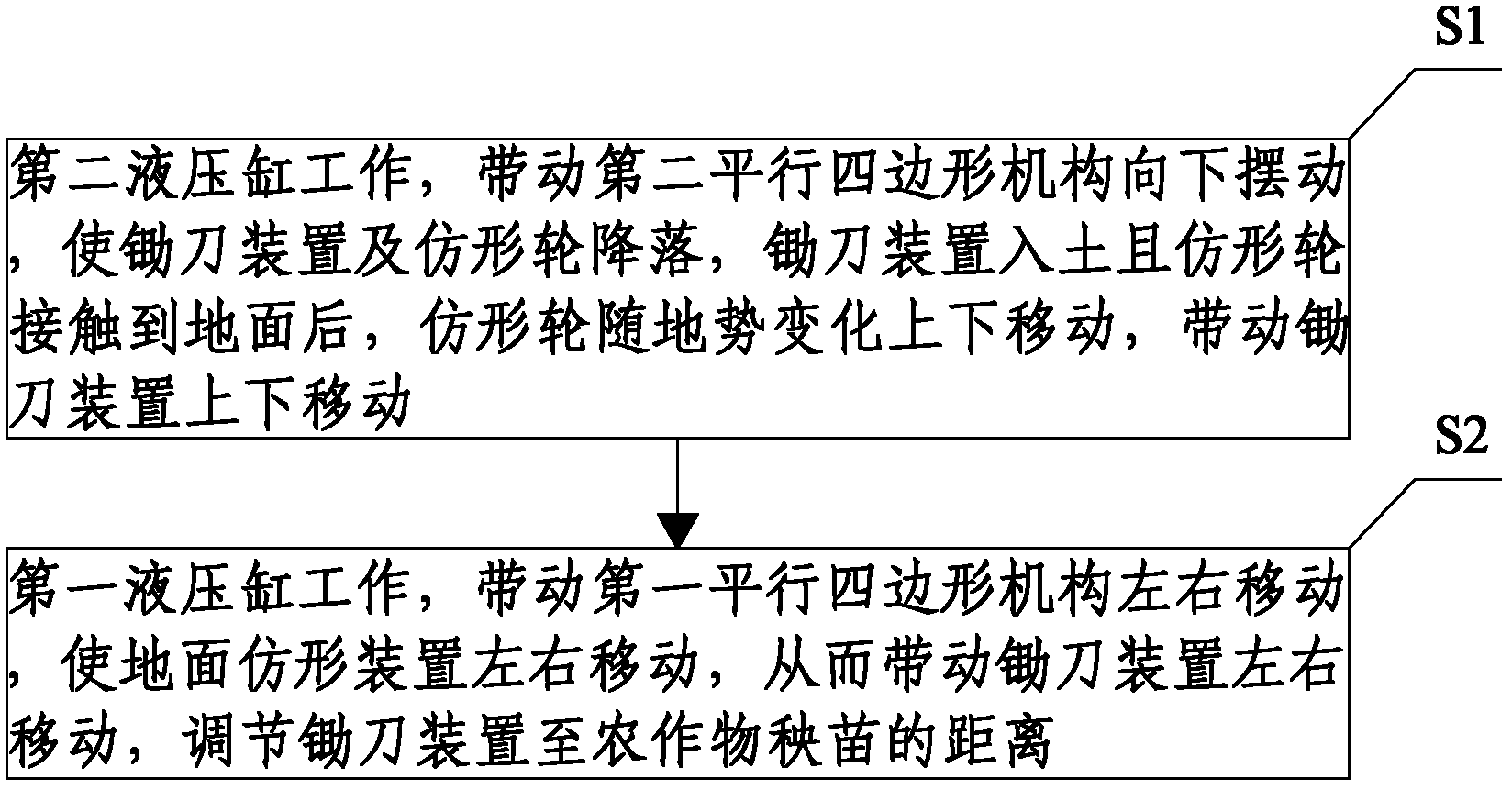

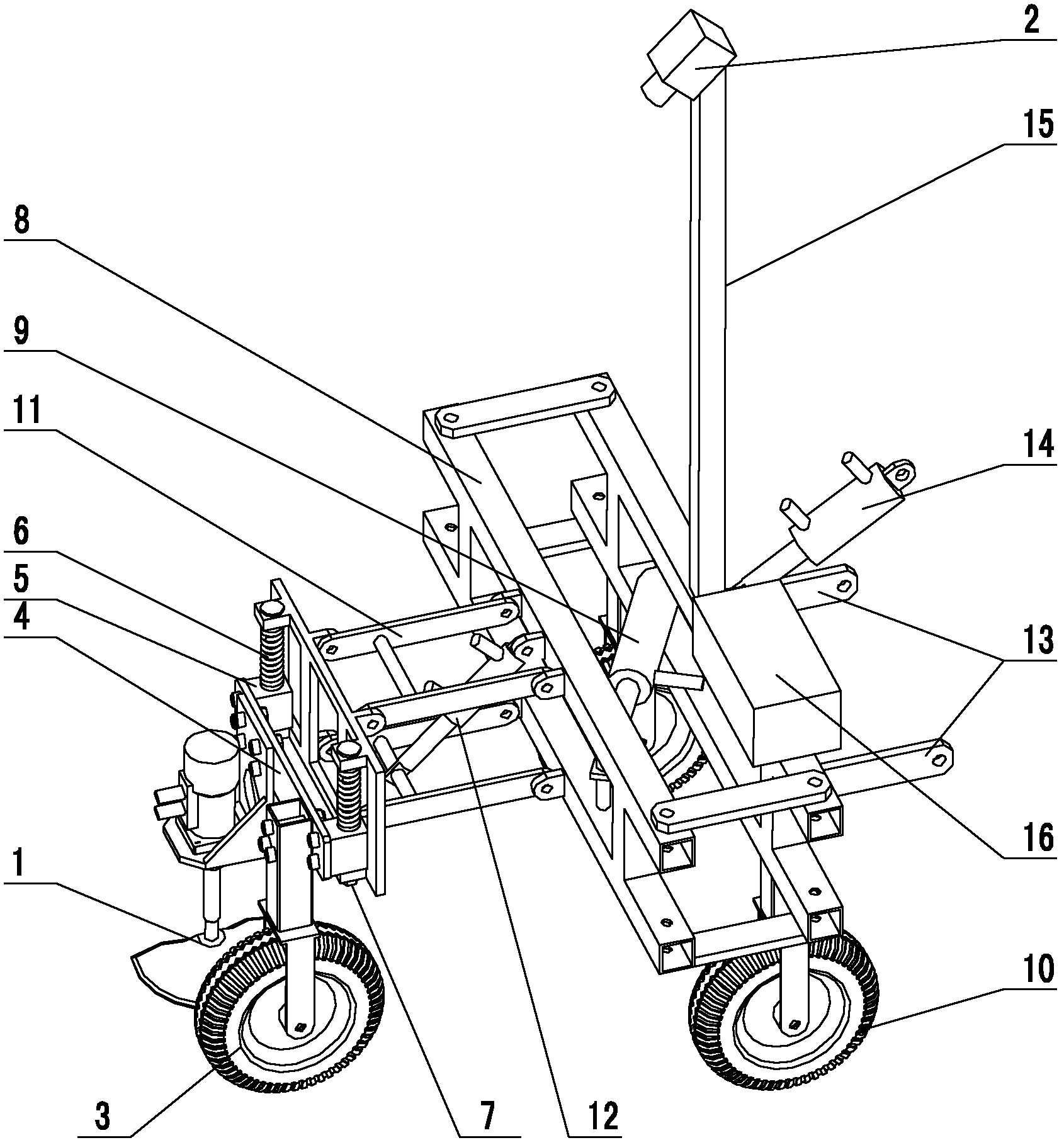

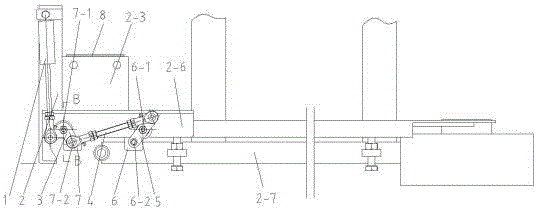

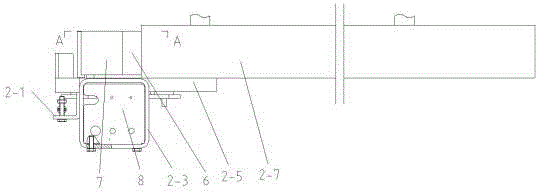

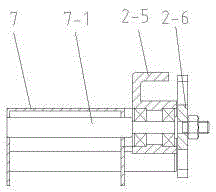

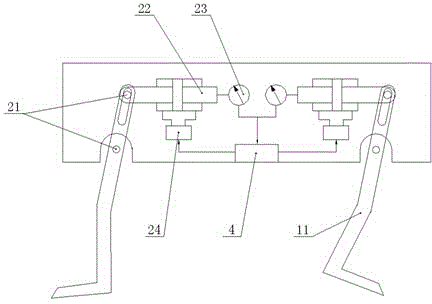

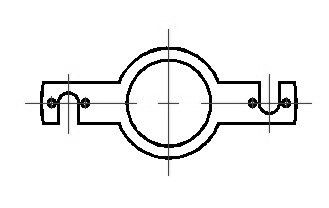

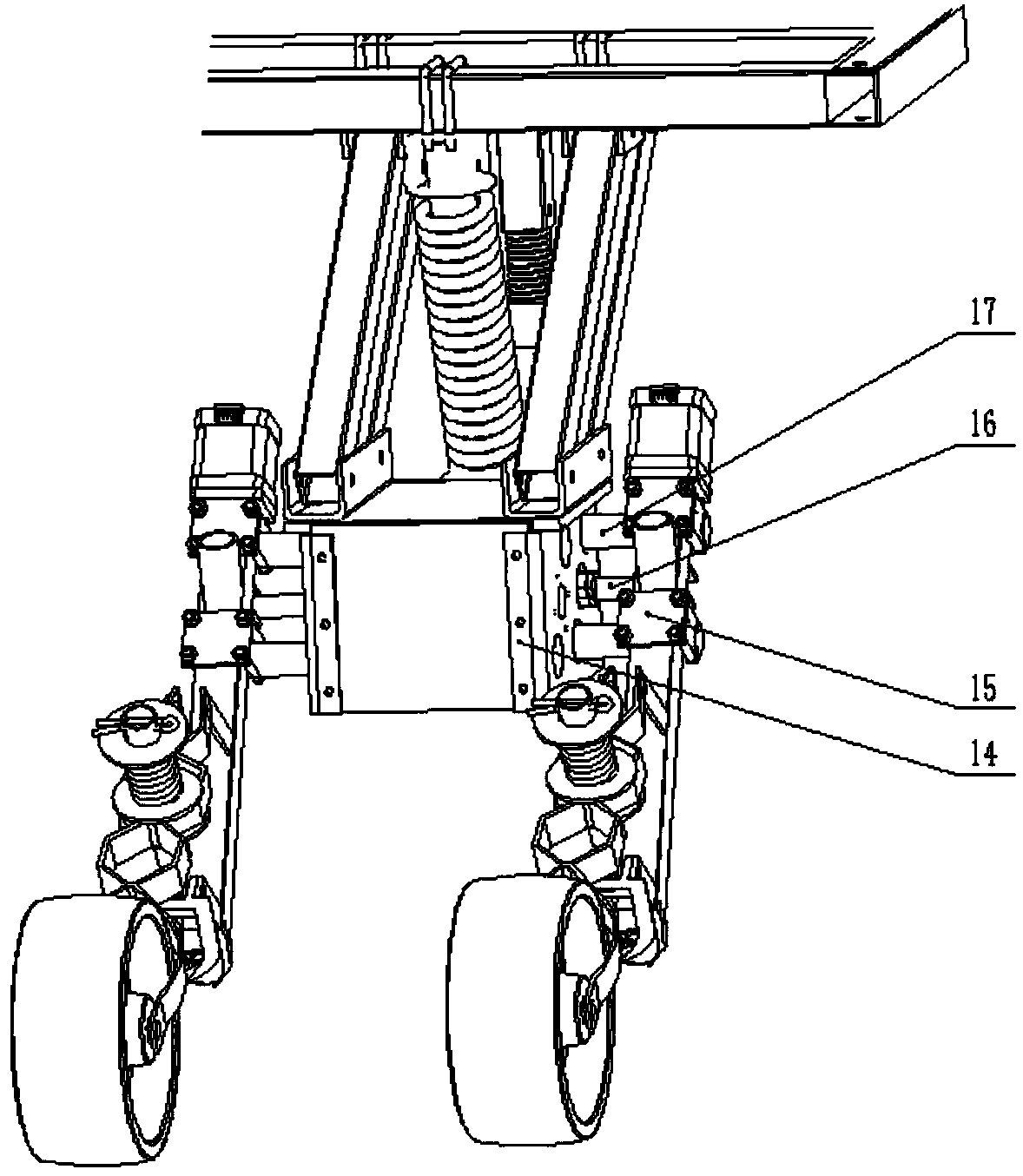

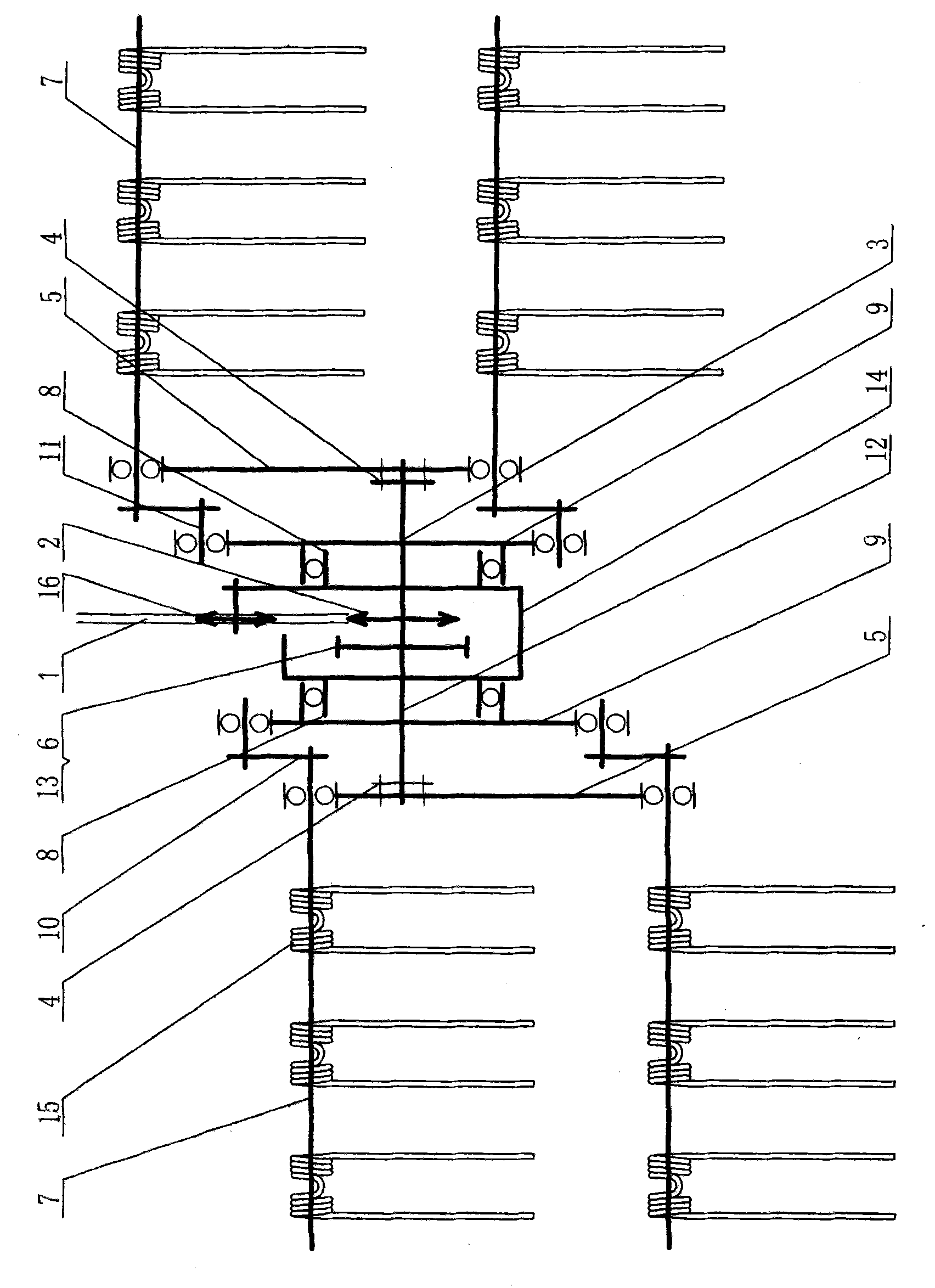

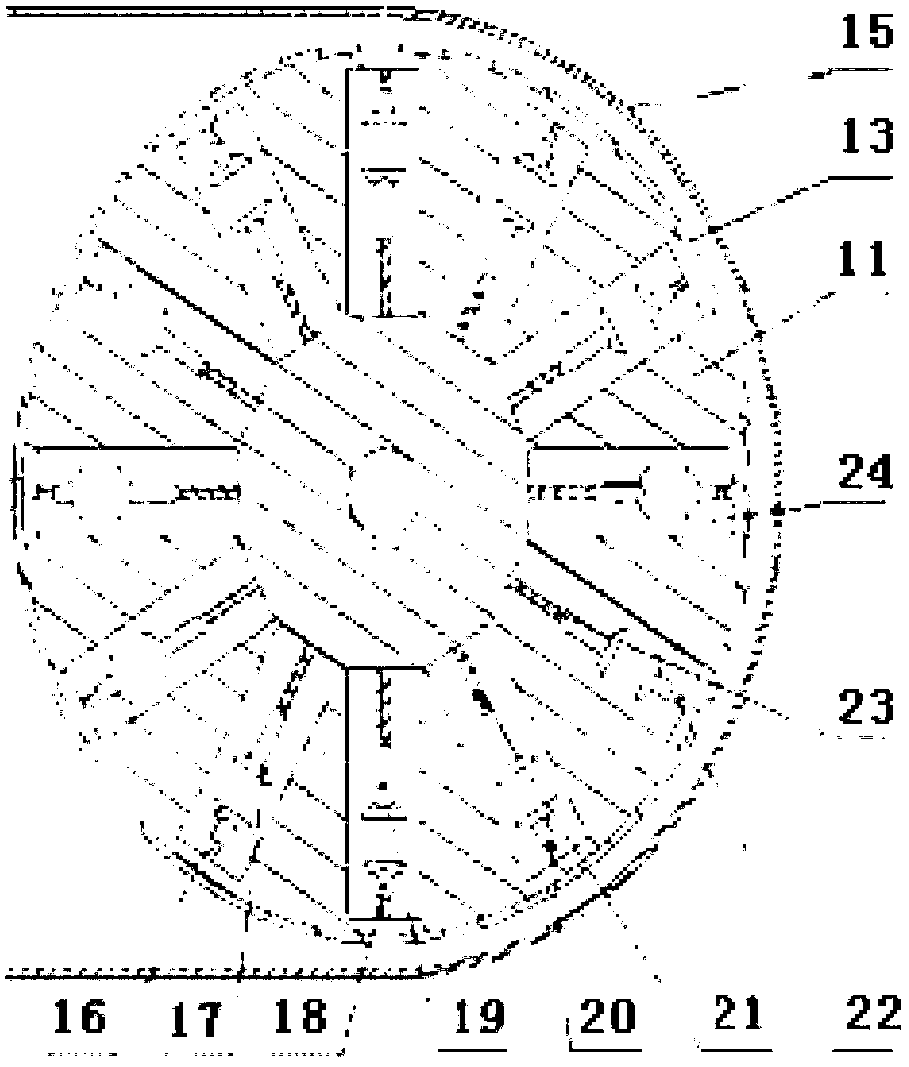

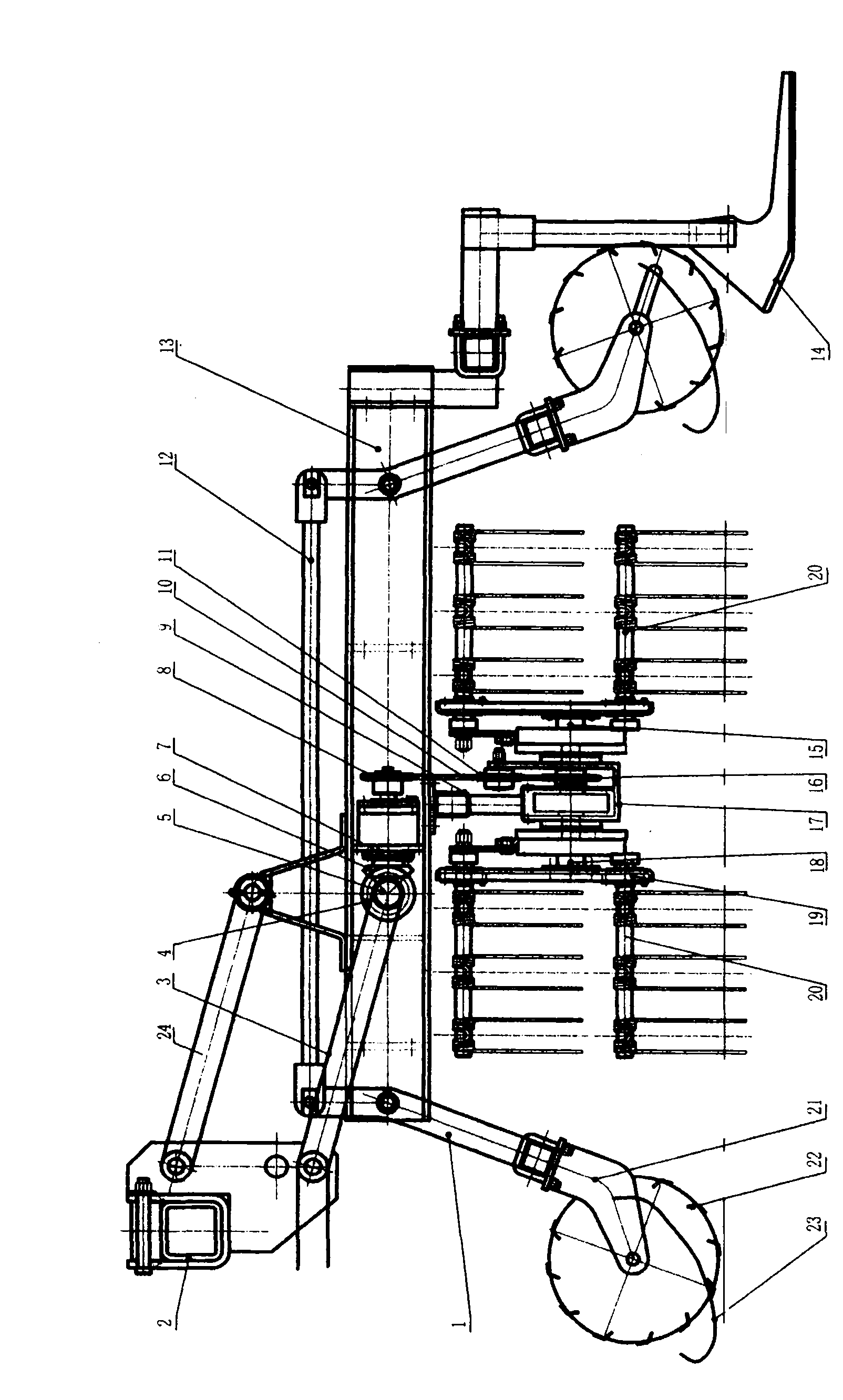

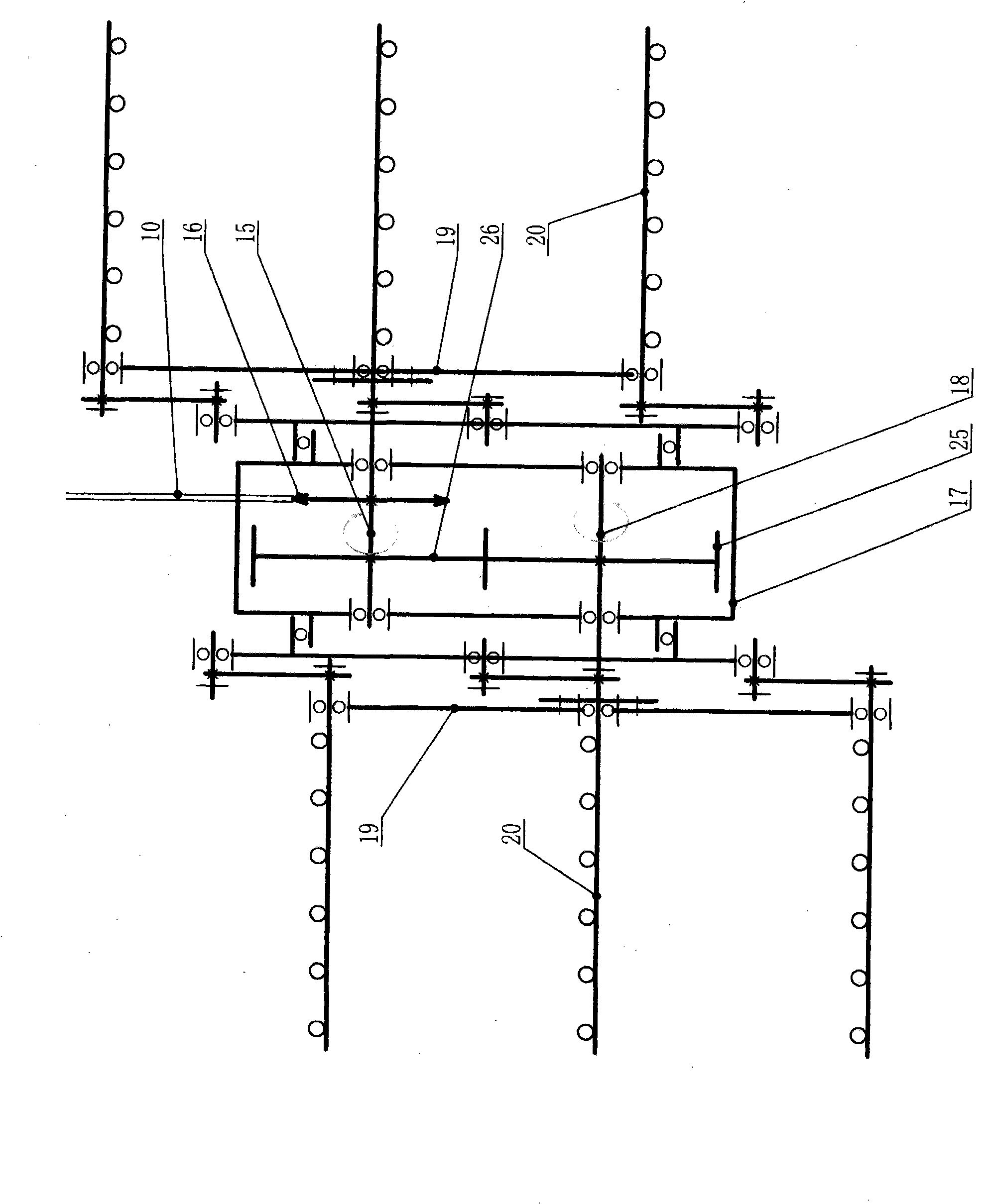

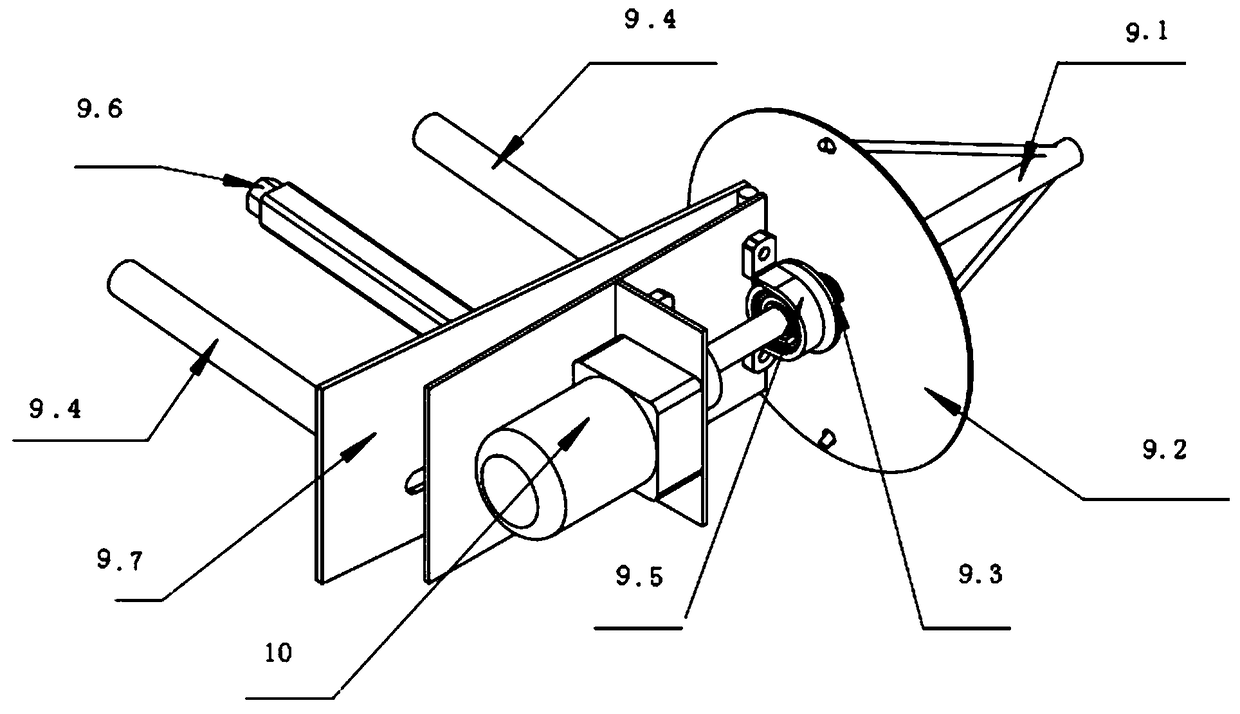

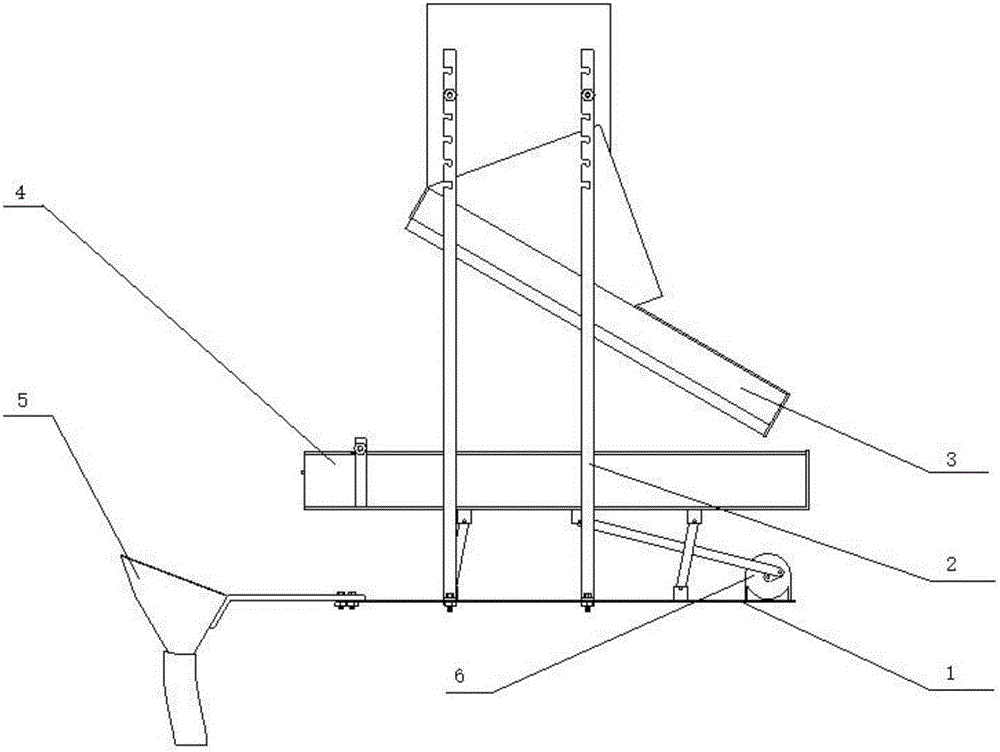

Device for weeding between seedlings and method for weeding

InactiveCN102282922AEffective protectionLow injury rateSoil-working equipmentsWeed killersHydraulic cylinderAgricultural engineering

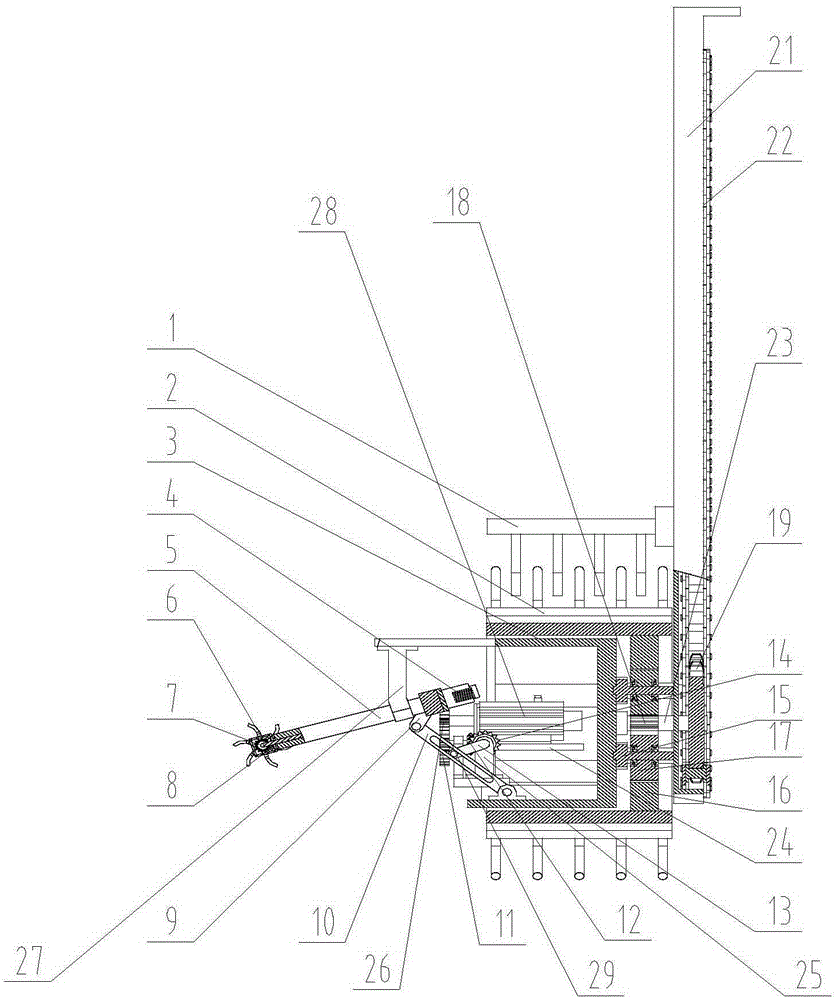

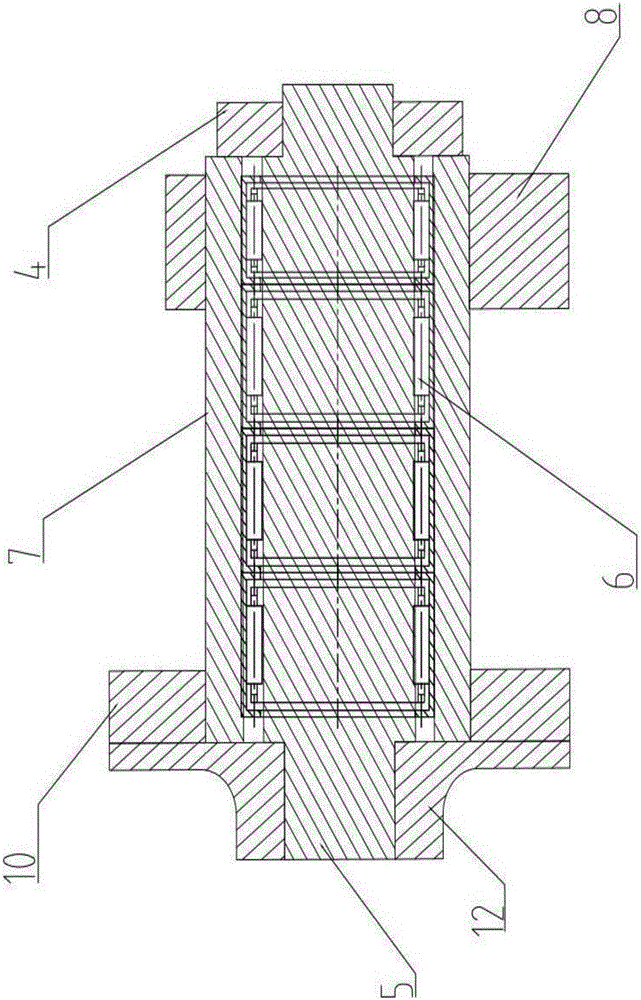

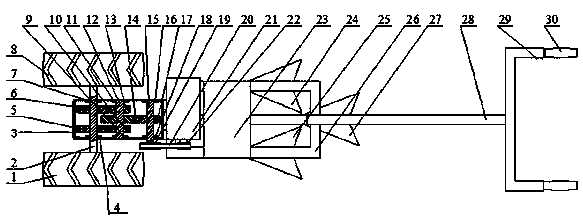

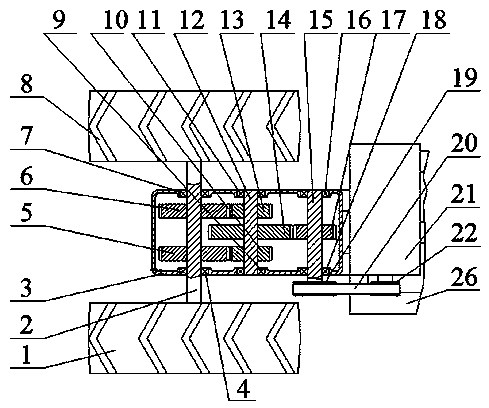

The invention discloses an inter-seedling weeding device and method, and relates to the technical field of agricultural machinery. The inter-seedling weeding device comprises a ground contour following device, a hoe blade lifting device, a tool setting device and a hoe blade device; and the ground contour following device comprises a contour wheel, a sliding plate, two sliding blocks, a spring and a cylindrical slide rail. The contour wheel and the hoe blade device are fixedly arranged on the sliding plate; and the sliding blocks are fixedly arranged on the sliding plate, and the sliding blocks and the spring are sleeved outside the cylindrical slide rail. The hoe blade lifting device comprises a second parallelogram mechanism and a second hydraulic cylinder, and the second hydraulic cylinder is arranged at the opposite sides or the adjacent sides of the second parallelogram mechanism. The tool setting device comprises a first parallelogram mechanism and