Patents

Literature

32results about How to "Realize mechanized processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

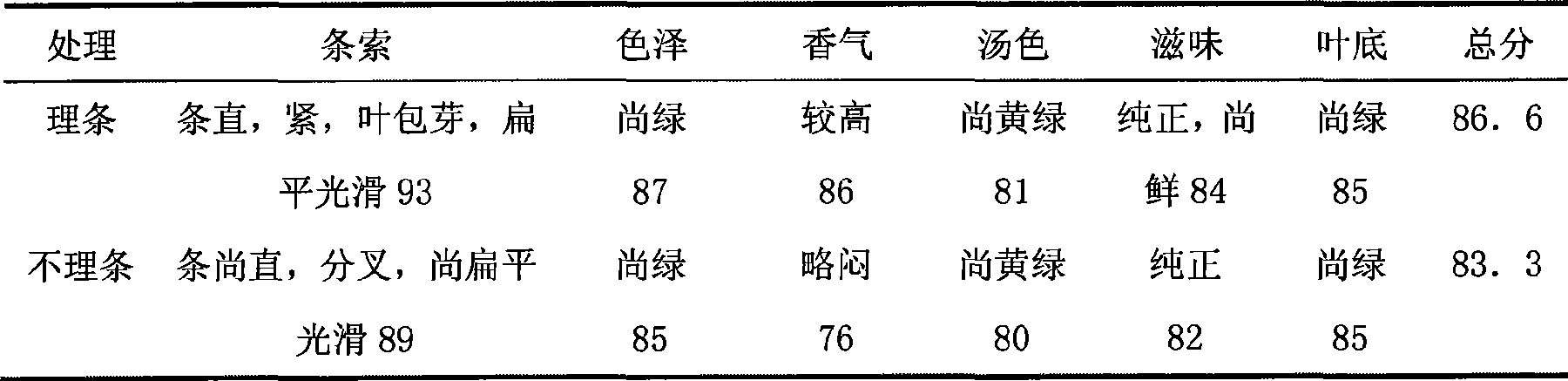

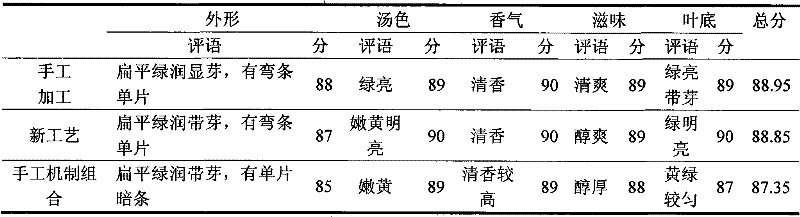

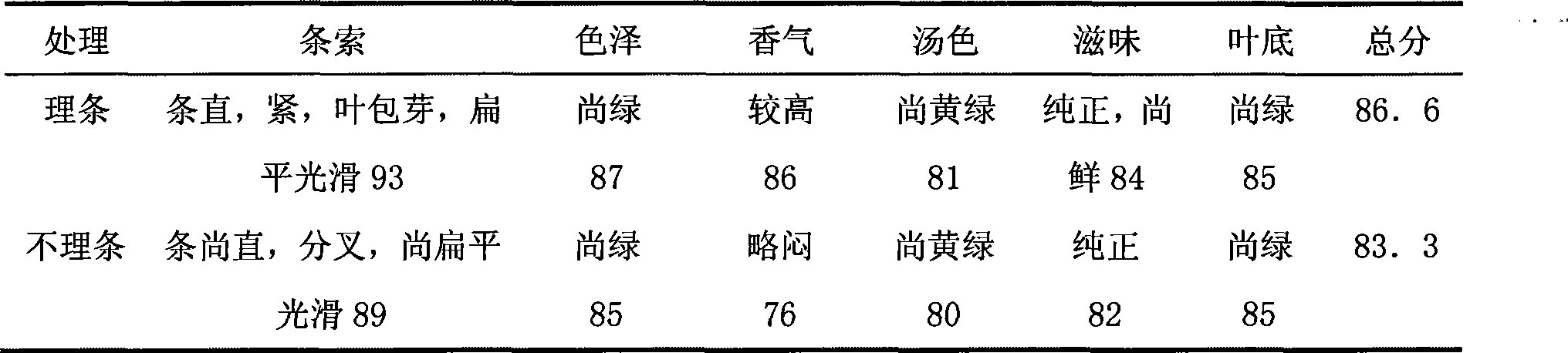

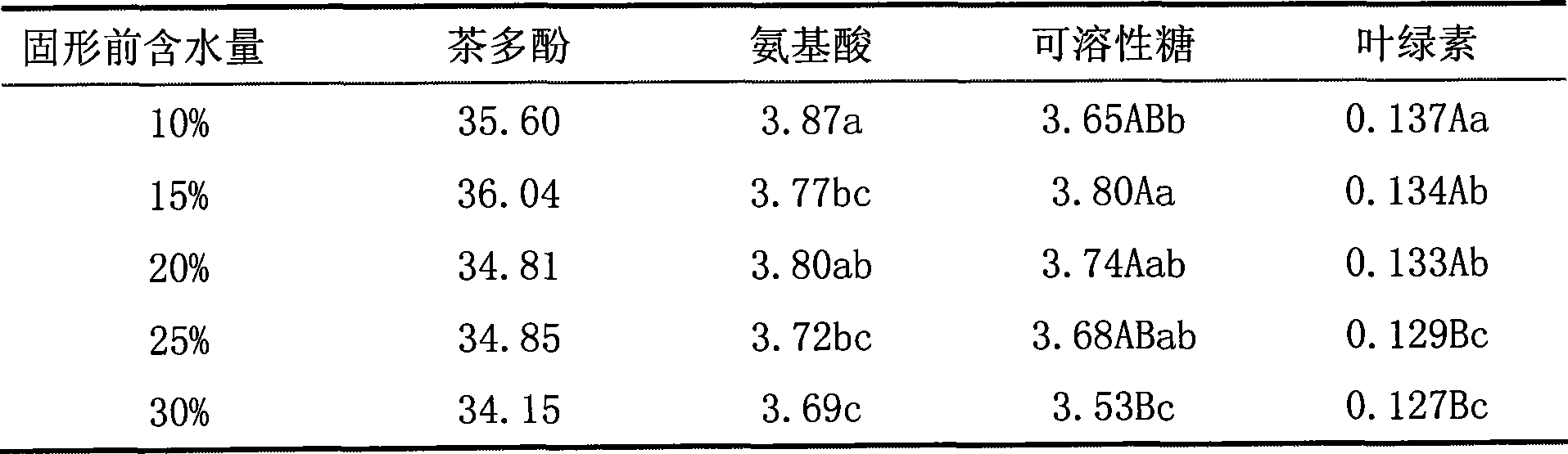

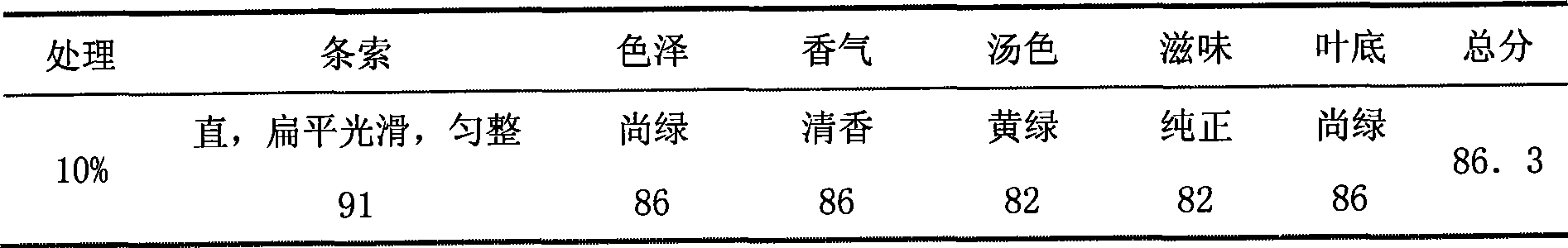

Mechanized method for processing flat green tea

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing flat green tea. The method is characterized in that fresh green tea leaves are prepared into well-known tea with a flat shape through spreading, enzyme deactivating, sorting, pressing, solidifying, flavoring and other steps. The flat well-know tea has the characteristics of flat and smooth strips, no fragment, unpolished rice like color and luster, constant chestnut fragrance, green and bright color of liquor color, fresh and pure taste, tender, uniform, green and bright leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

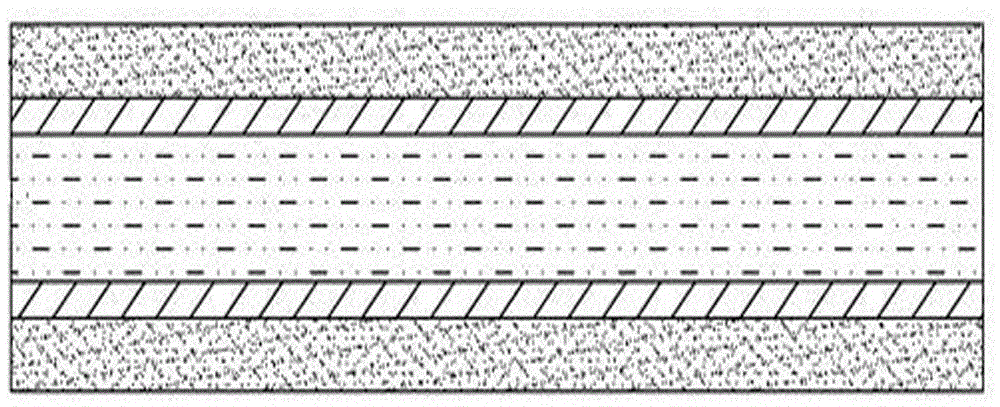

Inorganic inflaming retarding straw fiberboard and production method thereof

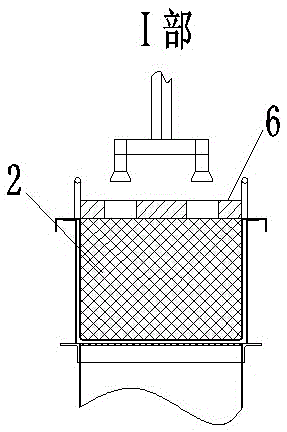

The invention discloses an inorganic inflaming retarding straw fiberboard and a production method thereof. The inorganic inflaming retarding straw fiberboard comprises three layers of straw fiber layers, wherein a cotton yarn net is arranged between each two adjacent straw fiber layers, the cotton yarn nets are respectively bonded to the adjacent straw fiber layers through inorganic inflaming retarding adhesive material layers, and the straw fiber layers are slab materials made of straw fibers and inorganic inflaming retarding adhesives. According to the inorganic inflaming retarding straw fiberboard, the cotton yarn nets are arranged in the straw fiberboard, the cotton yarn nets are used as reinforcement bodies, the inorganic inflaming retarding adhesives are used as bonding agents, not only is good strength of the inorganic inflaming retarding straw fiberboard guaranteed, but also the results that no artificial formaldehyde is released from the inorganic inflaming retarding straw fiberboard and the inflaming retarding level of the inorganic inflaming retarding straw fiberboard reaches an A2 level are guaranteed, and furthermore straw fibers are abundant in source, low in production cost, simple to process and high in production efficiency, and mechanization processing can be achieved during the whole production process.

