Mixed color spinning achievement method and device based on five primary color CMYKW rough yarn coupling drafting

A technology of color spinning and five primary colors, applied in the field of mixed color spinning based on CMYKW five primary color roving coupling drafting, can solve the problems of small amount, insufficient reflection, insufficient absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

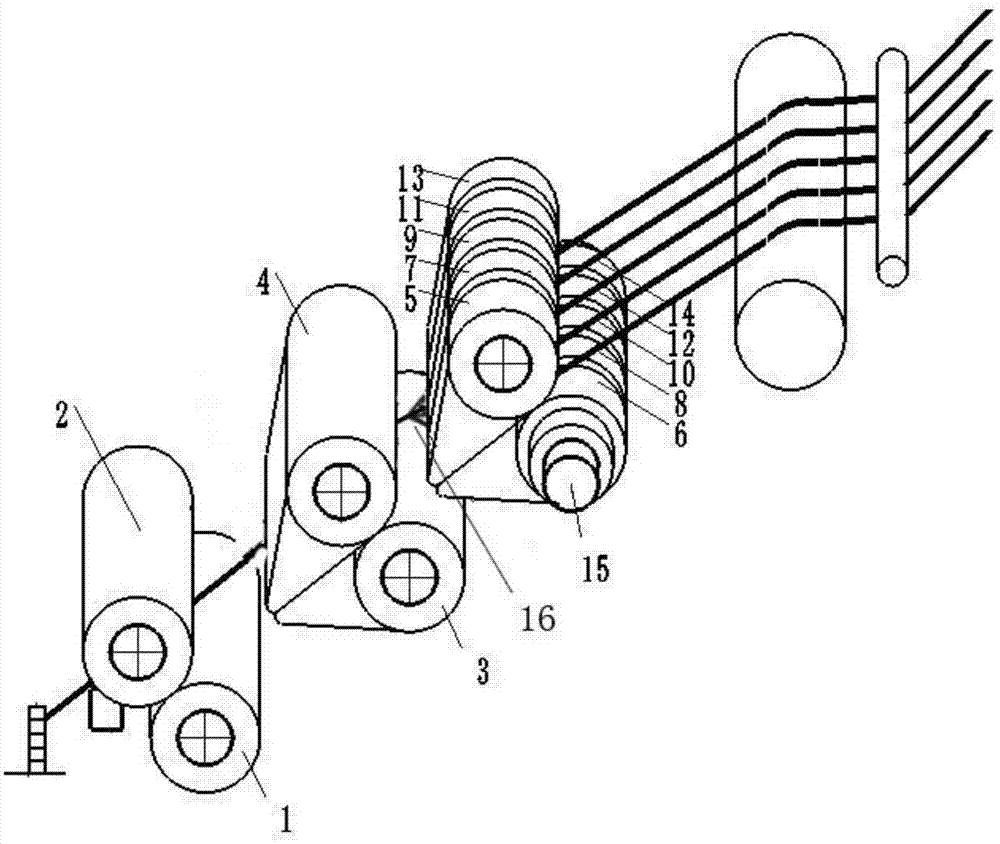

[0046] A method based on CMYKW five-primary-color roving coupling drafting to realize mixed-color spinning, specifically comprising:

[0047] 1) The drafting and twisting system includes front rollers, middle rollers and combined rear rollers arranged front and rear; the combined rear rollers have five rotational degrees of freedom, which include the first rear roller and the second rear roller arranged side by side on the same rear roller shaft. roller, the third rear roller, the fourth rear roller and the fifth rear roller; the first rear roller, the second rear roller, the third rear roller, the fourth rear roller and the fifth rear roller respectively at speed V h1 , V h2 , V h3 , V h4 and V h5 Movement; front roller at speed V q sports;

[0048] 2) The first rear roller, the second rear roller, the third rear roller, the fourth rear roller and the fifth rear roller are respectively drafting five basic color yarns of yellow, magenta, cyan, black and white; keep the fr...