a first hydraulic cylinder; and the first hydraulic cylinder is arranged on the opposite sides or the adjacent sides of the first parallelogram mechanism. According to the inter-seedling weeding device and method, disclosed by theinvention, the hoe blade can be protected and the seedling injuring rate during weeding can be reduced.

Owner:CHINA AGRI UNIV

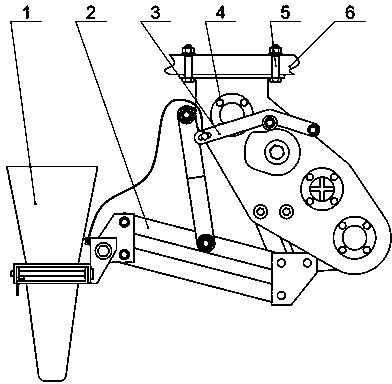

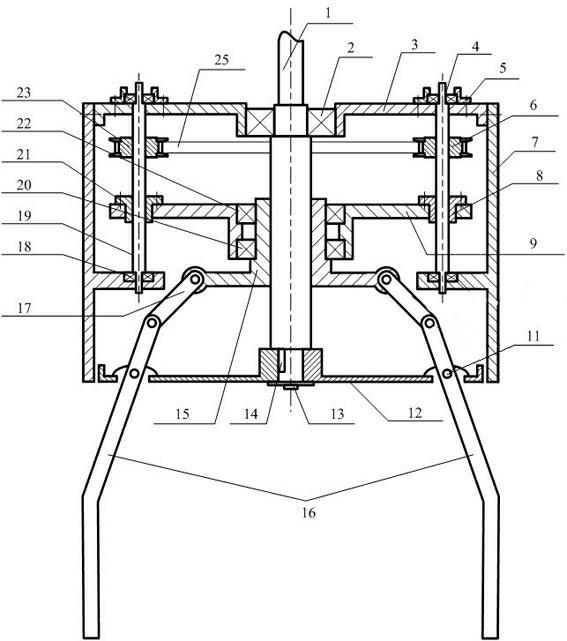

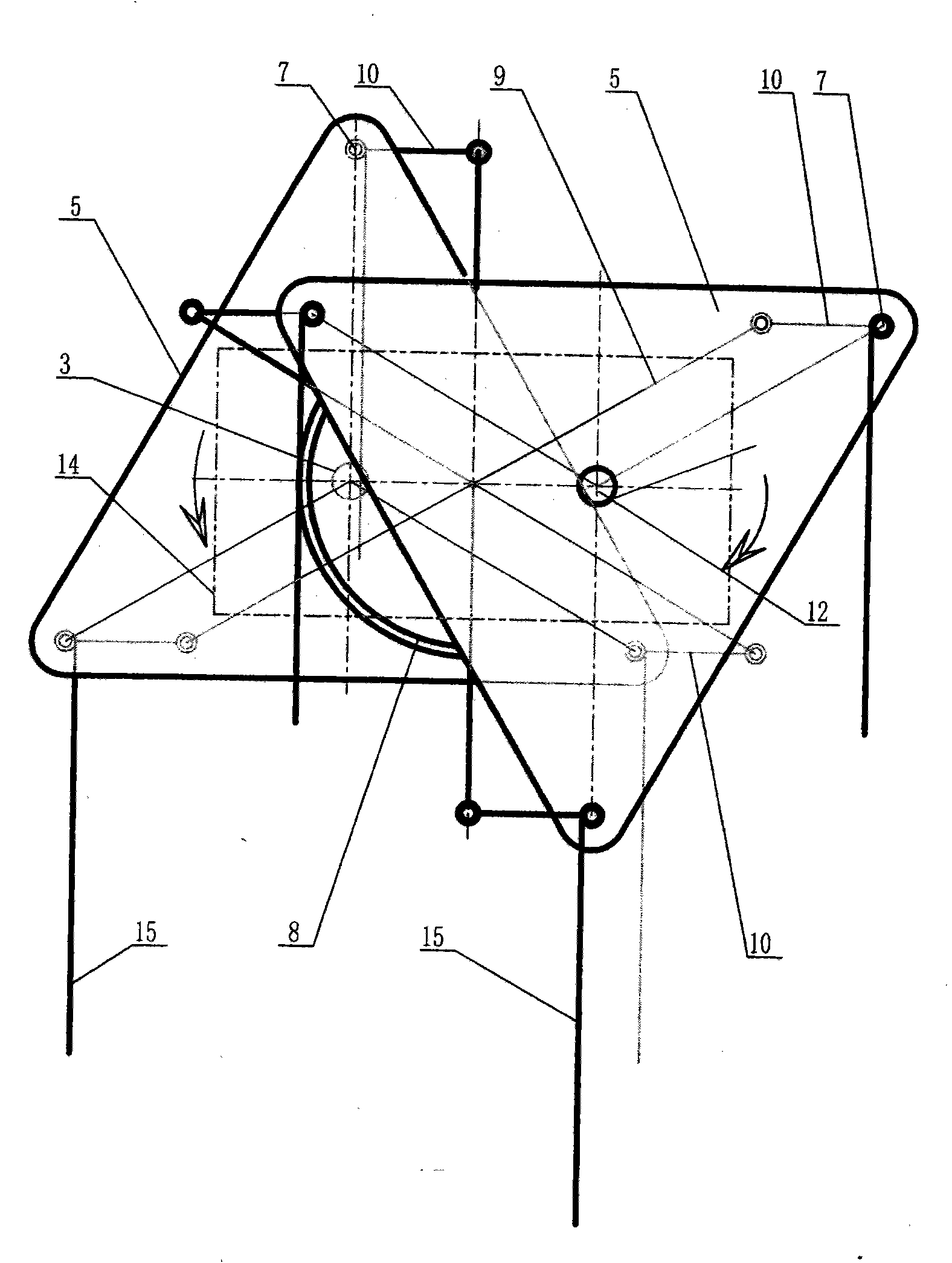

Transplanting mechanism capable of implementing continuous perpendicular planting

The invention discloses a transplanting mechanism capable of implementing continuous perpendicular planting. The translating mechanism comprises a transmission box, a planting arm assembly, a planter and a cam starting mechanism, wherein the transmission box is fixed on a stander; three output shafts, an input shaft and two hanging shafts are arranged on the transmission box; the first output shaft, the second output shaft and the two hanging shafts are arranged on one side of the transmission box and are used for hanging the planting arm assembly and driving the planting arm assembly; the third output shaft and the input shaft are arranged on the other side of the transmission box; the third output shaft is used for mounting and driving the cam starting mechanism; the input shaft is connected with an output shaft of a planter handpiece; the planting arm assembly consists of a four-rod mechanism, a five-rod mechanism and two parallel mechanisms; the planter is hung on the planting arm assembly through a square shaft. The transplanting mechanism disclosed by the invention is compact in structure, has the advantages of low seedling injury rate, low seedling leakage rate, low seedling burying rate, low seedling exposure rate and high seedling growth rate and can completely meet an agriculture requirement on oilseed rape transplanting.