Owner:LIANYUNGANG BAOLISEN IND

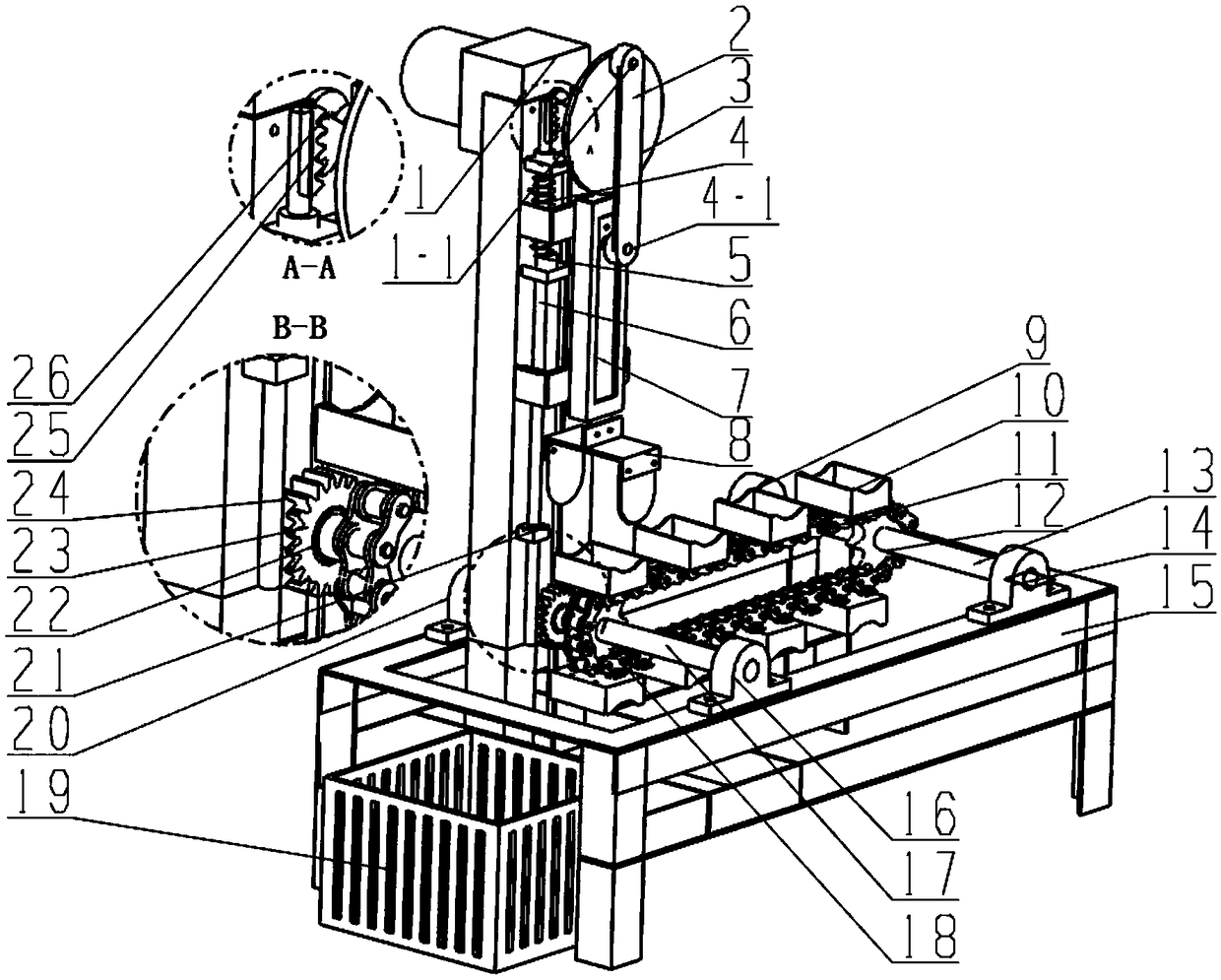

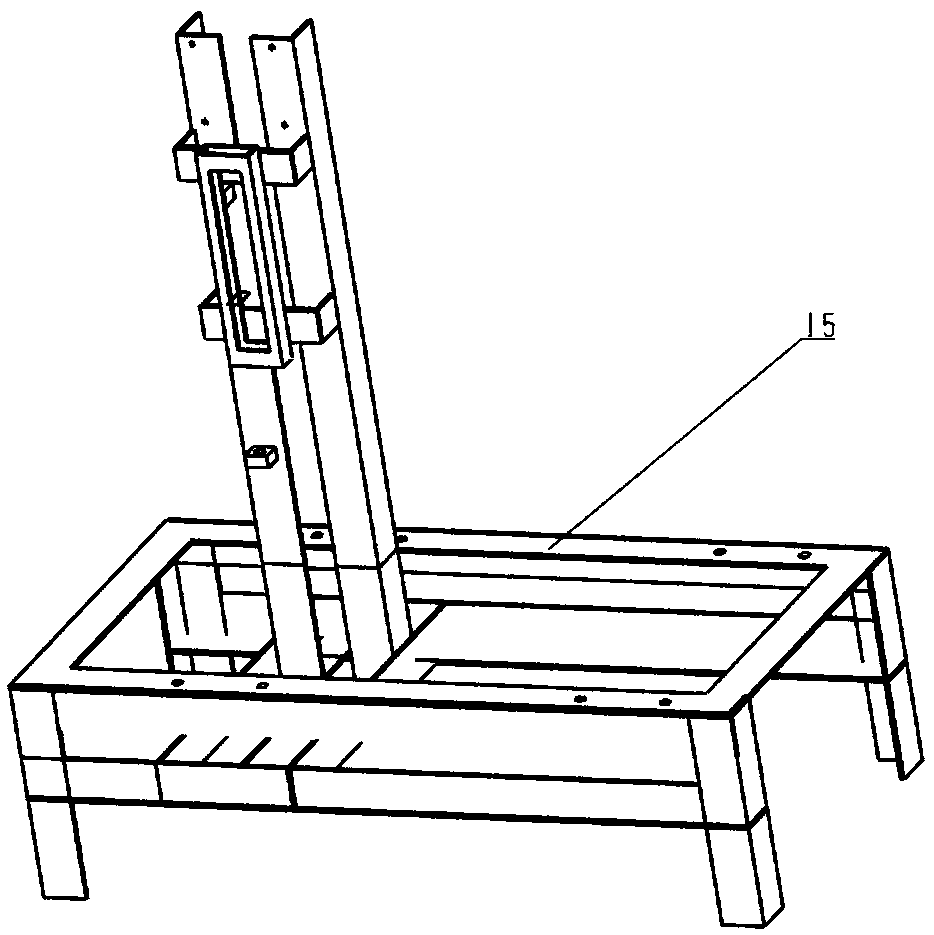

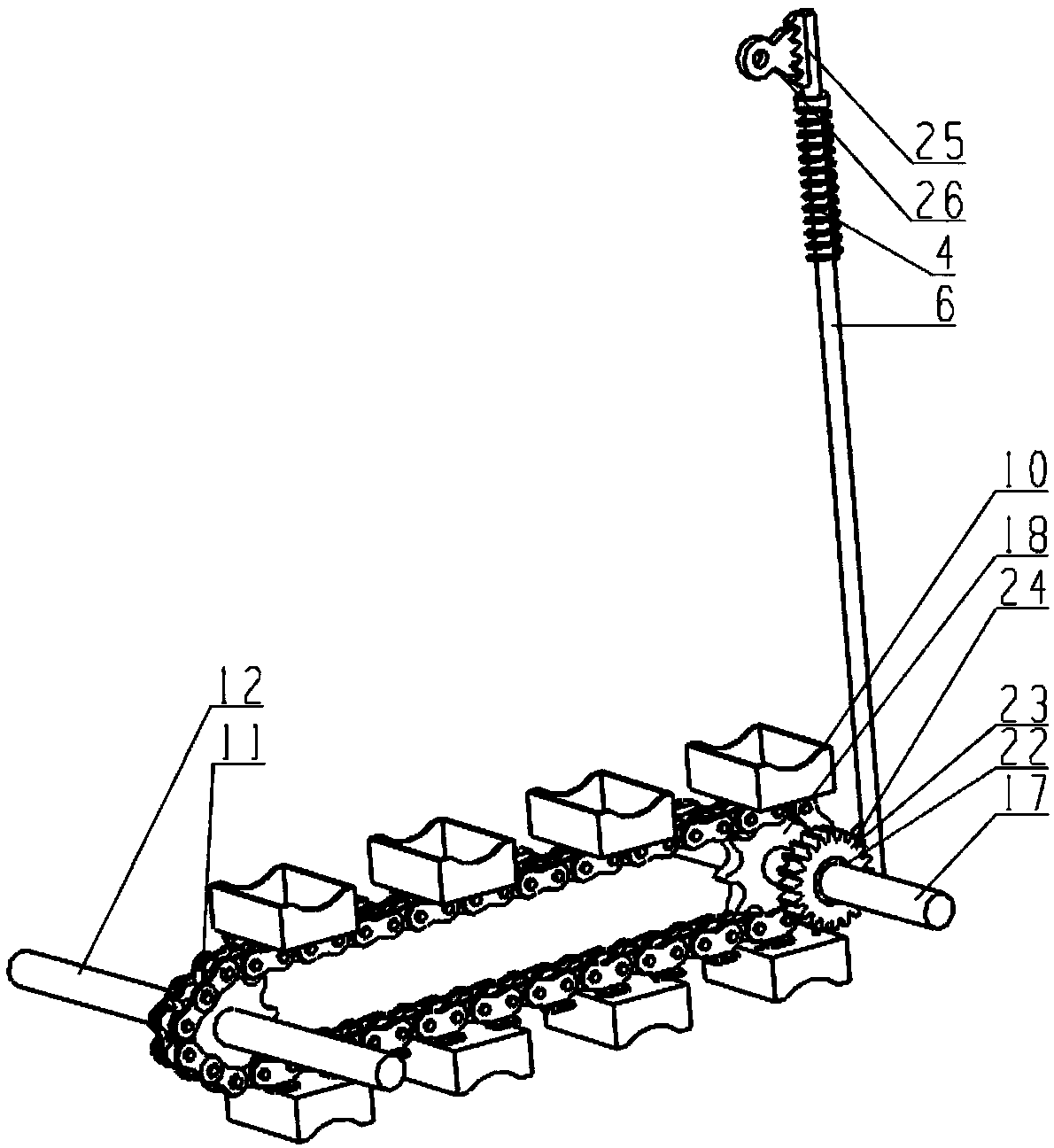

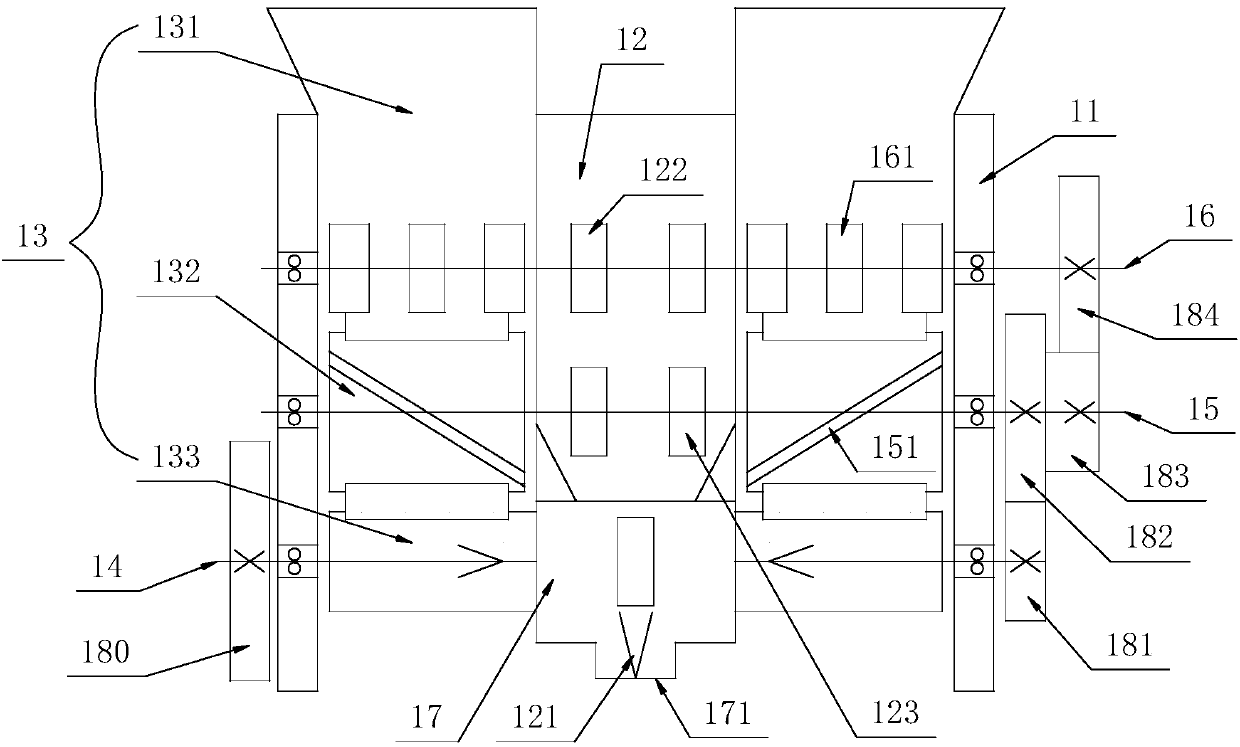

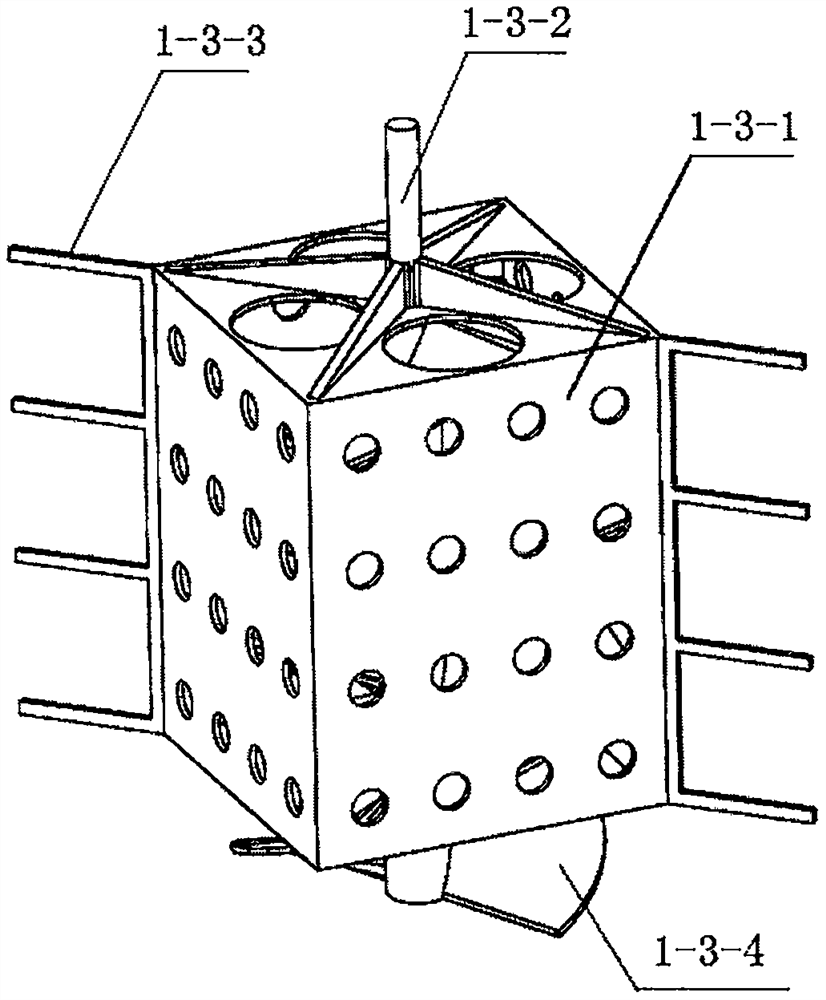

Garlic root and stem cutting apparatus

PendingCN109288105ARealize mechanized productionAchieve one-way movementFood treatmentDrive shaftAgricultural engineering

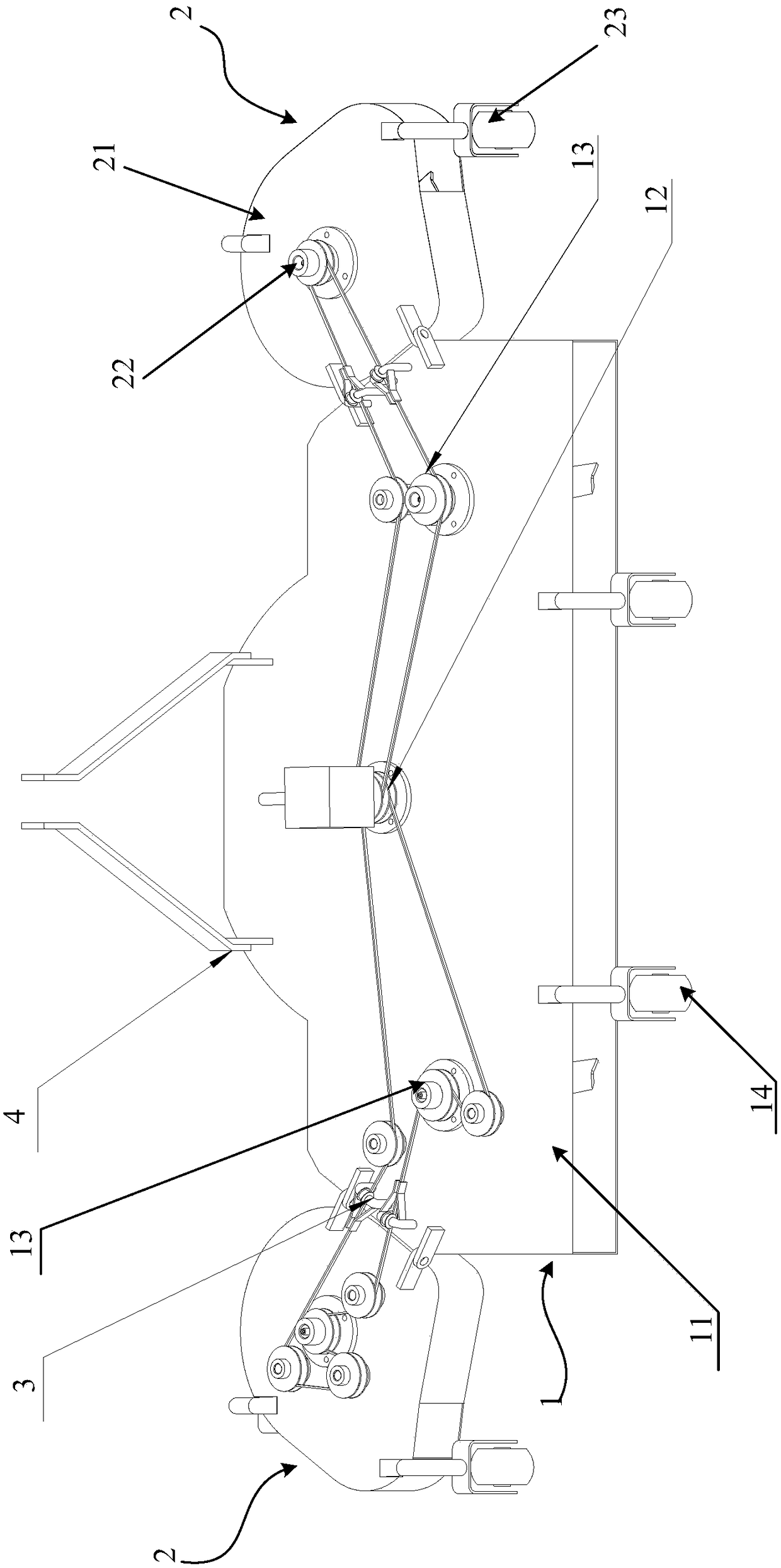

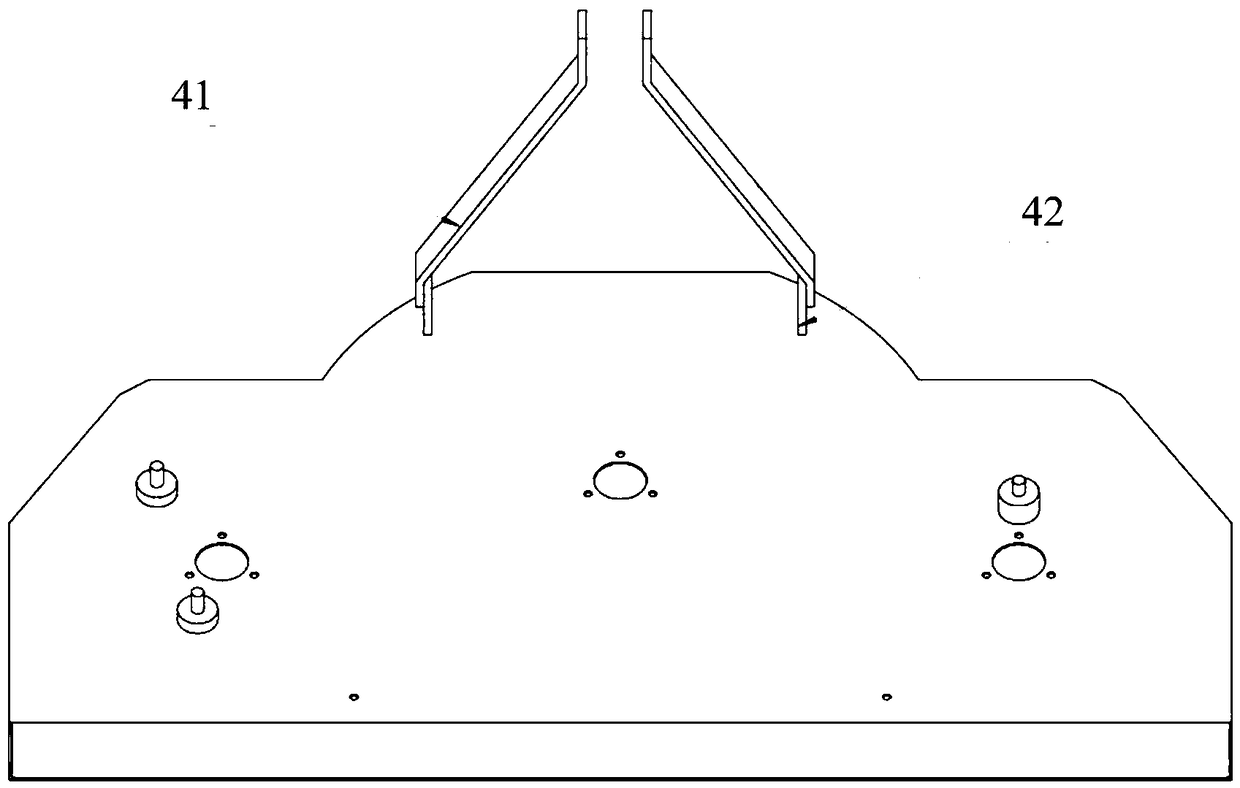

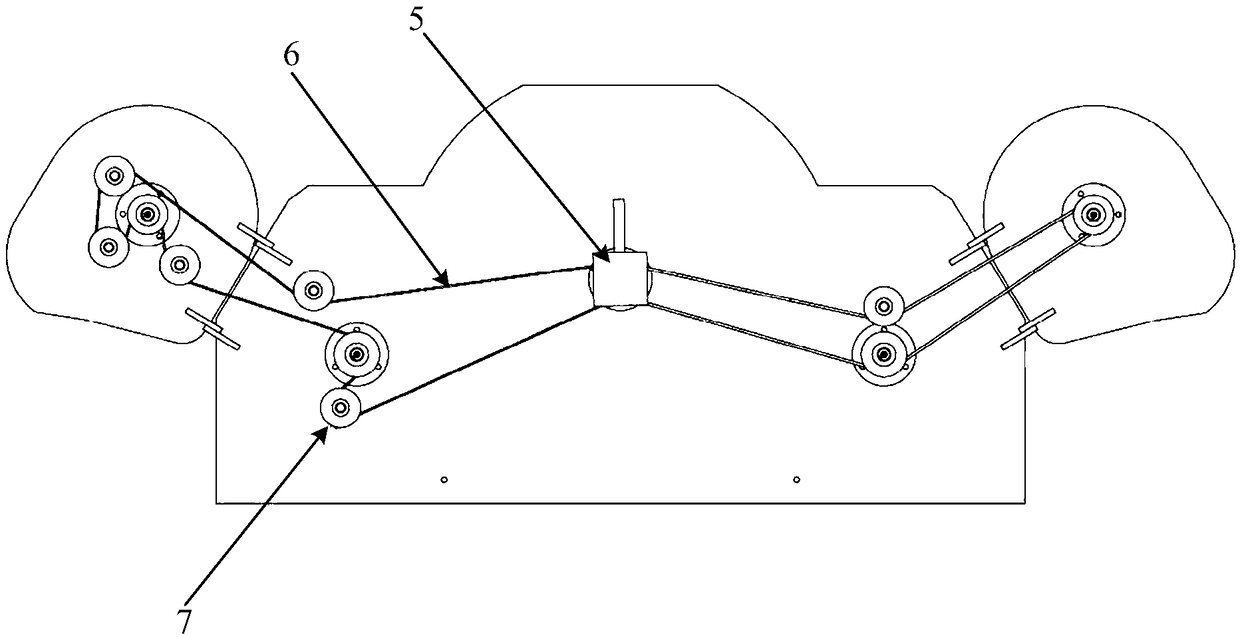

The invention discloses garlic root and stem cutting apparatus. A linkage feeding and positioning mechanism of the garlic root and stem cutting apparatus comprises a machine frame, a bearing seat, a transmission shaft, a chain wheel, a chain, a conveyor tray, a straight gear, racks, a transmission rod, a spring and a sector gear; the bearing seat is fixed on the machine frame; the transmission shaft cooperates with the bearing seat; the straight gear and the chain wheel cooperate with the transmission shaft; the chain is installed on the chain wheel; the conveyor tray is installed on the chain; the transmission rod cooperates with a positioning hole on the machine frame; the racks are installed at two ends of the transmission rod; the spring is installed at an upper part of the transmission rod; and the sector gear is installed on a motor transmission shaft. A crank slider cutting mechanism comprises a motor, an eccentric wheel, positioning shafts, a connecting rod, a slider and a blade; the motor is installed on the machine frame; the eccentric wheel cooperates with the motor transmission shaft; two ends of the connecting rod are respectively connected with the eccentric wheel andthe slider via the positioning shafts; the slider cooperates with a chute on the machine frame; and the blade is installed on the slider. Manpower is replaced by machine by using the garlic root andstem cutting apparatus ; and thus, machinery production of semi-finished garlic products is realized.

