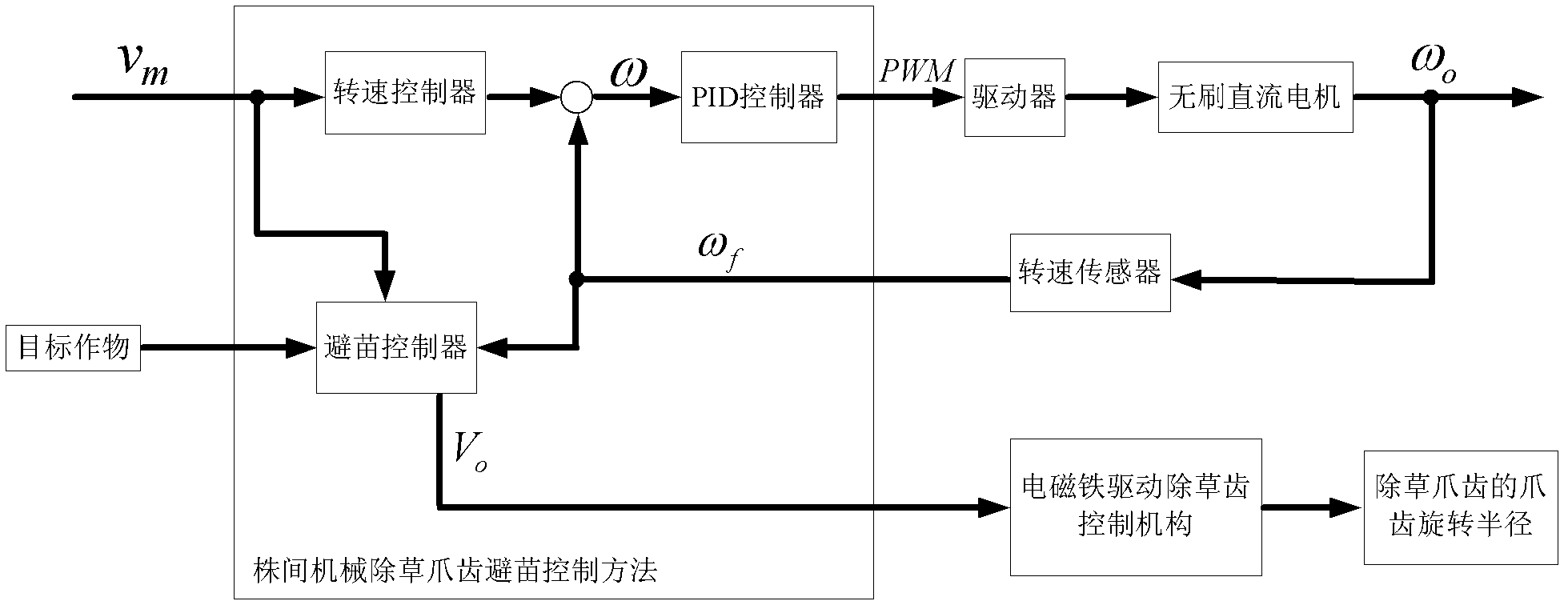

Seedling avoidance control method for inter-row mechanical weeding claw

A technology of mechanical weeding and control methods, which is applied in the field of mechanical weeding, and can solve problems such as the influence of forward speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A method for controlling seedling avoidance by mechanical weeding among plants, characterized in that it comprises the following steps:

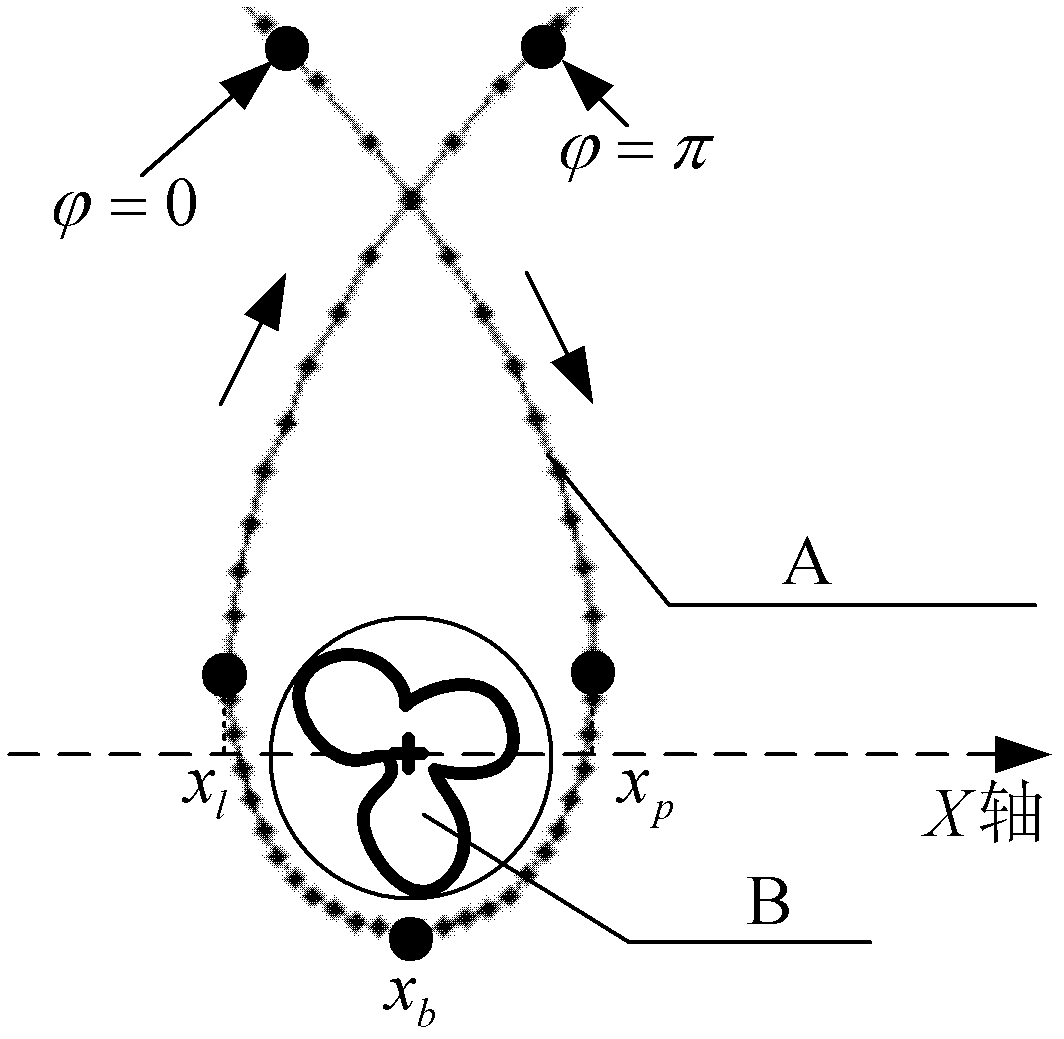

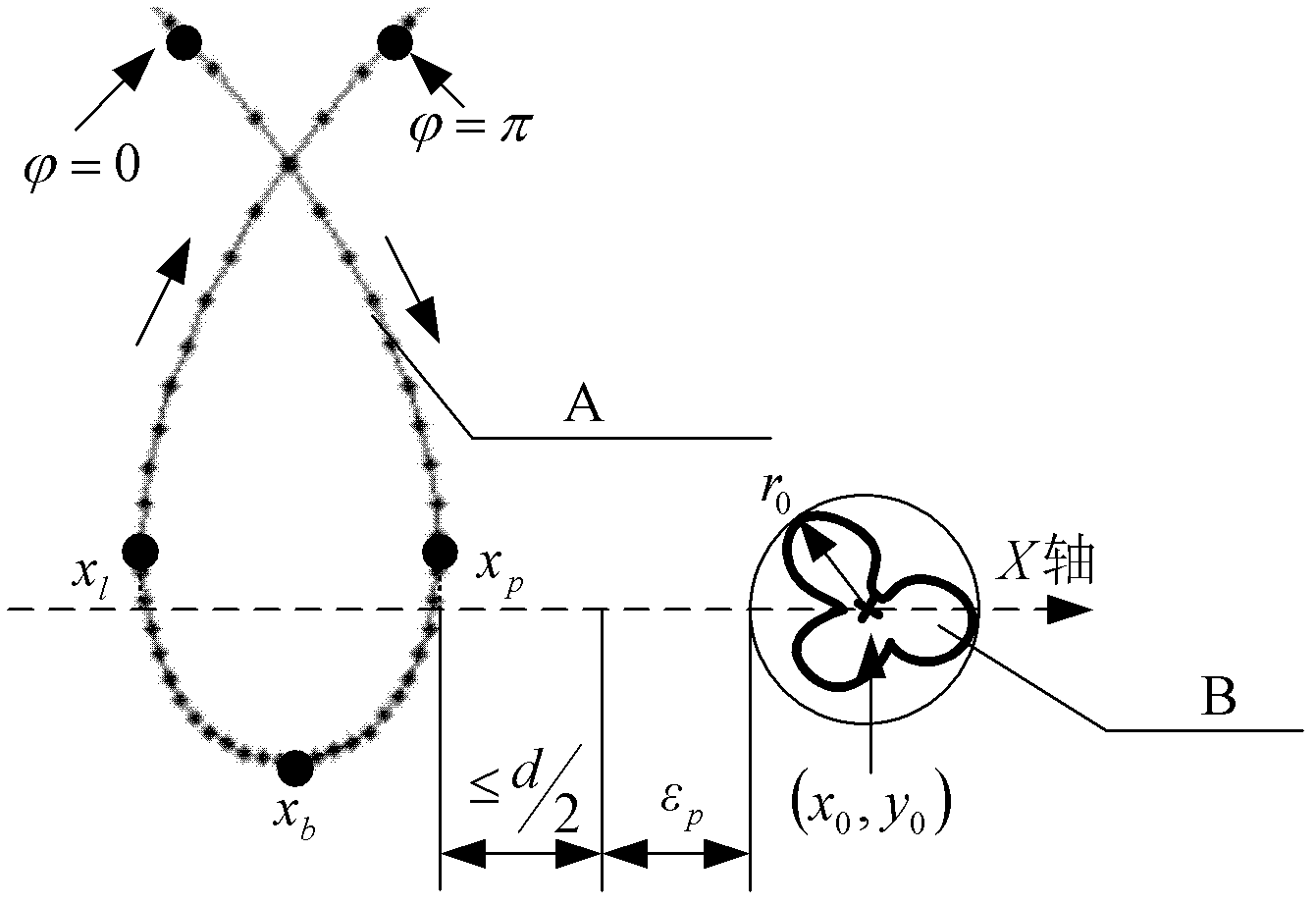

[0061] 1. According to the forward speed v of the weeding claws m , the actual angular velocity ω o , running time t (the initial running time is defined as 0), the initial central angle γ of claws, the central angle β between adjacent claws, and the rotation radius R of claws r , and the functional relationship between the distance H between the rotation center of the weeding claws and the center of the target crop row, the trajectory equation of the weeding claws is established, and the trajectory of each weeding claw can be predicted according to the trajectory equation:

[0062] The coordinate system XOY is established with the center line of the target crop row as the X axis, and the trajectory equation of the weeding claws is established according to formula (1). There are eight weeding claws in the weeding device, and the radi...

Embodiment 2

[0092] The present embodiment is the same as embodiment one except the following features: in order to reach the inter-plant coverage rate, the determination method of the ratio λ of the actual rotational speed of the weeding claws and the forward speed is that the widest distance of the ring buckle is 0.5 times of the distance between the plants. .

Embodiment 3

[0094] This embodiment is the same as Embodiment 1 except for the following features: the determination method of the ratio λ between the actual rotational linear speed and the forward speed of the weeding claws is a simulation analysis method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com