Owner:HUNAN AGRICULTURAL UNIV

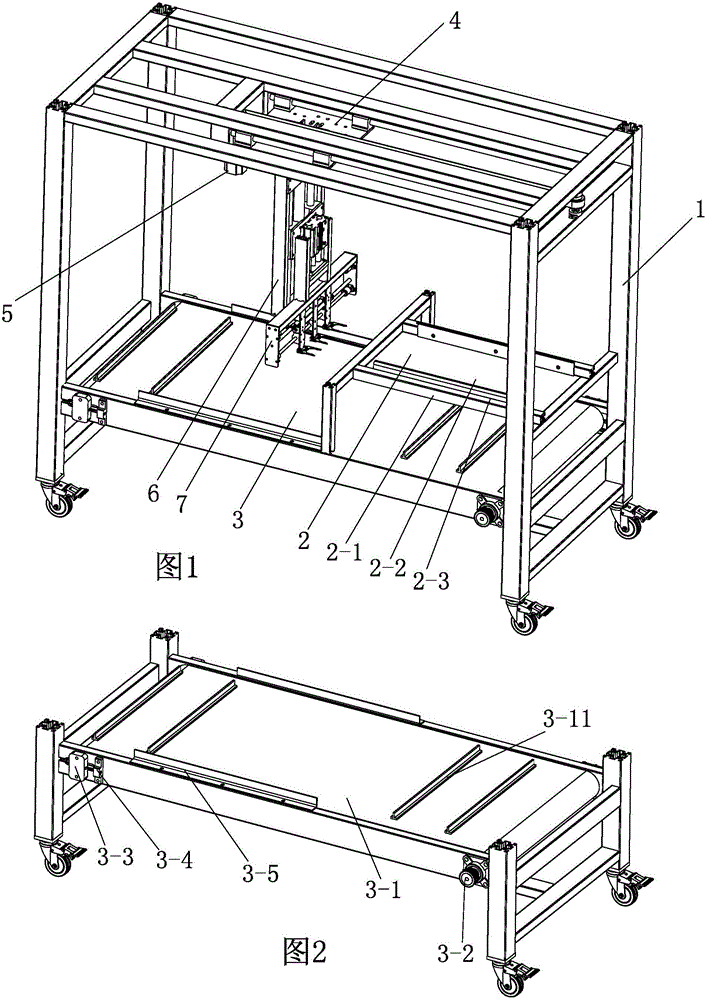

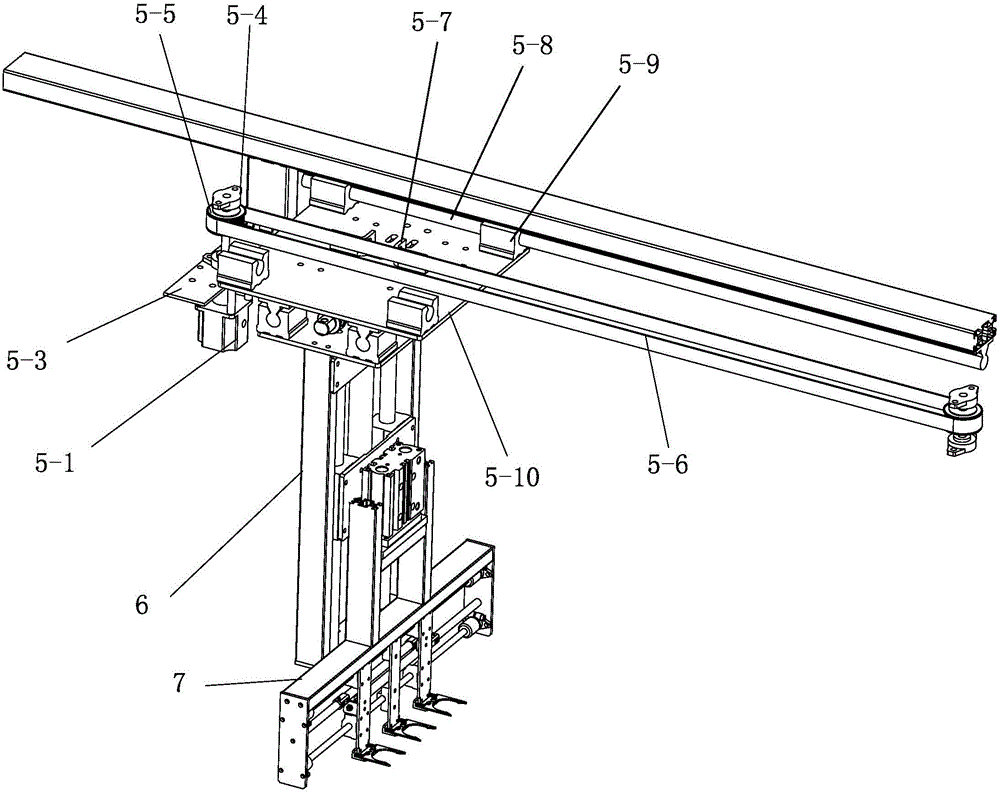

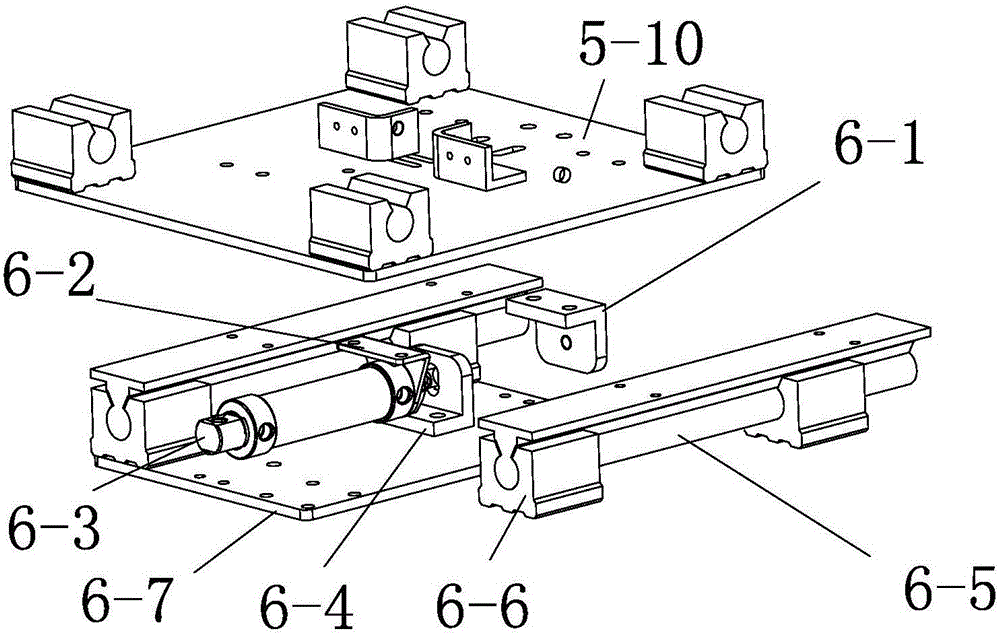

Greenhouse plug tray seedling transplanting machine

The invention relates to a greenhouse plug tray seedling transplanting machine. The invention aims to provide a device through which various plug tray seedlings in small plug trays can be precisely and quickly transplanted into large plug trays positioned in a delivery mechanism, the seedlings are not damaged, and besides, the device has the advantage of being compact in structure. The greenhouse plug tray seedling transplanting machine is characterized by comprising a framework which is provided with wheels and can move on the ground. The greenhouse plug tray seedling transplanting machine is characterized in that a seedling taking region for placing of the small plug trays is formed in the framework, a transplanting manipulator mounted on the framework is arranged in the framework, and a seedling placing region for placing of the large plug trays is positioned under the seedling taking region; the seedling taking region comprises a supporting plate which is horizontally fixed to the framework and is used for supporting and holding; the seedling placing region comprises a plug tray conveyor belt which is horizontally positioned on the framework through belt rollers, and a motor for driving the belt rollers to rotate.

Owner:ZHEJIANG SCI-TECH UNIV

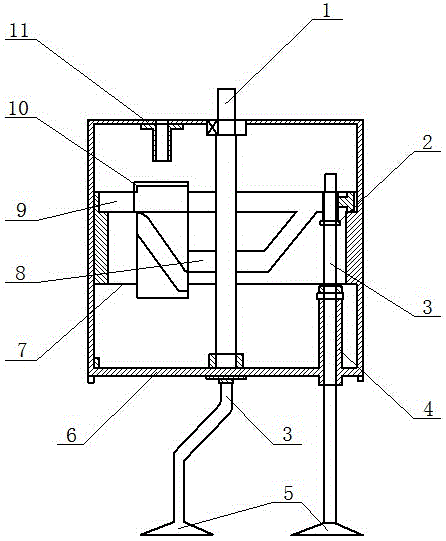

Seedling falling control mechanism of potted seedling transplanting machine

ActiveCN104855013AFalling smoothlyConvenient seedling timeTransplantingAgricultural engineeringSeedling

The invention relates to a seedling falling control mechanism of a potted seedling transplanting machine and belongs to the technical field of agricultural machinery. The seedling falling control mechanism comprises a front opening and closing plate, a rear opening and closing plate and a seedling falling frame; the front opening and closing plate and the rear opening and closing plate are arranged at an output end of a seedling conveying barrel base plate and comprise a folded horizontal plane respectively; the seedling falling frame extends upward from the front end of the seedling conveying barrel base plate; the upper portion of the outer side of the front opening and closing plate and the upper portion of the outer side of the rear opening and closing plate and the middle of an inverted V-shaped lever piece and the middle of a straight lever piece are supported on a fixing plate through a horizontal pin shaft in a hinged mode respectively, wherein the fixing plate is arranged at the front end of the seedling conveying barrel base plate; the lower portion of the folded horizontal plane of the front opening and closing plate is hinged to the inner lower end of the inverted V-shaped lever piece and the lower portion of the folded horizontal plane of the rear opening and closing plate is hinged to the lower end of the straight lever piece; the upper end of the straight lever piece and the inner lower end of the inverted V-shaped lever piece are hinged to two ends of a connecting rod respectively; the upper portion of the seedling falling frame is hinged to a cylinder body of a cylinder; the lower end of a piston rod of the cylinder, which extends downward, is hinged to an outer lower end of the inverted V-shaped lever piece. According to the seedling falling control mechanism of the potted seedling transplanting machine, the accurate control on the seedling falling time of potted seedlings can be facilitated and meanwhile a seedling falling opening is gradually opened, the opening speed can be convenient to control, and accordingly the potted seedlings can reliably fall down and the seedling injury rate and the seedling fall rate are significantly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

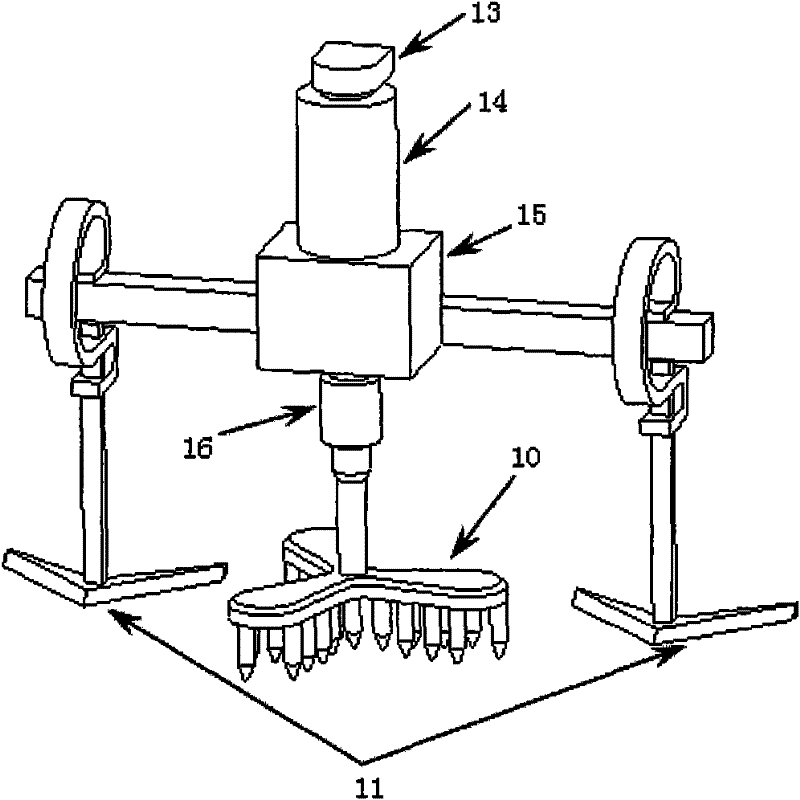

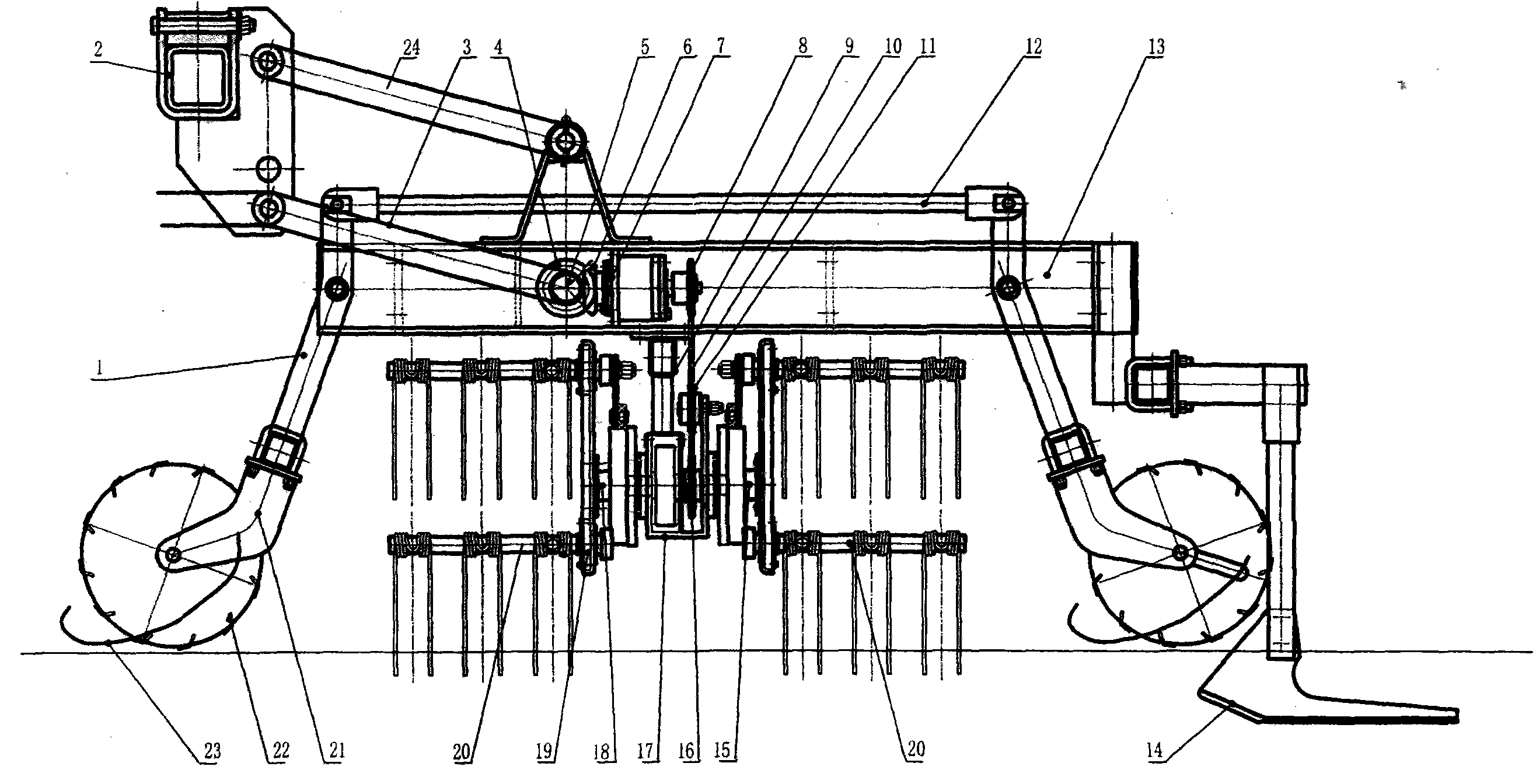

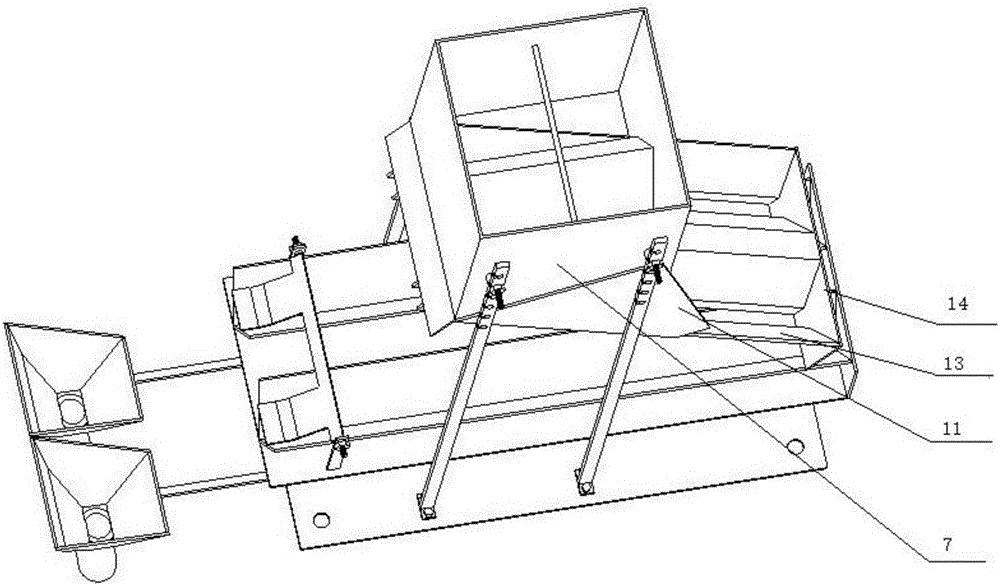

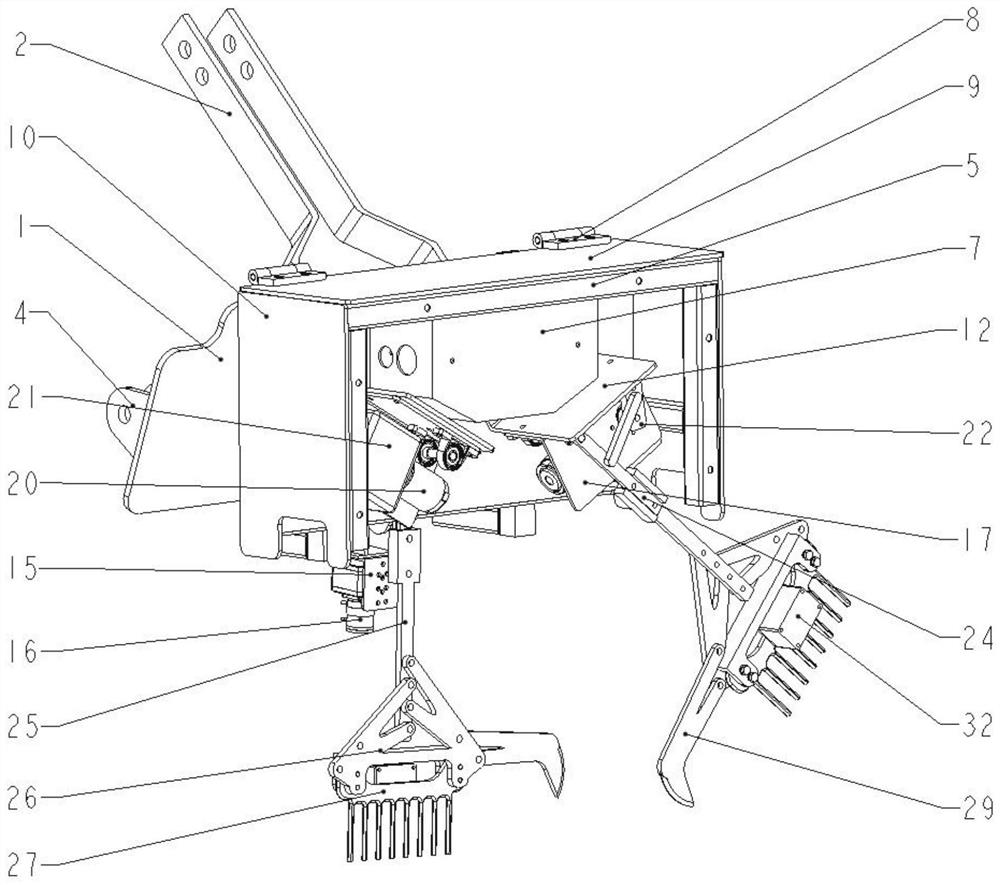

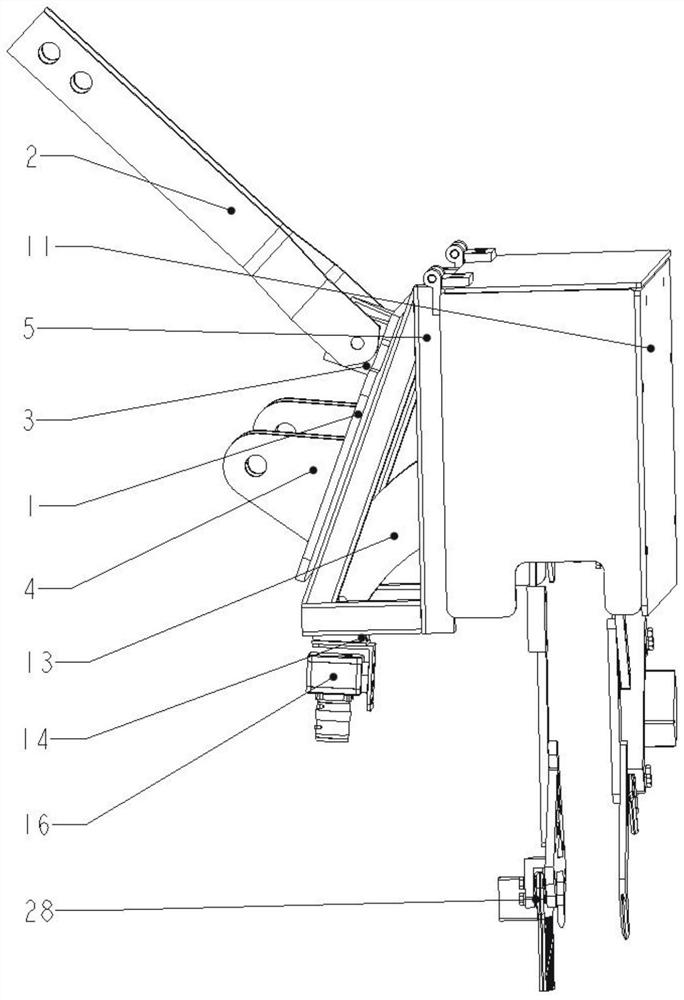

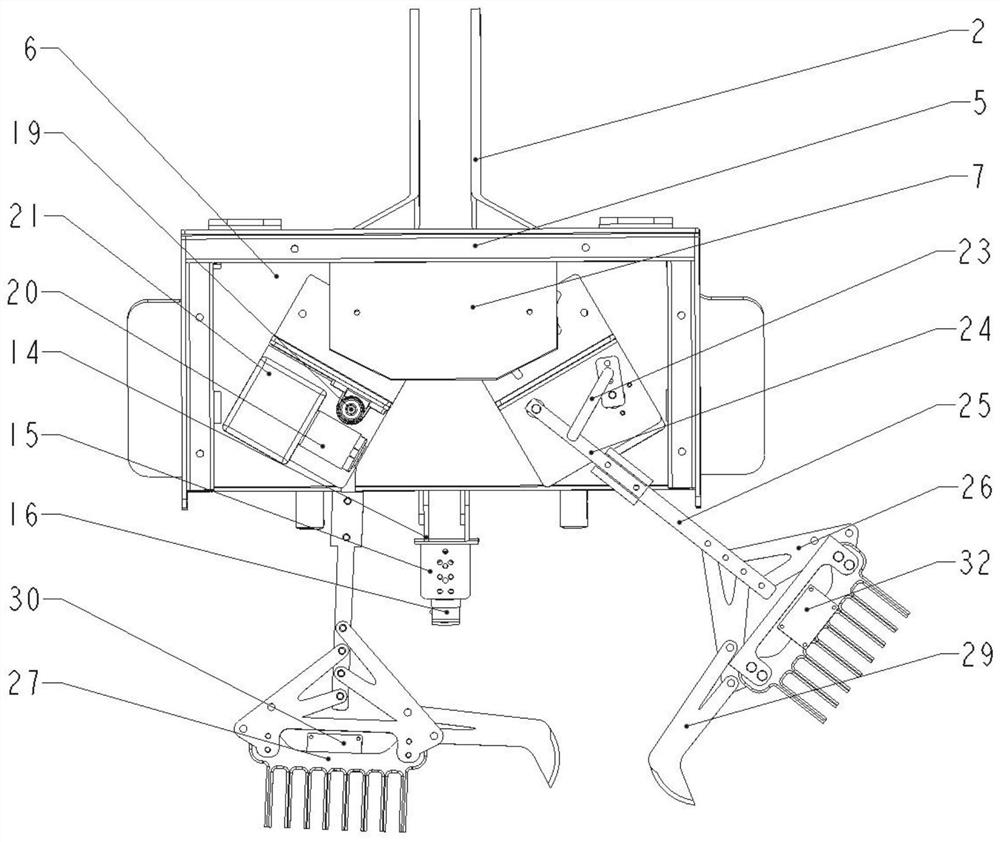

Intelligent comprehensive crop weeding device and method

ActiveCN104904700AReduced walking speed range requirementsEasy to controlWeed killersAgricultural scienceAgricultural engineering

The invention discloses an intelligent comprehensive crop weeding device and method. The intelligent comprehensive crop weeding device comprises a rack, a vision and intelligent electric control system, a depth and height adjusting device, a line space weeding device, a plant space weeding device and an intelligent pesticide spraying device. A three-point suspension mechanism located on the rack is connected with a walking machine. The vision and intelligent electric control system is used for acquiring relative position information of a plant and plant space weeding shovel and a nozzle and controlling the work states of the plant space weeding device and the intelligent pesticide spraying device. The depth and height adjusting device is used for adjusting the embedded depth of a line space weeding shovel and the plant space weeding shovel and the height of a chassis of the rack. The line space weeding device and the plant space weeding device are used for removing weeds of the line space of plants and weeds between the plants. The intelligent pesticide spraying device is used for removing the weeds which grow at the roots of the plants and can not be removed by the plant space weeding shovel. By the adoption of the intelligent comprehensive crop weeding device and method, the plants are protected against damage caused by the plant space weeding shovel, the problem that crop growth is impeded by the weeds growing at the roots of the plants is solved, and the weeds of the line space and the weeds between the plants of crops are comprehensively removed.