Owner:GUANGXI UNIV

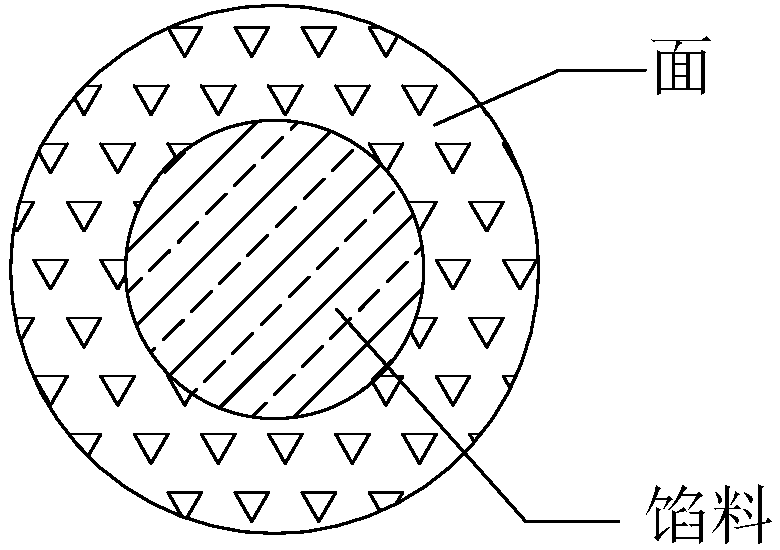

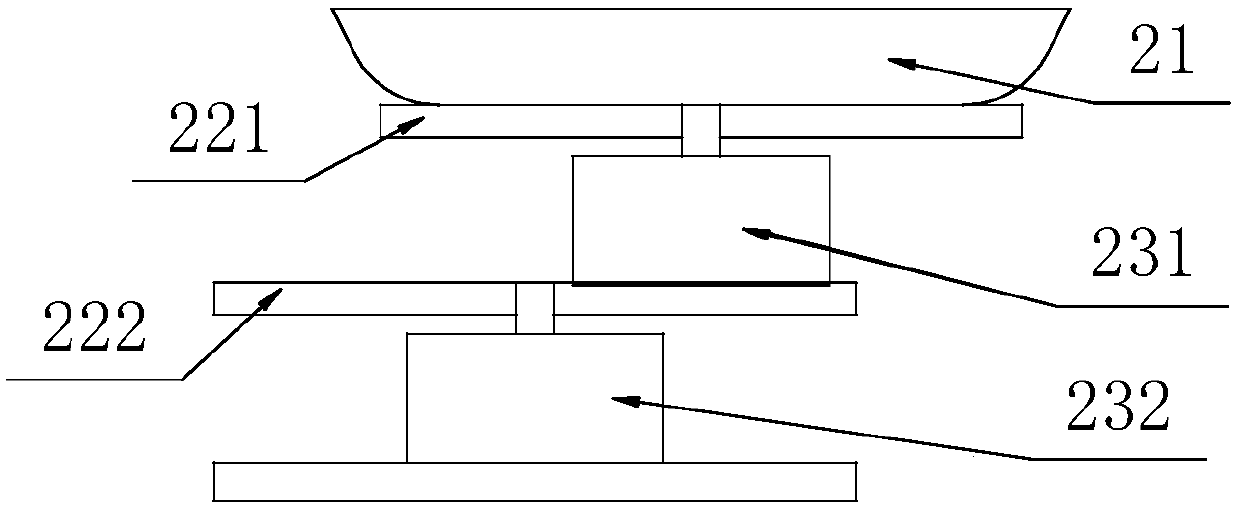

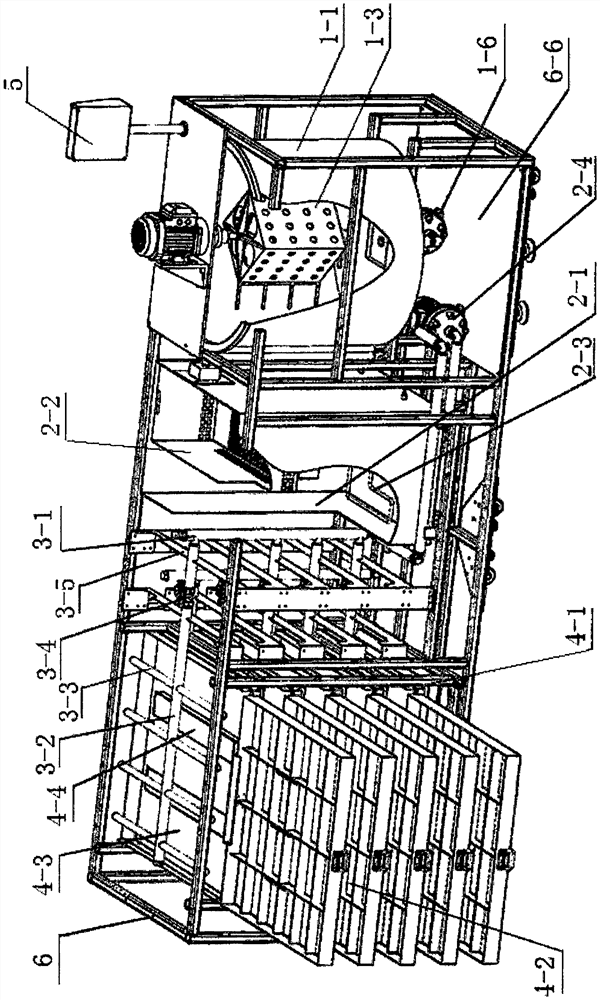

Cooked wheaten food processing equipment and method for making cooked wheaten foods through cooked wheaten food processing equipment

ActiveCN107581205ARealize mechanized processingImprove work efficiencyMixing/kneading structural elementsBakery productsEngineeringFood item

The invention provides cooked wheaten food processing equipment. The cooked wheaten food processing equipment comprises a food strip processing device, a food shaping device and a food cooking device,wherein the food strip processing device comprises a stuffing barrel and dough kneading devices, and the operations of dough mixing, dough kneading, stuffing stirring and food strip extrusion are realized by simultaneous rotation of a first shaft, a second shaft and a third shaft; as for the food shaping device, a driving device is used for driving a food plate to move in the horizontal directionto realize food shaping; and the food cooking device realizes continuous food cooking by electric heating. The invention also provides a method for making cooked wheaten foods through the cooked wheaten food processing equipment. The cooked wheaten food processing equipment disclosed by the invention is used for making stuffed cooked wheaten foods, so that making of the stuffed cooked wheaten foods is mechanized, the limitation of manual operation is broken through and the work efficiency is improved.

Owner:李才生

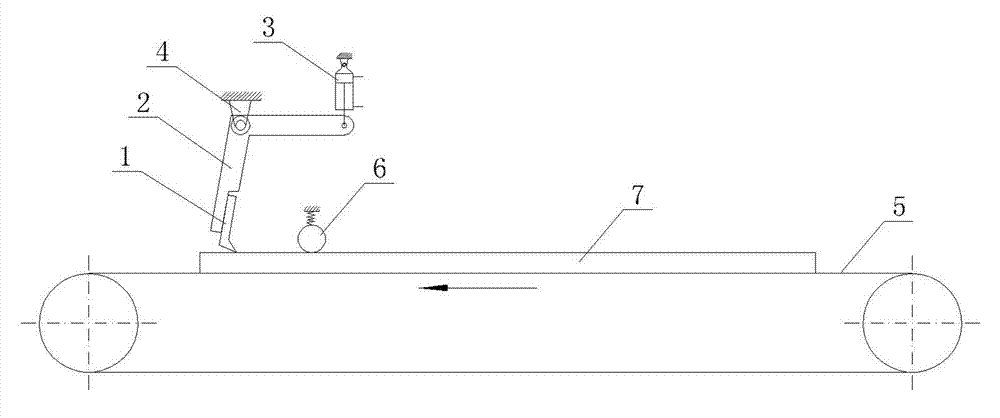

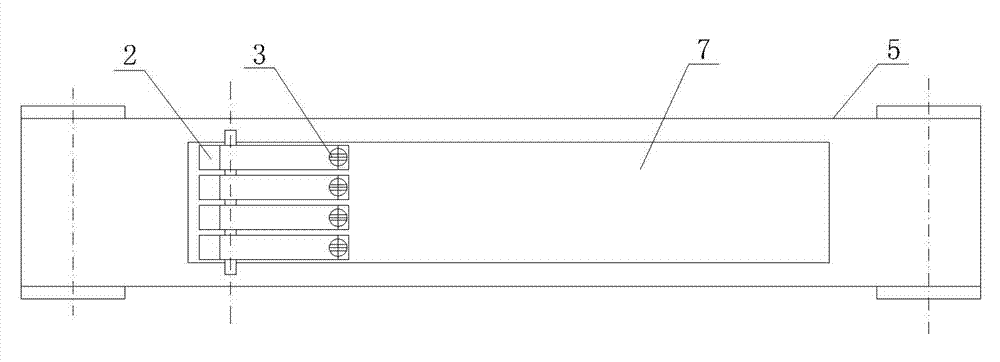

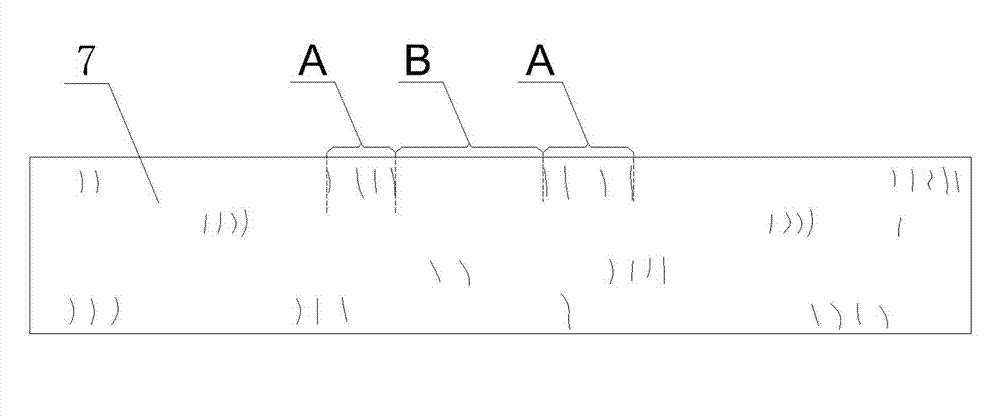

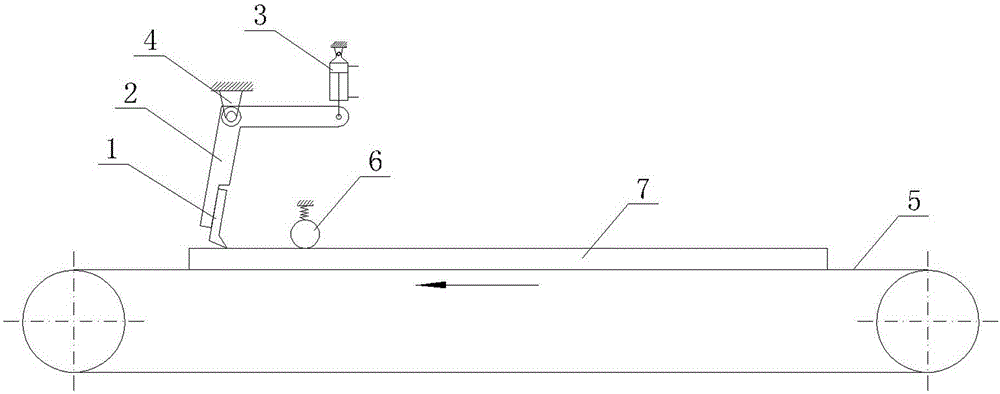

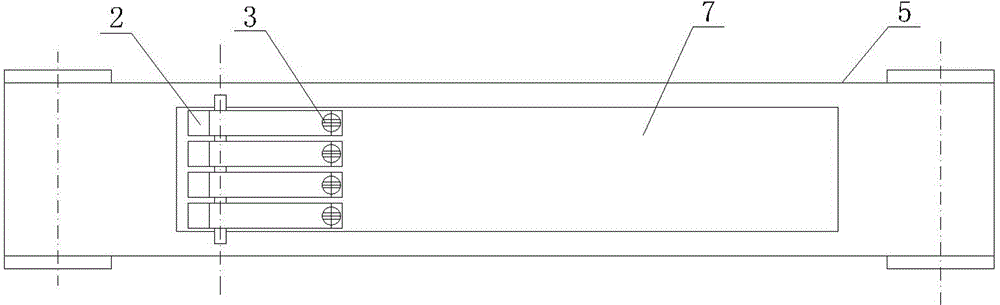

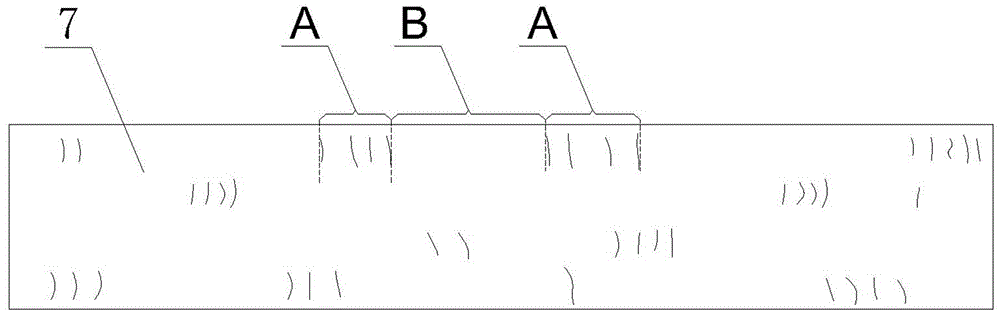

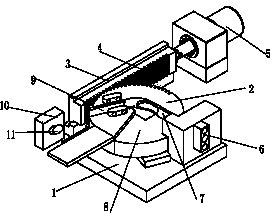

Method and device for processing slash marks on surface of pseudo-classic board

InactiveCN102729306AReduce labor intensityImprove processing efficiencyWood working apparatusEngineeringWood panel

The invention discloses a method for processing slash marks on the surface of a pseudo-classic board. According to the method, the slash marks are processed by a method for simulating artificial cutter jumping by using a device for processing the slash marks. The device for processing the slash marks comprises scrapers, swing frames, cylinders and a conveying mechanism; the swing frames are driven by changing the ventilation sequence and air pressure of rod cavities on the cylinders to swing, so that the scrapers process the slash marks on the upper surface of the board, the mechanized processing of the slash marks on the surface of the pseudo-classic board is realized, and the processing efficiency is improved; and the depths of the slash marks, the lengths and separated distance of slash mark areas and the distribution of the slash marks in the width direction of the board can be regulated, so that the processed slash marks are irregular, and an emulation effect of manual operation is achieved. The device for processing the slash marks is simple in structure and low in manufacturing cost; and the surface of the board processed by utilizing the device for processing the slash marks is good in pseudo-classic effect, the production efficiency is improved, and the production cost is reduced, so the method and the device for processing the slash marks can be widely applied to the processing and manufacturing of the surface of the pseudo-classic board.

Owner:GUANGDONG YIHUA TIMBER IND +1

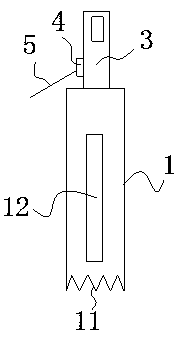

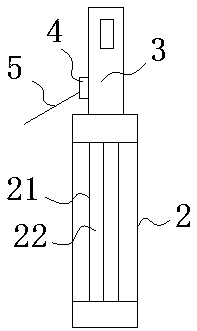

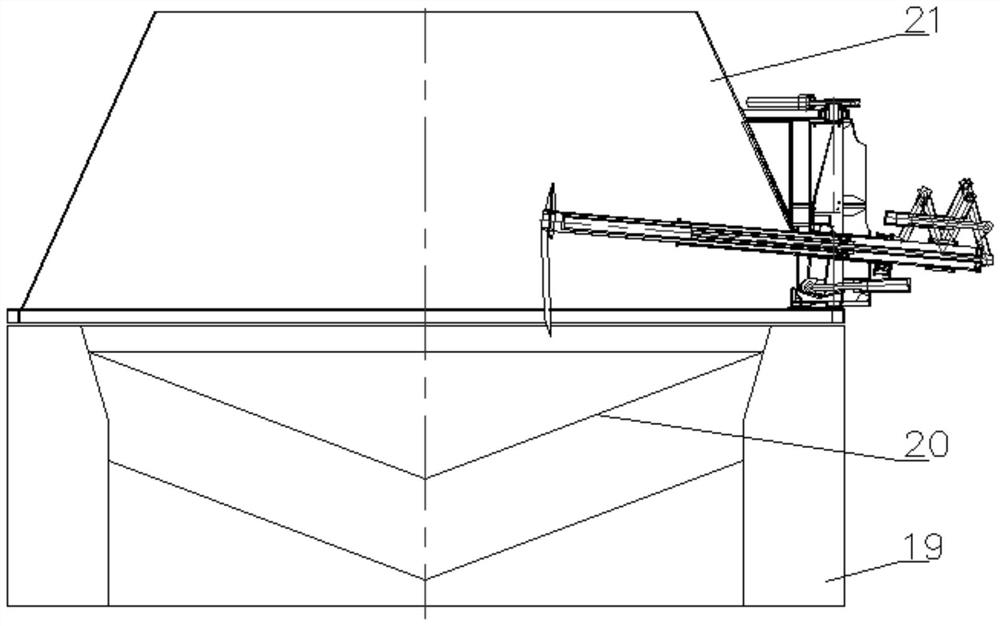

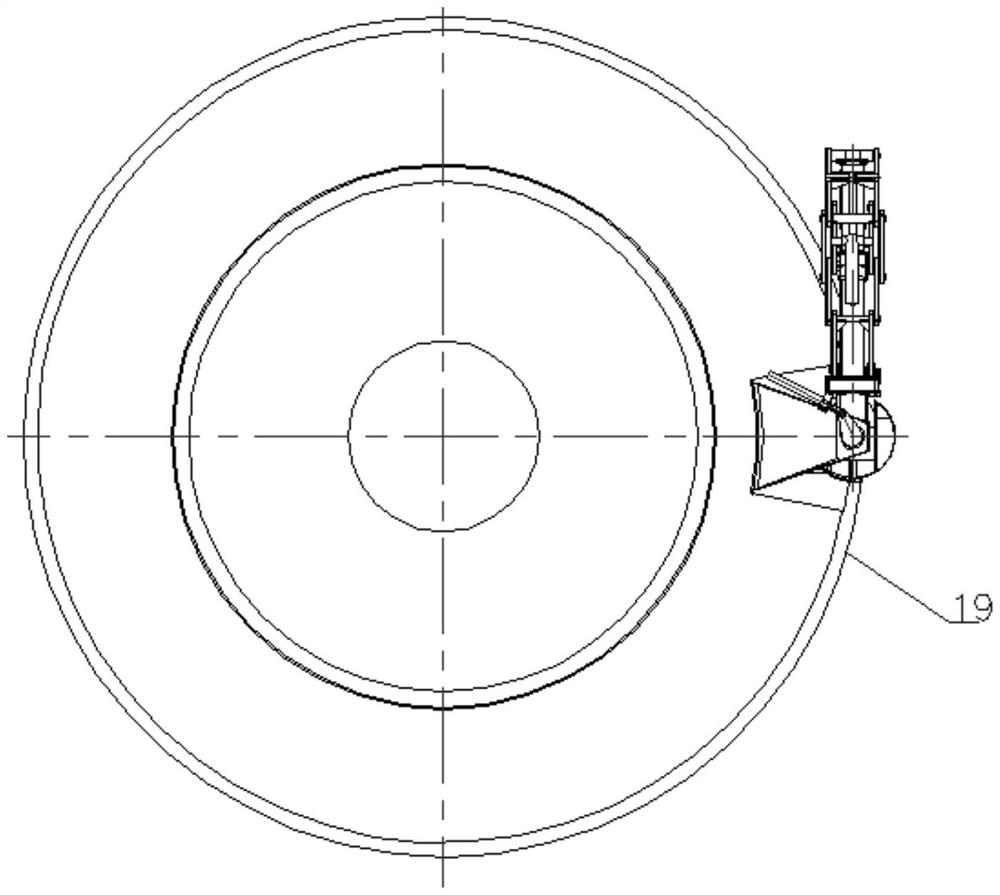

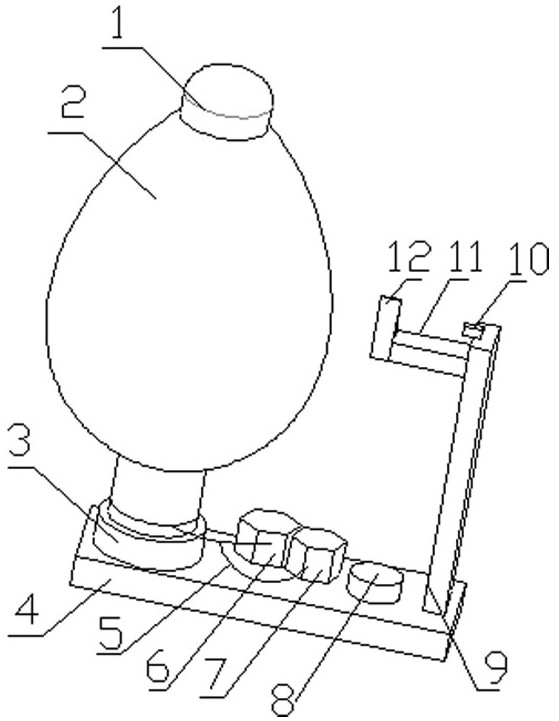

Flesh removing device for Exocarpium Citri Rubrum

InactiveCN110839920ARealize mechanized processingReduce manufacturing costFood treatmentMining engineeringStructural engineering

The invention provides a flesh removing device for Exocarpium Citri Rubrum. Mechanical processing of fresh removing of the Exocarpium Citri Rubrum can be realized, the production cost of Exocarpium Citri Rubrum and Pu'er tea is reduced, and the production efficiency is improved. The flesh removing device for the Exocarpium Citri Rubrum comprises a coring drill barrel and a flesh removing drill barrel, wherein the bottom opening of the coring drill barrel is circumferentially provided with cutting sawteeth; the upper end of the coring drill barrel is a sleeve clamping end, and the barrel body of the coring drill barrel is made of a stainless steel sheet in a rolling manner; the middle section of the barrel body of the flesh removing drill barrel is axially provided with a plurality of slits; the slits divide the middle section of the flesh removing drill barrel into a plurality of cutting blades capable of bending and deforming outwards; the upper end of the flesh removing drill barrelis a sleeve clamping end, and the side wall of the lower end of the sleeve clamping end is provided with a microswitch; and the microswitch is connected with a switch rod which is obliquely suspendeddownwards.

