Electric mulching film removing machine and method

A technology of removing machine and mulching film, which is applied in the fields of botanical equipment and methods, collectors, agricultural machinery and implements, etc., can solve the problems of difficulty in reseeding crops, reducing the utilization rate of cultivated land, high labor intensity, etc., and solves the problem of low operation efficiency. , the effect of low manufacturing cost and compact mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and example the present invention will be described in further detail

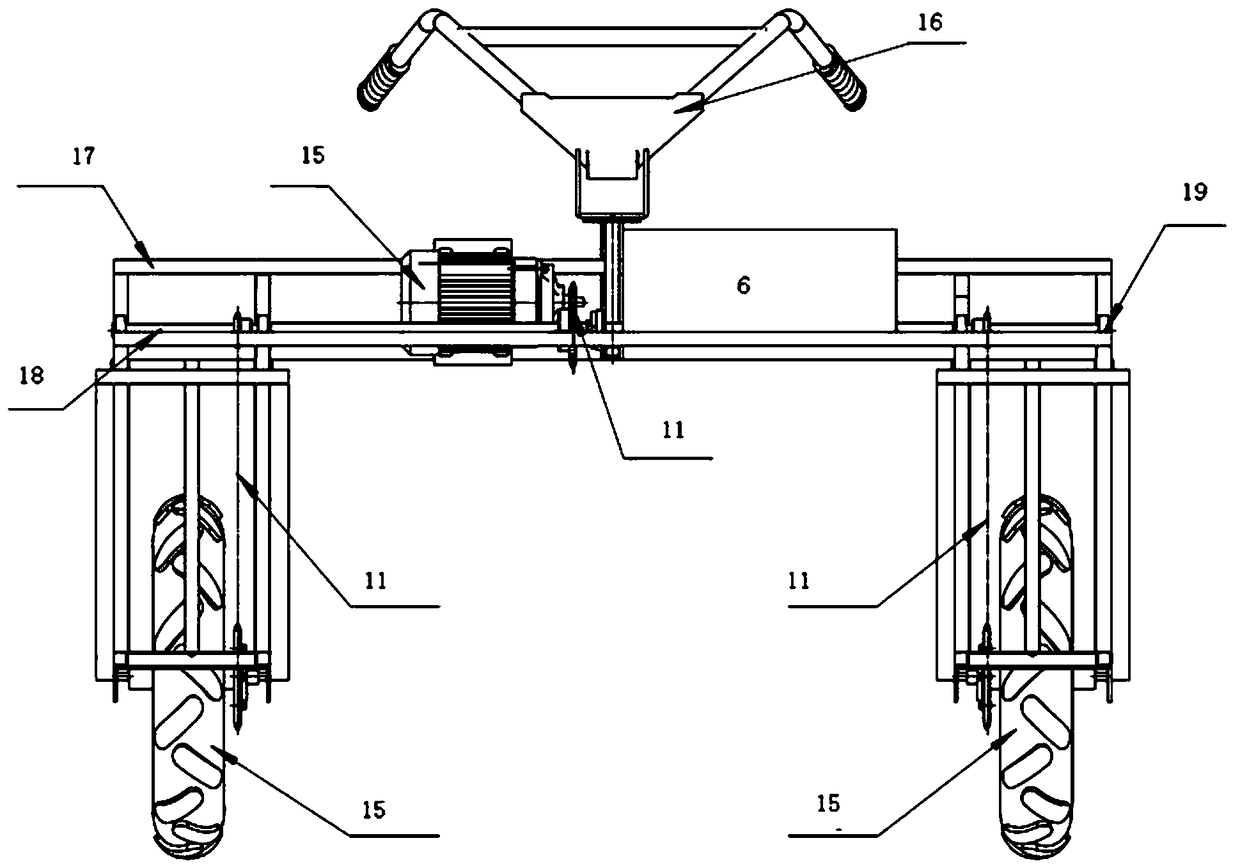

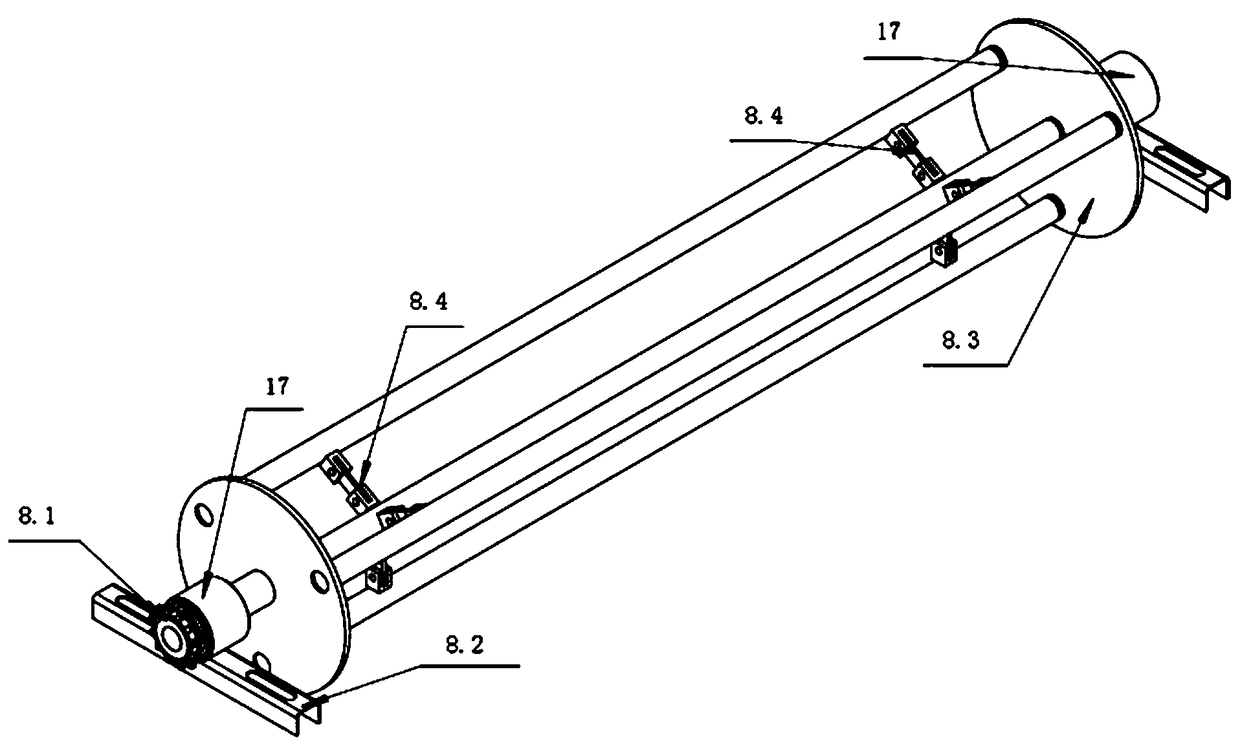

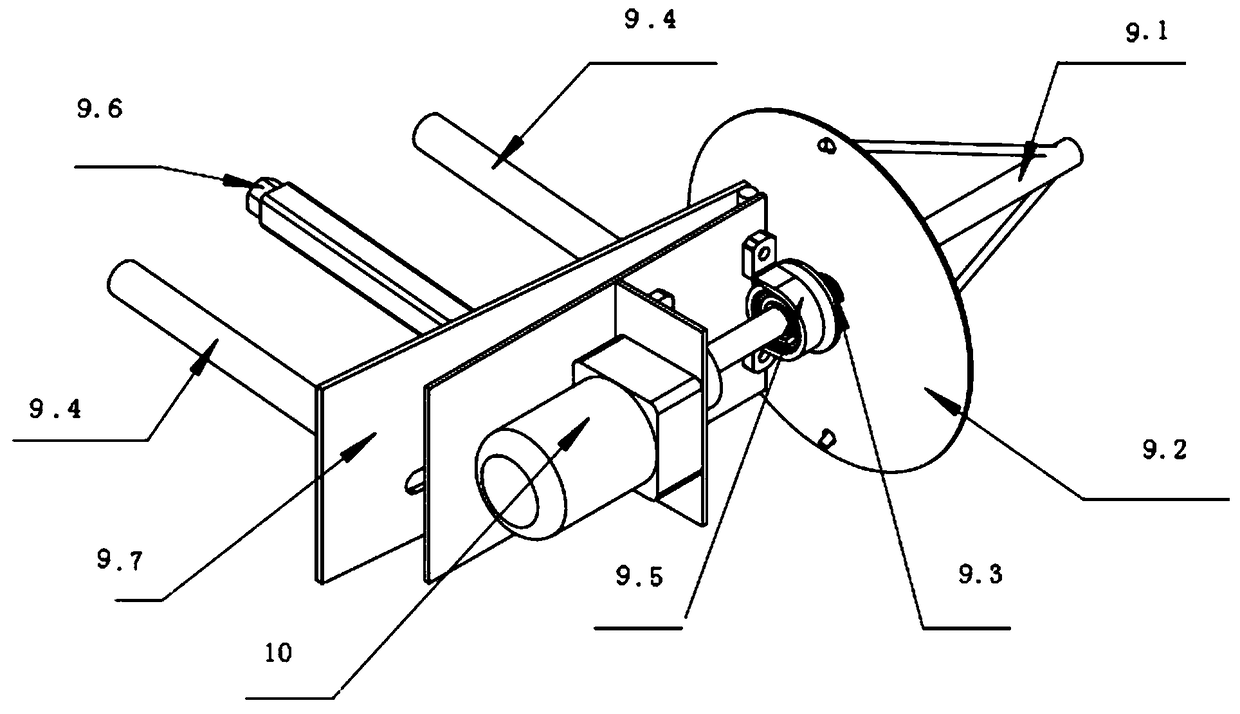

[0026] Such as figure 1 , 2 , shown in 3, 4, and 5, an electric plastic film removal machine includes: a driving traveling mechanism, a soil divider, a film roll, and a frame, the middle part of the frame is provided with a driving traveling mechanism, and the front part of the frame is provided with There is a soil divider, and a film reel is arranged at the rear of the frame; the film reel is divided into a full film rewinding wheel and a broken film reel, and the whole film reeling wheel is arranged on the upper frame body at the rear of the frame On the top, the broken film collecting wheel is set on the lower end frame body at the rear of the frame;

[0027] Described drive walking mechanism is connected by chain wheel, chain 11 and main shaft sprocket wheel chain by road wheel motor 15, main shaft two ends are respectively connected by chain whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com