Owner:JIANGSU UNIV

Machine vision based weeding robot system and method thereof

ActiveCN101990796BReduce pollutionEffective Mechanical WeedingSoil-working equipmentsWeed killersData controlRobotic systems

The invention discloses a machine vision based weeding robot system and a method thereof. The system comprises a robot moving platform, a field navigation device, a field grass identifying device, a weeding device and a robot control system; wherein the robot moving platform is used for executing advancing action of the robot system in the field; the field navigation device is used for acquiring navigation parameter required by movement of the robot system and sending the parameter to the robot control system; the field grass identifying device is used for acquiring field grass image information, identifying grass according to the field grass image information, obtaining identification data, calculating grass body coordinates and grass interval and sending the grass body coordinates and grass interval to the robot control system; the weeding device is used for executing weeding action; and the robot control system is used for controlling the robot moving platform to execute advancing action in the field according to the received navigation parameter and controlling the weeding device to execute weeding action according to the grass body coordinates and grass interval. The invention can realize rapid and accurate weeding operation on crop in the field.

Owner:江苏博田机器人有限公司

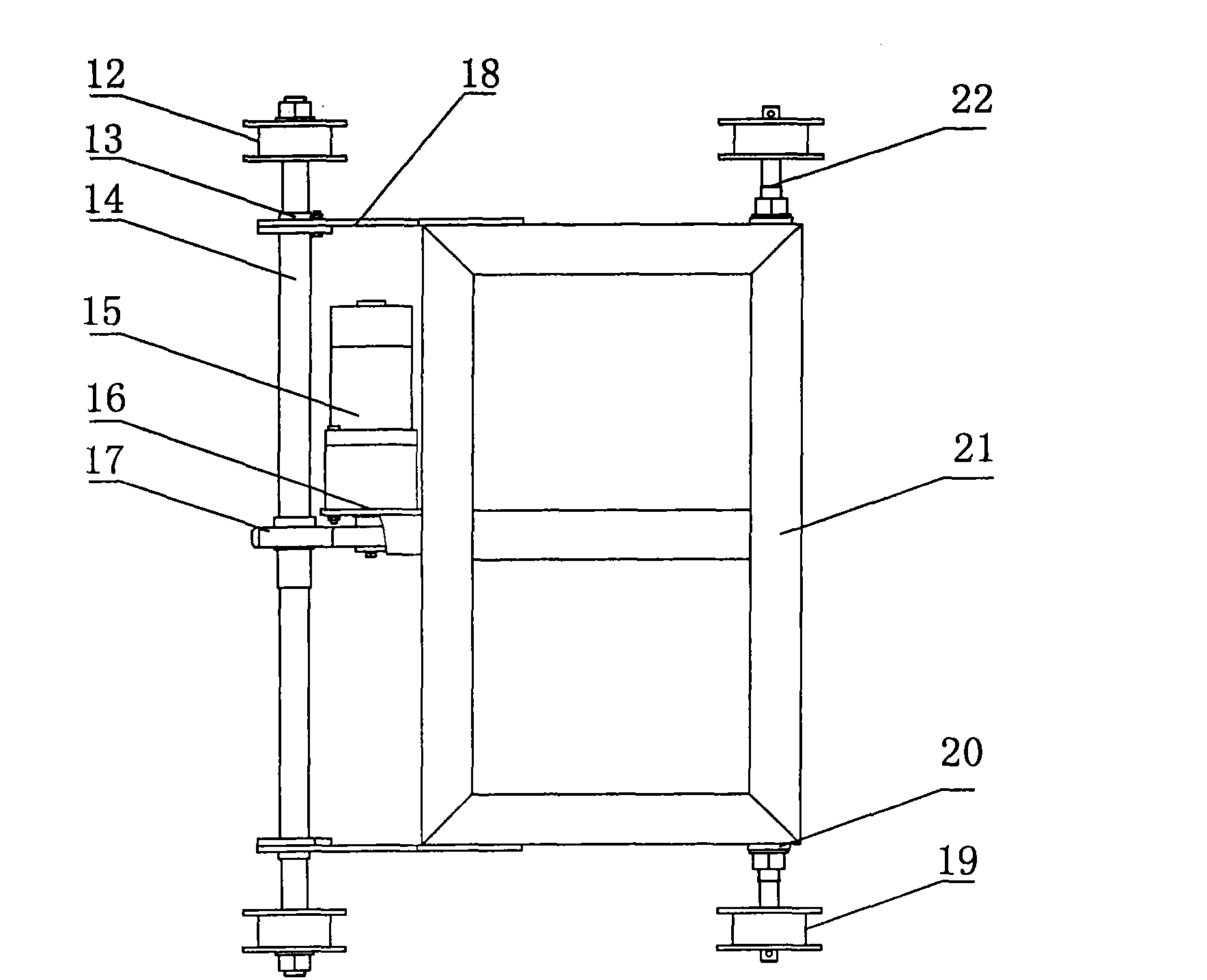

Paddy-bud seeder

The invention provides a paddy-bud seeder. The seeder consists of close slot-type electromagnetic vibration seed metering devices, an electric control type seeding mobile platform, a track frame and a direct-current power supply, wherein each close slot-type electromagnetic vibration seed metering device consists of a hopper type seed box, a seed metering disk, an electromagnet, a spring piece, aspring support, a controller and a control circuit; two close slot-type electromagnetic vibration seed metering devices are arranged on the top surface of the electric control type seeding mobile platform in parallel, and integrally arranged on the track frame; the electric control type seeding mobile platform consists of a platform frame, a front shaft, a rear shaft, a front support arm, a rear support arm, front wheels, rear wheels, a transmission gear, a direct-current gear motor and a controller; and the track frame consists of tracks, beams, support legs and wire holders and is a double track. The paddy-bud seeder has the advantages of uniform seeding, adjustable seeding speed, low seed-damaging rate and suitability for field operation; moreover, the paddy-bud seeder is matched with a slurry-mixing disc-type seedling technology.

Owner:GUANGXI UNIV

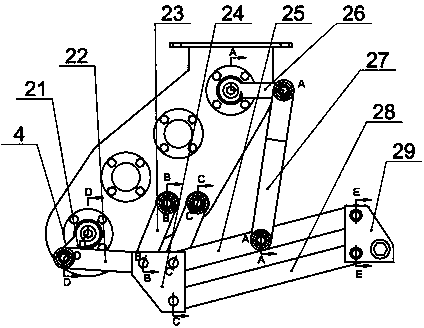

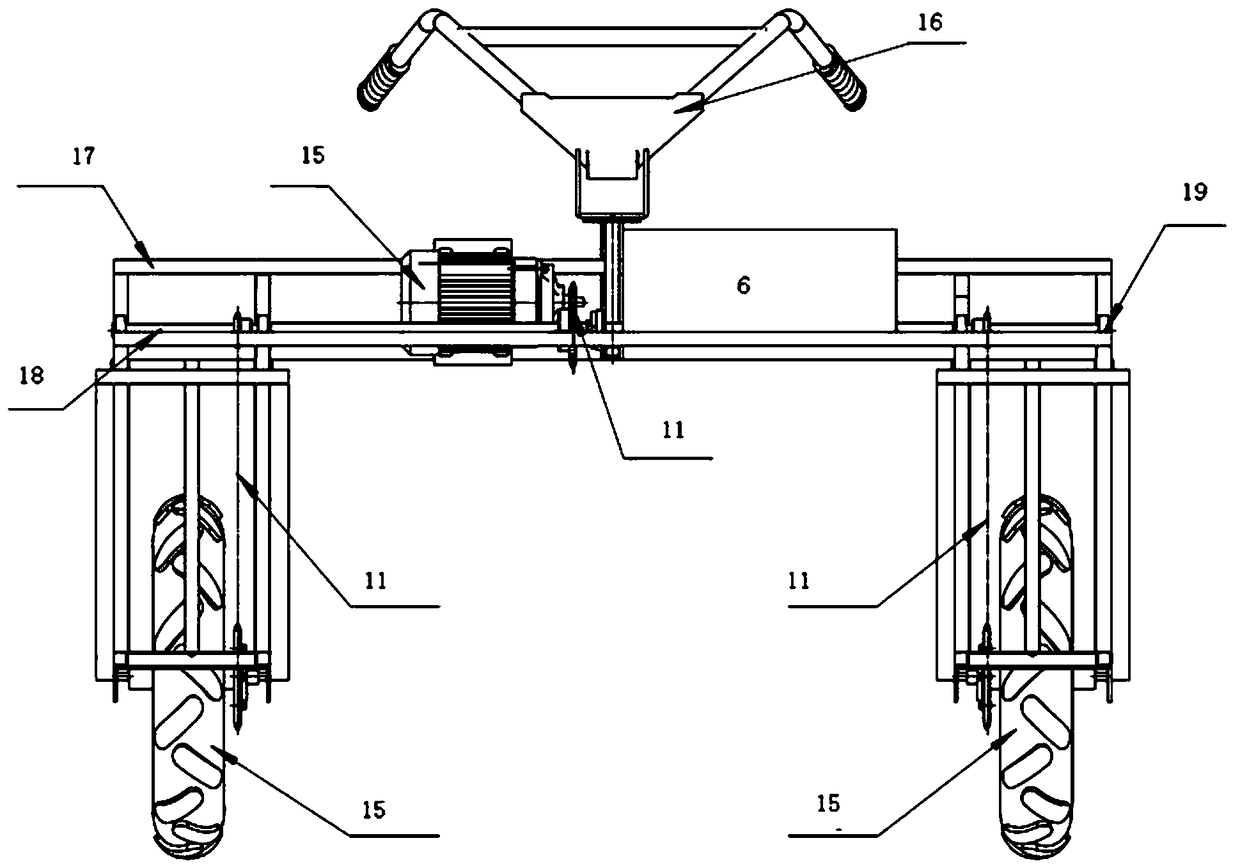

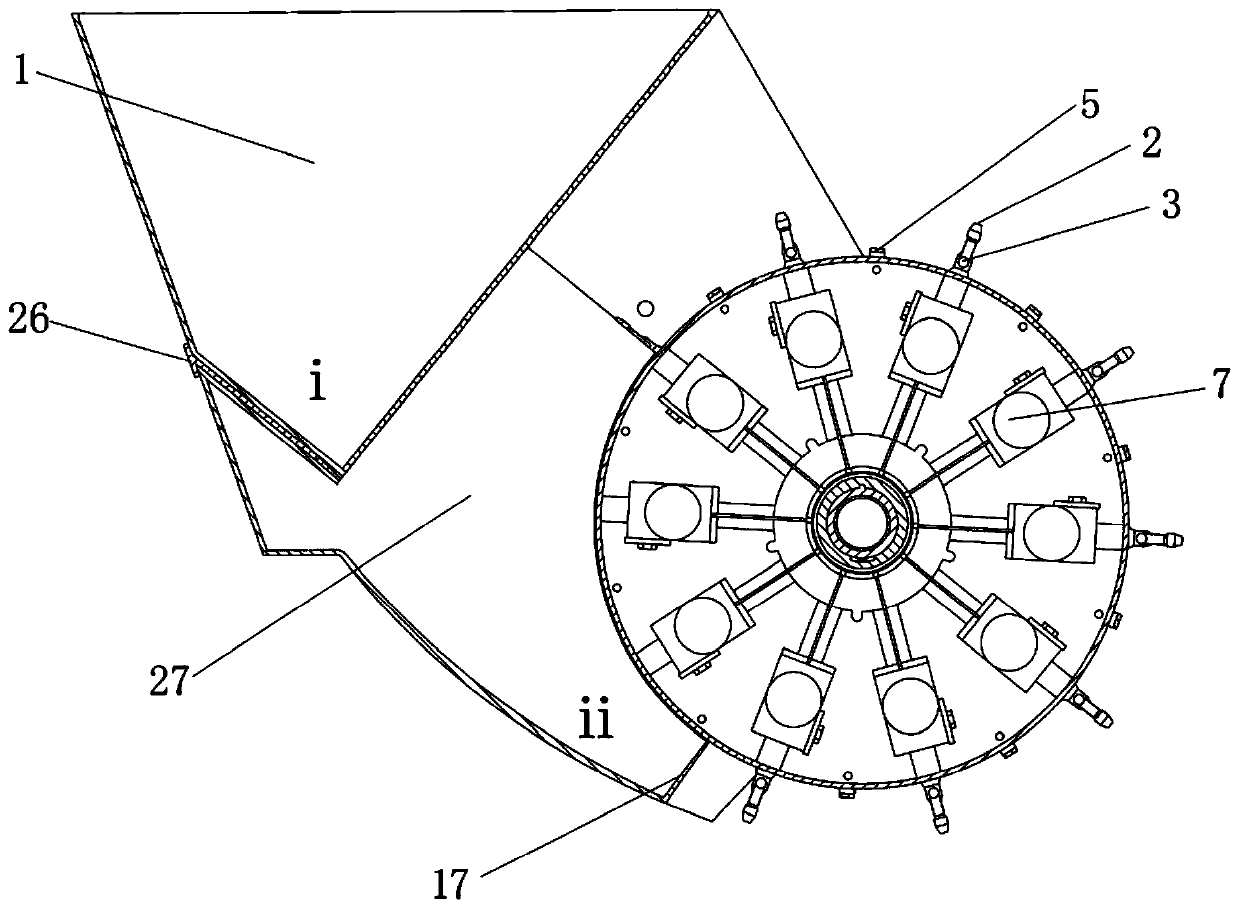

Lateral retractable intertillage weeding unit

InactiveCN105340391ANovel structureReasonable structureSoil-working equipmentsEngineeringPlant Weeds

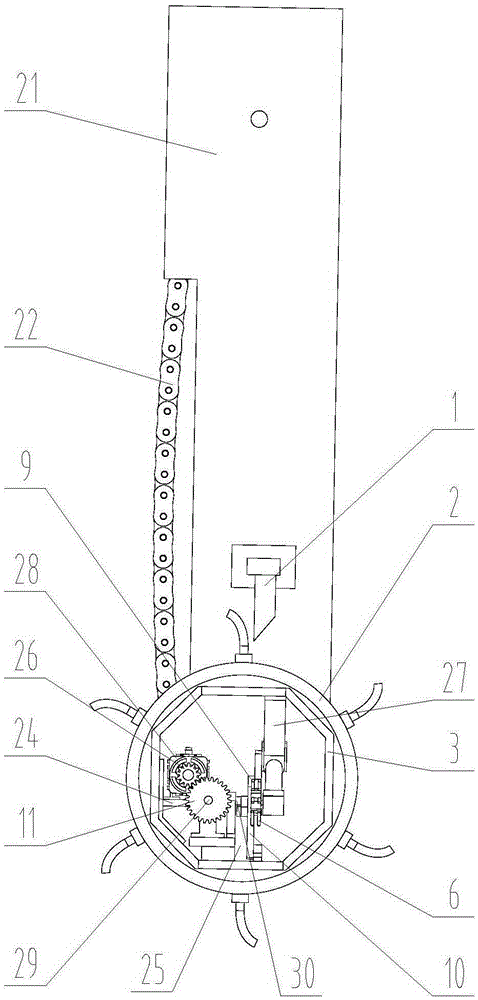

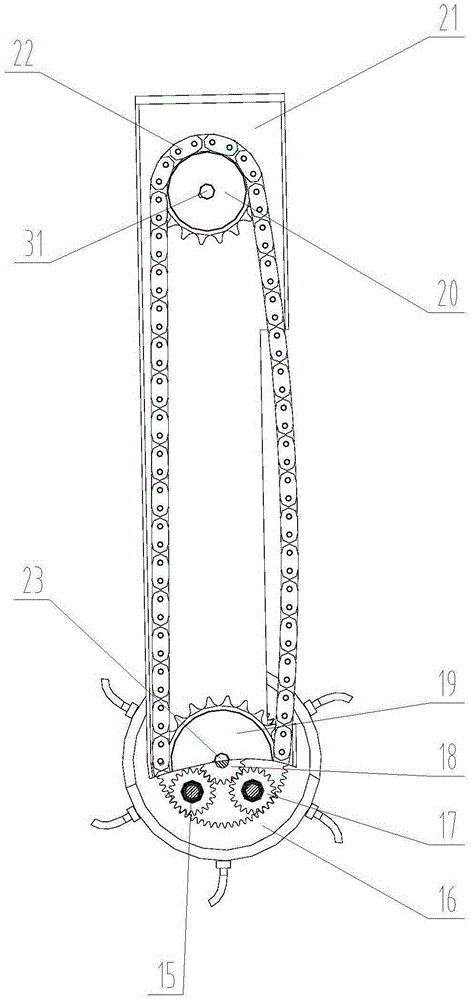

The invention discloses a lateral retractable intertillage weeding unit and belongs to agricultural machinery. A power transmission mechanism formed by a driving chain wheel, a driven chain wheel and a chain is installed on a unit plate through a power input shaft and a main driving shaft, an inter-line weeding tooth roller assembly is assembled on the unit plate in a rotary mode through a planet gear shaft, a planet gear, a sun gear and an annular gear, a fixed inner shell is arranged in a roller cavity of the inter-line weeding tooth roller assembly through a planet gear shaft, and a suspension arm frame, a main motor base plate and a base frame are fixedly installed on the fixed inner shell; an inter-plant weeding telescopic boom provided with an inter-plant weeding driving motor, bevel gears A and B, an inter-plant weeding claw assembly and a connecting rod is assembled on the suspension arm frame, a main motor provided with a driving cylindrical gear is installed on the main motor base plate, a driven cylindrical gear, a shaft I, a driving bevel gear, a driven bevel gear, a shaft II and a driving rod are installed on the base frame, and a swing rod is hinged to the connecting rod and the driving rod. By the adoption of the unit, inter-seedling intertillage weeding can be achieved without touching seedlings, and seedling damage rate is low.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

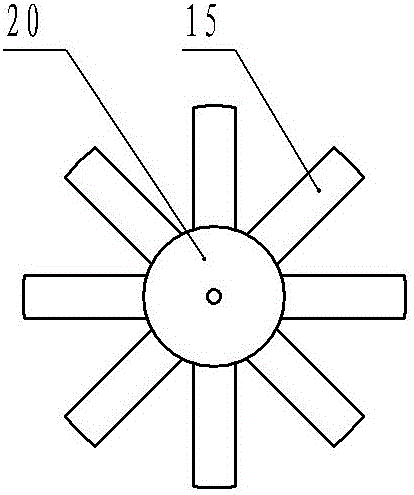

Horizontal disc type weeding claw device

ActiveCN102217437ASimple structureImprove performanceSoil-working equipmentsWeed killersCircular discAgricultural engineering