Owner:化州市正源堂化橘红实业有限公司

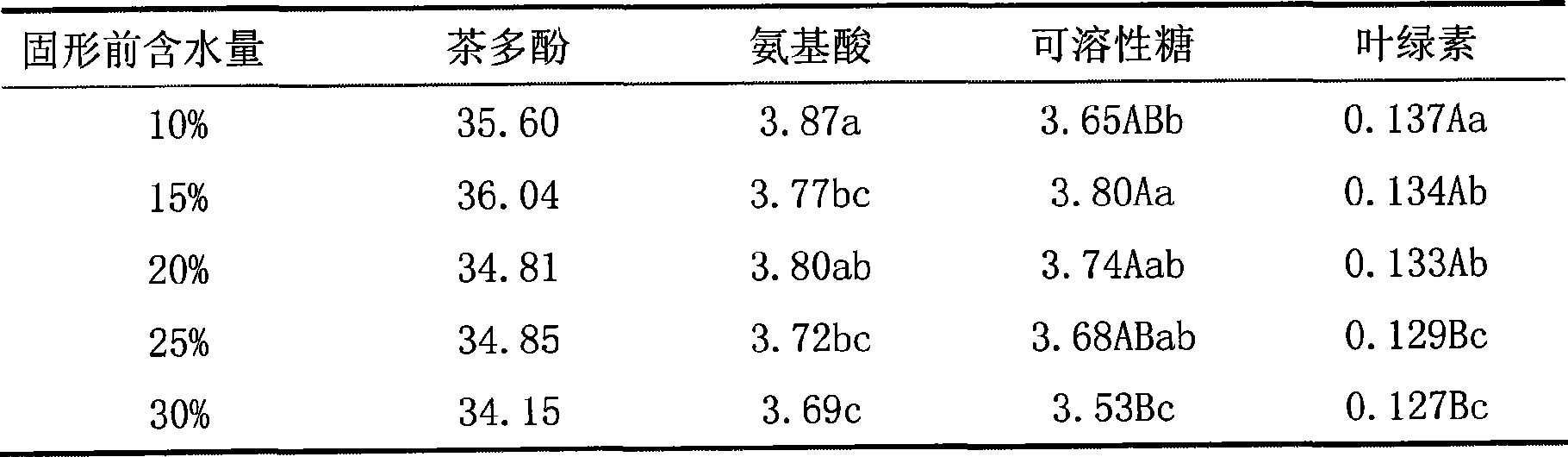

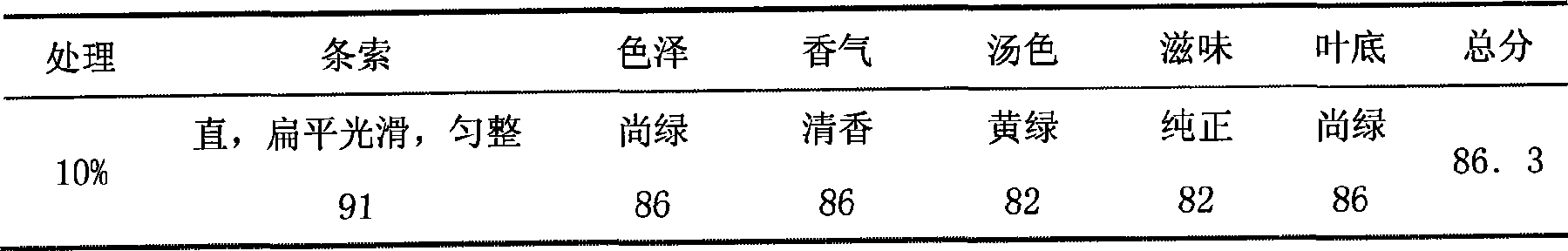

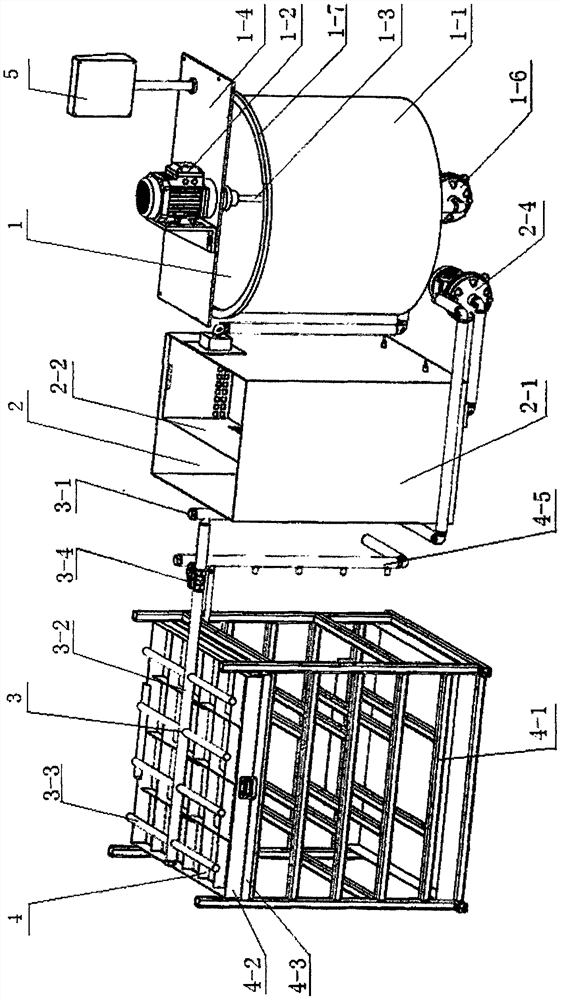

A flat famous green tea processing method

InactiveCN101548700BRealize mechanized processingGuaranteed qualityPre-extraction tea treatmentMicrowaveOff Treatment

The present invention provides a flat shape famous green tea processing method, which includes: firstly performing spreading and greening processing to fresh leaves, and then continuously performing roller de-enzyming, microwave tempering, automatic grounding, and then using a cooling storage machine for cooling the grounded leaves, frying drying after the leaves are cooled and enter in a flat teafrying machine, finally determining whether it is needed to enter a hexagon brightness dried machine for hair-off treatment or directly use far infrared perfuming machine to performing perfuming. Theinvention integrates the use of stacked-type multiple layer placing frame, roller de-enzyming, microwave de-enzyming machine, automatic tea carding machine, cooling storage machine, drying machines,hexagonal brightness drying machine / far-infrared perfuming machine and the like machining processes and equipment for integrated considering, so that the appearance of the obtained product is flat andsmooth, fragrant, to realize mechanization machining of flat famous green tea.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

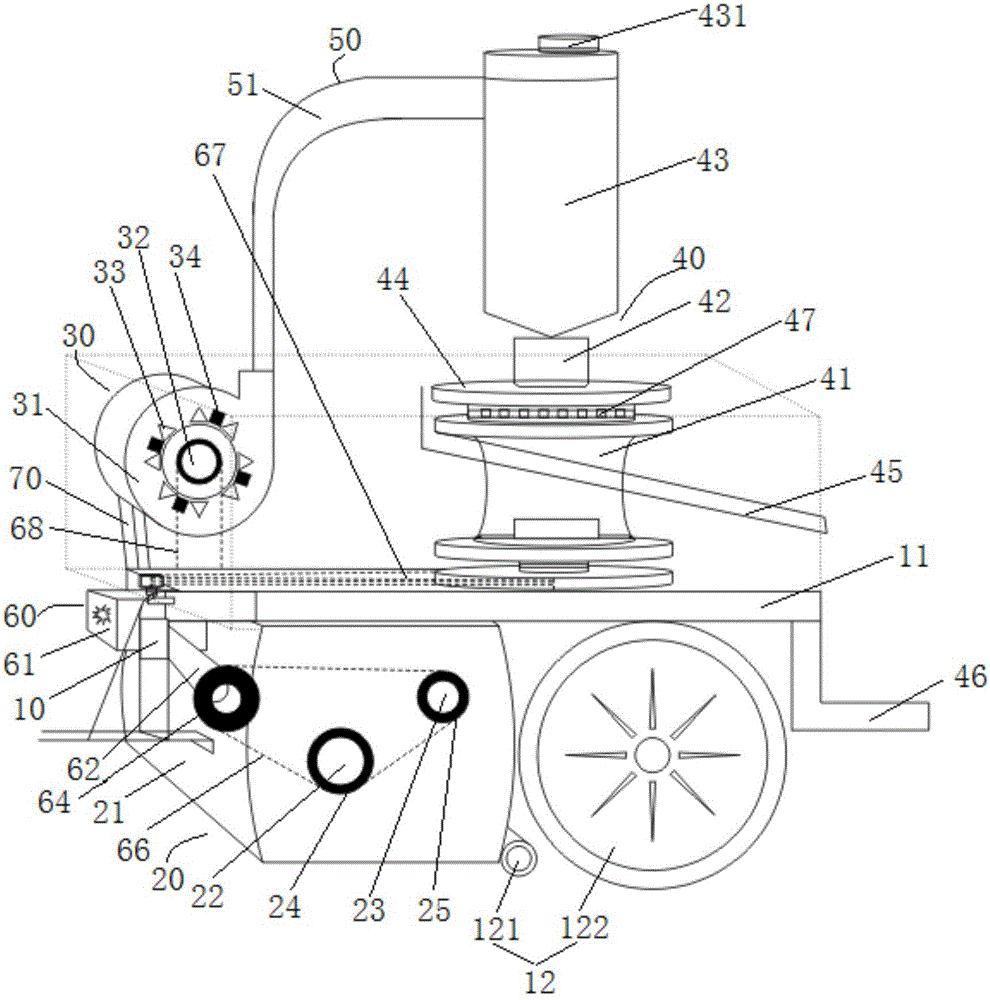

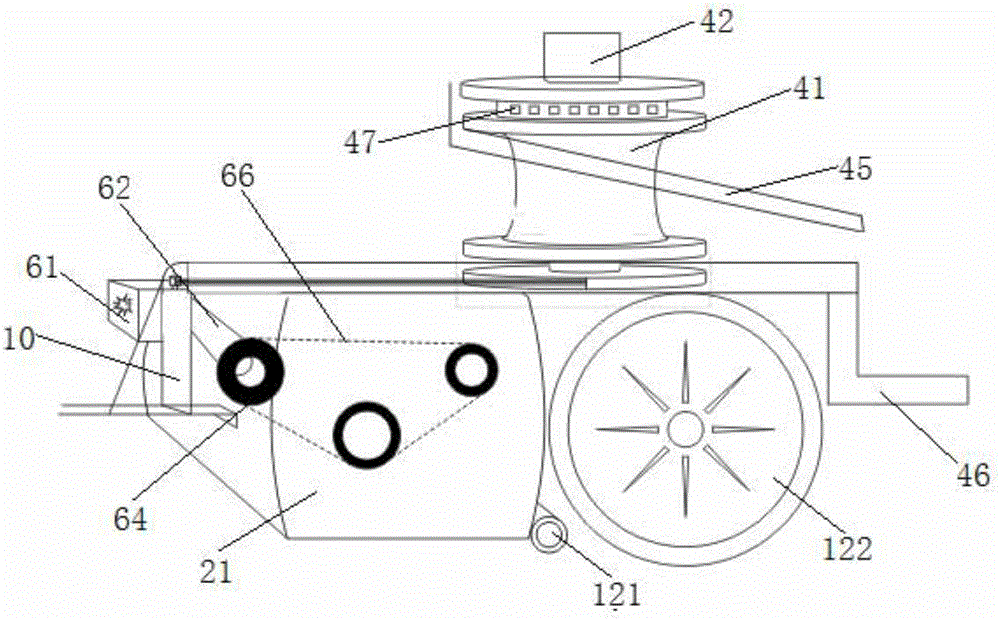

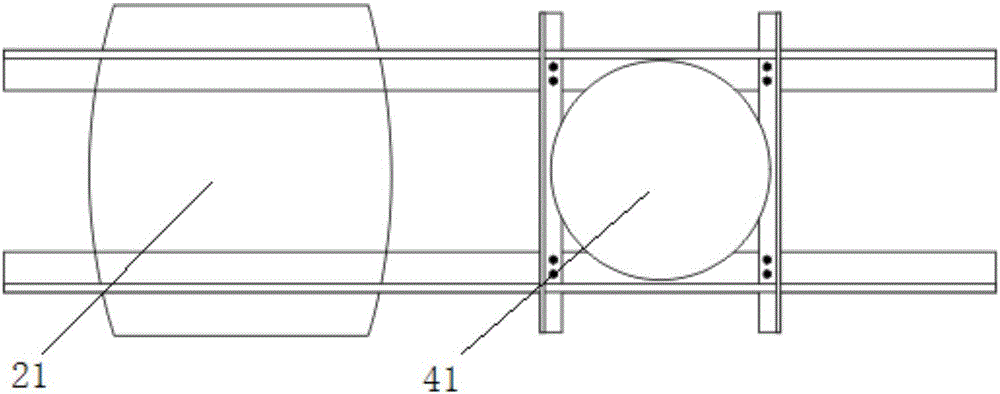

Biomass briquetting device

PendingCN106732179AReduce shipping costsRealize mechanized processingFeeding-stuffBiofuelsBiomassMoving parts

The invention provides a biomass briquetting device which comprises a rack, a recycling mechanism, a grinding mechanism, a briquetting mechanism, a conveying mechanism and a transmission mechanism, wherein the rack is provided with a tray and a moving part; the recycling mechanism is mounted on the rack; the grinding mechanism is mounted on the rack and connected with the recycling mechanism; the briquetting mechanism is mounted on the tray; the conveying mechanism is connected with the grinding mechanism to convey the substance treated by the grinding mechanism to the briquetting mechanism; the transmission mechanism is in drive connection with the recycling mechanism, the briquetting mechanism and the grinding mechanism; and under external drive force, the transmission mechanism drives the recycling mechanism, the briquetting mechanism and the grinding mechanism to move. The biomass briquetting device provided by the invention realizes mechanical processing, industrial production and industrial utilization and development of the biomass industry, reduces labor input, lowers the transportation cost and production cost, remarkably improves the production efficiency and reduces the combined cost of the product.

