Garlic root and stem cutting apparatus

A cutting device and root neck technology, applied in application, food processing, food science, etc., can solve the problems of high labor intensity, unsafe operation, low labor efficiency, etc., to reduce labor intensity, improve work efficiency, and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further detail below with reference to the drawings and embodiments.

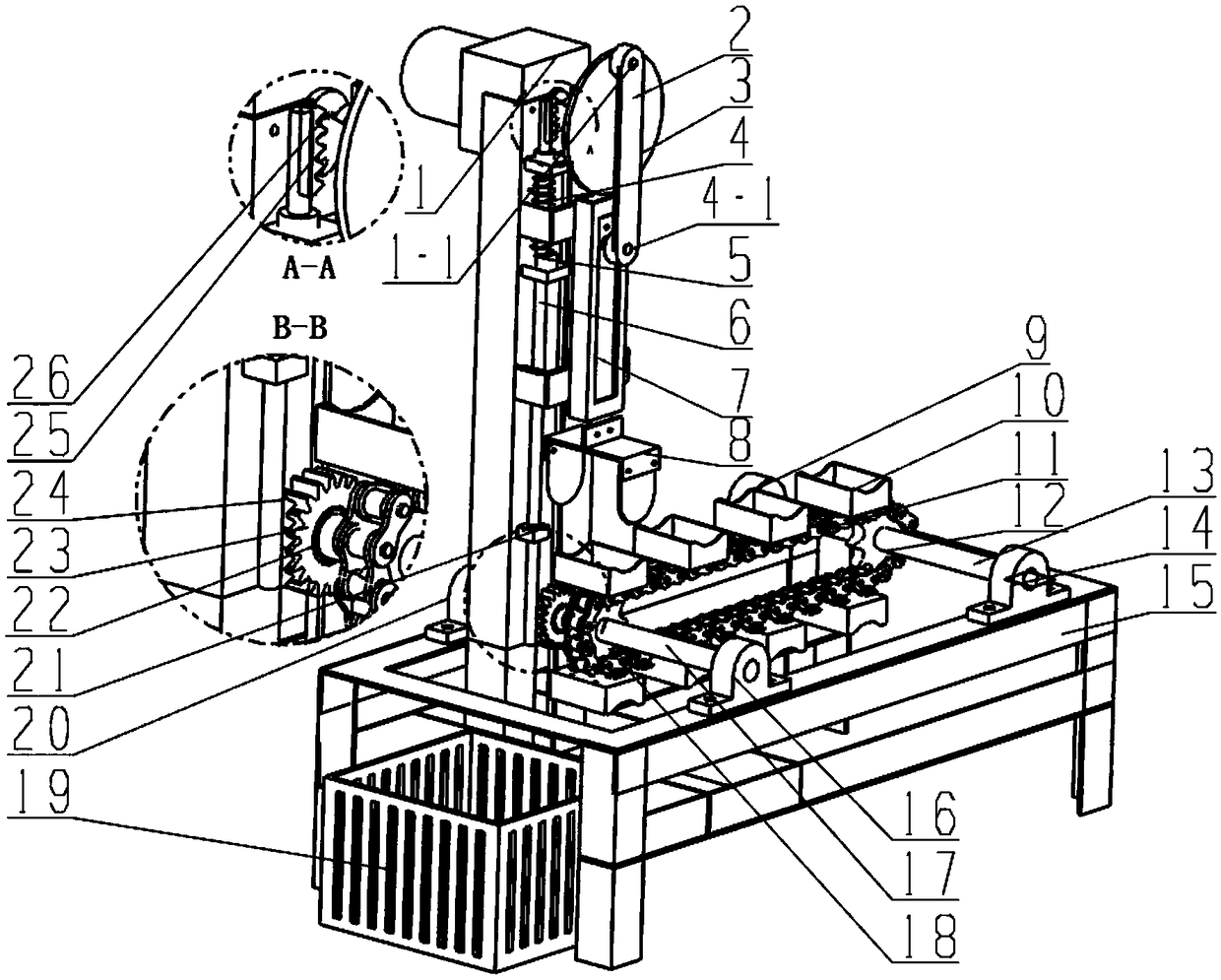

[0021] Such as Figure 1 to Figure 4 As shown, the garlic root neck cutting device of the present invention includes a linked feed mechanism and a crank slider cutting mechanism. The specific structure and connection relationship are:

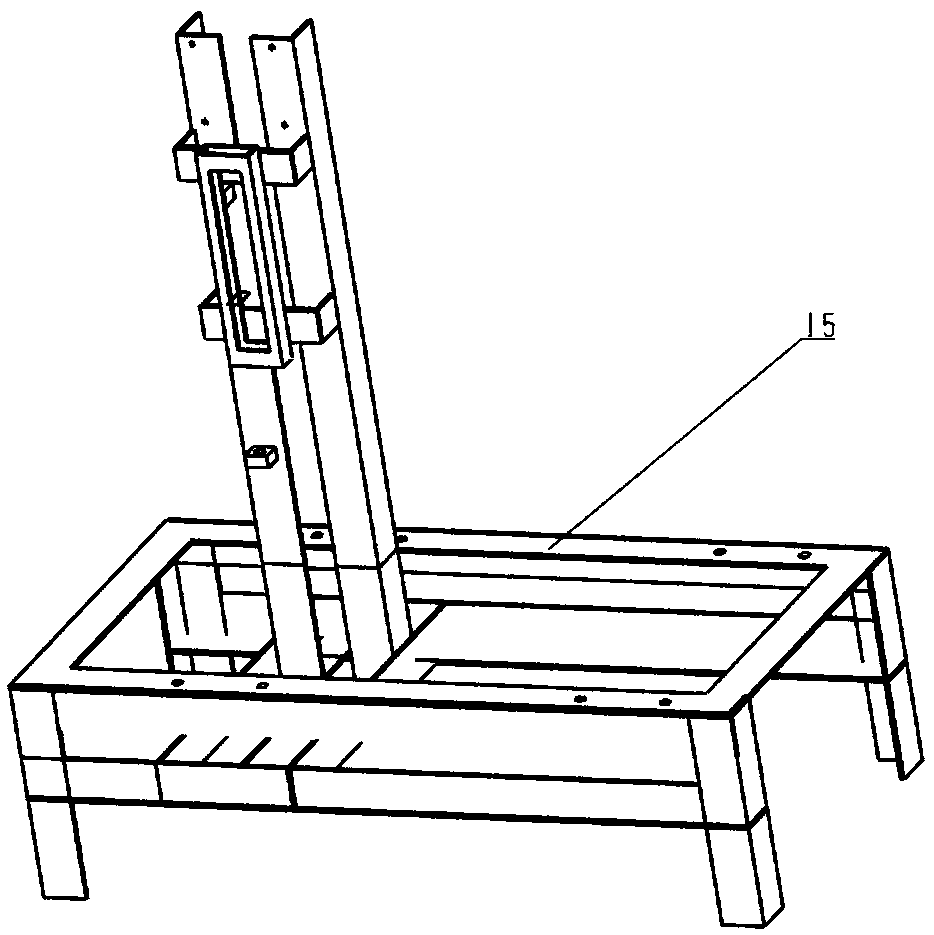

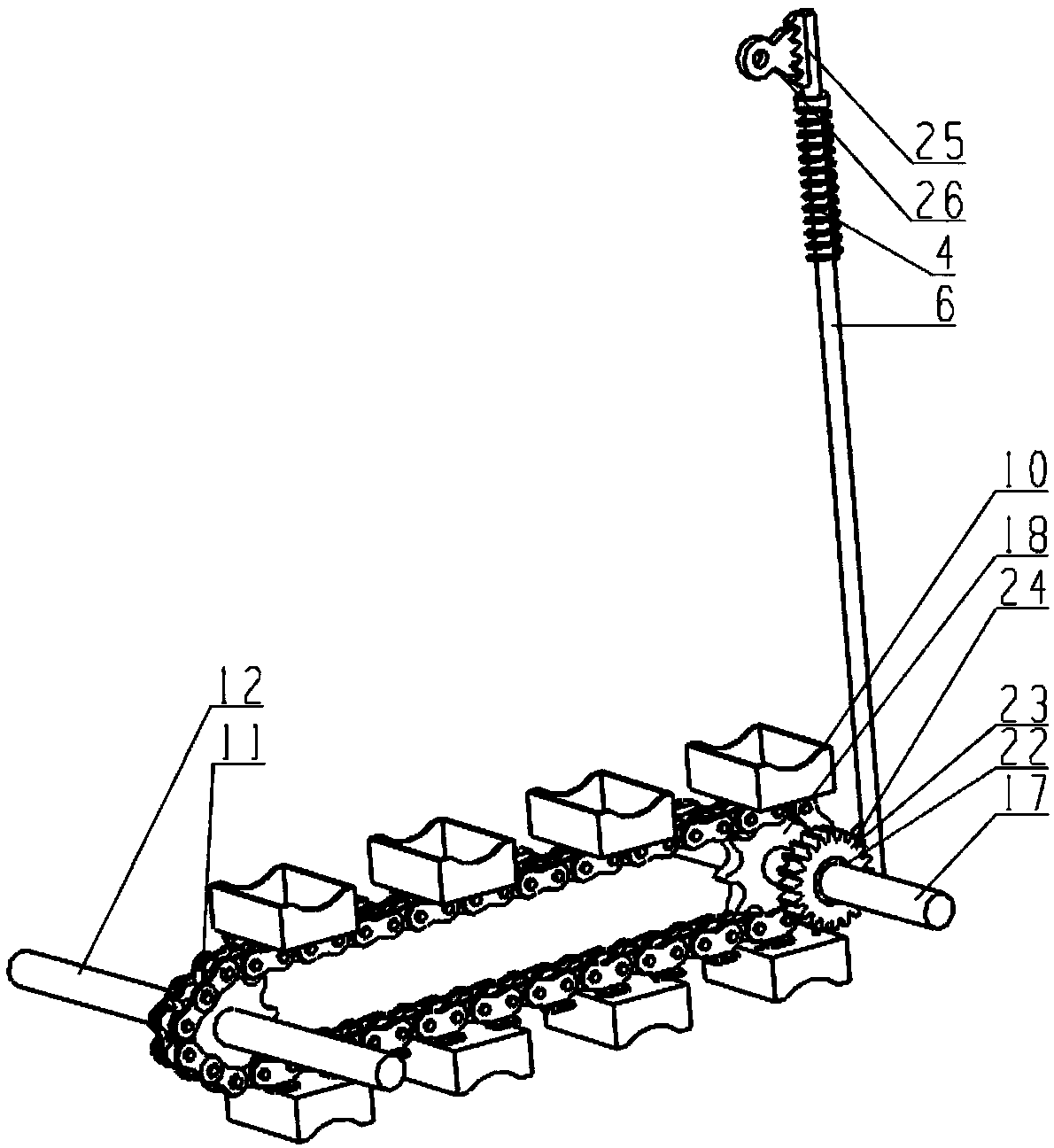

[0022] The linked feed positioning mechanism includes a frame 15, a first bearing seat 9, a second bearing seat 14, a third bearing seat 16, a fourth bearing seat 20, a first transmission shaft 13, a second transmission shaft 17, a chain 11 , the first sprocket 12, the second sprocket 18, the conveying disc 10, the spur gear 23, the first rack 24, the second rack 25, the transmission rod 6, the spring 4 and the sector gear 26, the first bearing seat 9. The second bearing seat 14, the third bearing seat 16 and the fourth bearing seat 20 are fixed on the frame 15, the first transmission shaft 13 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com