Owner:SOUTH CHINA AGRI UNIV

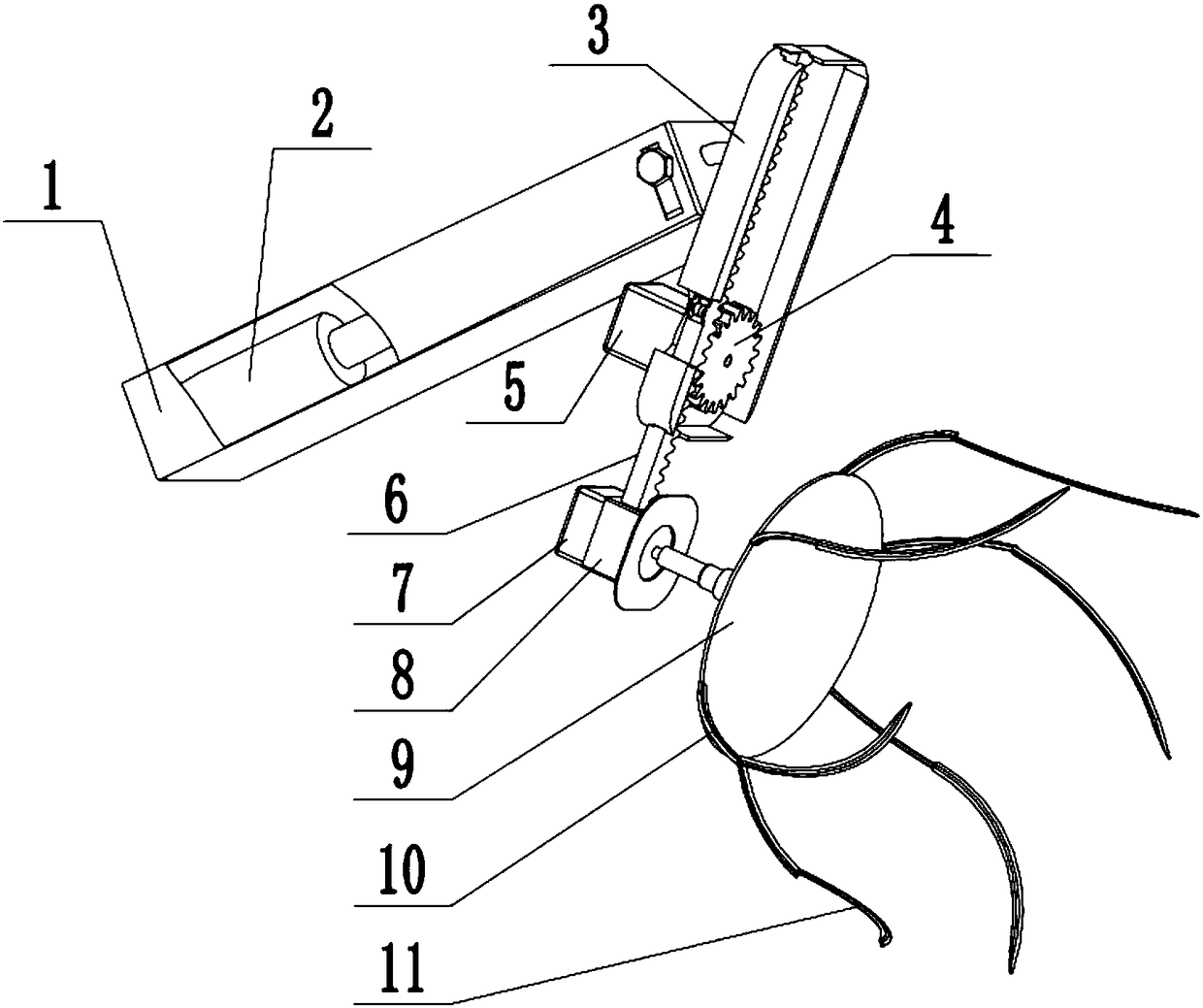

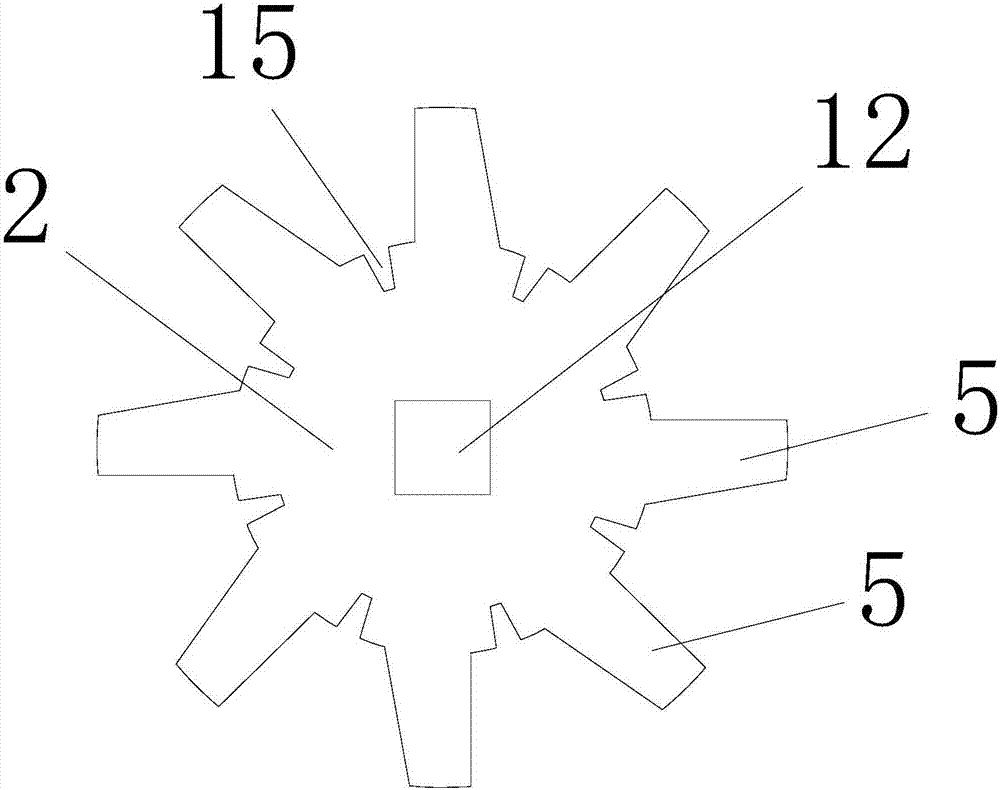

Inter-seedling weed remover assembled on mechanical trash cultivator

ActiveCN108419460AMeet and adapt to the requirements of precision agricultural operationsNovel structureSoil-working equipmentsPush pullControl theory

The invention provides an inter-seedling weed remover assembled on a mechanical trash cultivator and belongs to agricultural machinery. A telescopic push-pull rod is assembled in a cantilever type fixed sleeve; a transmission case shell is mounted on the outer end part of the telescopic push-pull rod in a mode that a vertical inclination angle can be adjusted; a motor A, a cylindrical gear and a rack are respectively assembled on the transmission case shell; the cylindrical gear is fixedly arranged on the motor shaft of the motor A; the cylindrical gear is meshed with the rack; a mounting baseprovided with a motor B and a toothed disc assembly is fixedly arranged on the rack; the motor shaft of the motor B is connected with the toothed disc assembly; a plurality of tooth holders are assembled on the toothed disc assembly; and inter-seedling weed removing and soil loosening teeth are mounted on the tooth holders. The inter-seedling weed remover completes weed removing and soil loosening operations for inter-seedling parts of crops by adopting an avoiding mode under the condition of not touching crop seedlings, and meets fine cultivation requirements; and the inter-seedling weed remover has the characteristics of novel and reasonable structure, low seedling damage rate, reliable use, good work synchronicity, smooth operation and high adaptability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

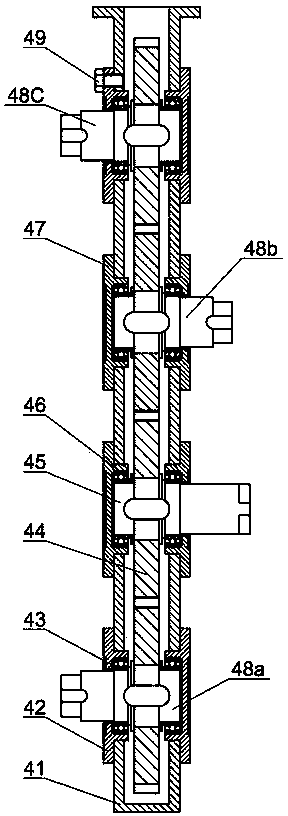

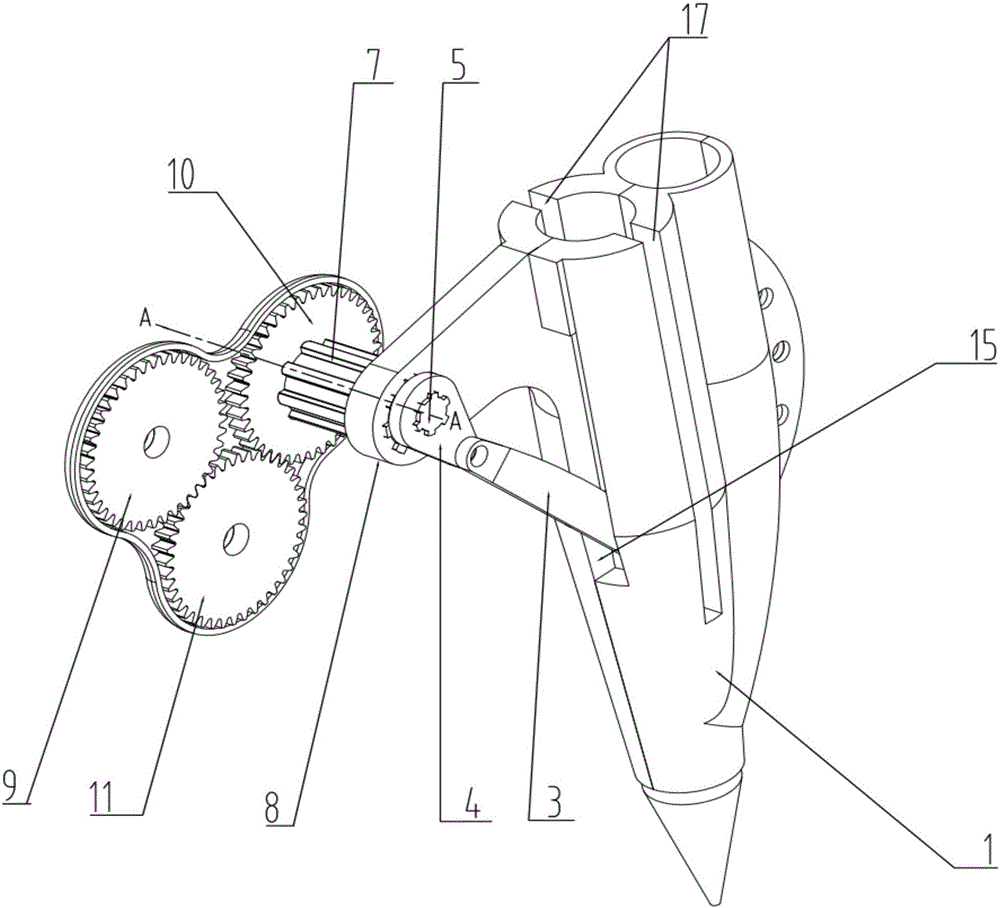

Mechanism for combining hole pricking work as well as ejecting and applying work of solid fertilizers

InactiveCN105960892ANovel structural designSmall sizePlantingFertiliser distributersNeedle roller bearingLeft half

theThe invention provides a mechanism for combining hole pricking work as well as ejecting and applying work of solid fertilizers, and belongs to agricultural machines. a left half housing and a right half housing are fixed, a hole pricking piston chamber and a fertilizer feeding chamber which are communicated are formed in the left half housing and a right half housing, and a hole pricking piston is assembled in the hole pricking piston chamber; an external spline sleeve is fixed on the left half housing, and a spline spindle is installed in a trepanning of the external spline sleeve by a needle bearing; a rocking arm is fixed on one end of the spline spindle, and the outer end and the inner end of a connecting rod are respectively connected to the rocking arm and the hole pricking piston in hinged connection; a sun gear, an intermediate gear and a planetary gear are installed in a gear box; the planetary gear is fixed to the external spline sleeve, and the other end of the spline spindle is inserted and fixed in a spline bore on the gear box. Planetary gears are used for driving the integrated mechanism for linking hole pricking as well as ejecting and applying work of solid fertilizers in order to complete synchronous and continuous operations of hole pricking and hole fertilization of solid fertilizers; the mechanism has the characteristics of novel, reasonable and compact structure, high working efficiency, good working quality, low usage failure, and low injury rate of seedlings.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

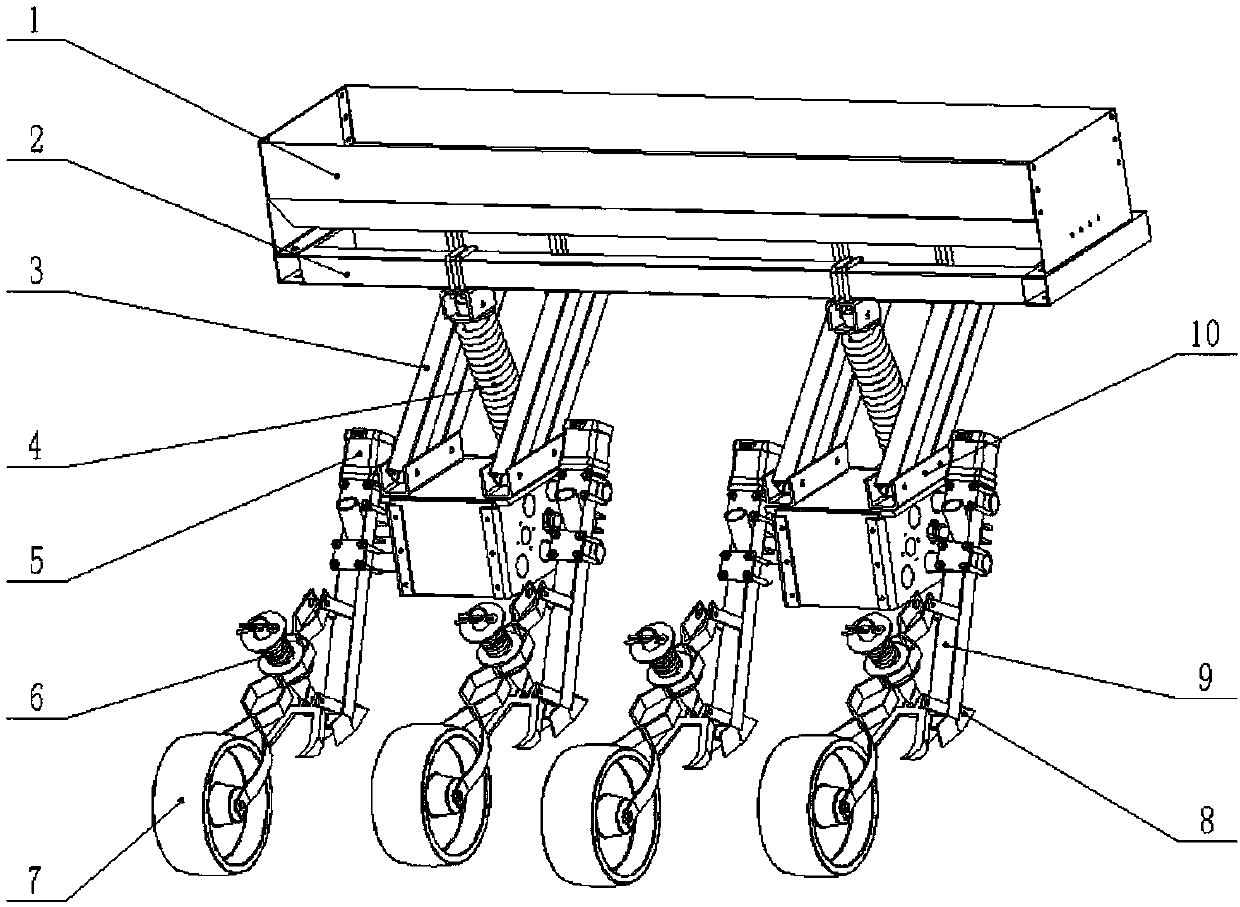

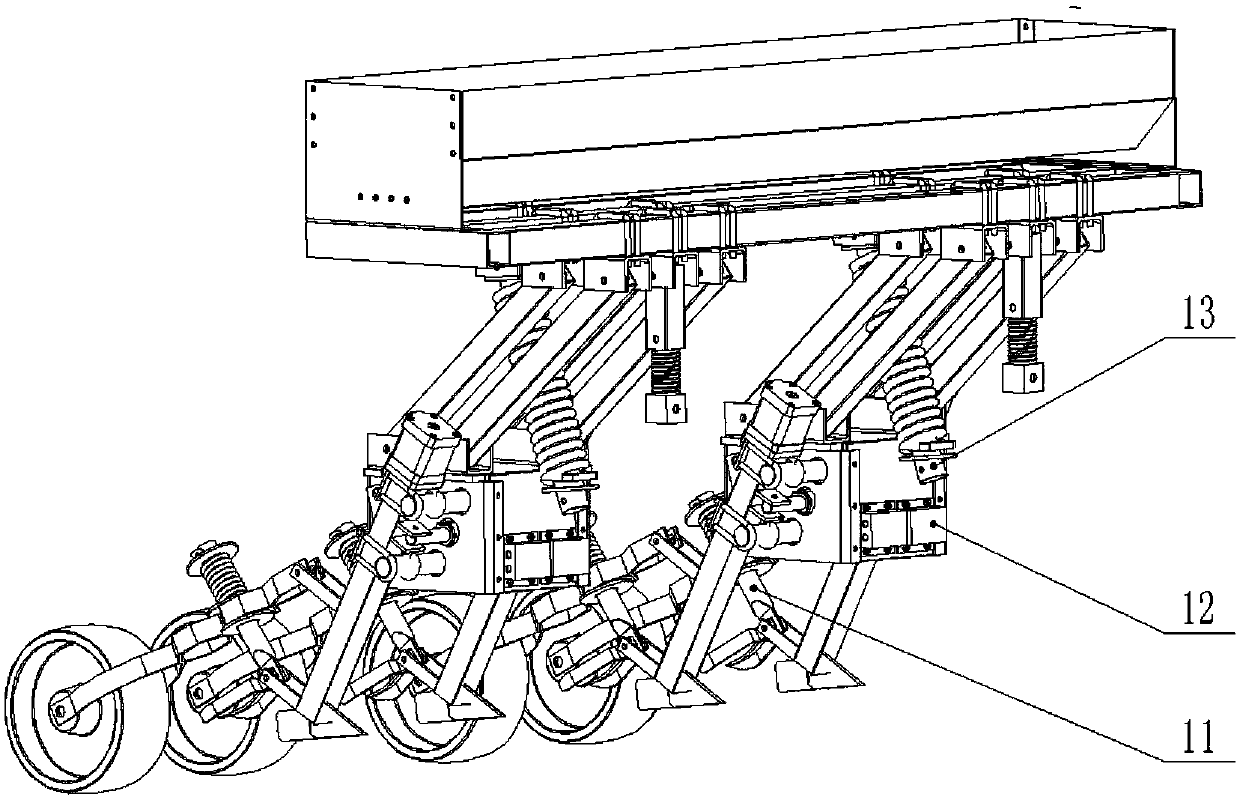

A rate-variable fertilizing machine used for corn and achieving self-adaptive line spacing

InactiveCN108029303AImprove the efficiency of fertilization operationsLow injury ratePlantingFertiliser distributersGrowth plantMachine vision

The objective of the invention is to provide a rate-variable fertilizing machine used for corn and achieving self-adaptive line spacing. The rate-variable fertilizing machine mainly includes image taking devices, line spacing adjusting devices, ultrasonic wave detecting devices, rate-variable fertilizing devices, soil covering and pressing mechanisms, four-bar feeler mechanisms, a rack and a fertilizer tank. The rate-variable fertilizing machine is mounted to a high clearance tractor. A machine vision technology is adopted. A host computer can output pulses having different frequencies to therate-variable fertilizing devices according to plant growth vigour information, thus achieving rate-variable fertilization, effectively saving chemical fertilizers and increasing the utilization rateof chemical fertilizers. In addition, an ultrasonic wave detection technique is adopted, distances between the machine and plants are detected by ultrasonic wave detectors, and the host computer adjusts fertilizing positions in real time through the line spacing adjusting devices according to the distances, thus adapting to different spacing values and ensuring optimum fertilization effects.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

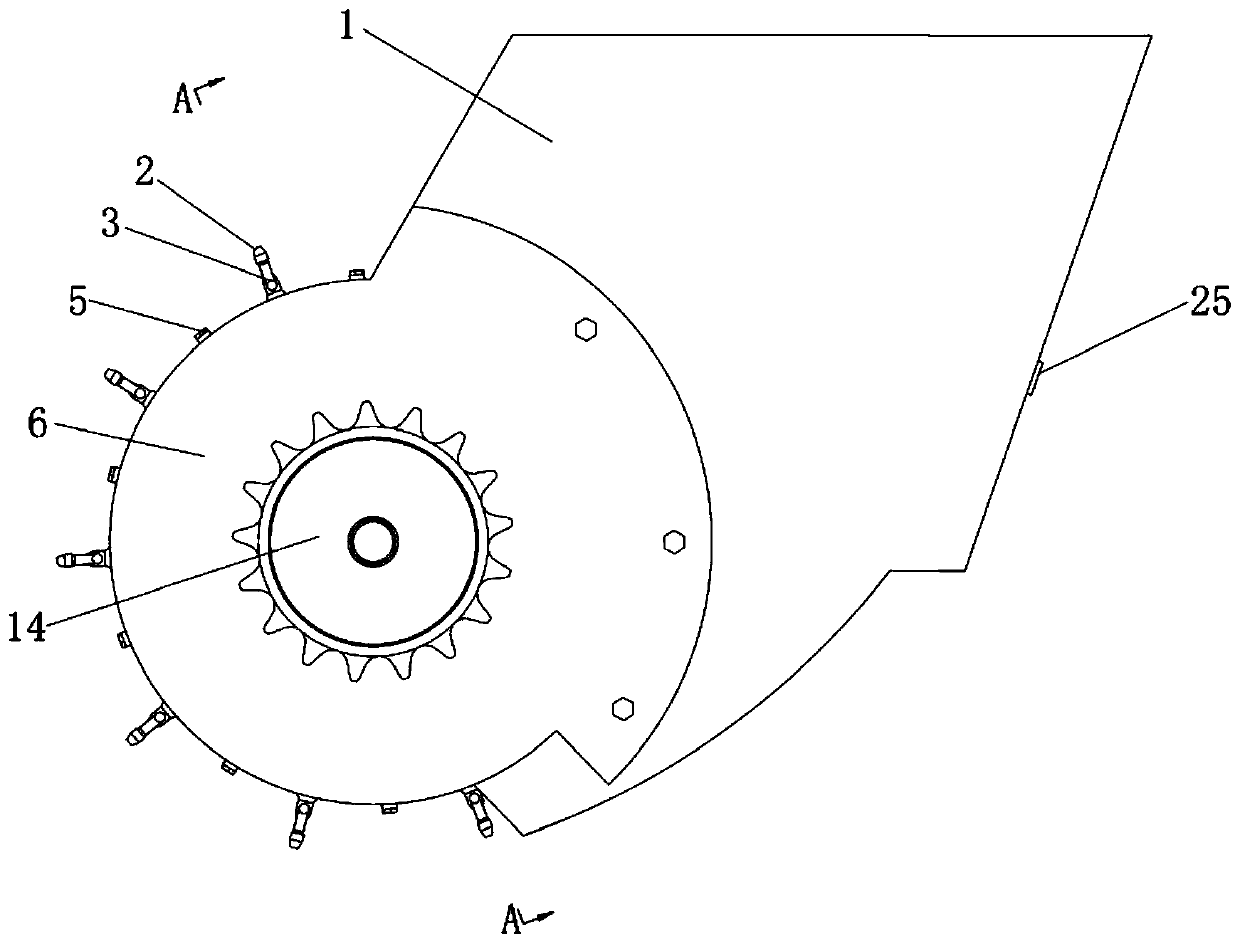

Seed metering apparatus applicable to precise small-quantity seeding of small-granule seeds

InactiveCN103959964AReduce extrusion pressureLow injury rateSeed depositing seeder partsSowingEngineering

The invention relates to a seeding apparatus of agricultural machinery and provides a seed metering apparatus applicable to precise small-quantity sowing of small-granule seeds. The apparatus can arrange seeds into a line and sow the seeds in sequence. The apparatus comprises a seed filling box, a seed restricting separator plate, seed metering separation blades, a seed filling groove, a seed clearing piece, a hairbrush and a seed clearing slit, wherein the seed filling groove is an annular groove which can arrange seeds into a line, the seed restricting separator plate restricts the amount of seeds above the seed filling groove, reduces extrusion force on seeds and decreases the damage rate of seeds, the seed metering separation blades are low, which facilitates seed filling, the hairbrush is used to reduce damage to seeds, gaps are arranged between the hairbrush and the seed metering separation blades, so shearing force on seeds is reduced, and the seed clearing piece prevents seeds from being stuck in the seed filling groove, thereby preventing miss-seeding.

Owner:HEBEI AGRICULTURAL UNIV.