Owner:中天同圆太阳能高科技有限公司

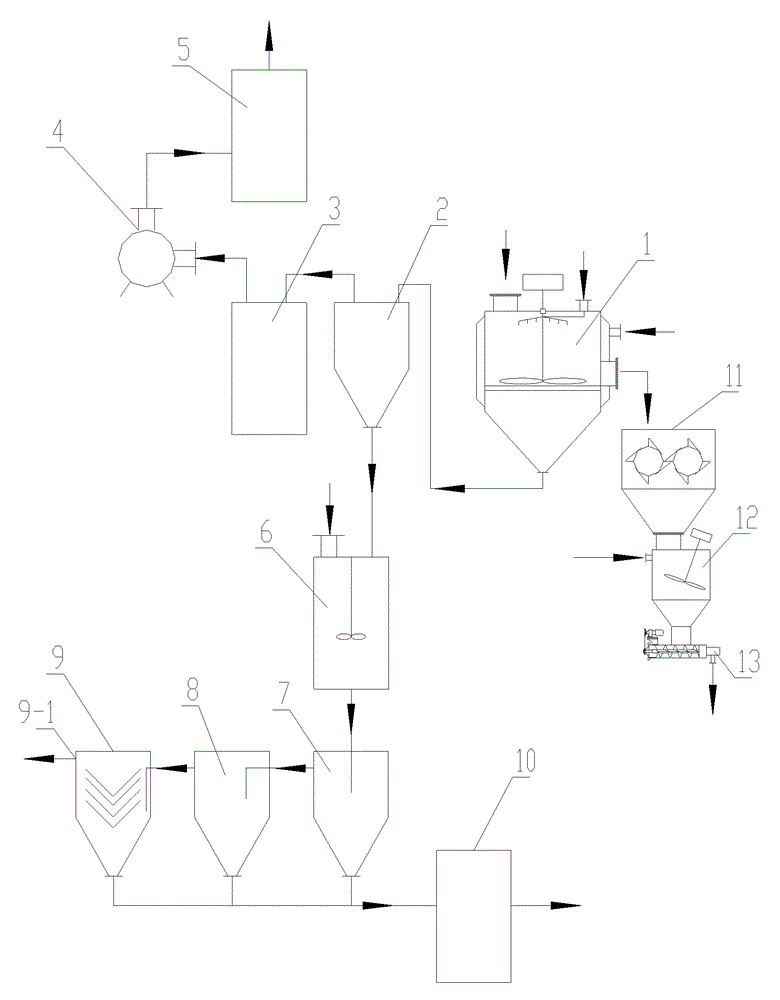

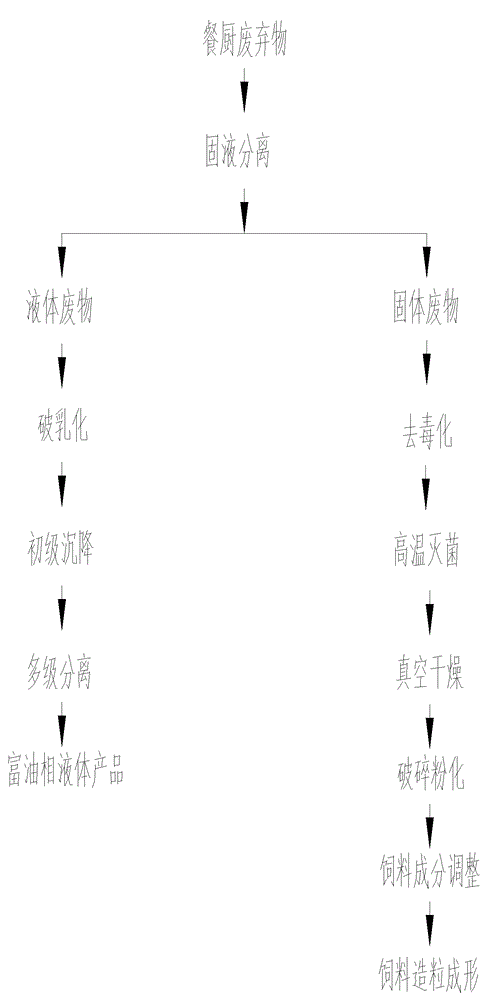

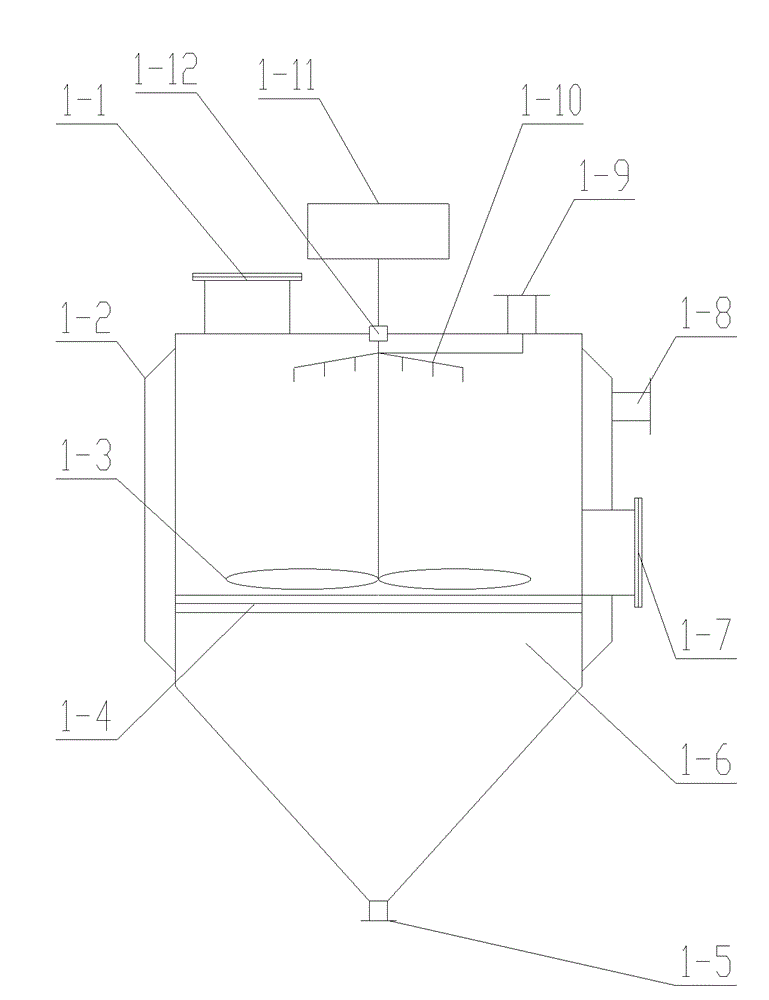

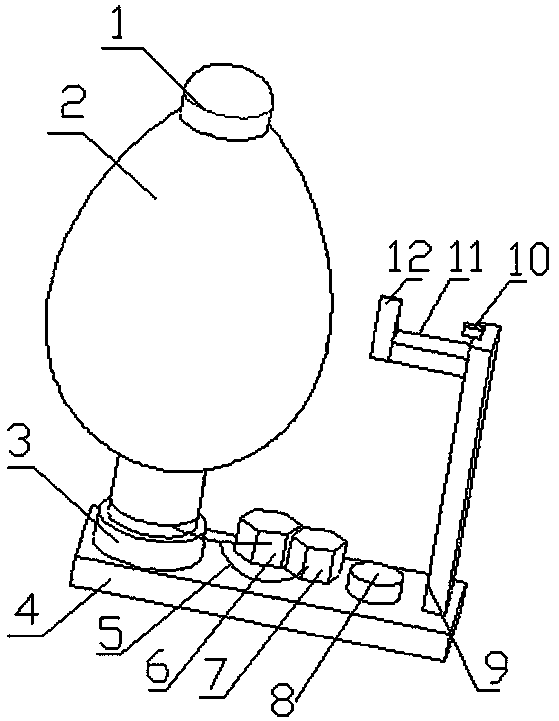

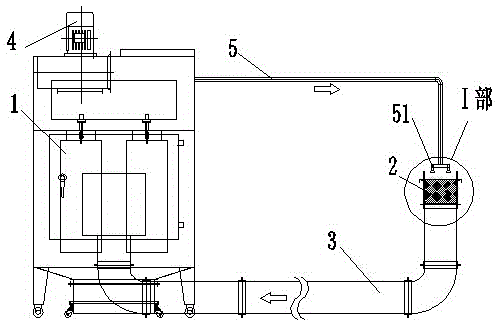

Innocent recycle treatment equipment for kitchen waste

InactiveCN102211107BReduce contentShort processing timeFatty oils/acids recovery from wasteFeeding-stuffDemulsifierSolid component

The invention discloses innocent recycle treatment equipment for kitchen waste, which comprises a solid-liquid separating device, a liquid collecting tank, a buffer tank, a vacuum pump, a tail gas purifying device, a demulsifier, a settling separating device, a multi-stage separating device, a wastewater treatment device, a crushing device, an ingredient adjusting device and a feed forming device. The equipment performs innocent recycle treatment on the kitchen waste, fully recycles the kitchen waste, converts solid ingredients in the kitchen waste into an animal feed, converts liquid ingredients into chemical materials for preparing lubricating oil, soaps and other products, and changes the waste into treasure.

Owner:TIANJIN AGRICULTURE COLLEGE

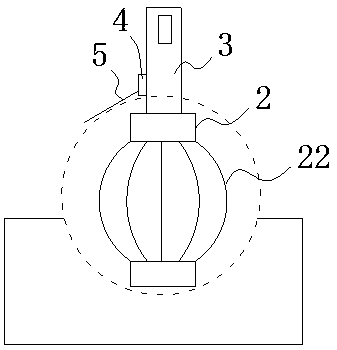

Automatic squid body peeling machine

ActiveCN109169814ARealize mechanized processingHigh peeling efficiencyCephalopods processingFish skinningDistance sensorsEngineering

The invention discloses an automatic squid body peeling machine, and belongs to the technical field of auxiliary equipment for fishery processing. The automatic squid body peeling machine comprises ahollow rotary bar, a hollow rubber body, a reduction motor, a base, pipelines, an air extractor, an inflator, a controller, a first electric lifting rod, a distance sensor, a second electric lifting rod and a scraper; the hollow rubber body sleeves the hollow rotary bar; the reduction motor is installed under the hollow rotary bar; the base is installed under the reduction motor; the air extractor, the inflator, the controller and the first electric lifting rod are sequentially installed on the base; the distance sensor is installed on an upper part of the first electric lifting rod; the second electric lifting rod is installed on the left side of the first electric lifting rod; the scraper is installed on the left side of the second electric lifting rod; and the hollow rotary bar, the airextractor and the inflator are connected by the pipelines. The automatic squid body peeling machine has the following advantages: the automatic squid body peeling machine adopts an inflatable structure, so that coating, shaping and taking-out of squids are facilitated; and thus, mechanized processing of squid is realized with peeling efficiency greatly improved.

Owner:ZHEJIANG OCEAN UNIV

Processing device for weed bodies between rows of ridging orchard

ActiveCN108738407ARealize mechanized processingReduce labor intensitySoil-working equipmentsWeed killersEngineeringUltimate tensile strength

The invention relates to a processing device for weed bodies between rows of a ridging orchard. The device comprises a main body weed-cutting mechanism composed of a main body board, a gearbox arranged on the main body board and a main weed-cutting knife. The main weed-cutting knife is used for cutting off weed bodies in field ditches. Additionally, the front end of the main body board is equippedwith a suspension device and the back end thereof is equipped with main body ground wheels. The processing device also comprises two floating weed-cutting mechanisms which are symmetrically arrangedon left and right sides of the main body board. The floating weed-cutting mechanisms comprise floating boards and auxiliary weed-cutting knives. The weed-cutting knives are used for cutting off weed bodies on ridge slopes. Additionally, the insides of the floating boards are hinged onto the main body board. The outside of the floating boards are equipped with floating ground wheels such that the floating boards float along with the shapes of the ridge slopes. The processing device for weed bodies between rows of the ridging orchard can eliminate weeds in the ditch fields and on the ridge slopes in sync. Mechanical processing of the weed bodies between rows of the ridging orchard is achieved. Therefore, labor intensity of worker is reduced. Additionally, weeding efficiency is effectively increased.

Owner:HEBEI AGRICULTURAL UNIV.

Method for crushing spices

InactiveCN104668069AGuarantee processing qualityReduce temperature riseGrain treatmentsFood flavorMaterials science

The invention discloses a method for crushing spices. The method comprises the following concrete steps: sending the spices to low-temperature extrusion-grinding crushing equipment; and grinding the spices into superfine powder at a low temperature by adopting a jacket filled with a cooling medium. The low-temperature grinding micro-crushing method for the spices, disclosed by the invention, can be used for achieving mechanical processing; in comparison with a traditional universal crushing method, the method disclosed by the invention has the advantages that materials which are hard to crush at the normal temperature can be crushed, the small material temperature increment is caused during crushing, and the freshness, color, flavor, taste and various active substances of the powder material can be retained, so that the method is especially suitable for crushing the spices which are relatively high in content of volatile components; the processing quality of the spices is greatly guaranteed; the superfine degree of a processed product has incomparable advantages.

Owner:TAIZHOU BETTER FOOD INGREDIENTS

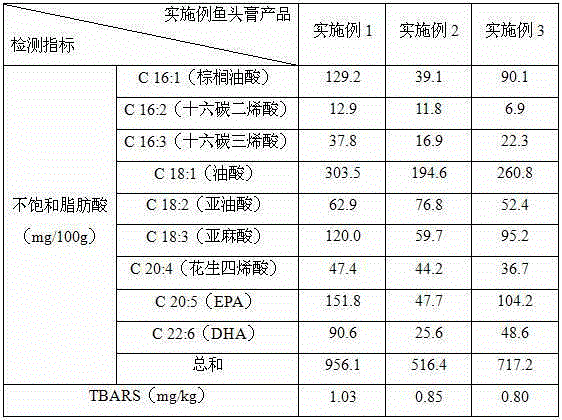

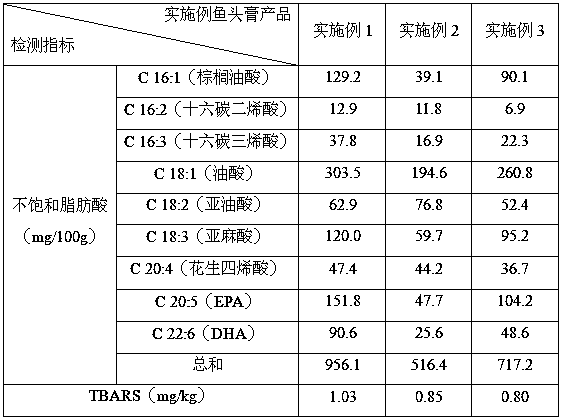

Production method for fish head paste rich in polyunsaturated fatty acid

ActiveCN105410742ABroaden the way of processing and utilizationEfficient use ofFood scienceNutritionBiology

The invention provides a production method for fish head paste rich in polyunsaturated fatty acid. The production method comprises the following steps: firstly, fish heads without gills are cleaned, crushed and added with a fishy smell elimination agent, homogenating is carried out, the pH value is adjusted to be less than or equal to 3.0, stirring and pumping filtration are carried out, the filtrate is collected, and fish head paste without fishbone is obtained; secondly, fish maw flesh is cleaned and added with the fishy smell elimination agent, homogenating and filtering are carried out, and fish maw flesh paste is obtained; thirdly, the fish head paste without fishbone and the fish maw flesh paste are taken at a mass ratio of 1:0-0.4 and mixed uniformly, a stabilizing agent and an emulsifier are added, the pH value is adjusted to 3.5-4.5, homogenating is carried out, and mixed fish flesh paste is obtained; fourthly, seasoners are added, the mixture is mixed uniformly, loading and disinfection are carried out and fish head paste is obtained. The production technology is simple, the cost is low, and the method is suitable for industrial production. The fish head paste product has a high unsaturated fatty acid content and has rich nutrients, the TBARS value is low, the fish head paste has no fishy smell and has a good special flavor.

Owner:湖南汇湘轩生物科技股份有限公司

Walnut shell breaking machine

InactiveCN107495397AImprove processing qualityIncrease export rateHuskingHullingWalnut NutEngineering

A walnut shelling machine, comprising an extruding device and an extruding plate, the extruding device is placed on the extruding plate, a shaft is arranged in the middle of the extruding plate, the shaft is fixed on the frame, and the outer surface of the shaft is evenly divided Roller, the upper part of the extrusion plate is provided with a feeding port, the feeding port is placed on the upper cover, the lower part of the upper cover is provided with an end cover, and the lower part is provided with a lower cover; the advantages of the present invention are: The advantages are: simple structure, realizing mechanized processing, liberating productivity, improving efficiency, improving walnut processing quality and export rate, improving shell breaking rate and whole kernel rate, and good shell breaking performance.

Owner:李颂

A kind of production method of fish head paste rich in polyunsaturated fatty acid

ActiveCN105410742BBroaden the way of processing and utilizationEfficient use ofFood scienceFlavorTBARS

The invention provides a production method for fish head paste rich in polyunsaturated fatty acid. The production method comprises the following steps: firstly, fish heads without gills are cleaned, crushed and added with a fishy smell elimination agent, homogenating is carried out, the pH value is adjusted to be less than or equal to 3.0, stirring and pumping filtration are carried out, the filtrate is collected, and fish head paste without fishbone is obtained; secondly, fish maw flesh is cleaned and added with the fishy smell elimination agent, homogenating and filtering are carried out, and fish maw flesh paste is obtained; thirdly, the fish head paste without fishbone and the fish maw flesh paste are taken at a mass ratio of 1:0-0.4 and mixed uniformly, a stabilizing agent and an emulsifier are added, the pH value is adjusted to 3.5-4.5, homogenating is carried out, and mixed fish flesh paste is obtained; fourthly, seasoners are added, the mixture is mixed uniformly, loading and disinfection are carried out and fish head paste is obtained. The production technology is simple, the cost is low, and the method is suitable for industrial production. The fish head paste product has a high unsaturated fatty acid content and has rich nutrients, the TBARS value is low, the fish head paste has no fishy smell and has a good special flavor.

Owner:湖南汇湘轩生物科技股份有限公司

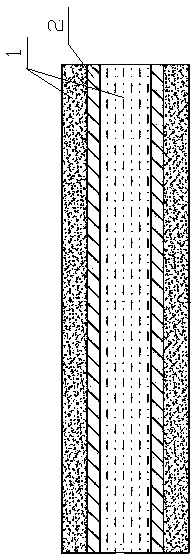

Inorganic flame retardant straw fiberboard and production method thereof

ActiveCN104108128BNo artificial formaldehyde releaseHigh strengthDomestic articlesFlat articlesYarnUltimate tensile strength

The invention discloses an inorganic inflaming retarding straw fiberboard and a production method thereof. The inorganic inflaming retarding straw fiberboard comprises three layers of straw fiber layers, wherein a cotton yarn net is arranged between each two adjacent straw fiber layers, the cotton yarn nets are respectively bonded to the adjacent straw fiber layers through inorganic inflaming retarding adhesive material layers, and the straw fiber layers are slab materials made of straw fibers and inorganic inflaming retarding adhesives. According to the inorganic inflaming retarding straw fiberboard, the cotton yarn nets are arranged in the straw fiberboard, the cotton yarn nets are used as reinforcement bodies, the inorganic inflaming retarding adhesives are used as bonding agents, not only is good strength of the inorganic inflaming retarding straw fiberboard guaranteed, but also the results that no artificial formaldehyde is released from the inorganic inflaming retarding straw fiberboard and the inflaming retarding level of the inorganic inflaming retarding straw fiberboard reaches an A2 level are guaranteed, and furthermore straw fibers are abundant in source, low in production cost, simple to process and high in production efficiency, and mechanization processing can be achieved during the whole production process.

Owner:LIANYUNGANG BAOLISEN IND

Device for removing powder coating

InactiveCN105107664ARealize mechanized processingEasy to operateSpraying apparatusEngineeringPowder coating

The invention relates to a device for removing powder coating. The device comprises a powder recovery chamber (1) and an accommodation unit (2) arranged outside the powder recovery chamber (1). A suction fan (4) for sucking an accommodation substance, that is, powder, into the powder recovery chamber (1) through a suction tube (3) is arranged at one end of the accommodation unit (2). An air outlet of the suction fan (4) extends to the other end of the accommodation unit (2) through a blowing tube (5). According to the device for removing powder coating, powder is removed through the air flowing principle, and mechanical treatment is achieved; compared with a traditional manual powder removing mode, the device is easy to operate and good in powder removing effect.

Owner:YANGZHOU LEXUD MACHINERY MFG

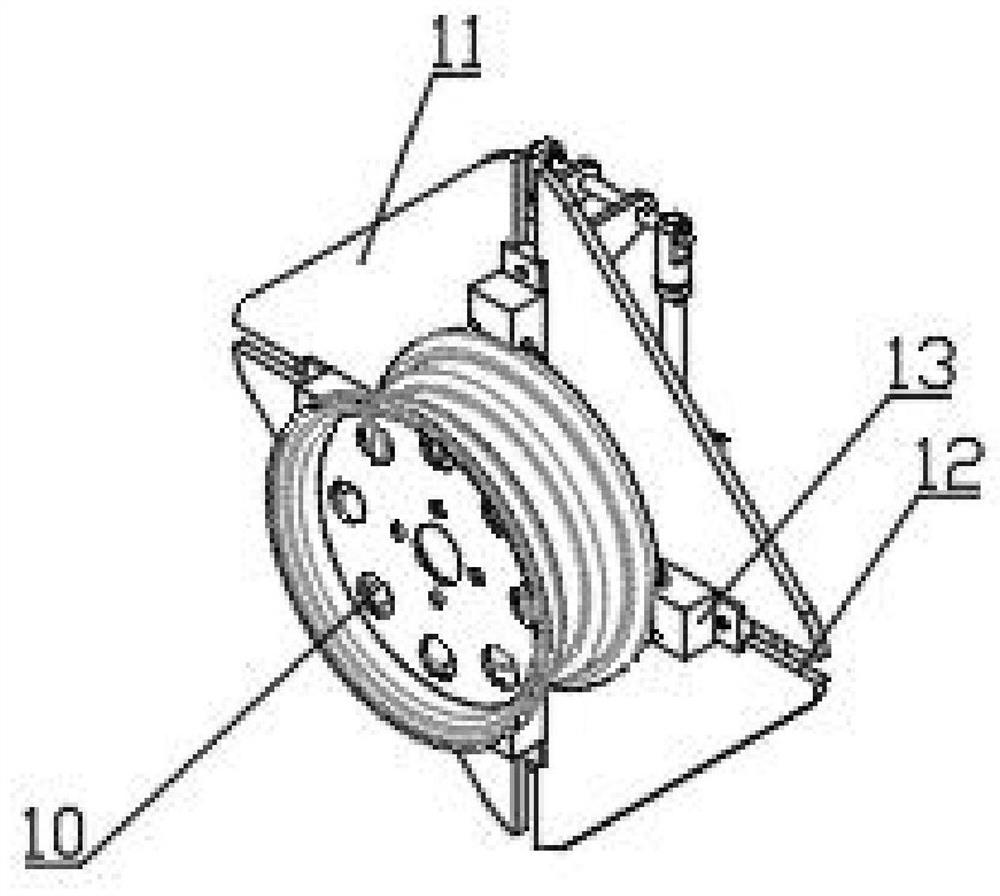

Protective forklift wheel transfer device

InactiveCN112276584AEasy to installEasy to handleOther manufacturing equipments/toolsMetal working apparatusHydraulic cylinderTransmission belt