Embodiment 2

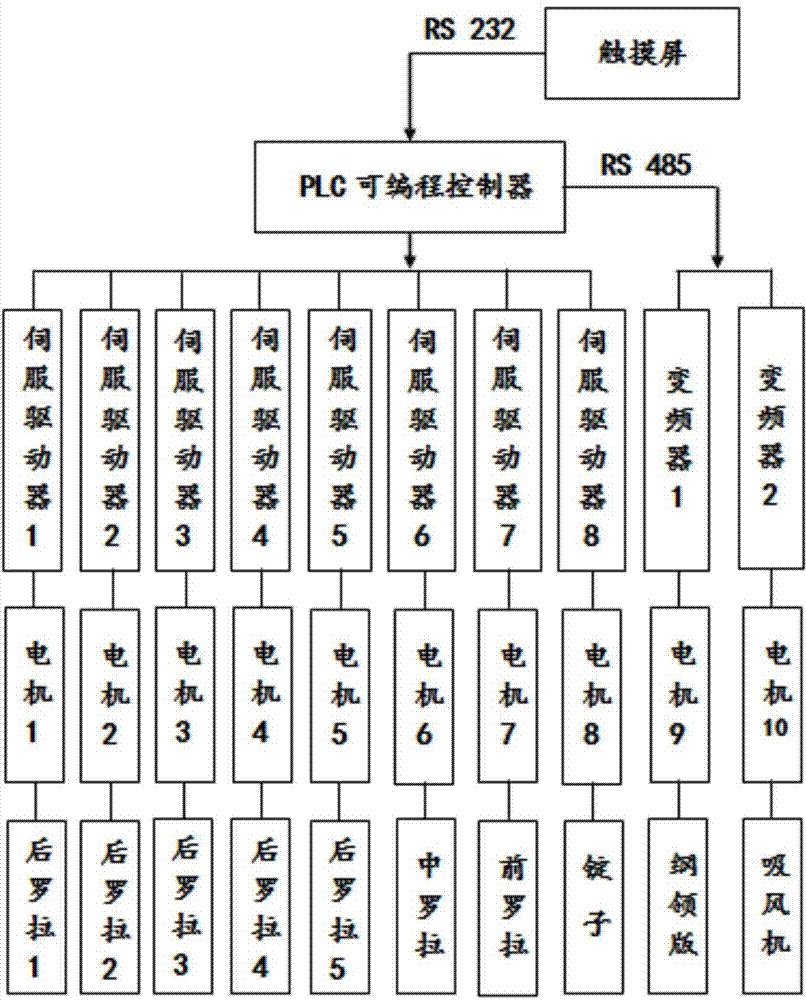

[0067] A device for mixed-color spinning based on CMYKW five-color roving coupling drafting, which includes a control system and an actuator. The actuator includes a five-component split-and-combine type synchronous two-stage drafting mechanism, a twisting mechanism, and a winding forming mechanism. ; The secondary drafting mechanism includes a primary drafting unit and a secondary drafting unit.

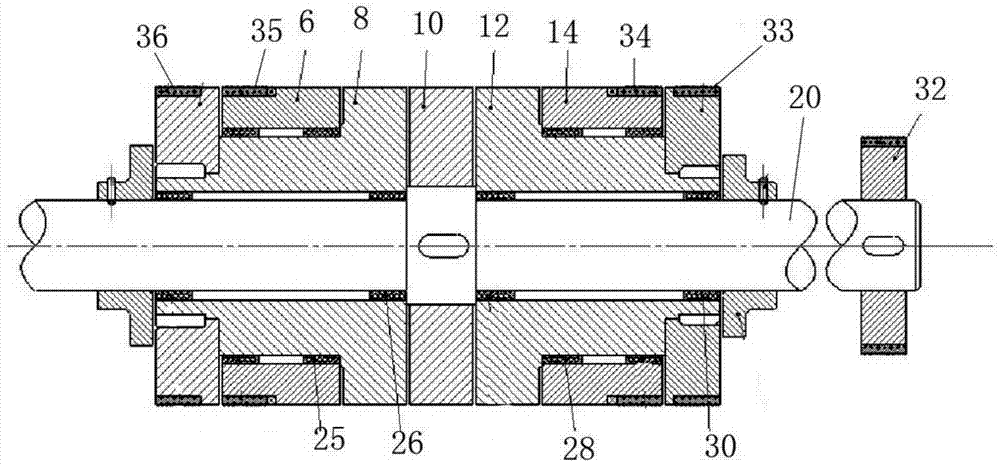

[0068] Such as figure 1 and 2 As shown, the first-stage drafting unit includes a combined rear roller 15 and a middle roller 3; the combined rear roller 15 has five rotational degrees of freedom, and includes the first rear roller 6 and the second rear roller arranged side by side on the same rear roller shaft 20 8. The third rear roller 10, the fourth rear roller 12 and the fifth rear roller 14; the five rear rollers are arranged adjacently in sequence, and their driving mechanisms are arranged on both sides of the five rear rollers; the secondary drafting unit includes the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com