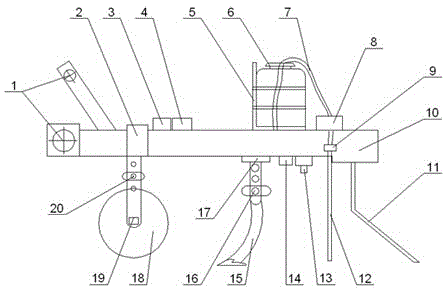

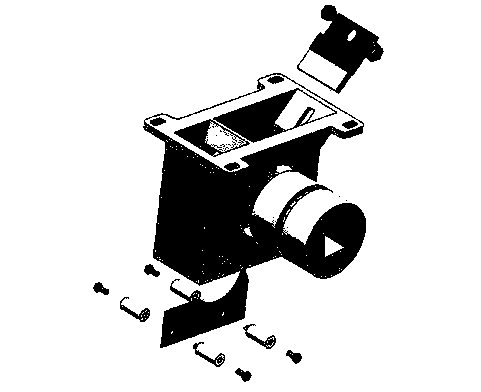

Combined vertical comb-type weeding mechanism for crop seedling with loose soil

The invention relates to a combined vertical comb-type weeding mechanism for crop seedlings with loose soil, which belongs to agricultural machinery. In the technical scheme, a transmission case is provided with a rear power output shaft and a front power output shaft in parallel, the rear power output shaft is provided with a driving sprocket and a driving cylindrical gear, the front power output shaft is provided with a driven cylindrical gear, the outer ends of the front power output shaft and the rear power output shaft are fixedly provided with a comb-type shaft with elastic comb teeth respectively through a flange coupling plate, a circular chute is arranged on outer side faces of the front wall and the back wall of the transmission case, a driven plate is arranged on the circular chute, a pin shaft is arranged on the driven plate, and the two ends of a connecting plate are fixedly connected with the comb-type shaft and the pin shaft respectively. The mechanism can make the elastic comb teeth on the comb-type shaft always maintain the upright state during the operation, has the advantages of novel and reasonable structure, stable insertion of the elastic comb teeth in the soil, high operating quality, high efficiency, low rate of injured seedlings and high adaptability, and can be widely applied in inter-tillage of soybeans, corns, beets, cereals, cotton and other crops.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

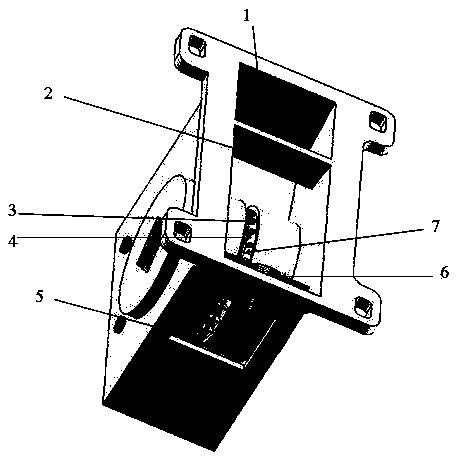

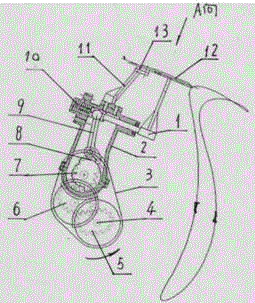

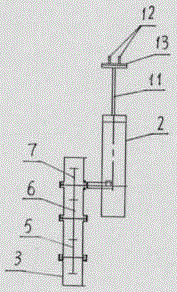

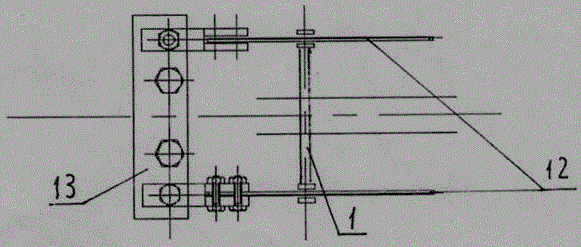

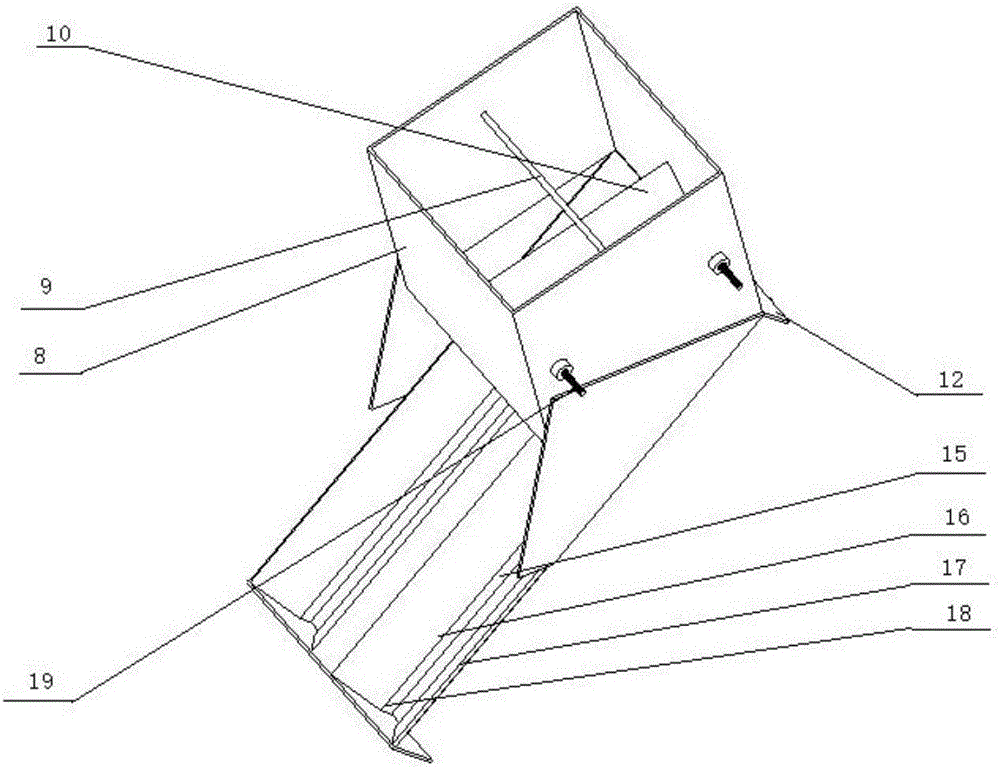

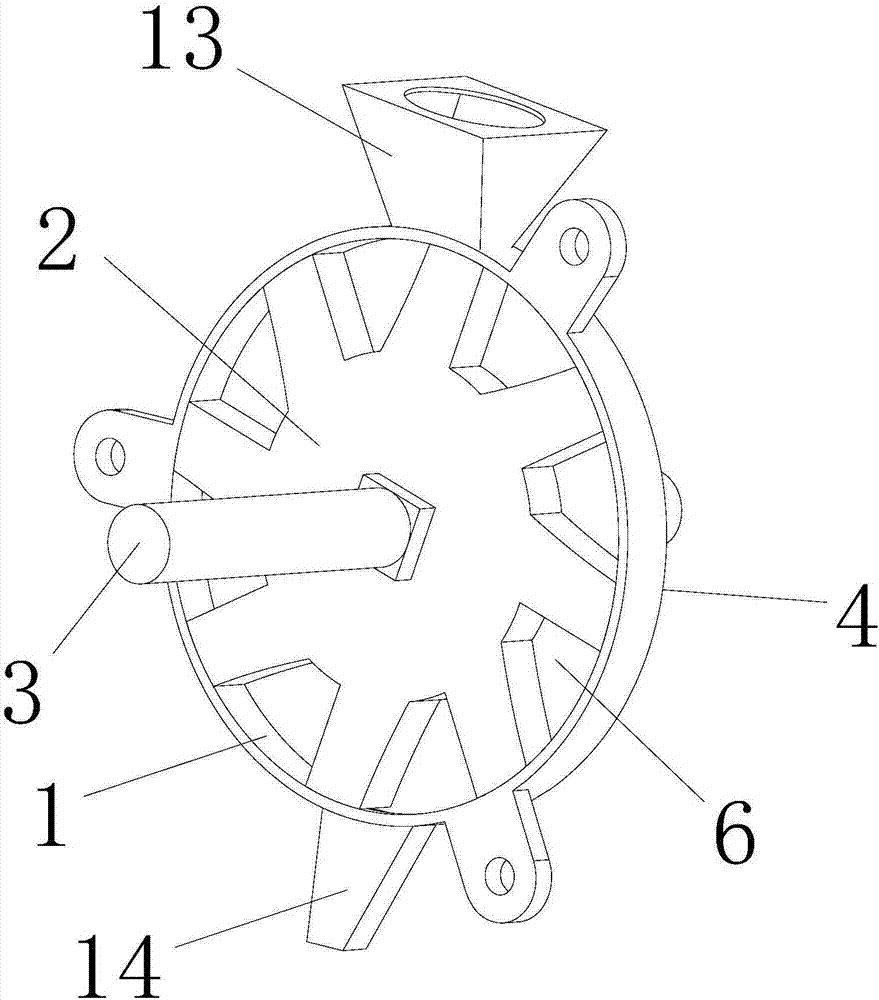

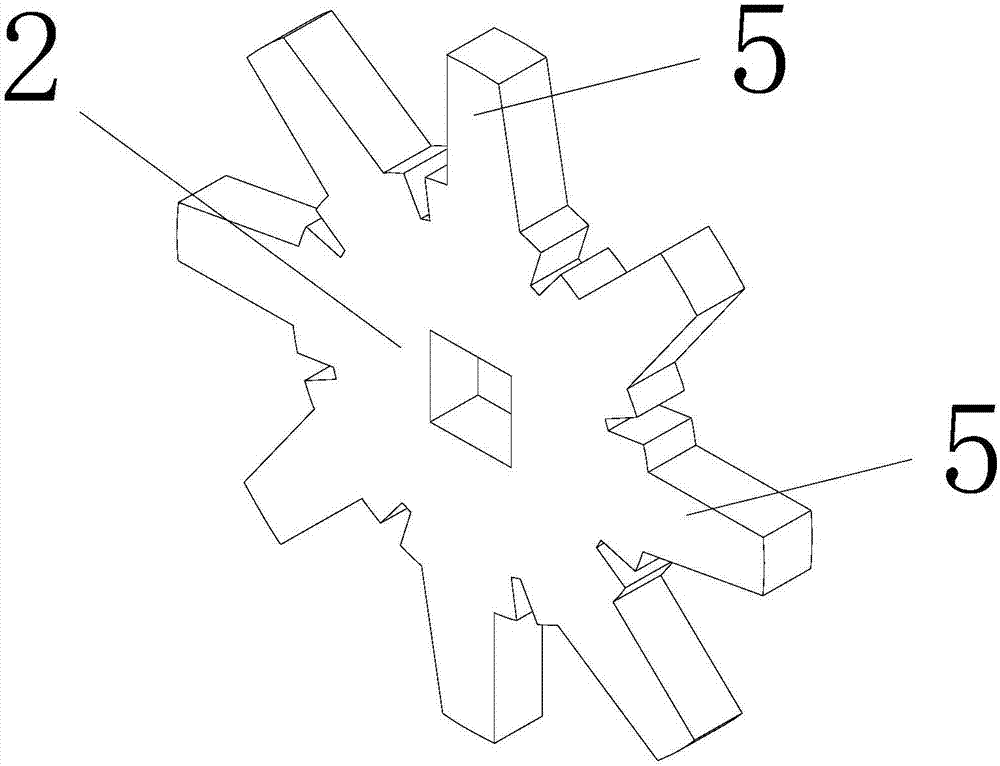

Executing mechanism for inter-plant mechanical weeding device for greenhouse vegetable planting

InactiveCN105075433ATo achieve the purpose of avoiding cropsReduce shockSoil-working equipmentsWeed killersGreenhouseAgricultural engineering

The invention belongs to the technical field of agricultural weeding devices, and particularly relates to an executing mechanism for an inter-plant mechanical weeding device for greenhouse vegetable planting. The executing mechanism comprises a main shaft rotating plate (6), a shell (11), a rail switching slide block device, a main shaft rotating plate device and shovel teeth (5). The main shaft rotating plate device is arranged in the shell (11). The lower end of the main shaft rotating plate device is connected with the main shaft rotating plate (6). The rail switching slide block device connected with the shell (11) is wound around the main shaft rotating plate device. The main shaft rotating plate device is composed of a main shaft (1), a T-shaped sleeve (2), a weeding shovel tooth rotating shaft (3), a spiral rail sleeve (4) and the main shaft rotating plate (6). The rail switching slide block device is composed of a rail (7), a lower side rail (8), an upper side rail (9) and a rail switching slide block (10). The executing mechanism is simple in structure, high in practicability, small in impact on crop seedlings, low in seedling damage rate and capable of lowering labor intensity and bringing great convenience to a user.

Owner:王万森

Offset double-disc clamping air suction type seed sowing device

InactiveCN103210721AGuaranteed single grain rateLow injury rateSeed depositing seeder partsAgricultural engineeringSowing

The invention discloses an offset double-disc clamping air suction type seed sowing device which belongs to the technical field of agricultural machinery. A seed box is fixedly connected with a seed sowing device cover, a vent pipe is respectively and fixedly connected with a shell and an airtight air box, and the lower end of a seed conveying disc shaft is movably connected with the seed sowing device cover; the upper end of the seed conveying disc shaft is fixedly connected with the center of a seed conveying disc; and the lower end of a seed sowing disc shaft is movably connected with a seed discharge device cover, the upper end of the seed sowing disc shaft is respectively and fixedly connected with a spherical curved surface seed feeding mechanism and a sowing suction disc, a seed discharge pipe is fixedly connected with one side of the seed discharge device cover and positioned right below a seed suction hole, a rubber wind shield is arranged above the seed suction hole, and one side of the rubber wind shield is fixedly connected with the side wall of the airtight air box. The device can have functions of discharging, feeding and sowing seeds of various shapes and sizes and ensures the single seed sowing rate; and the device does not miss holes and damage the seeds, can sow single seeds at hill spacing, uniformly sows, generates small variation, has a wide application scope and can continuously and stably rotate at high speed, so that the working speed of a sowing process is greatly increased, and novel equipment is provided for continuous high-speed operation of agricultural sowing machinery.

Owner:JILIN UNIV

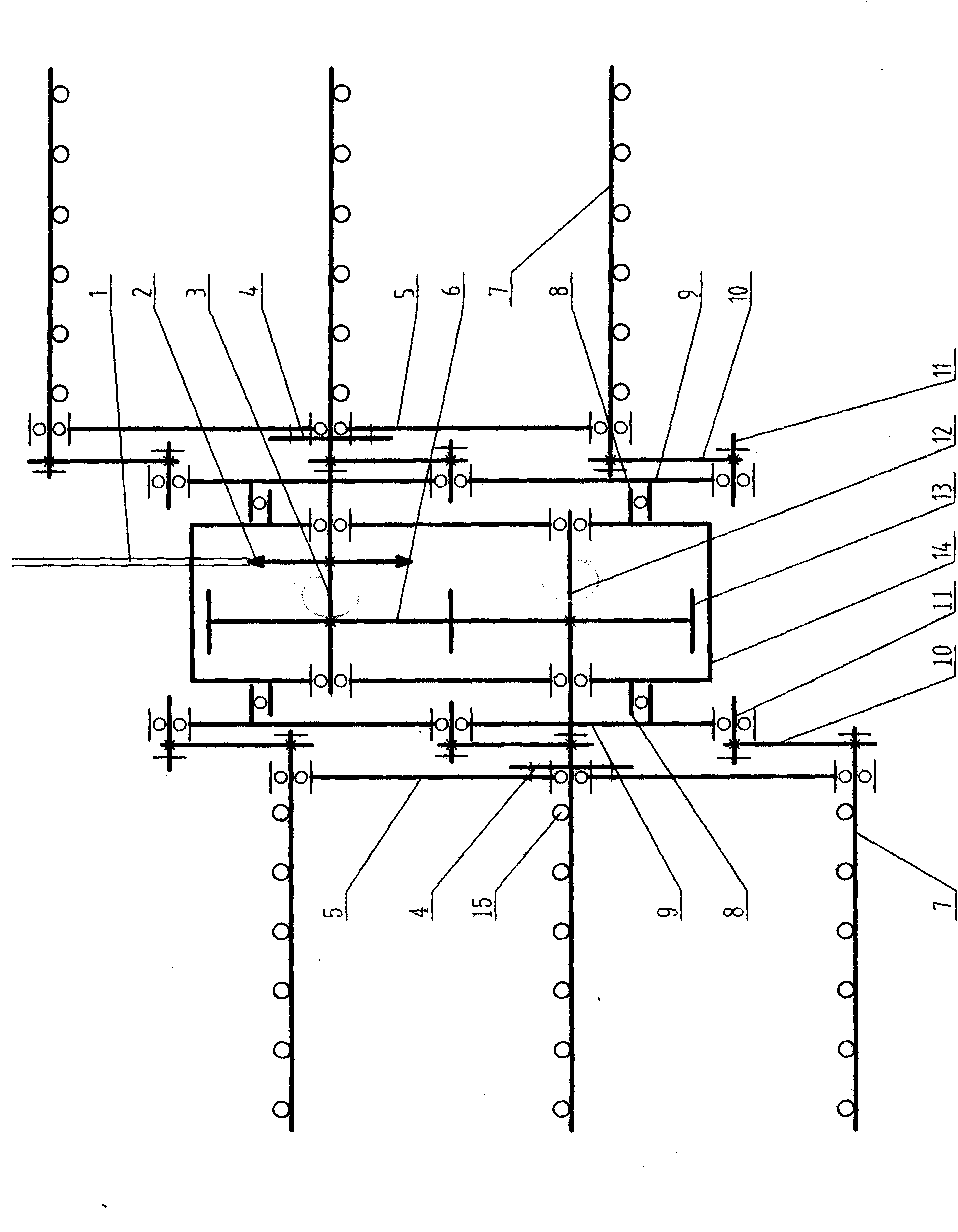

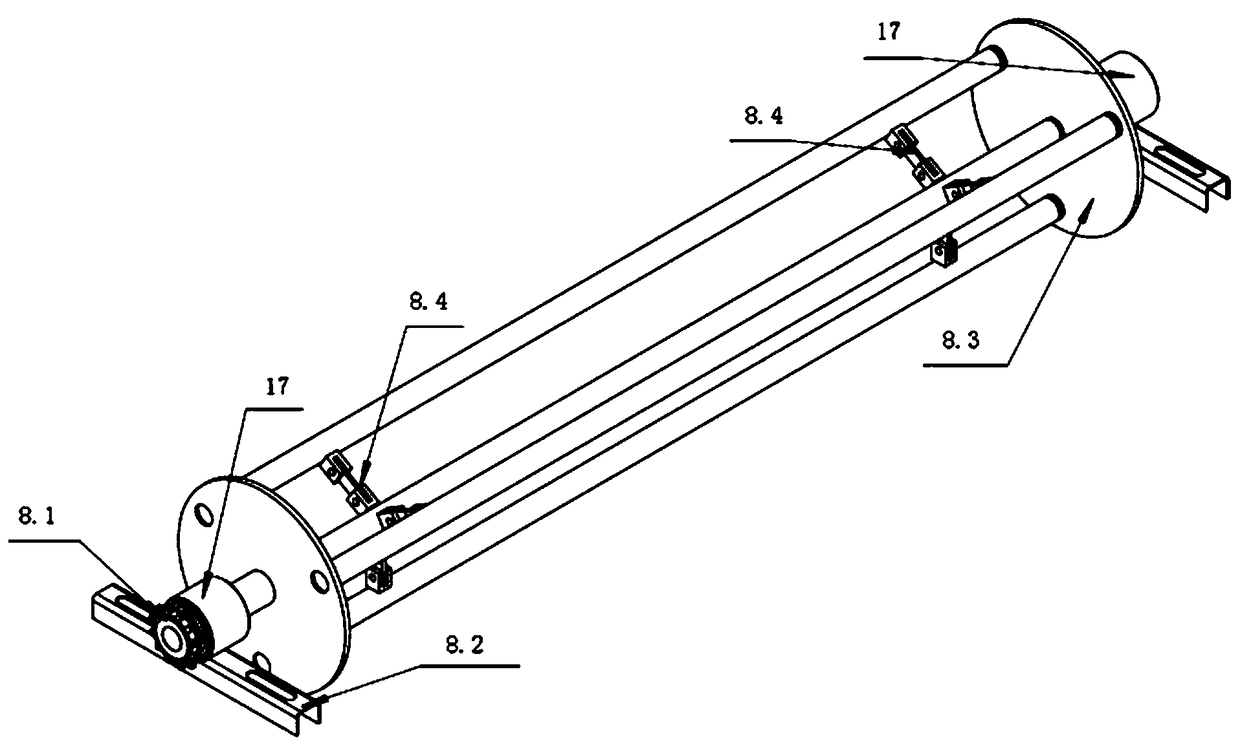

Uniset for mechanical soil-loosening and weeding of crop seedling belt

InactiveCN101785379AProfiling operation is smooth and reliableSame depth of entryAgricultural machinesSoil-working equipmentsGear wheelSprocket

The invention relates to a uniset for mechanical soil-loosening and weeding of crop seedling belts, belonging to agricultural machinery. A transmission assembly and a connecting frame are mounted on a uniset frame assembly, a driving box assembly is assembled on the lower side part of the connecting frame, a driven bevel gear and a power output chain wheel are respectively and fixedly mounted on a power input shaft and a power output shaft of the transmission assembly, a driving bevel gear and a drive chain wheel are coaxially mounted on the uniset frame assembly, a first drive chain is sleeved on the drive chain wheel, a power input chain wheel, a driving cylindrical gear and a driven cylindrical gear are assembled on the driving box assembly, a second drive chain is sleeved on the power output chain wheel and the power input chain wheel, an eccentric wheel assembly with an elastic weeding tooth assembly is assembled on a front power output shaft and a rear power output shaft of the driving box assembly and the single frame assembly is connected and mounted on a stand assembly through a parallel four-bar mechanism. The invention has favorable operation quality, low seedling-damaging rate, wide application range and stable operation.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Electric mulching film removing machine and method

PendingCN109429582AMechanically compactReduce manufacturing costPlant protective coveringsGatherer machinesManufacturing technologyAgricultural engineering

The invention belongs to the technical field of manufacturing of general mechanical equipment, and discloses an electric mulching film removing machine and a method thereof. The electric mulching filmremoving machine adopted by the method comprises a driving walking mechanism, a soil separator, a film rolling device and a machine frame. The middle part of the machine frame is provided with the driving walking mechanism, the front part of the machine frame is provided with the soil separator, and the rear part of the machine frame is provided with the film rolling device. The film rolling device is divided into a whole film rolling wheel and a broken film rolling wheel, the whole film rolling wheel is arranged on an upper end frame body at the rear part of the machine frame, and the brokenfilm rolling wheel is arranged on a lower end frame body at the rear part of the machine frame. The electric mulching film removing machine and the method is used for uncovering and cleaning the mulching film covered by crops during the growing period. The electric mulching film removing machine and the method can solve the problems of difficult film uncovering and collection at present, realizeautomatic film uncovering, improve production efficiency, reduce environmental pollution and realize land recycling.