The invention discloses a protective forklift wheel transfer device. The protective forklift wheel transfer device comprises a conveying belt, overturning supports, mounting mechanisms and wheel bodies; a plurality of sets of overturning supports are arranged on the conveying belt at equal intervals, and the mounting mechanisms used for fixing the wheel bodies are arranged on the overturning supports; each overturning support comprises a bottom plate, two sets of first supporting columns, two sets of second supporting columns, a rotating base, a mounting plate and hydraulic cylinders, the bottom face of the bottom plate is connected with the conveying belt, the two sides of the top face of the bottom plate are provided with the first supporting columns and the second supporting columns correspondingly, the two sets of first supporting columns and the two sets of second supporting columns are arranged in parallel correspondingly, buffer parts are arranged at the tops of the first supporting columns, the tops of the second supporting columns are connected with the mounting plate through the rotating base, the mounting mechanism is arranged on the top face of the mounting plate, and the hydraulic cylinders are arranged on the two sides of the bottom face of the mounting plate correspondingly and mounted on the top face of the bottom plate. The protective forklift wheel transfer device has the advantage that the wheel bodies can be continuously and mechanically machined and treated.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

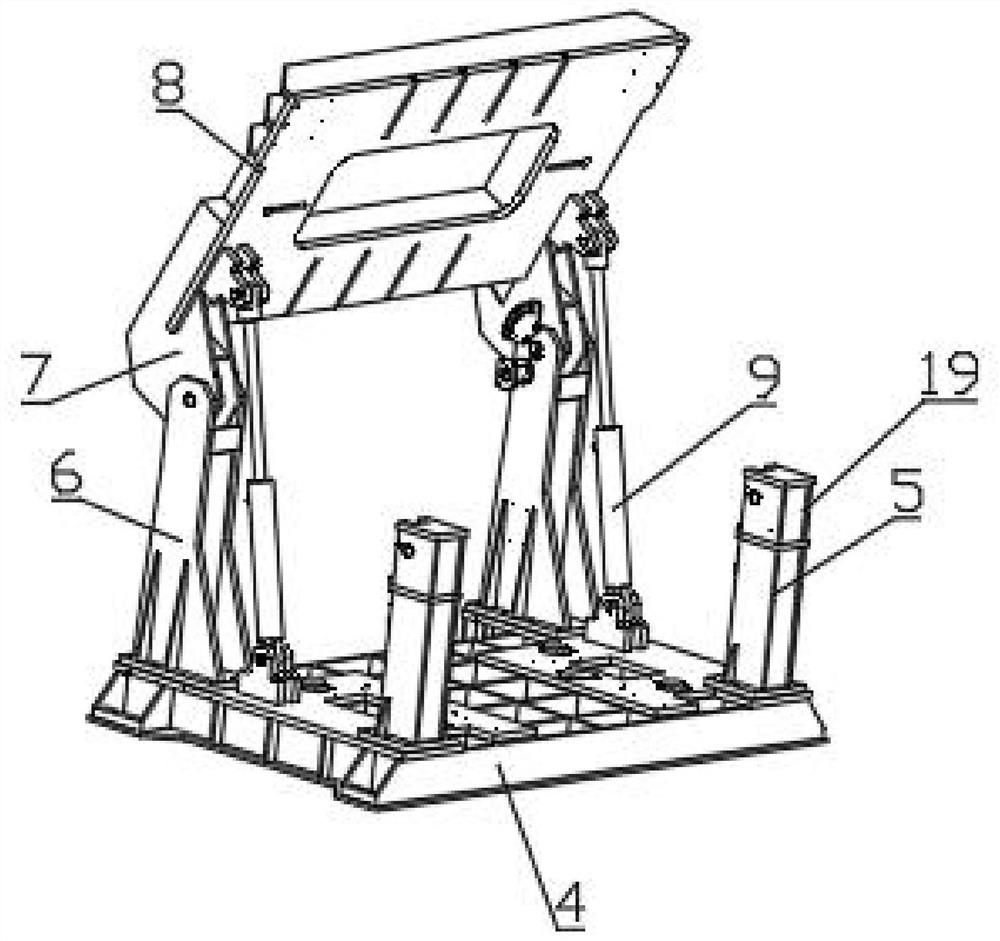

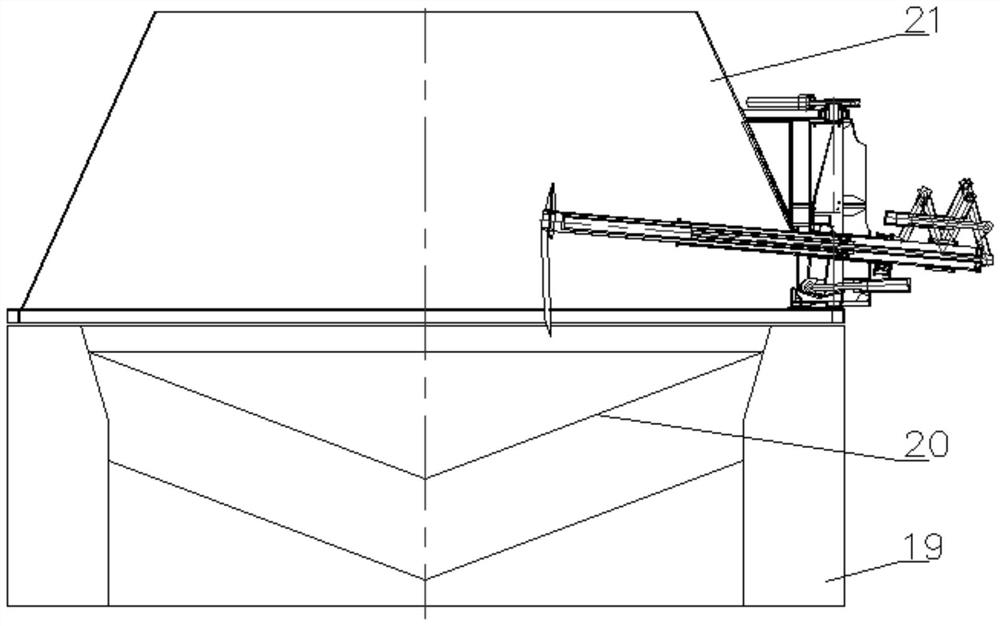

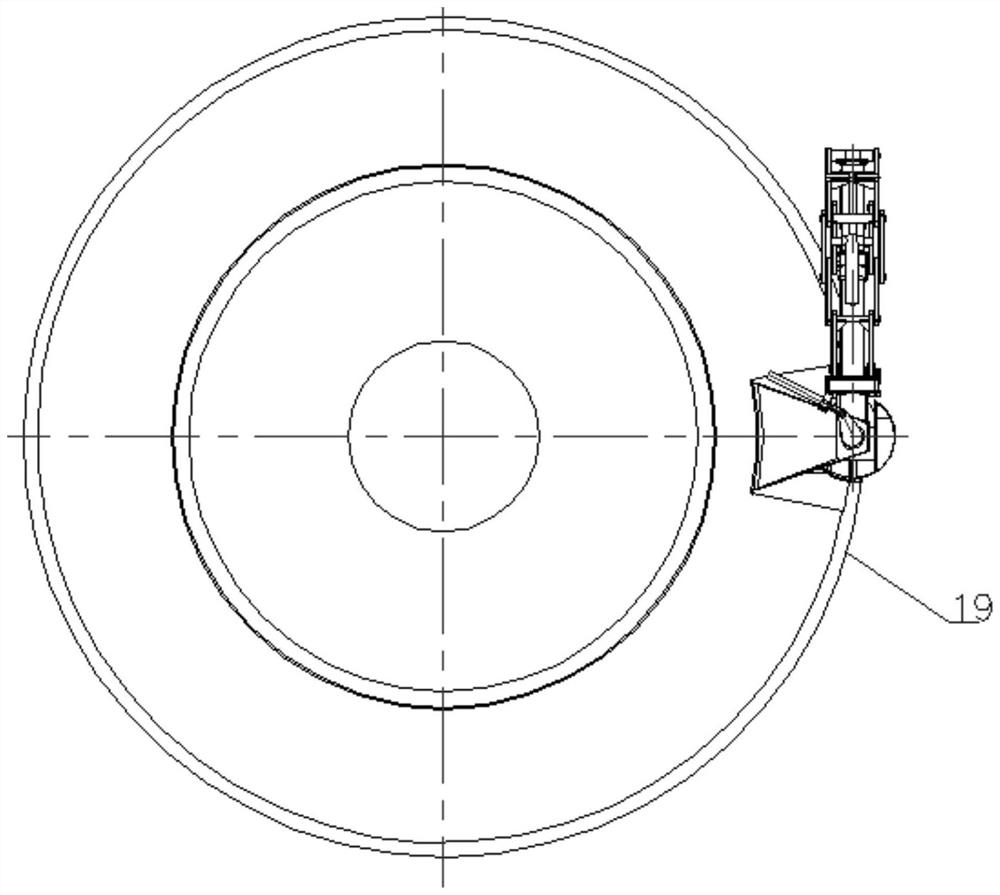

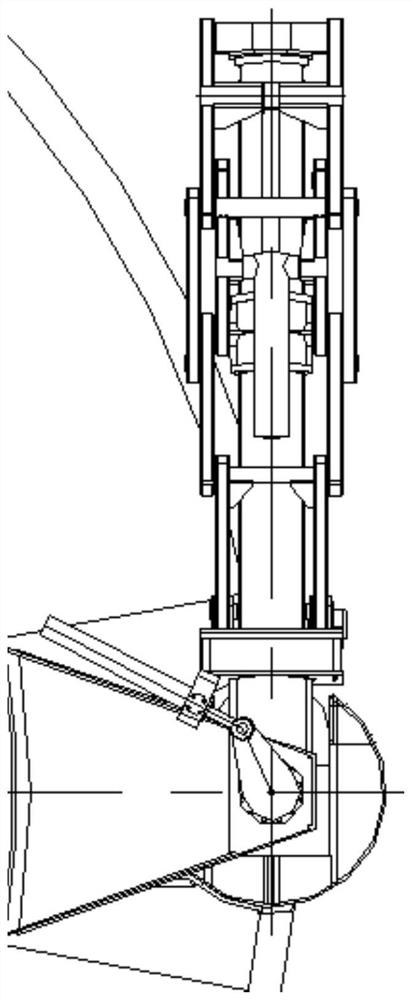

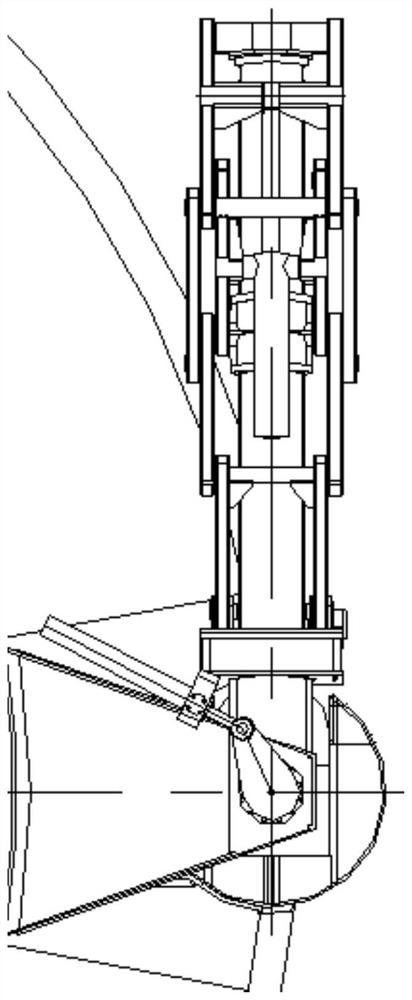

Manipulator of vertical sintering machine and application method thereof

ActiveCN111928659ARealize mechanized processingAvoid burnsCharge manipulationCharge treatment typeMachineManipulator

The invention provides a manipulator of a vertical sintering machine and an application method thereof. The manipulator comprises an operating arm, a transverse swinging oil cylinder and a pitch oil cylinder. The operating arm is arranged outside a hood, and can enter the hood to operate by stretching and can retract out of the hood from the hood, so as to isolate a high-temperature corrosive environment; an operating tool is arranged at the front end of the operating arm; the operating arm is hinged to a rotary table through a pitch axis of the operating arm; the rotary table is rotatably mounted on the outer wall of the hood; a cylinder rod of the transverse swinging oil cylinder is hinged to the rotary table through a hinge pin, and a cylinder barrel of the transverse swinging oil cylinder is hinged to the hood through a hinged support; the pitch oil cylinder is used for driving the operating arm to perform a pitching motion; and rotary sealing structures are arranged between the operating arm and the rotary table and between the rotary table and the hood. According to the manipulator, an abnormal fire behavior is treated mechanically and operating tools and operation staff areisolated in space, so that the operation staff can be prevented from being scalded by a high-temperature air flow in the machine. In addition, the manipulator can finish a charge level operation quickly, so that the yield loss can be reduced obviously.

Owner:徐州巨旋重型机械有限公司

Mechanized method for processing flat green tea

Owner:HUAZHONG AGRI UNIV

A vertical sintering machine operating manipulator and its use method

ActiveCN111928659BRealize mechanized processingAvoid burnsCharge manipulationCharge treatment typeMachineManipulator

The present invention proposes a vertical sintering machine operating manipulator and its use method. The manipulator includes a working arm, a swaying oil cylinder and a pitching oil cylinder. The working arm is arranged outside the machine hood, and can enter into the machine hood for operation by stretching and contracting. And it can be retracted from the inside of the hood to the outside of the hood, so as to isolate the environment of high temperature and corrosion; the front end of the working arm is equipped with working tools; the working arm is hinged on the turntable through a pitch axis of the working arm; the turntable is rotatably installed on the outer wall of the hood Above; the cylinder rod of the sway cylinder is hinged to the turntable through a pin shaft, and the cylinder barrel of the sway cylinder is hinged to the hood through a hinge seat; the pitch cylinder is used to drive the operating arm to do pitching motion; between the operating arm and the turntable, the turntable There is a rotary sealing structure between the engine cover and the machine cover. The invention realizes mechanized treatment of abnormal fire conditions, space isolation of working tools and operators, and prevents operators from being scalded by high-temperature airflow inside the machine. In addition, the manipulator can quickly complete the surface operation, which can significantly reduce the production loss.

Owner:徐州巨旋重型机械有限公司

Method and device for processing slash marks on surface of pseudo-classic board

InactiveCN102729306BRealize mechanized processingSimple structureWood working apparatusEngineeringAtmospheric pressure

The invention discloses a method for processing slash marks on the surface of a pseudo-classic board. According to the method, the slash marks are processed by a method for simulating artificial cutter jumping by using a device for processing the slash marks. The device for processing the slash marks comprises scrapers, swing frames, cylinders and a conveying mechanism; the swing frames are driven by changing the ventilation sequence and air pressure of rod cavities on the cylinders to swing, so that the scrapers process the slash marks on the upper surface of the board, the mechanized processing of the slash marks on the surface of the pseudo-classic board is realized, and the processing efficiency is improved; and the depths of the slash marks, the lengths and separated distance of slash mark areas and the distribution of the slash marks in the width direction of the board can be regulated, so that the processed slash marks are irregular, and an emulation effect of manual operation is achieved. The device for processing the slash marks is simple in structure and low in manufacturing cost; and the surface of the board processed by utilizing the device for processing the slash marks is good in pseudo-classic effect, the production efficiency is improved, and the production cost is reduced, so the method and the device for processing the slash marks can be widely applied to the processing and manufacturing of the surface of the pseudo-classic board.