Owner:LUOYANG YITONG ELECTRICAL SCI & TECH

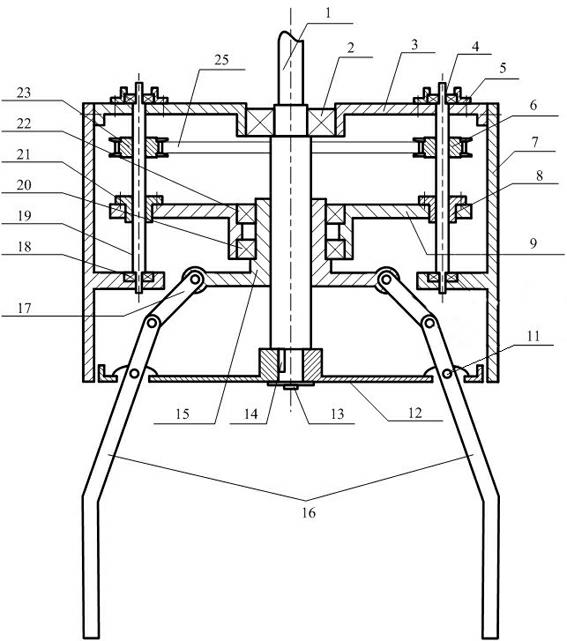

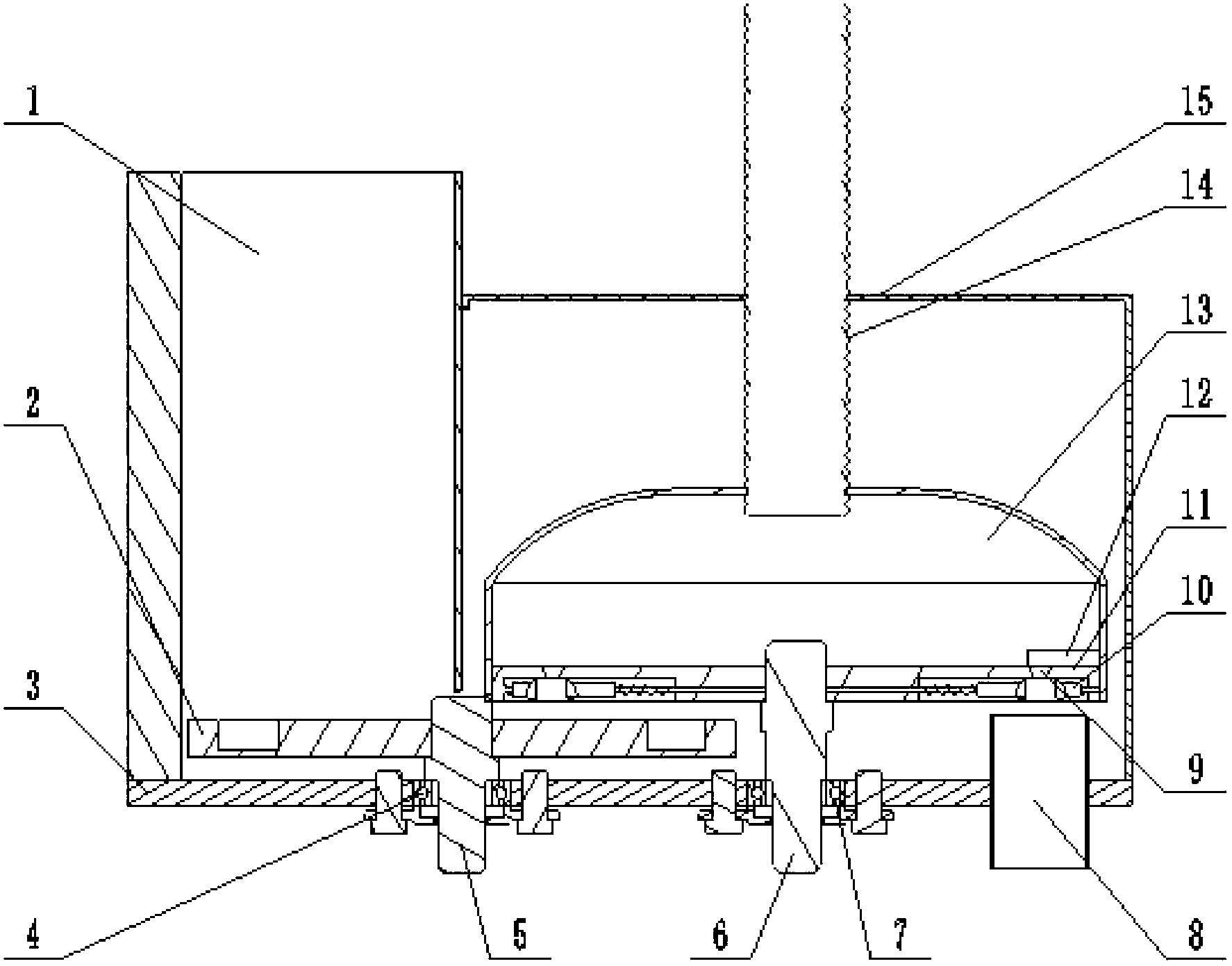

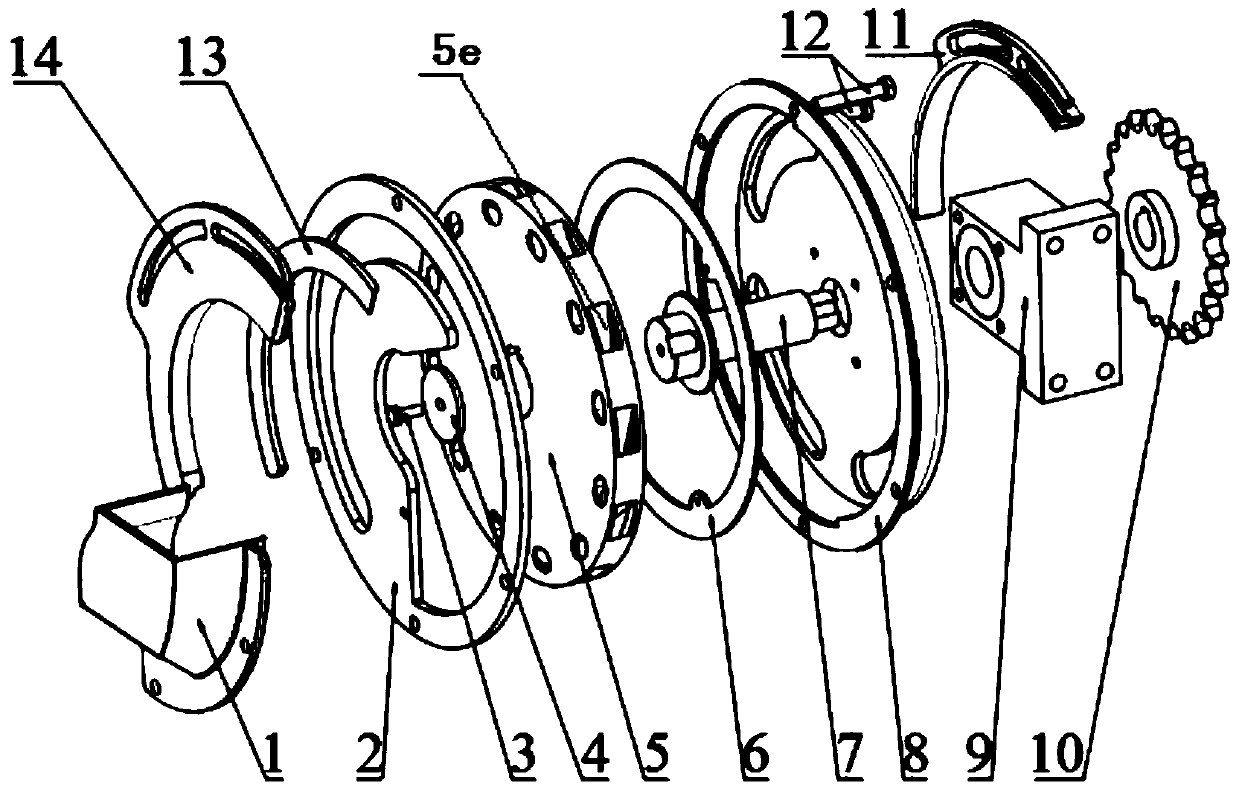

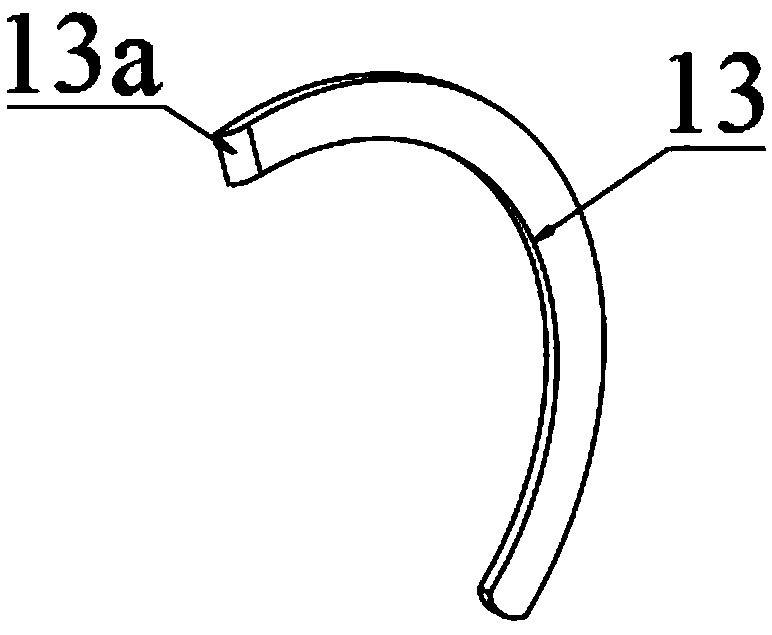

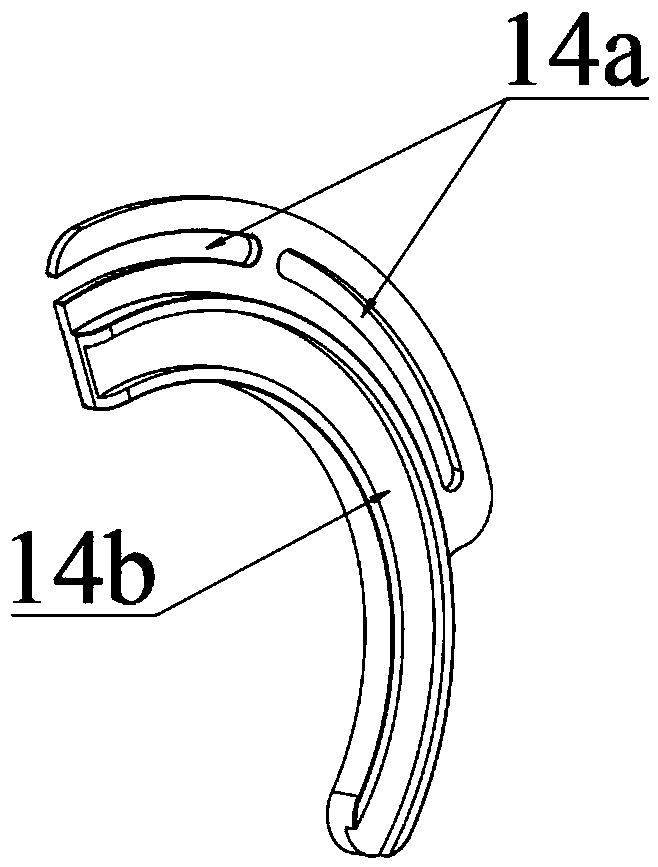

Reverse-rotation soil-clamping type dry land bowl-taking transplanting mechanism with Lagrange planetary gear train

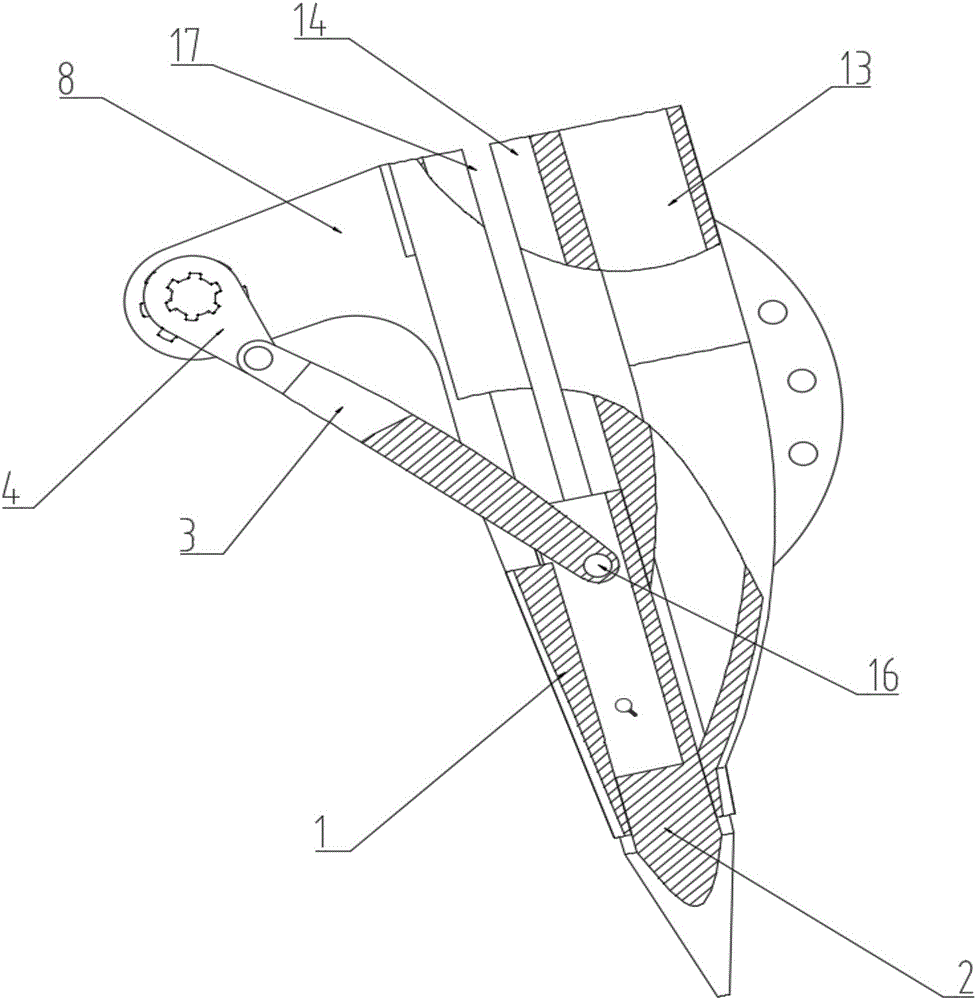

InactiveCN105144945ANovel structureLow injury rateTransplantingAgricultural engineeringTransplanting

The invention relates to a reverse-rotation soil-clamping type dry land bowl-taking transplanting mechanism with a Lagrange planetary gear train and belongs to the field of agricultural machines. The mechanism comprises the non-constant-speed Lagrange non-circular gear planetary gear train composed of a planet carrier, a Lagrange non-circular solar gear, an intermediate gear and a planetary gear. A transplanting arm shell is fixedly installed on the Lagrange non-circular planetary gear, a cam, a poking fork, a compression spring, a seedling taking and pushing frame and a support are assembled on the transplanting arm shell, a seedling taking position adjusting plate of a hinged seedling needle set is fixedly assembled on the support, the seedling needle set is sleeved with the upper side portion of the seedling taking and pushing frame, and the planet carrier rotates anticlockwise. According to the mechanism, the seedling needle set is inserted into bowl body soil from the lower side portions of seedling bowls to clamp out the bowl seedlings from seedling trays, the bowl seedlings are directly transplanted into dry land soil, and the reverse-rotation soil-clamping type dry land bowl-taking transplanting mechanism has the advantages of being novel in structure, reasonable, simple, low in seedling-damage rate, good in operation quality and reliable to use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Vibrating sugarcane sowing device

ActiveCN106717358AGuaranteed decentralizationSort evenlySeed depositing seeder partsProduction rateDispersity

The invention discloses a vibrating sugarcane sowing device, which comprises a substrate, a support frame, an automatic dispersing and sorting device, a vibrating sowing device, a receiving funnel and a DC motor, wherein the automatic dispersing and sorting device is arranged on the support frame; the vibrating sowing device is located at the lower part of the automatic dispersing and sorting device and is connected with the base through a four-bar mechanism and a crank-link mechanism; and the receiving funnel is arranged in front of the base. By adopting the vibrating sugarcane sowing device, the dispersity of sugarcanes before sowing can be ensured; the replanting rate is reduced; the sugarcanes are sorted and branched, so that sowing is more uniform, the injury rate is low and the sowing speed is high. The vibrating sugarcane sowing device is conveniently carried on a sugarcane planter carrier, the labor intensity can be reduced and the operation productivity is improved.

Owner:GUANGXI UNIV

Negative pressure seed sucking and positive pressure seed cleaning type precise seed-metering device and seed-metering method thereof

ActiveCN110249761ASuction and dropEasy accessSeed depositing seeder partsPositive pressureElectromagnetic valve

The invention discloses negative pressure seed sucking and positive pressure seed cleaning type precise seed-metering device and a seed-metering method thereof. The seed-metering device comprises an airway system, a circuit system and a sowing system. The airway system is composed of an air suction way, a seal ring, a negative pressure pipe, a positive pressure pipe, a two-position three-way electromagnetic valve, a seed sucking branch pipe and a seed sucking nozzle. The circuit system is composed of a combined type electric brush ring, a negative electrode slide ring guide rail, a main control slide ring guide rail and a two-position three-way electromagnetic valve. The sowing system is composed of a seed chamber, a flexible seed baffle and a flow limiting plate. The two-position three-way electromagnetic valve 7 is installed on the supporting plate and connected with the other two-position three-way electromagnetic valve, a wire of the two-position three-way electromagnetic valve 7 is connected with the combined type electric brush ring, and electric brushes make contact with the slide ring guide rails. A bottom plate rotates to drive the combined type electric brush ring for supplying power to the electromagnetic valves to rotate, the electric brushes installed on the combined type electric brush ring make contact with a conductive rail and a non-conductive rail in the main control slide ring guide rail, and therefore the conversion of the on and off of the electromagnetic valves is realized, the electromagnetic valves act, and the negative pressure seed sucking function and the positive pressure seed cleaning function are realized.

Owner:ZHEJIANG UNIV

Planting method of tulips

InactiveCN105284336AOvercome the miss rateOvercome the disadvantage of high replay rateHorticultureUltimate tensile strengthTractor

The invention discloses a planting method of tulips, pertaining to the technical field of agriculture. The planting method of tulips comprises following five steps: selecting soil, selecting and disinfecting bulbs, mechanically sowing, applying fertilizers to soil and performing post-harvest treatment. A planting and sowing machine for tulips is utilized in the manner of matching a tractor so that operation such as trench digging, sowing, earthing and ridging is finished at one time. The planting method of tulips has following beneficial effects: the above-mentioned operation is advantaged by protecting and picking, labor-saving, seed-saving, fertilizer-saving and is uniform in depth; by utilizing mechanical sowing, sowing quality is increased and labor intensity is decreased; seeds are discharged accurately and rapidly; leakage sowing rate is considerably decreased; sowing precision and efficiency are enhanced; defects of a scoop-type sower such as high leakage sowing rate and re-seeding rate are solved; and the percentage of damaged seeds is low during work.

Owner:XINJIANG TULIP BIOTECH LTD

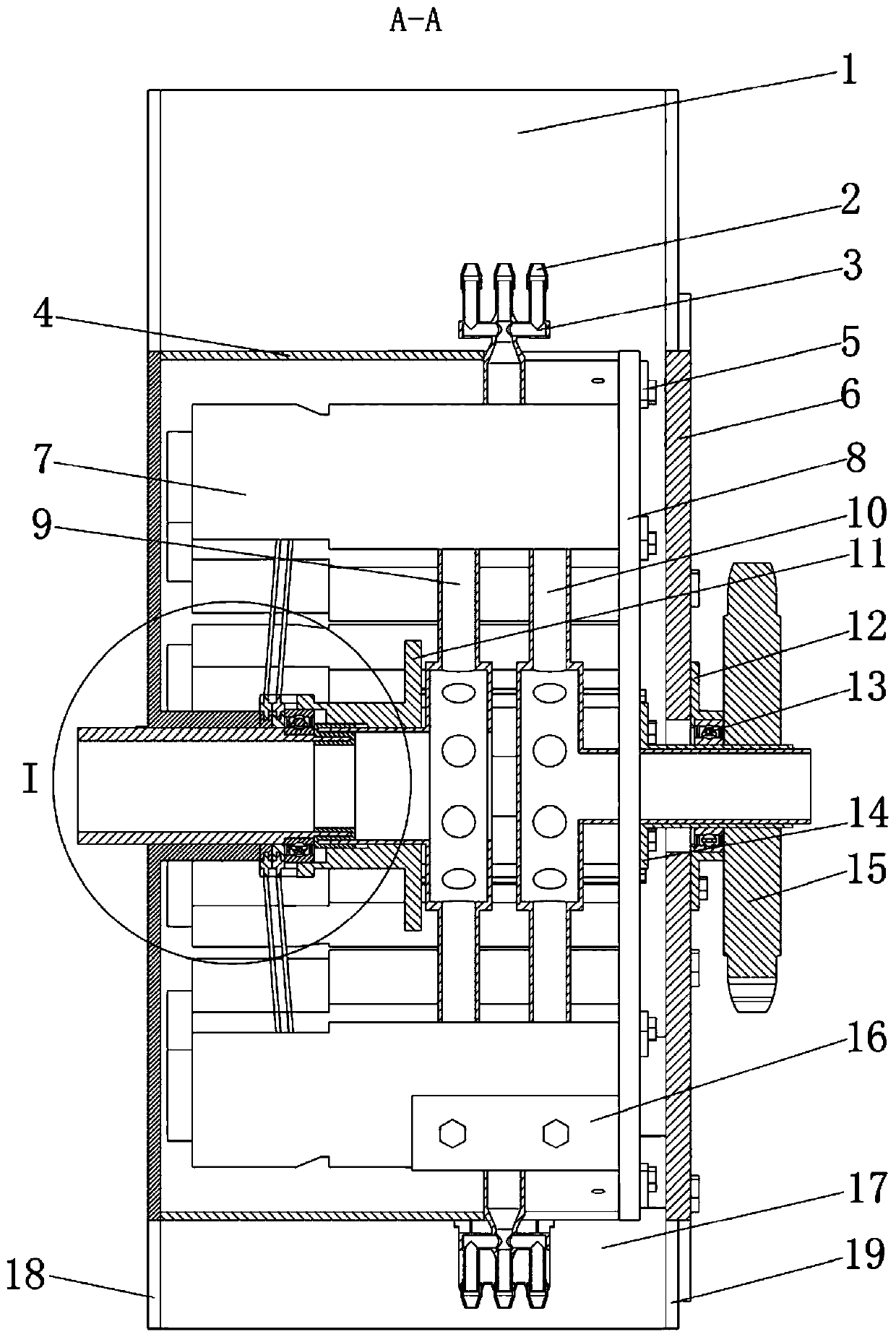

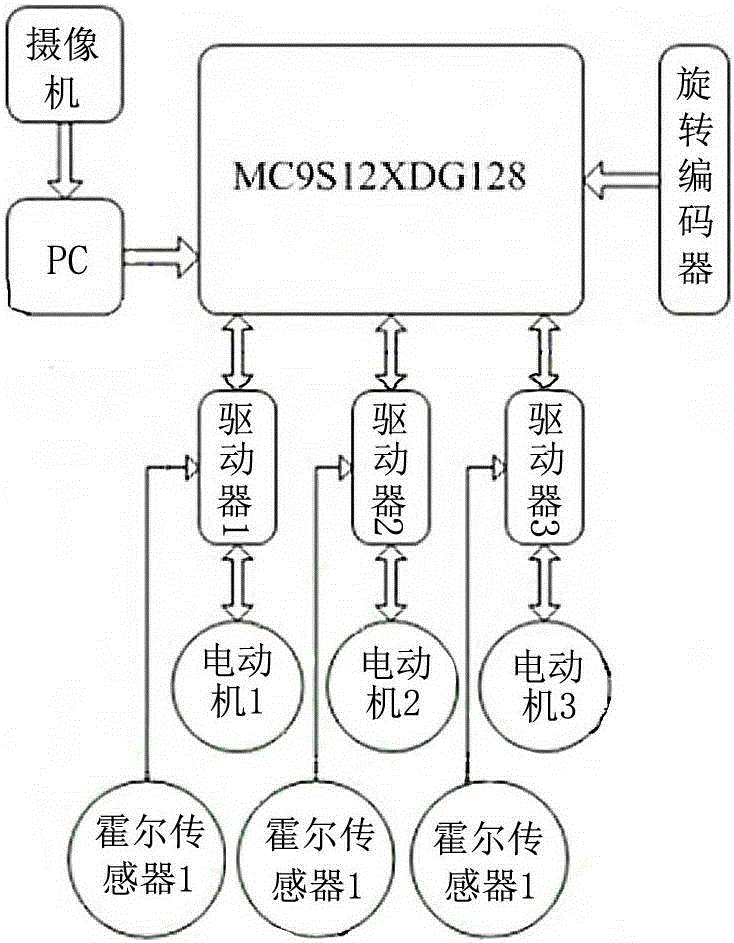

Inter-plant electrically driven hoeing control system

InactiveCN106717166ALow injury rateMeet the needs of the working environmentProgramme controlComputer controlMicrocontrollerDual core

The invention provides an inter-plant electrically driven hoeing control system for an electrically driven hoeing machine according to the demand for mechanical hoeing of a greenhouse. The system uses an MC9S12XDG128 double-core single chip microcomputer as a hardware core, and integrates real-time signal input of a Hall sensor and a rotary encoder, visual information, received in real time, of an upper computer (PC) is interrupted through an RS232 serial port, real-time communication with a lower computer (electric motor driver) is performed by adopting a CAN bus, the rotating speed and a rotating angle of a disc hoe knife are controlled in real time, and accordingly inter-plant hoeing and seedling avoidance are achieved. A hoeing test result in the greenhouse indicates that the advancing speed is 1.2 km / h, and the seedling damage rate is lower than 10%.