Owner:GUANGDONG YIHUA TIMBER IND +1

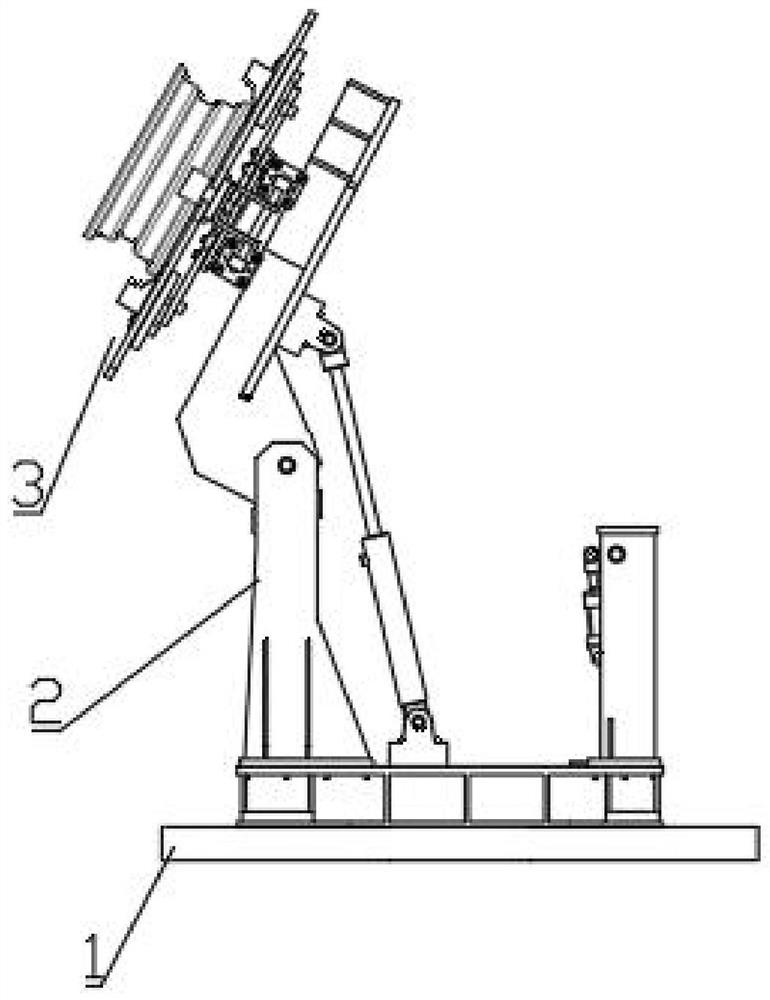

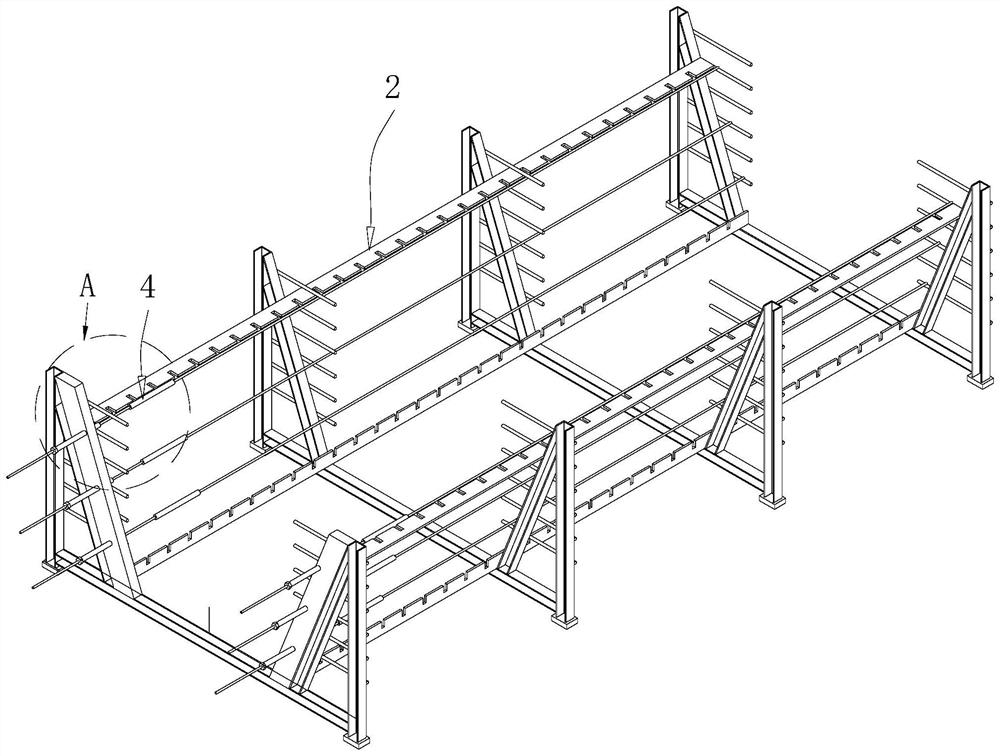

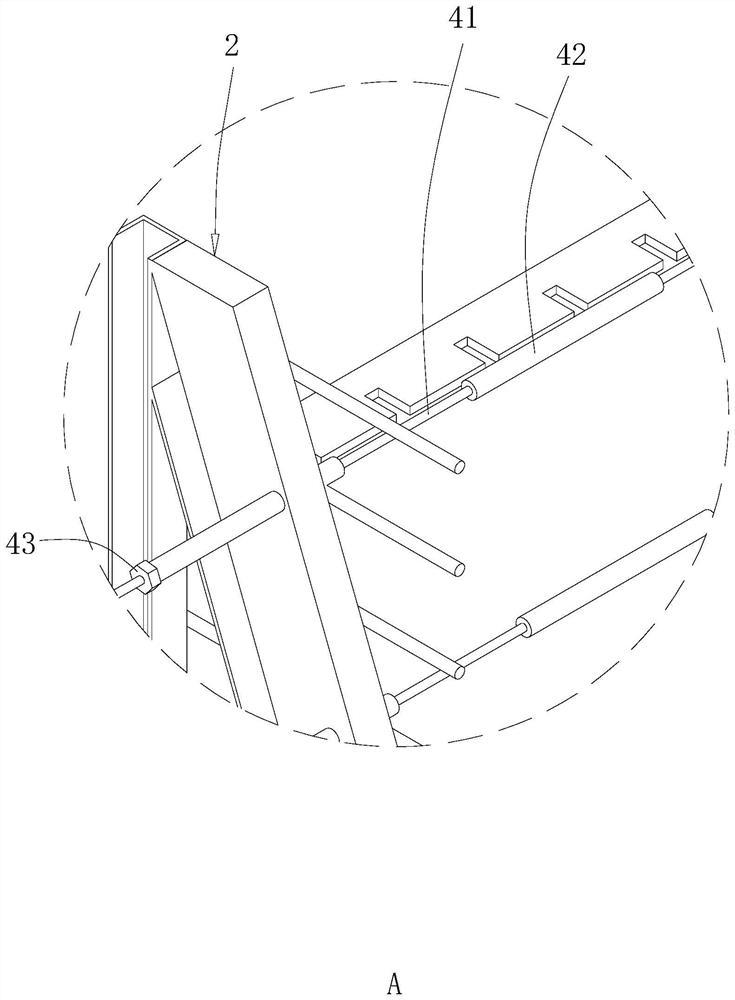

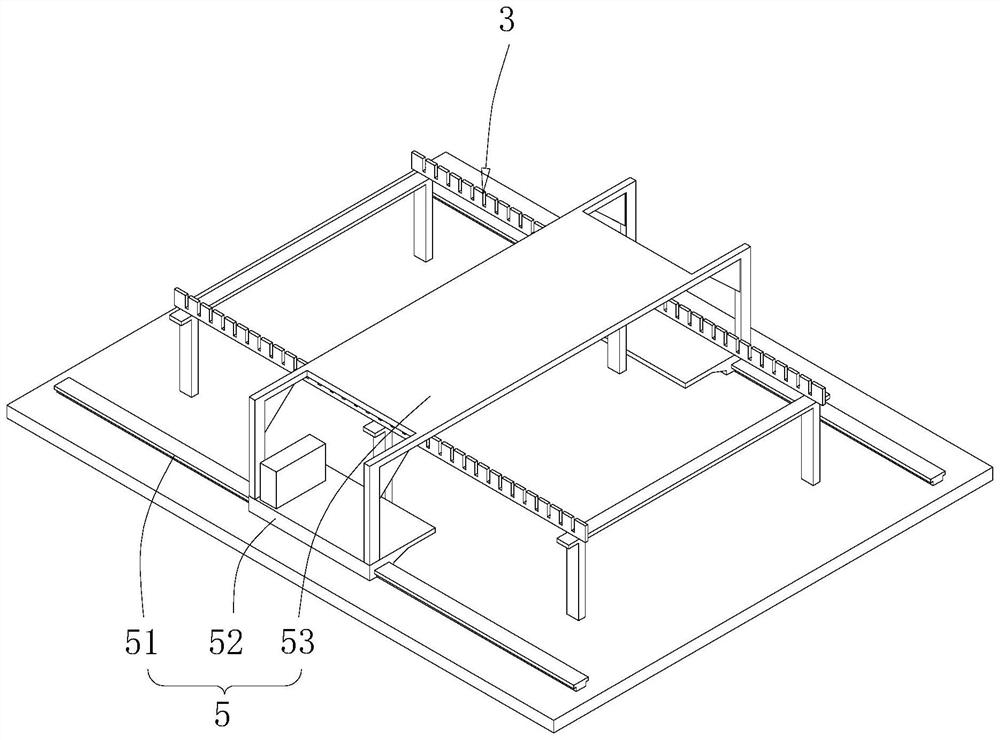

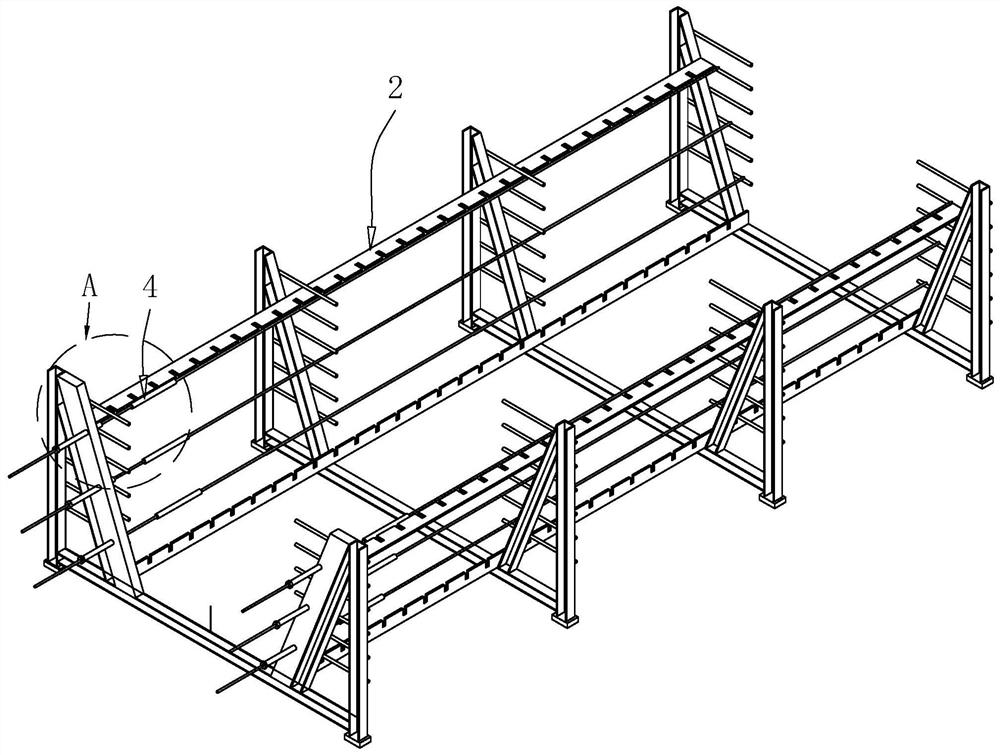

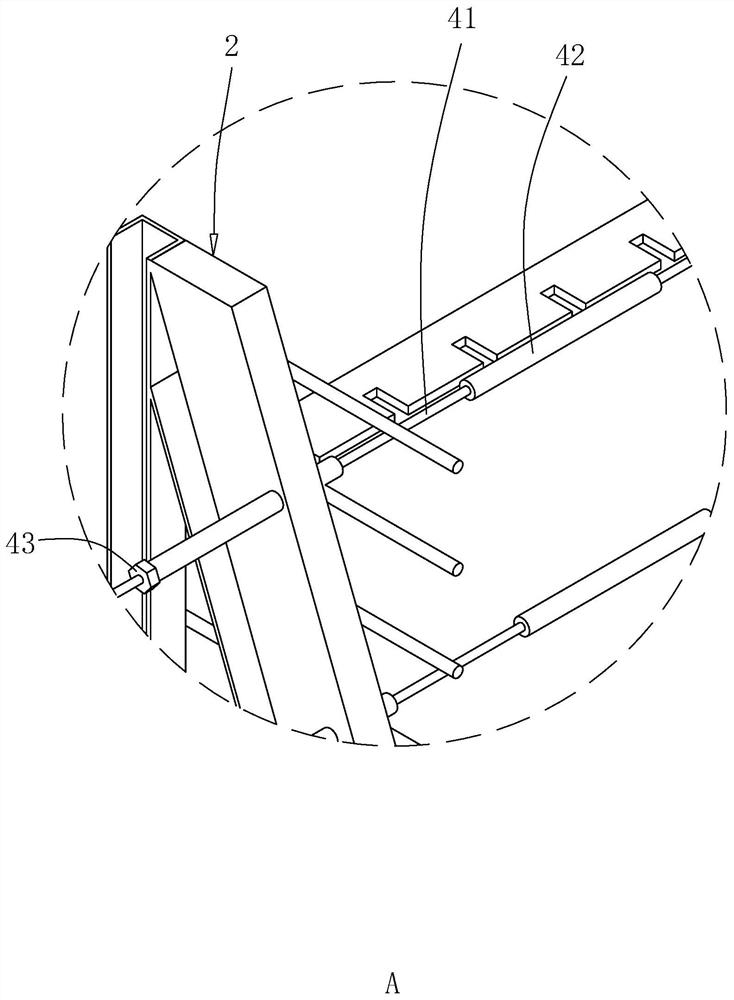

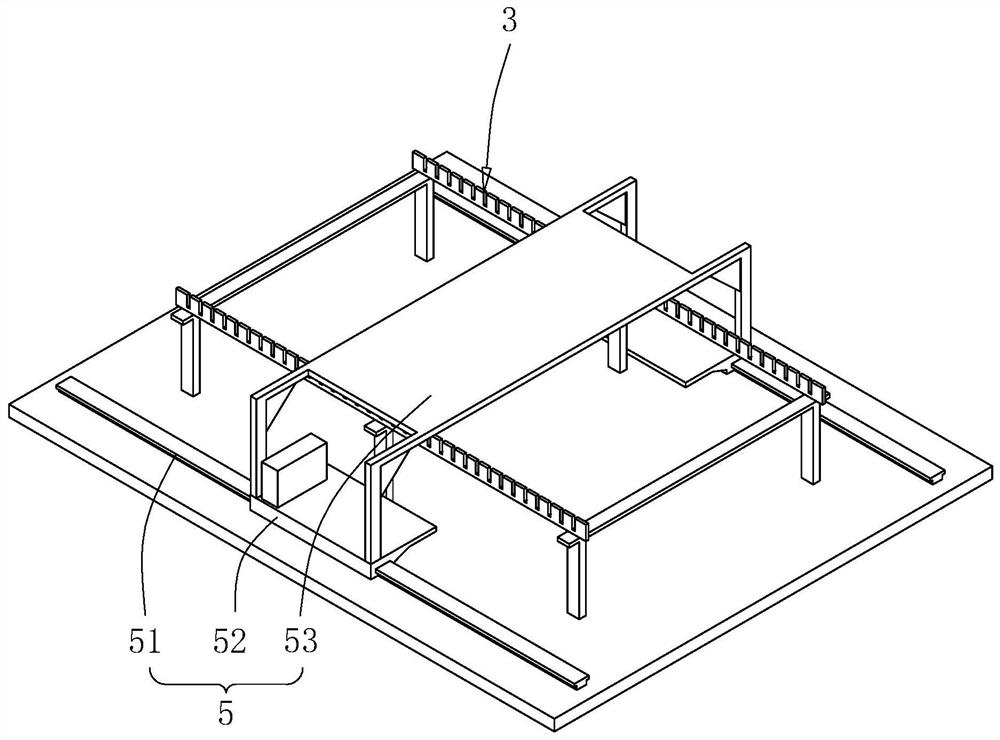

A construction method for prefabricated box girders in high-cold and high-altitude areas

ActiveCN112809908BImprove machining accuracyImprove welding qualityCeramic shaping apparatusPre stressClassical mechanics

This application relates to the field of prefabricated box girders, in particular to a construction method for prefabricated box girders in high-cold and high-altitude areas, which includes the following steps: constructing a closed greenhouse, pouring a girder pedestal; Tire frame; steel bar processing; installation, tying, welding of bottom web steel bars, installation of embedded parts, to obtain bottom web steel bar skeleton; binding, welding of roof steel bars, to get roof steel bar skeleton; making prestressed pipes, installation of prestressed pipes; hoisting Bottom web steel frame to the preset position of beam-making pedestal; install side formwork; install inner formwork and fix the inner formwork against floating; hoist the roof steel frame; install liner in prestressed pipe; pour bottom slab concrete and web concrete And roof concrete; maintenance, formwork removal; prestressed beams are pierced, prestressed beams are stretched, prestressed tunnels are grouted and anchored; beams are moved and stored. The application has the effect of ensuring the prefabrication efficiency and quality of box girders in alpine and high altitude areas.

Owner:IN THE TUNNEL BUREAU OF THE SECOND ENG +1

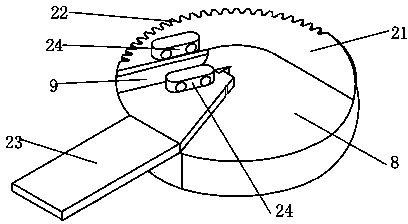

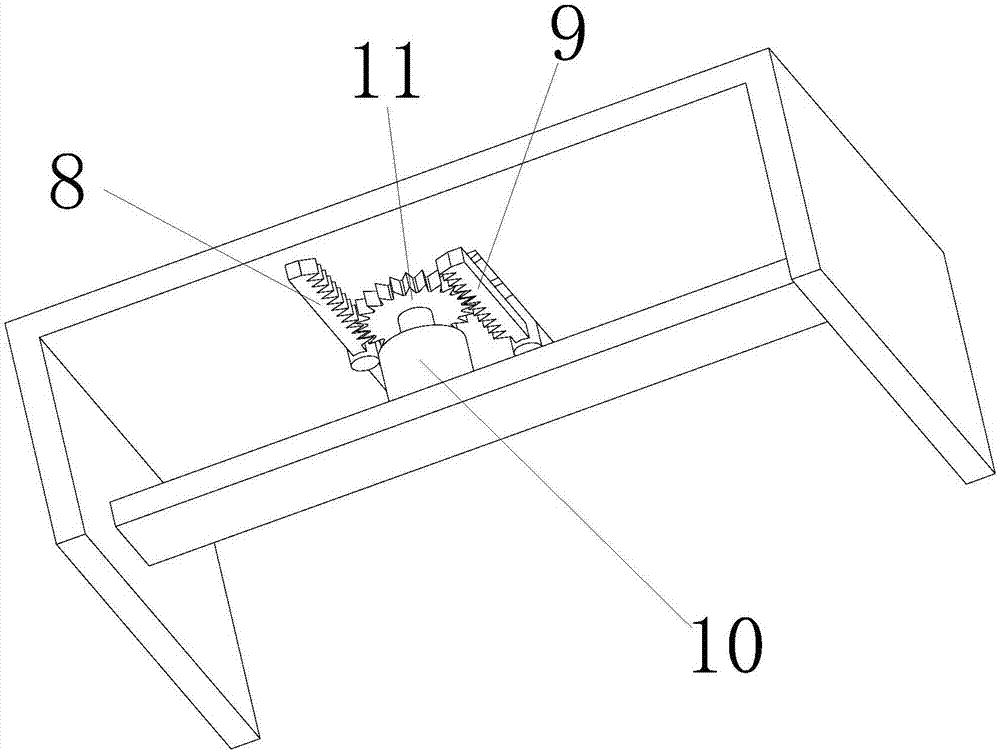

Gear of workpiece rotating stamping die

The invention belongs to the technical field of metal processing tools and particularly relates to a gear of a workpiece rotating stamping die. The gear of the workpiece rotating stamping die comprises a gear body, wherein the gear body is provided with a workpiece groove for workpiece placement; one end of the workpiece groove extends to the edge of the gear body, and the other end of the workpiece groove extends into the gear body to be connected with a fan-shaped groove; one side of the gear body, which is far away from the fan-shaped groove, is provided with a gear rack, and one side of the gear body, which is positioned between the fan-shaped groove and the workpiece groove, is provided with a stopping workpiece extending to outside. In the invention, the mechanical processing of a tubular workpiece is realized, thereby increasing the efficiency and achieving the large-scale and industrialized production.

Owner:HUZHOU IRON FORCE METAL PROD

Squid main body automatic peeling machine

ActiveCN109169814BEasy to take outRealize mechanized processingCephalopods processingFish skinningElectric machineEngineering

The utility model relates to an automatic peeling machine for squid main body, which belongs to the technical field of fishery processing auxiliary equipment. It includes a hollow rotating rod, a rubber hollow body, a geared motor, a base, a pipe, an air extractor, an inflator, a controller, a first electric lifting rod, a distance sensor, a second electric lifting rod and a scraper. The hollow rotating rod is covered There is a rubber hollow body, a geared motor is installed on the lower part of the hollow rotating rod, a base is installed on the lower part of the geared motor, an air extractor, an inflator, a controller and the first electric elevating rod are installed on the base in sequence, and the upper part of the first electric elevating rod is installed with The distance sensor, the second electric lifting rod is installed on the left side, and the scraper is installed on the left side of the second electric lifting rod. The structure is convenient for the squid to be inserted into the shape and taken out, thus realizing mechanized processing and greatly improving the peeling efficiency.

Owner:ZHEJIANG OCEAN UNIV

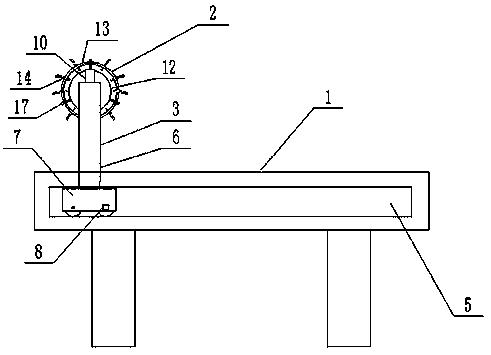

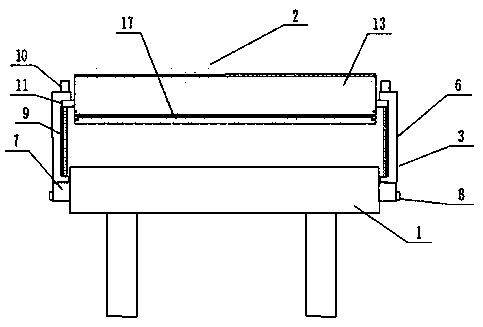

Processing device for cut marks on antique looking wooden board surface

InactiveCN108972743AAntique effect is goodImprove processing efficiencyProfiling/shaping machinesEngineeringControllability

The invention belongs to the technical field of wood board processing, and discloses a processing device for cut marks on an antique looking wooden board surface. The processing device for the cut marks on the antique looking wooden board surface comprises: a working platform, a knife roll and a bracket. A clamp is arranged on the table surface of the working platform, and grooves are arranged ontwo opposite sides of the working platform. The bracket comprises two support rods vertically distributed on two sides of the working platform, and the bottom ends of the two support rods are fixed ona fixing seat provided with idler wheels at the bottom, the fixing seat is matched with the grooves, and the fixing seat is provided with a first driving device connected with the idler wheels. Screwrods are arranged on the inner sides of the two support rods, a second driving device is connected with the tops of the two screw rods, the two ends of the knife roll are fixed on the two screw rodsthrough connecting blocks, the knife roll comprises a roller shaft and a cylindrical knife rest mounted on the outer side of the roller shaft, the cylindrical knife rest is provided with a threaded hole for fixing a knife, the knife comprises a knife head and a knife handle, and the knife handle is provided with a thread matched with the threaded hole. The processing device has a simple and reliable structure, strong controllability, and achieves mechanized processing of the cut marks on the wooden board surface.