Owner:赵俭

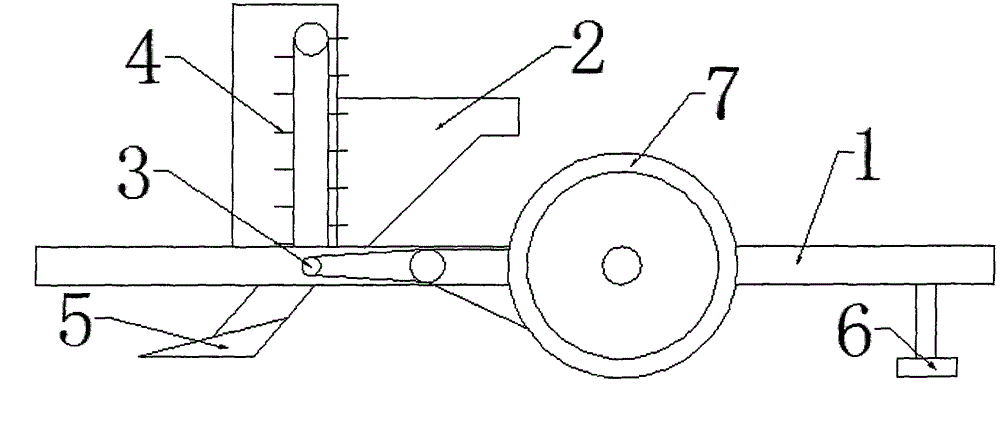

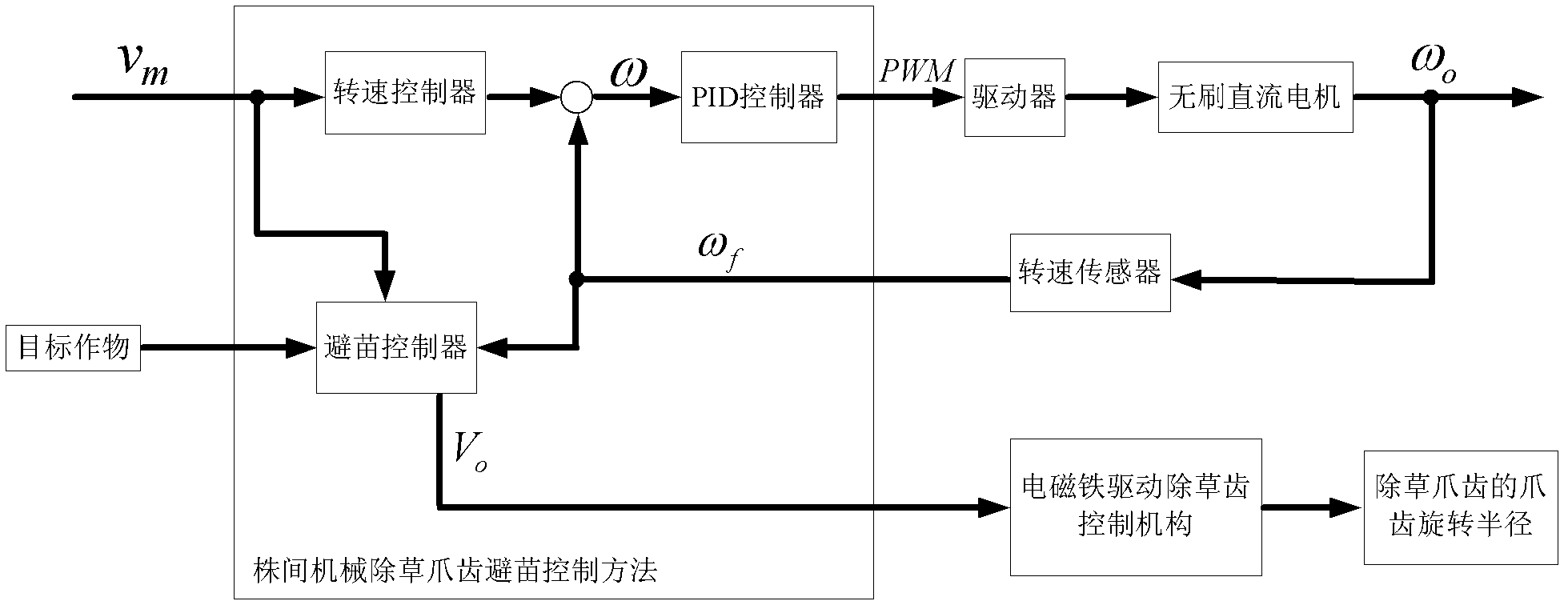

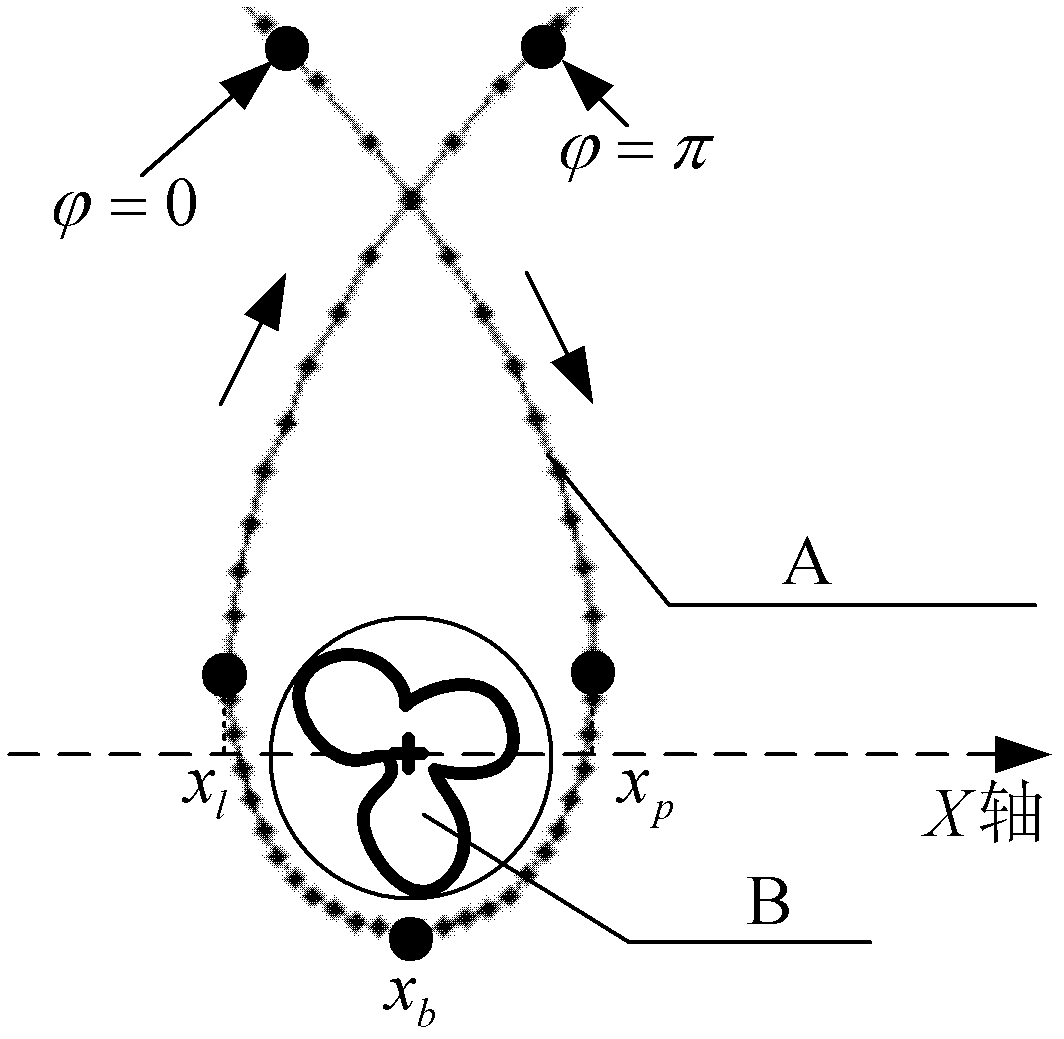

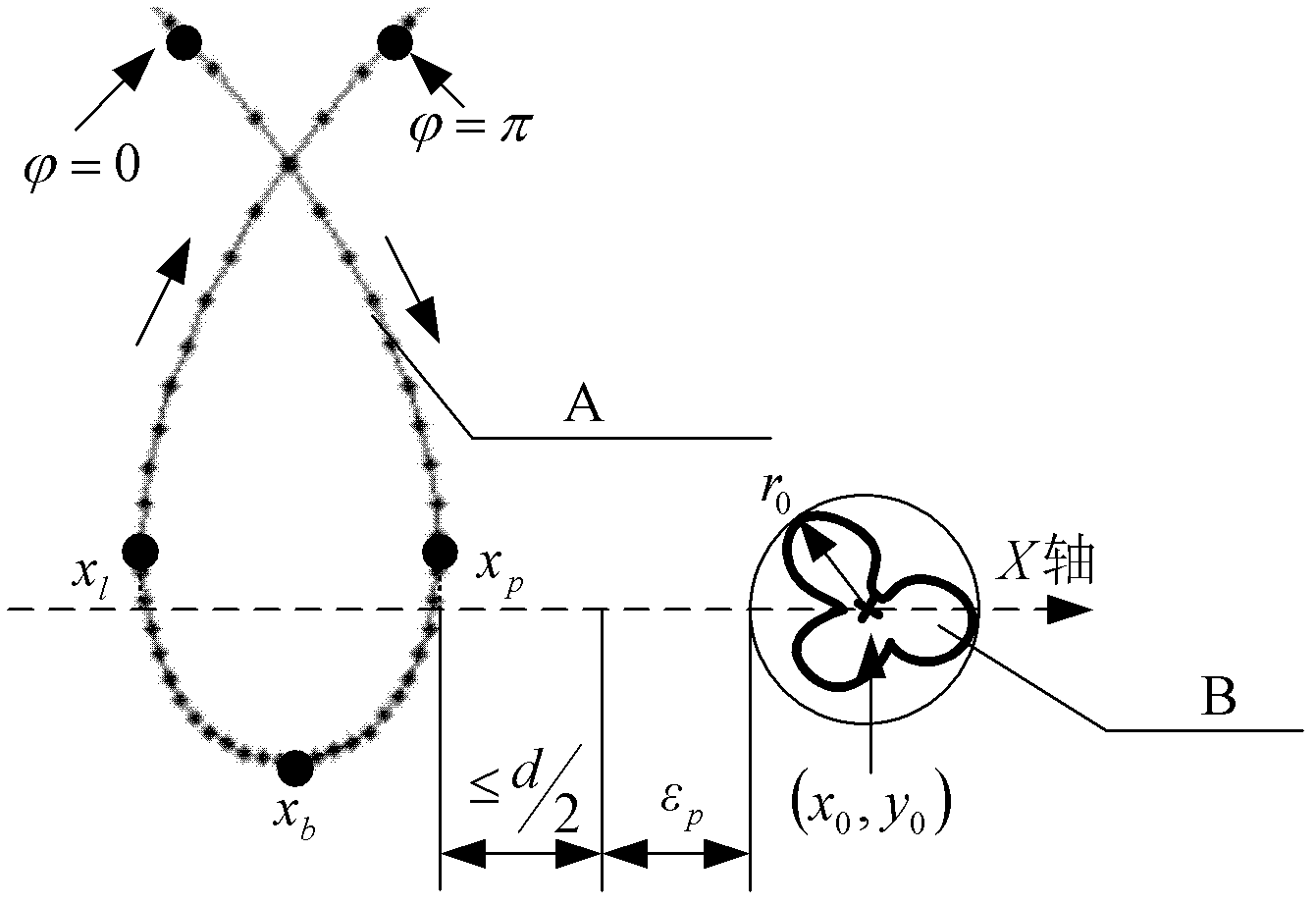

Seedling avoidance control method for inter-row mechanical weeding claw

InactiveCN102598903AImprove weed control effectLow injury rateSoil-working equipmentsWeed killersProportion integration differentiationControl signal

The invention discloses a seedling avoidance control method for an inter-row mechanical weeding claw, which includes: determining an equation of motion trajectory of the weeding claw and relevant parameters; using a target angular velocity PID (proportion integration differentiation) controller matching with forward velocity to obtain stable and accurate rotational speed of the weeding claw; obtaining a predicted motion trajectory of the weeding claw by the claw motion trajectory equation, the forward velocity, an actual angular velocity, a forward velocity error and an actual angular velocity error; analyzing three judgment conditions for collision between the weeding claw and a target plant in positional relation of the weeding claw predicted motion trajectory to the target plant; and outputting a control decision on the weeding claw according to judgment results. The principle of trochoidal motion intra-row weeding is fully utilized, so that precise and reliable rotation speed of the intra-row weeding claw and precise and reliable avoidance control signals can be provided. The method is adaptable to intra-row weeding devices or systems with the target plant avoiding function and using the trochoidal principle, the efficiency of intra-row mechanical weeding can be improved, and damage rate of seedlings can be lowered.

Owner:SOUTH CHINA AGRI UNIV

Rice precise direct-seeding and cavitating device

ActiveCN107124942AChange speedEnhanced cavitationDibble seedersAgriculture gas emission reductionCircular discCavitation

The invention discloses a rice precise direct-seeding and cavitating device, which comprises a shell, a cavitating disk and a transmission shaft, wherein a disk cavity is formed in the shell, and the cavitating disk is arranged in the disk cavity; the cavitating disk comprises a connecting portion connected with the transmission shaft and a plurality of cavity partition plates radially extending out of the outer side of the connecting portion, a seed cavity is formed among every two adjacent partition cavity plates and a cavity wall of the disk cavity, a seed inlet for seeds to enter the seed cavities is formed in the upper portion of the disk cavity, and a seed output opening for the seeds in the seed cavities to be output is formed in the lower portion of the disk cavity; when the seed inlet is communicated with the seed cavities, the seeds can enter the seed cavities through the seed inlet; when the seed cavities are communicated with the seed output opening, the seeds in the seed cavities are output from the seed output opening. The rice precise direct-seeding and cavitating device disclosed by the invention is simple and reliable, convenient and quick to install, capable of effectively improving cavitation of sowing in line and capable of meeting different requirements of rice precise hole sowing.

Owner:SOUTH CHINA AGRI UNIV

Vibration mechanical weeding device based on machine vision

PendingCN112674068AImprove the growing environmentPrecise avoidanceTelevision system detailsAgricultural machinesAgricultural scienceEcological environment

The invention discloses a vibration mechanical weeding device based on machine vision, relates to the field of agricultural machinery, and is particularly applied to intelligent field weeding of various crops in the agricultural field. The device is composed of a three-point suspension, a machine body, a visual part and an executing mechanism. The vibration mechanical weeding device can be suitable for weeding operation of the various crops in different growth periods. Meanwhile, a traditional agricultural machine three-point suspension hanging manner is adopted, various field walking platforms can be carried, and the device can adapt to various complex field environments. According to the device, a machine vision technology is applied, a visual recognition system is deployed on the device, and after grass seedlings are recognized and positioned through a camera, a tail end execution device is controlled to conduct seedling avoiding weeding. Meanwhile, the device innovatively adopts the manner that a vibration tooth comb vibrates and crushes soil to rake grass to the soil surface, damage to ridges is reduced to the minimum, meanwhile, the effect of loosening the soil is achieved, the use amount of chemical herbicides is reduced, the ecological environment is protected, the weeding efficiency is improved, and the weeding and seedling damage rate is reduced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Electric weeding and soil loosing machine

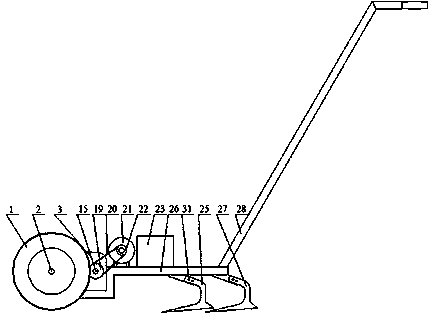

InactiveCN103404257AImprove work efficiencyNo pollutionSoil-working equipmentsWeed killersReduction driveReducer

The invention discloses an electric weeding and soil loosing machine, and belongs to the field of agriculture electromechanical equipment. The machine comprises wheels, a reducer, an electric motor, a storage battery, weeding shovels, a frame and an armrest, wherein the two wheels are connected together through a wheel shaft; two bearings and two gears are mounted on the wheel shaft; the wheel shaft is matched with the reducer through the bearings; the two gears are respectively matched with gears in the reducer; the reducer, the electric motor and the storage battery are mounted at the upper part of the frame; a driven wheel is mounted on the reducer; a driving wheel is mounted on the electric motor; the power between the electric motor and the reducer is transmitted by a belt between the driving wheel and the driven wheel; the storage battery provides a power source to the electric motor; three weeding shovels are mounted at the lower part of the frame through bolted connection; two weeding shovels are arranged behind the front weeding shovel side by side; the armrest is mounted on the frame; a power switch is arranged on the armrest; one handle of the armrest is a speed variable switch handle. The machine is simple in structure and convenient to use, reduces labor and time, and is high in work efficiency.

Owner:KUNMING UNIV OF SCI & TECH

Silkworm cocoon mouth peeling machine

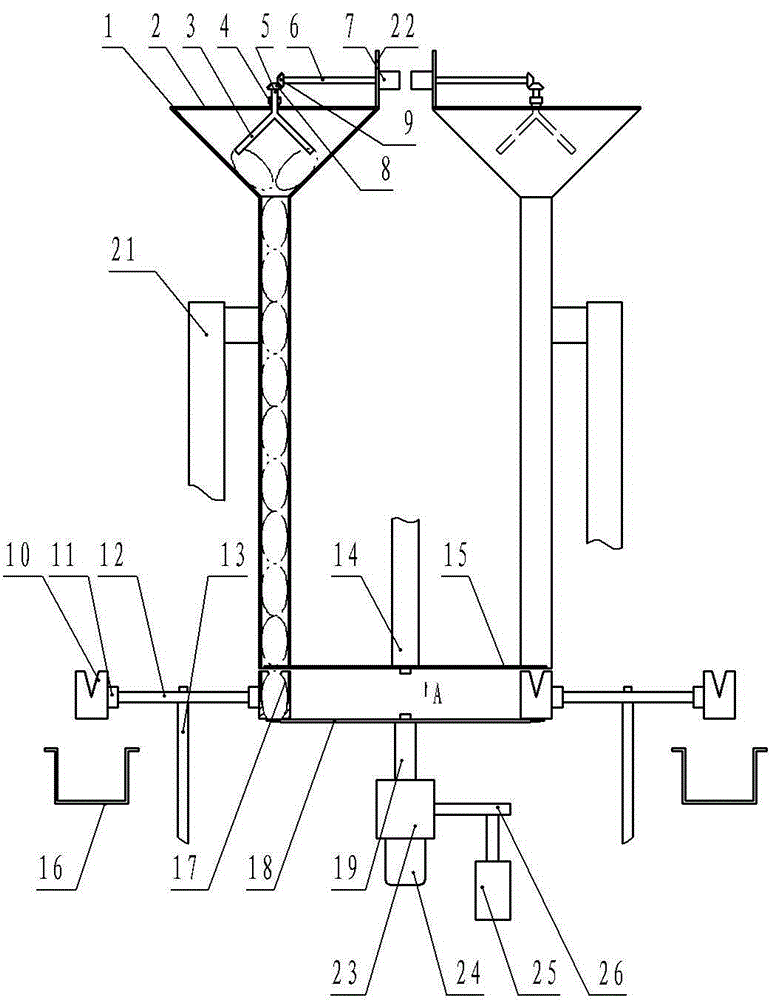

ActiveCN105145501ASimple structureReduce manufacturing costAnimal husbandryAgricultural engineeringEngineering

The invention discloses a silkworm cocoon mouth peeling machine and relates to the technical field of sericulture. The machine comprises more than two vertical hoppers; each hopper is formed by a conical upper hopper and a round pipe-shaped conveying channel vertically arranged; the conveying channel is fixed via a rack; the upper end of the hopper is provided with a hopper cover; a stirring device is mounted on the hopper cover; the lower end of the conveying channel is provided with a rotary baffle sheet; the rotary baffle sheet is connected to the rotating disc; the rotating disc is equipped with a first rotating shaft; the lower part of the conveying channel is provided with a cocoon picking device; the cocoon picking device is formed by a cocoon picking module, a rotary motor, a transverse rack and a second rotating shaft vertically connected with the transverse rack; the lower part of the cocoon picking module is provided with a cocoon cutter; the cocoon cutter is connected with a third rotating shaft; and the third rotating shaft is connected with an elevating device. By the use of the silkworm cocoon mouth peeling machine, problems of complicate silkworm cocoon mouth peeling device structure and high manufacturing cost can be solved.

Owner:LUZHAI GUISHENG COCOON SILK IND & TRADE

Side-filling front-throwing precise seeding device and seeding method thereof

PendingCN109618614ASeed cleaning range adjustmentSeeding height adjustmentDibble seedersSeed depositing seeder partsAgricultural engineering

The invention provides a side-filling front-throwing precise seeding device and a seeding method thereof. The side-filling front-throwing precise seeding device comprises a shell, a seeding wheel arranged in the shell and a rotating assembly used for driving the seeding wheel to rotate, wherein the rotating assembly comprises a rotating shaft and a bearing seat; the shell is fixedly arranged on the bearing seat, one end of the rotating shaft penetrates through the bearing seat and the shell and is fixedly connected with the center of the seeding wheel; the shell is provided with a cover platefor sealing the shell; one side of the cover plate, far away from the seeding wheel, is provided with a sealing plate and a seed box; one side of the seeding wheel, close to the seed box, is providedwith a plurality of seed inlets which can be communicated with the seed box; the seeding wheel is internally provided with an annular groove and a plurality of seed pockets arranged in the annular groove, and the shell is provided with a seeding positioning plate. The seeding scope and the seeding height of the seeding device can be adjusted, the seed pockets of the seeding wheel precisely form pits of the pockets, a gathering channel temporarily store multiple seed, the seeding consistency and cavitability are good, and the rate of cavitating and missing seeding is low.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com