Owner:河南省君煜实业有限公司

Construction method for prefabricated box girder in high-cold and high-altitude area

ActiveCN112809908AImprove machining accuracyImprove welding qualityCeramic shaping apparatusPre stressArchitectural engineering

The invention relates to the field of prefabricated box girders, in particular to a construction method of a prefabricated box girder in a high-cold and high-altitude area. The construction method comprises the following steps of constructing a closed greenhouse, and pouring a girder making pedestal; prefabricating a bottom web steel bar positioning jig frame and a top plate steel bar positioning jig frame; processing steel bars; mounting, binding and welding bottom web steel bars, and mounting embedded parts to obtain a bottom web steel bar framework; binding and welding top plate steel bars to obtain a top plate steel bar framework; manufacturing a prestressed pipe, and installing the prestressed pipe; hoisting the bottom web steel reinforcement framework to the preset position of the girder making pedestal; installing a side mold; installing an inner mold, and carrying out anti-floating fixing on the inner mold; hoisting the top plate steel bar framework; installing a liner pipe in the prestressed pipe; pouring bottom plate concrete, web plate concrete and top plate concrete; maintaining and removing the mold; arranging pre-stressed tendons in a penetrating mode, tensioning the pre-stressed tendons, and carrying out pre-stressed duct grouting and anchor sealing; and moving the girder and storing. The construction method has the effect of ensuring the prefabricating efficiency and quality of the box girder in the high-cold and high-altitude area.

Owner:IN THE TUNNEL BUREAU OF THE SECOND ENG +1

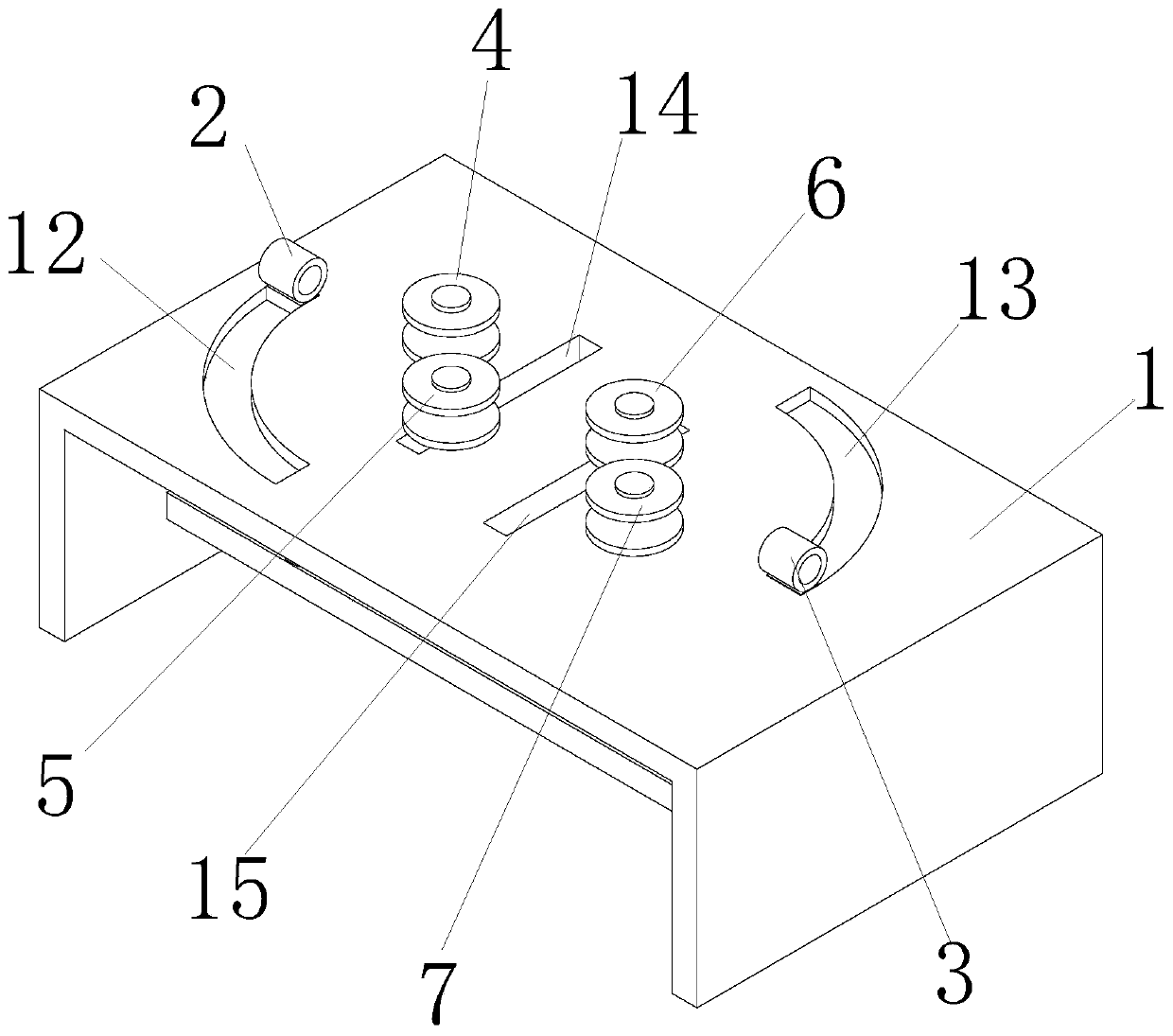

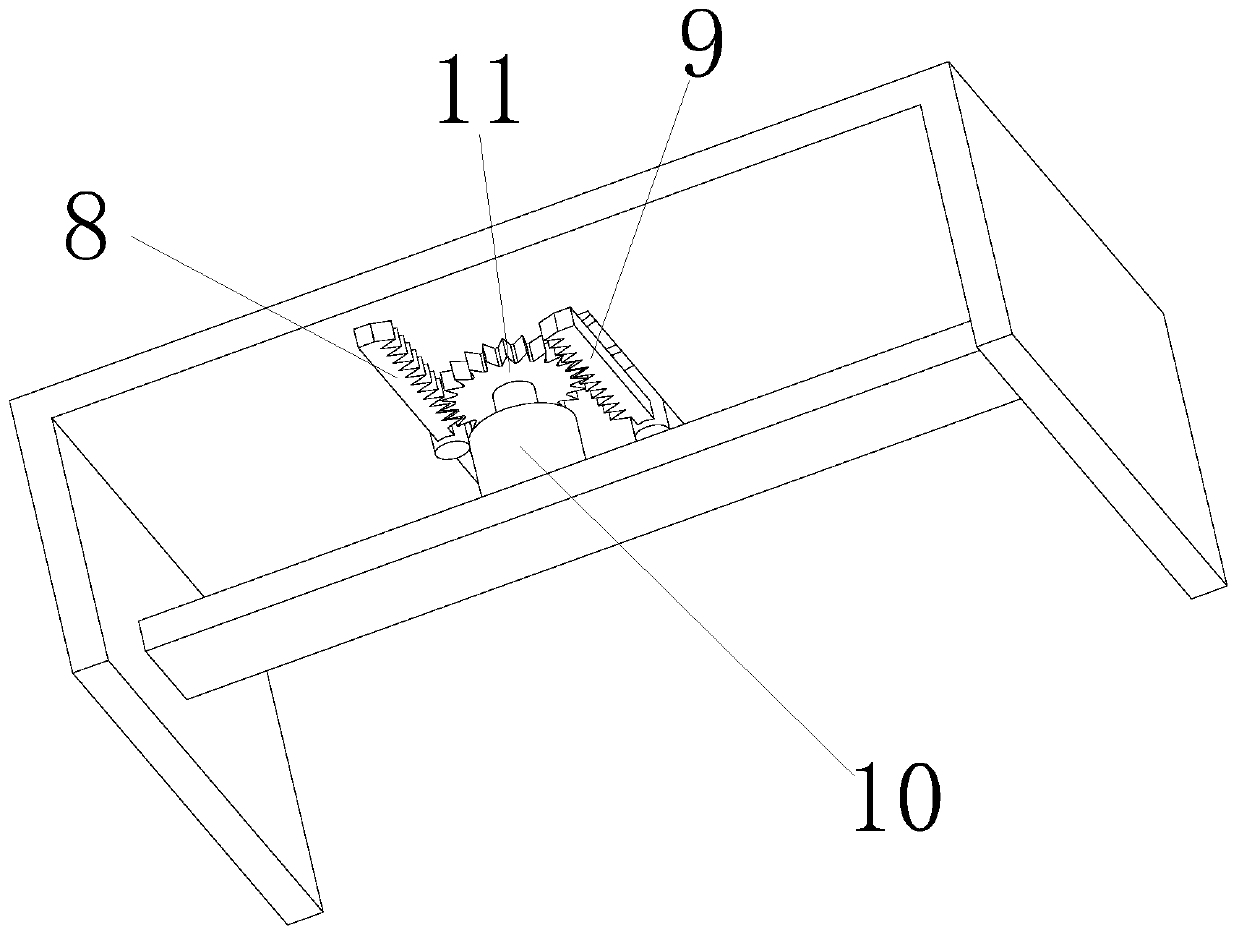

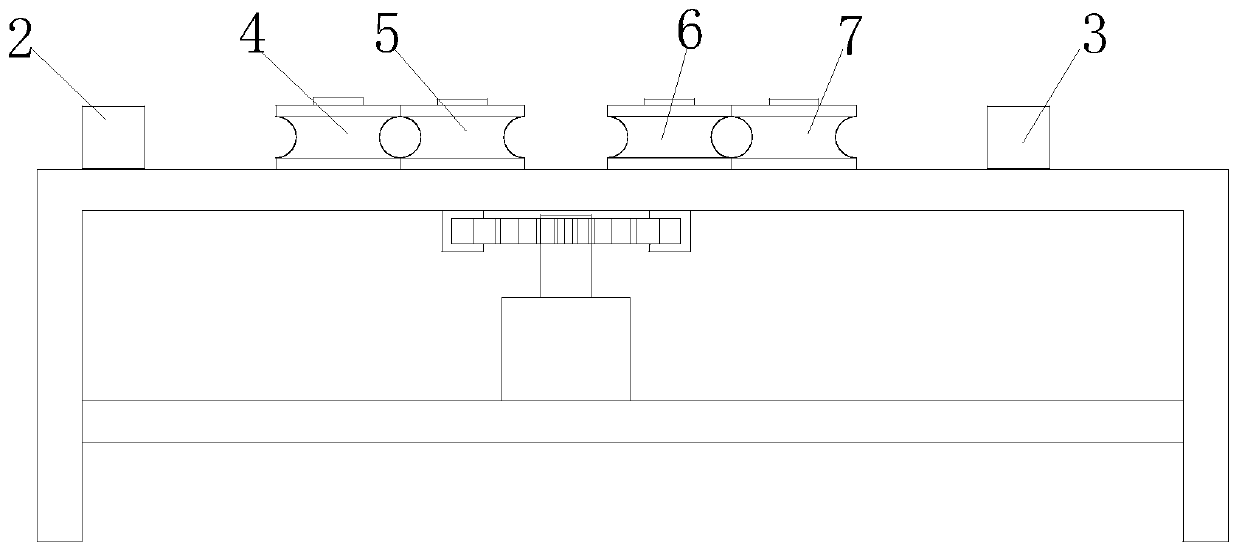

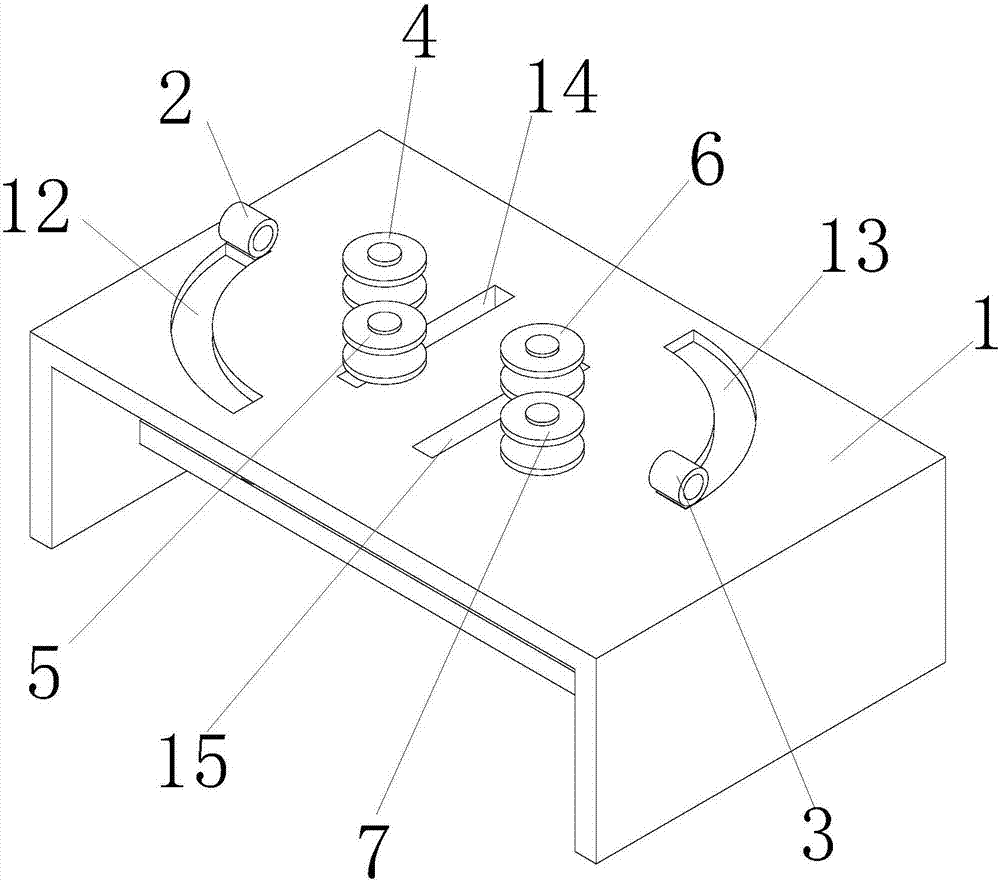

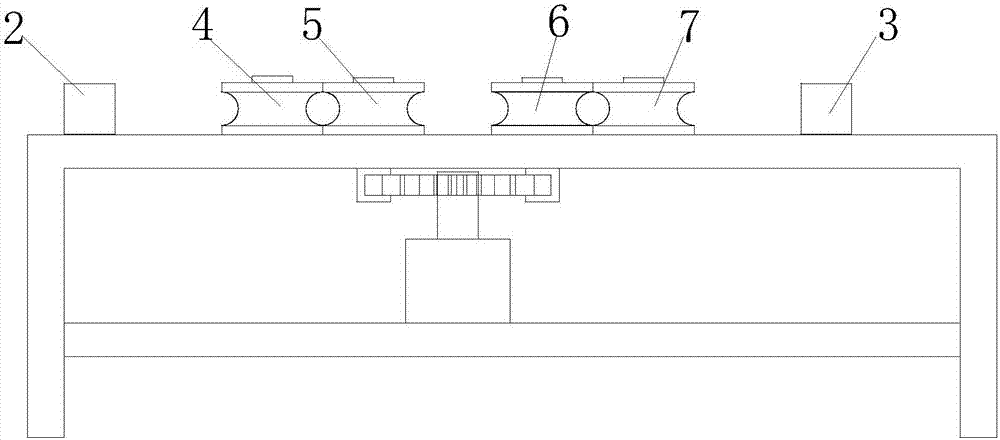

A kind of S-shaped curved pipe bending processing equipment

The invention relates to machining equipment for an S-shaped curve bend. The machining equipment comprises a working table, wherein a pipe sleeve I and a pipe sleeve II are arranged on the working table; the pipe sleeve I is mounted at the left end of the working table in an anticlockwise sliding manner; the pipe sleeve II is mounted at the right end of the working table in an anticlockwise sliding manner; a roller I, a first bending mold, a second bending mold and a roller II are distributed on a connecting line of the pipe sleeve I and the pipe sleeve II from left to right sequentially; a power system driving the first bending mold and the second bending mold to slide is connected with the first bending mold and the second bending mold and comprises a gear rack I connected with the first bending mold, a gear rack II connected with the second bending mold and a gear which is meshed with the gear rack I and the gear rack II and connected with a motor. The machining equipment for the S-shaped curve bend has the beneficial effects as follows: one-time machining molding of the S-shaped bend can be realized, interference in the bending process can be avoided, the machining difficulty is reduced, the machining time is saved, mechanical processing can be realized, the degree of automation is high, the production efficiency is improved, and large-scale production work can be performed.

Owner:芜湖德丰汽车零部件有限公司

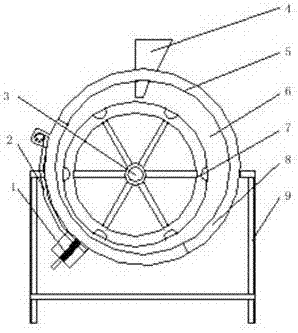

Cream-fat separation and cheese forming all-in-one machine based on traditional technology

The invention discloses a cream-fat separation and cheese forming all-in-one machine based on a traditional technology, relates to cream-fat separation and cheese forming equipment, and aims to solve the technical problems that an existing cheese processing method is time-consuming, labor-consuming and low in efficiency. The all-in-one machine comprises a raw milk stirring system, a heating and disinfecting system, a material distributing system, a mold device and a control system; wherein the raw milk stirring system comprises a raw milk stirring cylinder and a stirrer mounted in the raw milk stirring cylinder, and the stirrer is eccentrically mounted; the raw milk stirring system, the heating and disinfecting system, the material distributing system and the mold device are connected in sequence, and the raw milk stirring system, the heating and disinfecting system and the material distributing system are controlled by the control system. The all-in-one machine can automatically complete the integrated operation of grease separation, heating, filtering and cheese forming for dairy products, realizes mechanical processing of cream, butter and cheese, and can be applied to the field of dairy product processing.

Owner:SHIHEZI UNIVERSITY

Machining equipment for S-shaped curve bend

The invention relates to machining equipment for an S-shaped curve bend. The machining equipment comprises a working table, wherein a pipe sleeve I and a pipe sleeve II are arranged on the working table; the pipe sleeve I is mounted at the left end of the working table in an anticlockwise sliding manner; the pipe sleeve II is mounted at the right end of the working table in an anticlockwise sliding manner; a roller I, a first bending mold, a second bending mold and a roller II are distributed on a connecting line of the pipe sleeve I and the pipe sleeve II from left to right sequentially; a power system driving the first bending mold and the second bending mold to slide is connected with the first bending mold and the second bending mold and comprises a gear rack I connected with the first bending mold, a gear rack II connected with the second bending mold and a gear which is meshed with the gear rack I and the gear rack II and connected with a motor. The machining equipment for the S-shaped curve bend has the beneficial effects as follows: one-time machining molding of the S-shaped bend can be realized, interference in the bending process can be avoided, the machining difficulty is reduced, the machining time is saved, mechanical processing can be realized, the degree of automation is high, the production efficiency is improved, and large-scale production work can be performed.

Owner:芜湖德丰汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com